|

|

Post by pitobread on Sept 9, 2018 12:06:21 GMT -5

That seems perfect. I will check it out when I get back from camping. If I can get a bearing to take up the extra mm on the small end it should work great.

|

|

|

|

Post by pitobread on Sept 9, 2018 21:14:46 GMT -5

yup, checking all dimensions, it seems good. I will need to grind down the big end to fit the crank by .5mm a side but it will work.

Now to order up a .030 oversize KX100 piston and a rod.

|

|

|

|

Post by pitobread on Sept 11, 2018 10:25:11 GMT -5

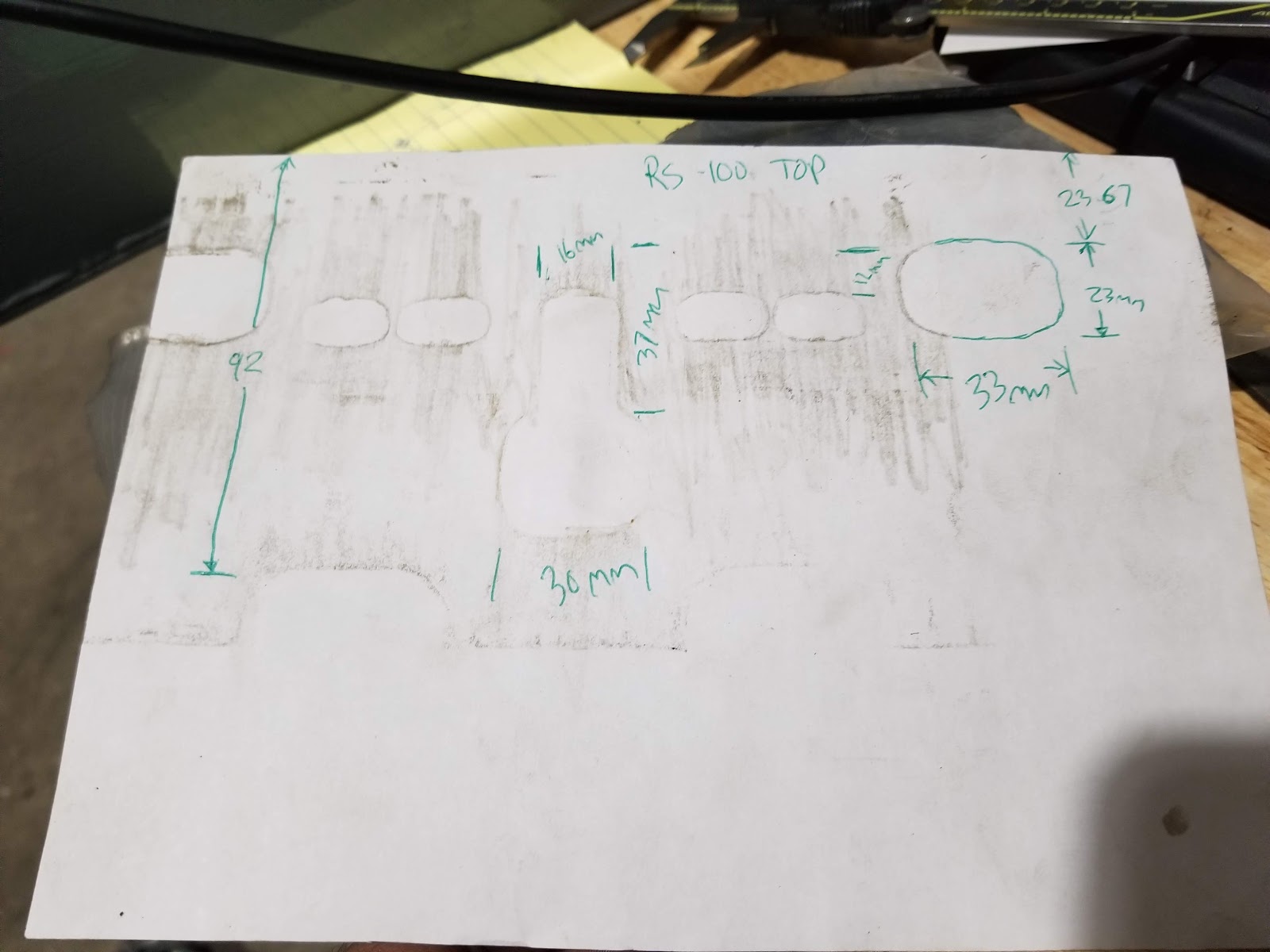

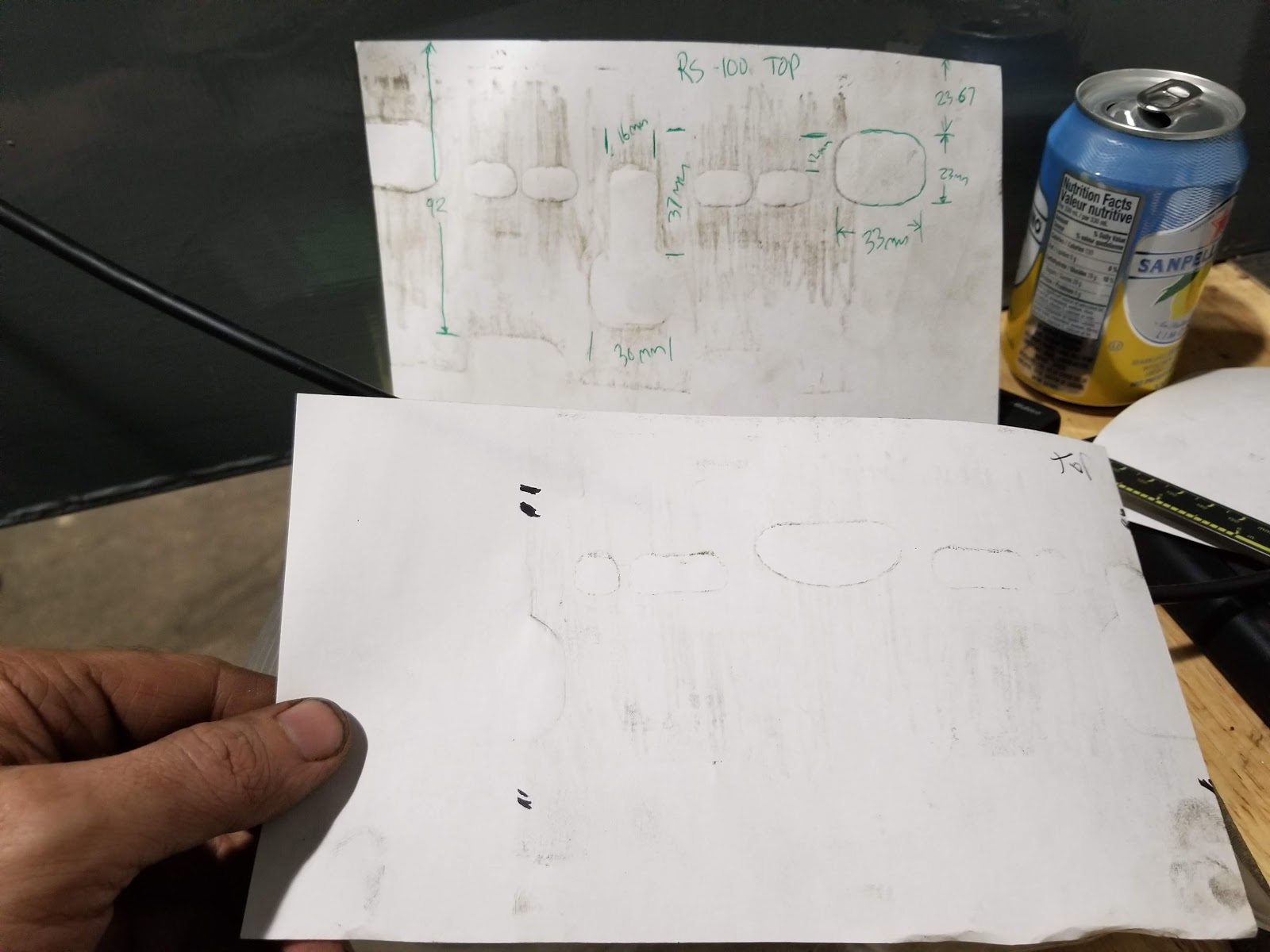

Here is an interesting turn of events. So i did some cylinder rubs, the new "MX/DT" is pretty sad. Lots of casting flash and the exhaust port is nice and wide, but small. Nice domed piston though. The RS though.. I mean from what I can measure from a service manual MarkT sent me, is pretty close to the good 73 MX cylinder... and the head has an Ok squish band as well.. But the RS uses a flat top piston, unlike both the old and new MX which from my research uses a domed piston. Also instead of having a small/large transfer setup, it has 2 of the same sized transfers. So it seems like I already have an MX cylinder of sorts. Or something that can be modified to be one fairly easily I have also found the rod, KTM 150sx, and using a prox bearing I can put the KX100 piston on there... will hopefully be on order soon from mongoose machine.   i will measure up the MX/DT cylinder next |

|

|

|

Post by pitobread on Sept 14, 2018 1:36:56 GMT -5

Well more progress So it seems like the reed inlet on the RS Cylinder is a no go for a bigger reed block. I have a KX65 Vforce 3 block that will fit, but would like to put in something bigger. Unfortunately due to the external sizing, I can't hog it out big enough to take any decent reed blocks here. The MX Cast cylinder will already accept one of the bigger reed blocks I have here, and also a GasGas TXT250 reed block, and probably would take a KX85 block. I may end up just using the cast iron cylinder, but it's sooooo heavy. I have also made my stator plate and rewound it, I need to make some more holes in it tomorrow but it's ready as well. Started with a Honda Dio Stator, I have tons of these. I turned the OD Down 1.5mm   Then I cut out a backing plate for the MX ignition pickup and the Dio backing. I also cut one of the poles off the plate to make room for the pickup.  Then I had to rewind the stator, it's fairly simple as it is single phase. Magnet wire and make sure you have the poles reversed every second one N/S/N/S in my case. This achieved by reversing the winding direction every pole. I have to tap the half wave in between two of the pairs of poles for my Regulator/Rectifier(Also off a Dio)  Other than I made the OD 1mm too big, It's a success. I will fix this problem and put thru holes for the wires in tomorrow and all done.  |

|

|

|

Post by pitobread on Sept 22, 2018 9:25:08 GMT -5

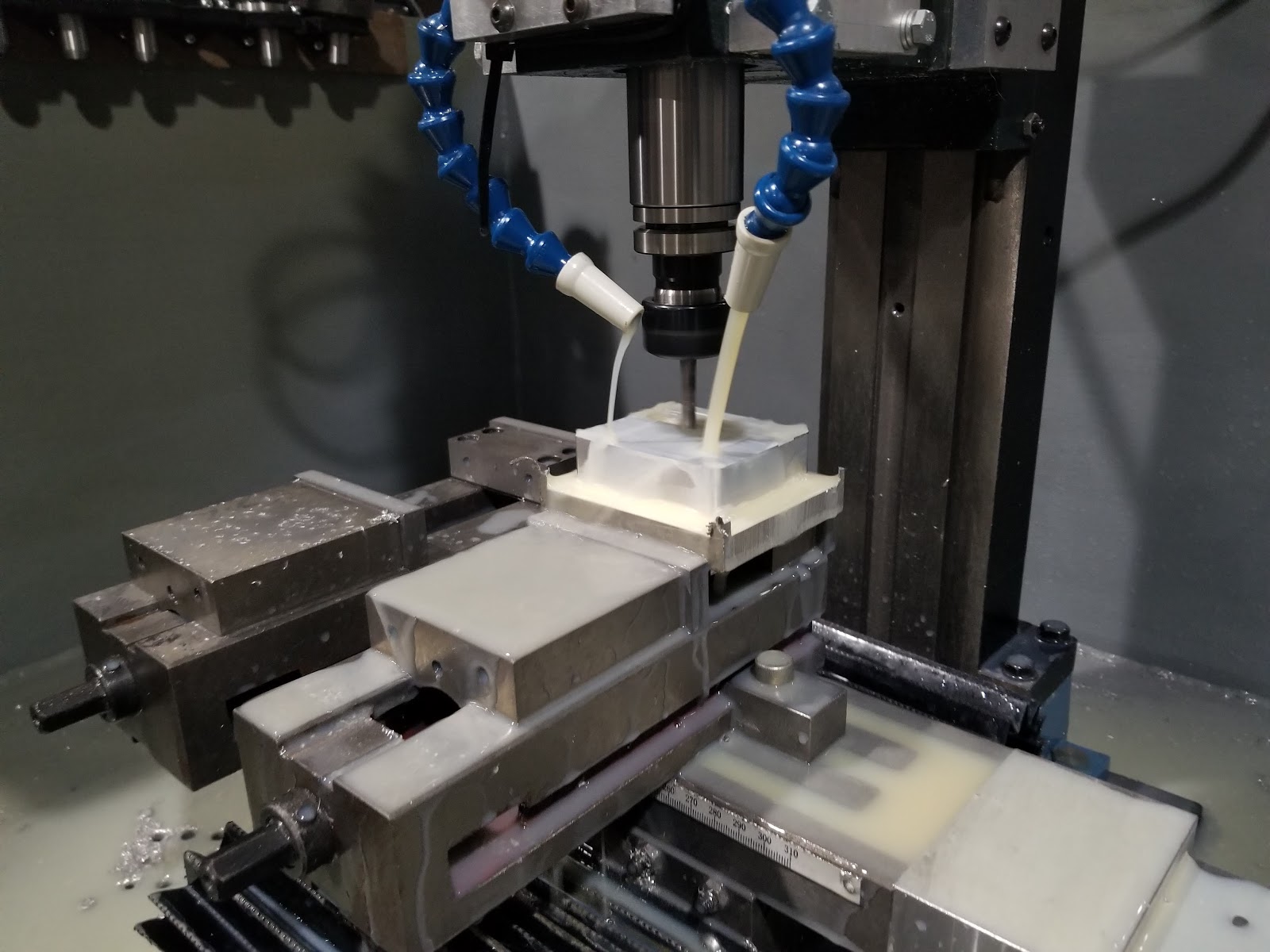

Well got the DT175 Reed Valve in the RS100 Cylinder with some help from my CNC. I also got the boot on as well, which turns out shares the part number with the 75 MX100(16hp). Has a bit of a built in reed stuffer.    I need to find some single petal reeds for this cage though either fiberglass or carbon .030. The only ones I can find are the boyesen dual reeds. I suppose I can make some with some sheet but perhaps someone knows other available reeds that will work on the DT/MX reed blocks. I also re stumbled on this guys blog, everything is in japanese, and he does both 2t and 4t stuff but he also does some pretty amazing dry clutch retrofits on small bore stuff. Kinda got the wheels spinning. Don't know if I will bite the bullet on that one yet. blogs.yahoo.co.jp/forgworkyasuji/MYBLOG/yblog.htmlStill waiting on piston and rod so I can see if my plan will even work. |

|

|

|

Post by 190mech on Sept 22, 2018 16:03:47 GMT -5

|

|

|

|

Post by pitobread on Oct 13, 2018 12:36:38 GMT -5

|

|

|

|

Post by pitobread on Oct 26, 2018 23:14:40 GMT -5

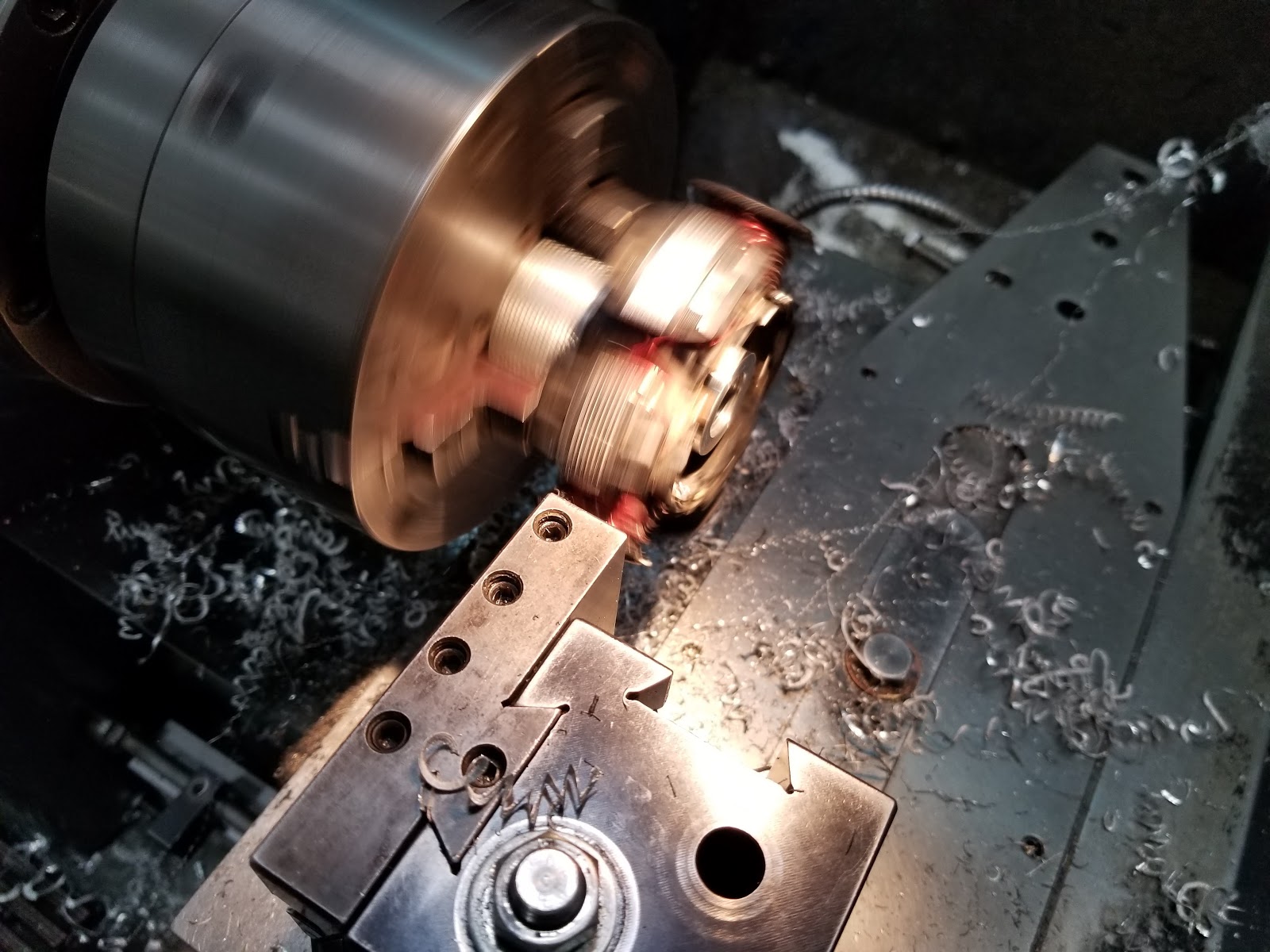

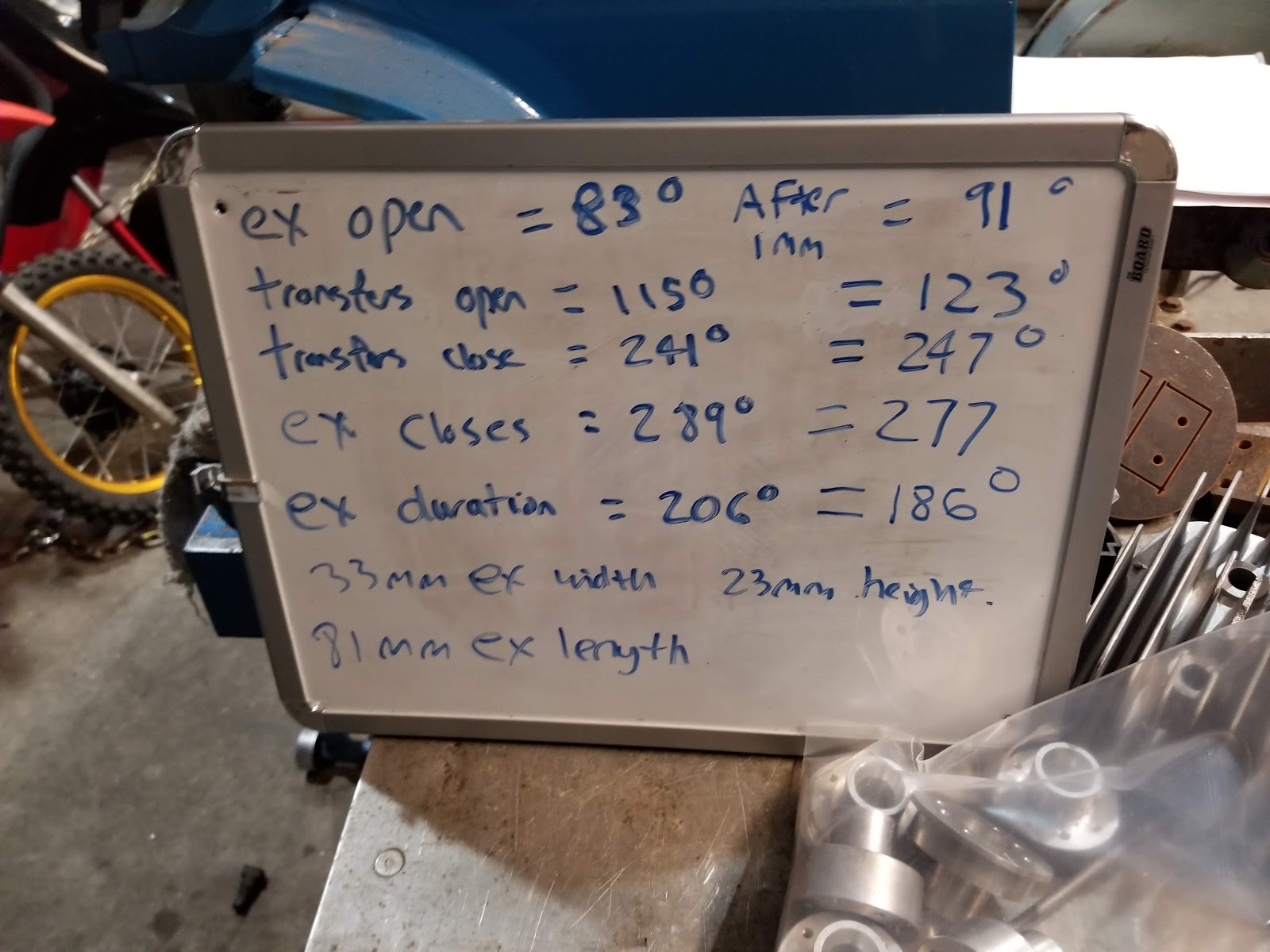

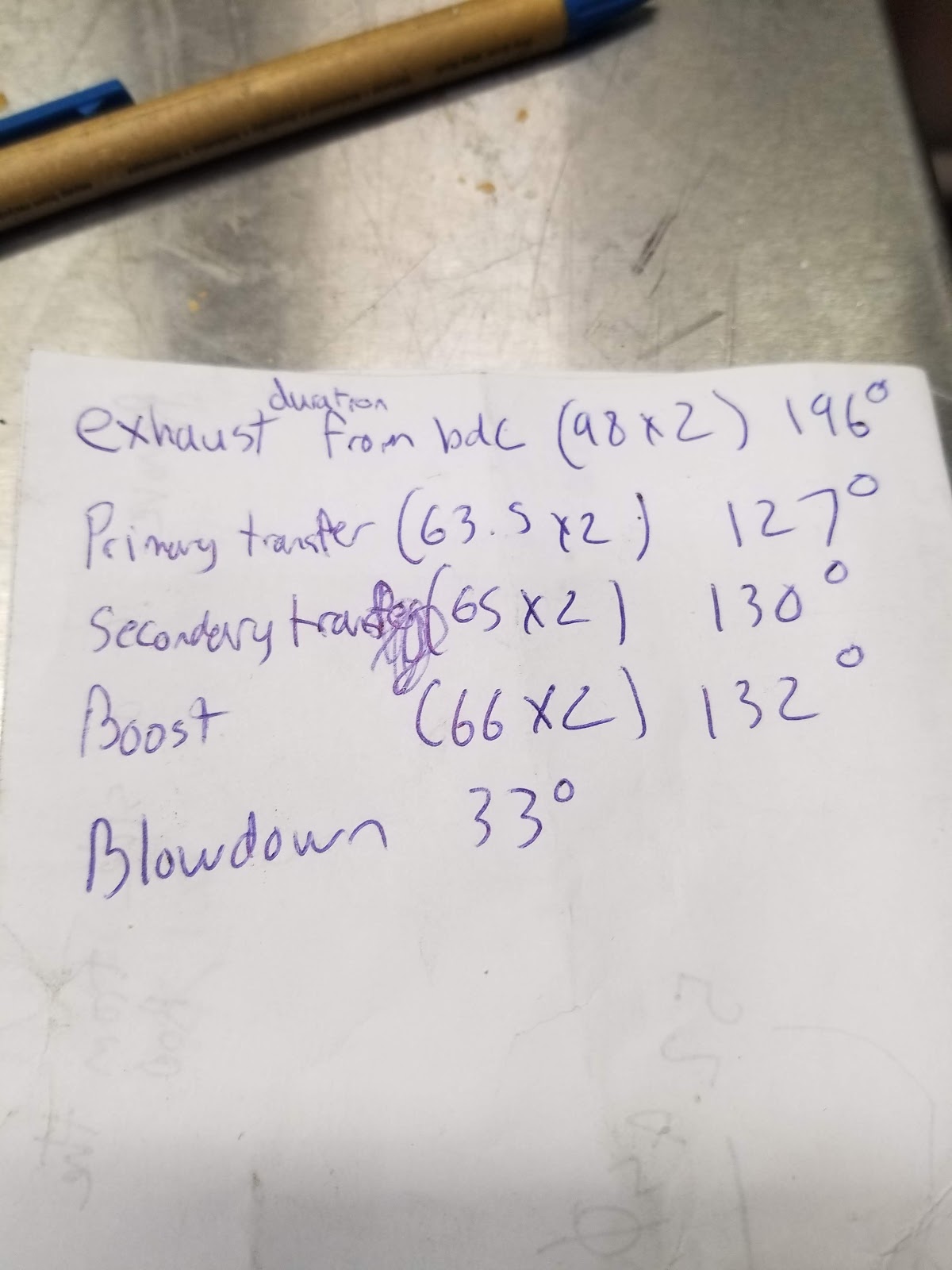

Started making my lil monster.  Crank making, 10mm longer rod.  Durations after longer rod and removing 1mm from base of cylinder.   Some port work  Kx100 Piston in it's hole and after cylinder decking...  Final numbers. |

|

|

|

Post by 190mech on Oct 27, 2018 4:44:16 GMT -5

Beautiful work!!

|

|

|

|

Post by pitobread on Oct 28, 2018 3:13:40 GMT -5

|

|

|

|

Post by pitobread on Nov 4, 2018 10:52:22 GMT -5

|

|

|

|

Post by pitobread on Nov 4, 2018 20:11:34 GMT -5

I started it tonight, I got the hybrid ignition working so I filled the float bowl and it flashed up 2nd kick.

Im super excite. Too bad there is so much paint work to do after I get all the hardware stuff done.

|

|

|

|

Post by ryan_ott on Nov 4, 2018 20:34:18 GMT -5

I think we need to hear it run. The hard work is done but now you need good weather for painting.

|

|

|

|

Post by pitobread on Nov 5, 2018 0:12:50 GMT -5

Im on it, just got a little bit of footage to chew through

|

|

|

|

Post by 190mech on Nov 5, 2018 4:48:41 GMT -5

Enjoyed your pipe calc vid!Gives folks a look at what it takes just planning a pipe..Takes me around 30 hours to fab a pipe..I think the "L cyl" goes to the piston face as in this drawing Frits made;  Gotta watch it again and figure how you are calculating bend cuts as I still do the 2D cardboard mockup and that takes a lot of time!  |

|