|

|

Post by 90GTVert on Mar 20, 2021 6:23:35 GMT -5

|

|

|

|

Post by captincvmn on Mar 20, 2021 7:35:07 GMT -5

Hood stacks

|

|

|

|

Post by ryan_ott on Mar 20, 2021 8:37:44 GMT -5

Who needs a muffler that looks about done to me.

|

|

|

|

Post by jloi on Mar 20, 2021 10:13:16 GMT -5

very nice work .

|

|

|

|

Post by 90GTVert on Mar 26, 2021 8:56:23 GMT -5

|

|

|

|

Post by Kenho21 on Mar 26, 2021 9:03:54 GMT -5

The exhaust is mostly done. It's not shown below, but I do have spring hooks added to hold the muffler on. I've got a bracket to support the rear of the pipe. Unfortunately nothing to support the muffler. Not fond of that, but there's nothing to hang a bracket on back there. I could make a long awkward bracket coming from the frame, but I don't see many other options. Not sure what I'm doing, if anything at this point. Kinda hard to believe the muffler won't crack at some point if left with only the slip on mount as it's support.    Looks very nice! |

|

|

|

Post by aeroxbud on Mar 26, 2021 16:58:35 GMT -5

I like the look of the pipe.

It's always the way. Soon as you throw stuff away, you need it.

|

|

|

|

Post by 90GTVert on Mar 30, 2021 8:09:30 GMT -5

I finally got back into a more normal sleep habit for a few days now. Hope it stays that way. Sunday was the first day that I woke up and actually felt human for weeks. I was ready to make some real progress and finish this exhaust... and then the phone rang as I was getting ready to head to the garage. A friend's welder was acting up and he wanted to build a frame for something so I let him take over the garage and there went that day. I got out there alone yesterday though, and got it mostly wrapped up. I couldn't leave the muffler unsupported. In my unmotivated state, that felt close enough, but more sensible thoughts prevailed with a little sleep. I made up a standoff that was welded to the frame and allowed me to have two bolt holes for a support bracket. I left extra material on the bottom of the long portion of the bracket so I could bend it back at a 90 degree angle in an attempt to improve rigidity. The small section without any bend between the long arm and the frame mounting part still let it flex more than I'd like, so I welded a steel rod to the back of the bracket. Still not perfect, but I think it will provide enough support to keep the muffler from failing in short order. The welds at the end section of the pipe are all ugly, but I may leave them. Perhaps some small amount of cleanup whenever I paint it, but I doubt I'll do much more to it.   |

|

|

|

Post by 90GTVert on Mar 30, 2021 18:23:33 GMT -5

|

|

|

|

Post by 190mech on Mar 30, 2021 19:39:27 GMT -5

Great work Brent!Cant get much better than that!!  |

|

|

|

Post by captincvmn on Mar 30, 2021 22:35:37 GMT -5

That bandsaw is getting a workout.

|

|

|

|

Post by 90GTVert on Mar 31, 2021 6:09:32 GMT -5

That bandsaw is getting a workout. It quickly became a go-to. The original blade wasn't great. Then I bought a 3 pack of DeWalt blades. For some reason the first one always skipped a spot and that caused it to grab, which you can see in most of the video. Then I changed the blade to another DeWalt blade from the same pack and now it's cutting great and smooth. The cuts for the bracket at the end of the vid are with the new blade. |

|

|

|

Post by 90GTVert on Apr 1, 2021 16:19:29 GMT -5

The stock foot peg bracket for this moped had a side stand attached to it. I was able to chop that off and weld it to the foot peg bracket that I made and it's in a suitable position. I thought I was going to have to weld a bar on to get ahold of it, but it's actually not bad as-is.  I got the kick lever below from amazon, since the one I had wouldn't clear the exhaust. It seems to be decent quality and works fairly well. I have plenty of clearance now. My only complaint is that it's a little tall and will be right up against my leg. Don't really want to chop it up. The bright side of the length is that it makes a very noticeable difference in how easily the engine can be turned over. amzn.to/3fCQYYa  I had a request to do a how to for stator replacement on the SSR Lazer, so I went ahead and did a step by step video for both the SSR and Piranha engine. The Piranha has a setup like most of us scoot folks are used to, where it's behind the flywheel. The SSR's stock engine makes it super easy because the flywheel basically looks like it's on backwards and the stator is attached to the engine cover. Here's that if you're interested : youtu.be/kR86GEJvYQE |

|

|

|

Post by 90GTVert on Sept 3, 2021 19:35:23 GMT -5

No, I haven't touched the SSR aside from moving it out of my way occasionally. I had a comment on a video with some info that may be interesting so I thought I'd post it here. From "F3D Racing" : " great video, we made a lot of testing with YX160 based engines with 184cc and TB Raceheads V2 (using takegawa S35) Cams. We used also LM-Exhaust Systems for Pitbikes. the ID of the Pipe is arround 31mm and the silencer had 38mm, we made a piece to reduce the silencer (similiar to a DB-insert) to 31mm. We also have a dynojet here, and found with the 31mm piece 1hp more power. So keep in mind to check your insert in your silencer, we also tested the same type as yours, and had arround 3hp loss of power. Thanks for the great details " Me : " How much do they typically put down stock and then after the big bore, head and cam? " F3D Racing : " 49ccscoot Results here (all rwp on dynojet) 160cc Stock with Nibbi PE26 (well recommended) 14-14,5 HP 160cc Stock with Nibbi PE28 (well recommended) 14,9-15,6 HP 184cc with Stock Head (compression adjusted) 15,7-16,8 HP but NM torque increase over 2nm 160cc with TB race head and S25 (ports stock not ported) 18-19hp 184cc with TB race head and s35 cam (ports stock not ported) 19-20,5 significant increase on torque nm 184cc with TB race Head and S35 cam (good porting + copper guides and seats) up to 22,8hp (thats currently the highes rating we had) For now i build one with a bigger inlet valve (custom made) hope to reach over 23rwp. All fuel tuned with a Bosch Lambda Sensor and a thread insert in the pipe. About lifetime, we have some engines running over 30-40hours and still going strong. Nothing crashed jet " |

|

|

|

Post by 90GTVert on Jan 9, 2022 10:18:03 GMT -5

Still no more actual work on this moped, but since we've had a couple of snows recently I've been working on wiring info. Not sure when I'll actually build a harness from scratch, but I will need to as the project moves on. I like to have a plan all laid out before I try to make a harness. It can be hard enough trying to get lengths right and connections in the proper spots without also trying to figure out where everything needs to go at the same time. Here's the diagram that's hopefully correct. CLICK TO ENLARGE.

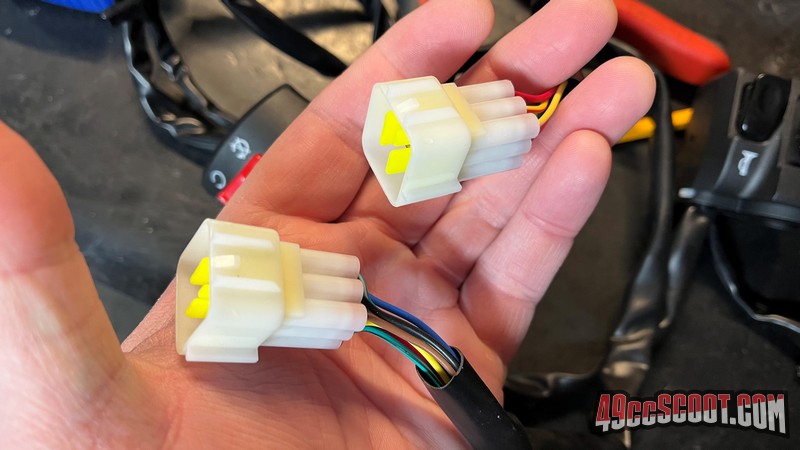

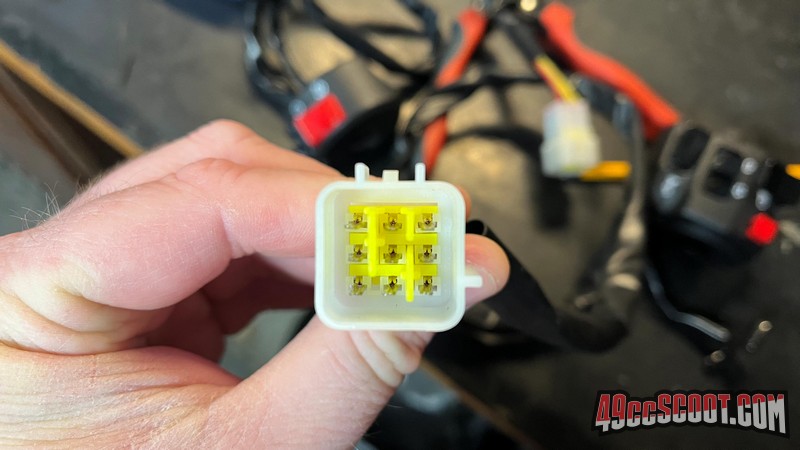

Here are the handlebar controls that I went with. I got them on amazon ( LINK). I chose them because they are very full featured, look good IMO and are pretty inexpensive. They've got lights off/parking/headlight, kill switch and starter on the right side. The left side has turn signals, a hazard light button, high/low beam, passing light momentary switch on the rear, and a horn button.  They come with sealed connectors.   Looks like they are 9 pin Furukawa connectors. Here's a link to the female kits that I believe should mate up to them : www.corsa-technic.com/item.php?item_id=240Nothing is installed and tested, but I've spent some time with a meter doing continuity checks and figuring this stuff out. I believe it will be accurate. Someone on amazon listed the wire functions of theirs and they don't match mine, so either one of us is wrong or using them in a different way or they may not always come with the same wiring. CLICK TO ENLARGE.

One thing that isn't ideal is that the kill switch has continuity in run, so it would be intended for either a ground to run or to provide power to a DC CDI. Unless I'm mistaken, this will be ground to kill. I can still use it, but my kill switch functions will be backwards. Not really a big deal. Where that could become a deal breaker is if you wish to use electric start. I do not. The starter button gets it's power only when the kill switch is in run. If using this with ground to kill systems like many scoots and mopeds have, you would need to do a bit of work to make the electric starter function. You'd either have to get in there and swap the power supply to the starter button to a different source, like ign switched power, or use relays to reverse the function of the kill switch. These controls include connections for brake switches, but one of those is kind of odd to me as well. The right side is typical. It provides ignition switched power and then a lead to the brake circuit for the brake switch. The left side is the odd one. It uses the wire that connects to flasher relay power for turn signals as the power source for that side's switch. I believe this should make the brake light flash. I don't need the left side, because I'll have a clutch. It could be a cool or crappy feature, allowing one lever to flash the lights and another to light them solid, depending on your preferences. As I wrote the above, I realized my diagram doesn't include foot brake switch connections because I'm so used to scoots so I may mod the diagram at some point. EDIT : Fixed. |

|