|

|

Post by 90GTVert on Sept 20, 2020 18:59:50 GMT -5

Passing this along here because it may be good info for anyone else doing a manual conversion. I got a comment to check out a stunt bike video, because you could see the clutch/brake hand controls in it. It never occurred to me to look at stunt bikes, but if you google "stunt bike clutch brake" you can even find videos about setting up the dual levers on the left side. I still think it will be much easier for regular riding and for me to use standard controls, but check that out if you are interested in dual levers on one side.

|

|

|

|

Post by captincvmn on Nov 11, 2020 12:40:04 GMT -5

Is the SSR build resting? It was going full tilt with the forks and tanks and foot pegs etc.

|

|

|

|

Post by 90GTVert on Nov 11, 2020 16:54:24 GMT -5

I kinda take it as it comes with my scoots. T2 has had all sorts of issues and actually runs so I've spent most of my time on that. The SSR is not forgotten. I was going to push it ahead in line and see if I could smooth out and paint the gas tank while the temps were still up. Then I thought, (if it turns out well) what are the chances that I keep a painted tank lying around and don't scratch it up all winter? Current thought is that exhaust will be the next task, but I don't have the pipe around or even know what size pipe I want to order.

Winter would probably also be a good time for me to try to figure out wiring. I'd like to do it as I did with T2 last time around and take the time to make up a wiring diagram before I actually make the wire harness.

I should probably also try to figure out where the oil cooler is going and how the intake/filter will sit before the tank gets any more work.

I know I'm not gonna register this thing in the winter and there's no way it's getting finished before that so I'm not in a great rush. That will be more trouble than it needs to be. Safeco says no more scooters/motorcycles on the same policy. I only keep 3 insured at any time so I'm not paying on multiple bikes that never leave the garage. T2, TMAX and the TaoTao aren't coming off (I keep telling myself Project TaoTao is coming back) and they say they won't add another. I really don't get why they want to turn down money, but I'll probably have to end up going with another agency. I may take all bikes off of Safeco, depending how the rates work out. Anyway, been too lazy to look elsewhere so far.

|

|

|

|

Post by aeroxbud on Nov 11, 2020 17:33:09 GMT -5

I could never understand the reason insurance companies wouldn't give a bigger discount on multiple bikes. You can only ride one at a time, so less risk for them.

|

|

|

|

Post by captincvmn on Nov 11, 2020 18:07:47 GMT -5

Makes sense. I was just wondering since several videos in a row rolled out. I know T2 has been keeping you quite busy. Your adoring public hasn’t forgotten SSR. Just curious so I thought I’d ask.

|

|

|

|

Post by CrankingWithCG on Nov 13, 2020 5:04:38 GMT -5

Sorry to sway conversation, but oooo project Taotao with a 1e40 swap?? Or...better yet...232 🙄

|

|

|

|

Post by 90GTVert on Nov 13, 2020 11:47:08 GMT -5

Sorry to sway conversation, but oooo project Taotao with a 1e40 swap?? Or...better yet...232 🙄 The main reason to do the TaoTao is to work with the 139QMB. I've got 3 scoots in the garage with 1E40QMBs. I owned a GY6 and was not a fan. Felt like too much money vs performance. I have considered finding out how hard it would be to put a bottom mount Piaggio engine in place of the bottom mount 139QMB. I dunno. I kind of like the idea of converting the 139QMB over to fuel injection one day. I'm not the biggest 4T fan, but a 72cc with EFI would be a pretty good rider. The big IF there being; are the budget EFI kits actually worth having and reliable for long? Plenty of places it could go, but an engine swap or anything crazy isn't high on the list. First things would be just updating about it and then testing stuff like air filter, exhaust, BBK, etc... |

|

|

|

Post by captincvmn on Nov 13, 2020 12:08:09 GMT -5

Might as well add coil-on-plug while you’re at it.

|

|

|

|

Post by CrankingWithCG on Nov 13, 2020 13:07:11 GMT -5

Sorry to sway conversation, but oooo project Taotao with a 1e40 swap?? Or...better yet...232 🙄 The main reason to do the TaoTao is to work with the 139QMB. I've got 3 scoots in the garage with 1E40QMBs. I owned a GY6 and was not a fan. Felt like too much money vs performance. I have considered finding out how hard it would be to put a bottom mount Piaggio engine in place of the bottom mount 139QMB. I dunno. I kind of like the idea of converting the 139QMB over to fuel injection one day. I'm not the biggest 4T fan, but a 72cc with EFI would be a pretty good rider. The big IF there being; are the budget EFI kits actually worth having and reliable for long? Plenty of places it could go, but an engine swap or anything crazy isn't high on the list. First things would be just updating about it and then testing stuff like air filter, exhaust, BBK, etc... I feel ya 😂. I personally love the 150s. The engines themselves are absolutely bulletproof little power houses when you tune them right. As for the rest of the scooter....gárbâge. 50s imo...ëxtrêmè gárbâge. They are really intriguing though. I personally wanna find an almost true 100cc kit and do almost everything besides a crank to see just how much you can get out of em |

|

|

|

Post by 90GTVert on Jan 19, 2021 12:00:24 GMT -5

I just ordered some parts for the exhaust. A little over $100, though some stuff will leave me with spare materials for later projects. The exhaust port is a little shy of 7/8", about 21.35mm. I'm planning to use 1.25" 16ga mild steel tubing. So with 0.065" wall thickness, the ID of the exhaust pipe should be 1.12" or 28.45mm. The pit bike performance exhausts seem to pretty commonly go with a ~28mm pipe, from head to muffler, from what I gather. Pretty well on par there, but I would like to do the tapered header like John showed on the previous page. I'm not sure how it will turn out, but if I can get the 28.45mm to taper down to 21.5-22mm where it meets the port, it sounds like a decent plan to me. The 1.25" section will go all the way into a 1.5" slip-on muffler (typical perforated style). Not sure if that's enough for wave termination, as it seems actual wave termination chambers are pretty big. I hope it's enough to at least get a pulse of moderate strength. I'm not confident at all that this will do anything, but it would be nice to think it may. Plus, I won't know what it does as I have no baseline short of bolting on the small 49cc exhaust and seeing restricted vs my exhaust. The slip on seems like a pretty good deal, including springs and spring hooks. Maybe it won't be really aggressive with the dB killer installed. The other bad thing is some cheap stuff pretty much falls apart. I'll need roughly a 90 degree bend shortly after the header connection, so I ordered a 1.25" U-bend with a 2" radius (actually 2 in case I need more bends). I was going to go with mandrelbends.com or other spots, but shipping was nuts. $30 shipping for a $13 U. I found the U on amazon with free shipping. Some of the tubing that I ordered is to make the header section and muffler entrance. It needs larger sections in those spots to mate up to each component. The 1/4" plate is for a header flange. Might as well make sure it's beefy if I have to go through the trouble of cutting it out. No one likes it when the thinner flanges bend as you tighten the header. The 1/8" rod is to be sure I have something to make spring hooks. The ones in the muffler kit may be stainless. I'll probably still end up using other material for any bracketing. Slip-On Muffler Kit : amzn.to/2M94E0f1.25" OD U-Bend (2) : amzn.to/2M7FDm51/4" x 4" x 12" Steel Plate : amzn.to/2LLcHAJ1.25" OD, 0.065 Wall Mild Steel Tube (3ft) : McMaster-Carr 7767T28 1.25" OD, 0.12" Wall Mild Steel Tube (1ft) : McMaster-Carr 7767T48 1.5" OD, 0.12" Wall Mild Steel Tube (1ft) : McMaster-Carr 7767T431 0.125" Steel Rod (3ft) : McMaster-Carr 6103N1 The peak HP on these, according to that dyno vid, is 4400-5400RPM and peak torque is 3500-4500. They're not very high revving engines and only put out what I guess would be 15-16BHP. Doesn't seem like they should really need 1 1/8" pipe as a performance exhaust, but 5/8" seems pretty small. It also seems like these things could use a cam to make more HP with it currently so low and making 17TQ vs 14HP. With the talk of reliability of these large pit bike engines, it may be that spinning them up faster and stressing them more is a really bad idea. I watched that video again and missed the screen at the end where they say that RPM figures are wrong and should be multiplied by 2. So actually the peak power is more like 8,800-10,800RPM and peak torque is 7,000-9,000. The good news there is that the pipe would have to be incredibly long for a tuned length suitable for ~5000RPM, but this cuts it in half. I do need to figure out what I want to go for with the tuned length RPM. Given the stories of reliability, making an attempt to extend power on the high end may not be the smartest decision for a street moped. It also seems like it would make a more street friendly setup if it had more power in the lower end of the curve. I'm thinking maybe try to set it up for 8500RPM and if it works at all it may help to keep it near peak a little longer on the low side. It could be that this all goes to hell whenever I actually try to get something together, depending how it may fit the bike. Here's a screenshot from the dyno video : source : www.youtube.com/watch?v=DI6huDyNQ08 Not exactly sure when it'll happen, but this will probably be the next step for the SSR project. The biggest fabrication parts should be done at that point. At least nuts and bolts kinda fab. The wiring harness will undoubtedly be an ordeal. |

|

|

|

Post by aeroxbud on Jan 19, 2021 17:25:40 GMT -5

I've missed this project. Good to see you revisiting it again.

|

|

|

|

Post by 90GTVert on Jan 25, 2021 19:27:56 GMT -5

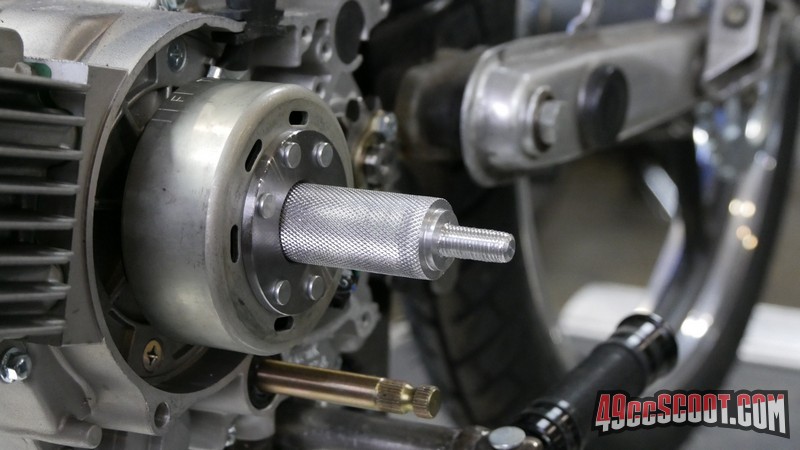

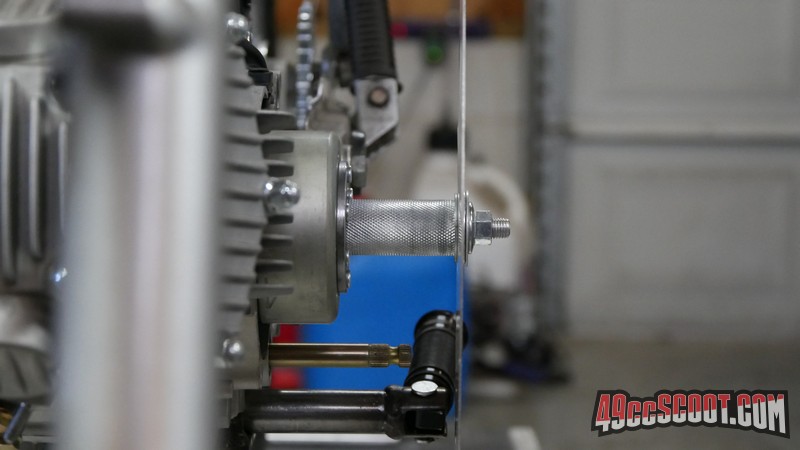

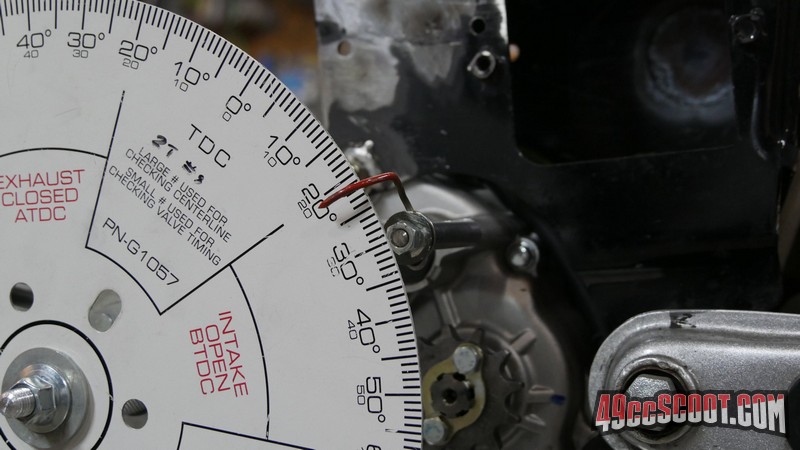

I've done nothing toward actually building an exhaust. Instead, I've decided to measure the exhaust valve opening and closing events to use with formulas/calculators. Not sure how much it'll really mean, since diameter and length are tied together in designs and no books or sites talk about a tapered header. Larger primary ID moves the tuned RPM higher and smaller ID shifts toward lower revs, at least according to Bell in Four Stroke Performance tuning. Anyway, I needed to be able to setup a degree wheel. I made a small adapter before, but wanted one that allowed me to setup the degree wheel on the bike if I wanted to so I made this one that will clear the shift shaft and the pegs when folded.   I cut a spacer and a piece of M6x1.0 all thread so I could use a piece of metal clothes hanger as a timing pointer.  I didn't have a piston stop for the small plugs so I cut a CR7HSA up to make one, with the addition of 2 1/4-20 nuts and all thread.  I still need to setup an indicator. I guess I'll measure EVO and EVC at 0.050" and 1mm. One or both of those should be acceptable. Most stuff just mentions the opening or closing points with no mention of at what lift. |

|

|

|

Post by captincvmn on Jan 25, 2021 20:55:45 GMT -5

I’ve been asleep at the wheel

I didn’t realize the SSR is a four stroke.

|

|

|

|

Post by 90GTVert on Jan 25, 2021 23:59:13 GMT -5

I didn’t realize the SSR is a four stroke. 2X the strokes = 1/2 as cool I sat back and thought, "What am I missing in my life?"... and apparently oil changes was the answer. |

|

|

|

Post by captincvmn on Jan 26, 2021 6:07:17 GMT -5

Maybe you could mix the oil with the gasoline? 🤔

|

|