Post by 90GTVert on Feb 22, 2010 14:14:23 GMT -5

While making a port map for my Airsal T6, I thought it might be a good idea to document the process for anyone that's never done it before. Making a cylinder port map is a fairly easy process, it just takes a little time. Once you have a port map, you can compare it with others. This can help you determine what modifications might need to be made to achieve the results you are looking for or if you should try a different cylinder altogether.

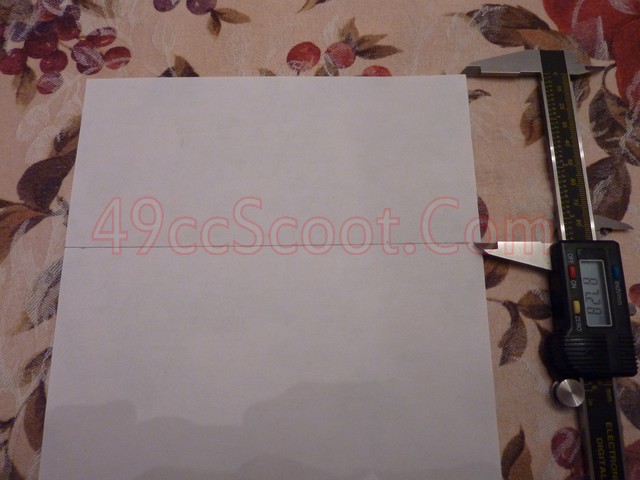

Start out by placing your cylinder (new or well-cleaned) on a flat surface. If you are using a pair of calipers to take measurements, make sure they are zeroed out before you start.

Measure the cylinder's bore and write down the measurement.

Measure the distance from the cylinders deck to the very bottom and take note of it. It is also a good idea to measure the distance from the cylinder's deck to it's base (where it would sit on the cases).

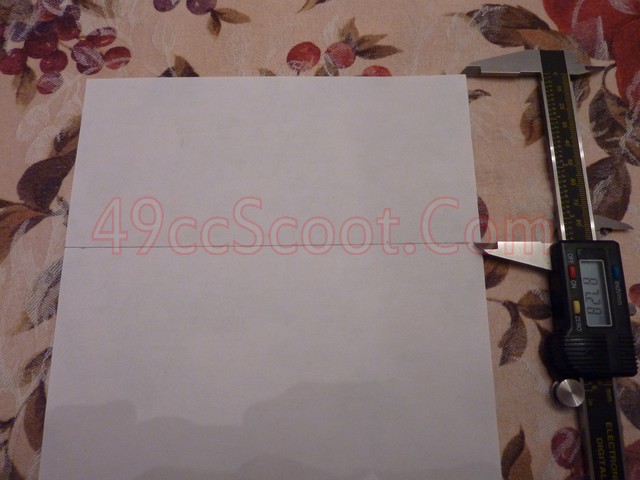

Get out a piece of plain white paper and create a line across it the same distance from the top as the measurement you just took of the cylinder from top to bottom. Cut the paper on that line.

Wrap the paper into a cylindrical shape and place it inside your cylinder's bore.

Hold the paper against the cylinder walls and keep it flush with the top and bottom of the center. Then mark the paper where it overlaps itself.

Remove the paper from the cylinder and connect the two lines with a ruler.

Cut the paper on that line, and there's your template for your port map.

Take a look inside your cylinder. Find the area(s) with the greatest distance between ports. This is where you will want to put the seam of your paper to make mapping easier and more precise.

Place the paper back into the cylinder, aligning the seam with the area you just identified. Tape the paper to the top and bottom so that it is secure while you are making your map.

Hold your cylinder up so that a light can shine through the ports or use a flashlight to shine through the ports. This will help you find them so you aren't scribbling all over the cylinder.

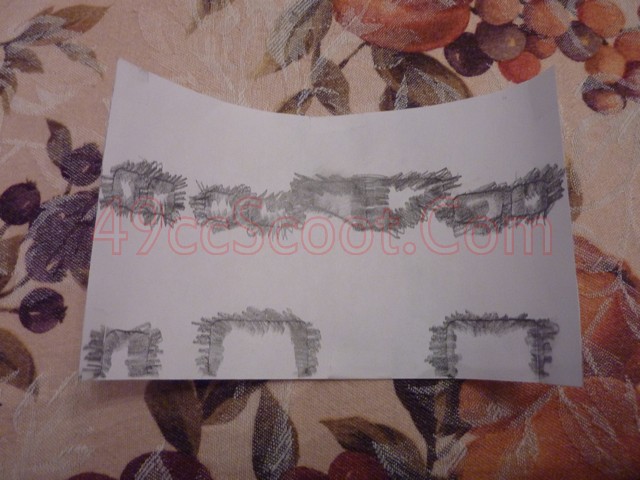

Once you've found a port, use a pencil to rub the edges of the port. If you are doing it correctly, you should be able to see the outline of your port.

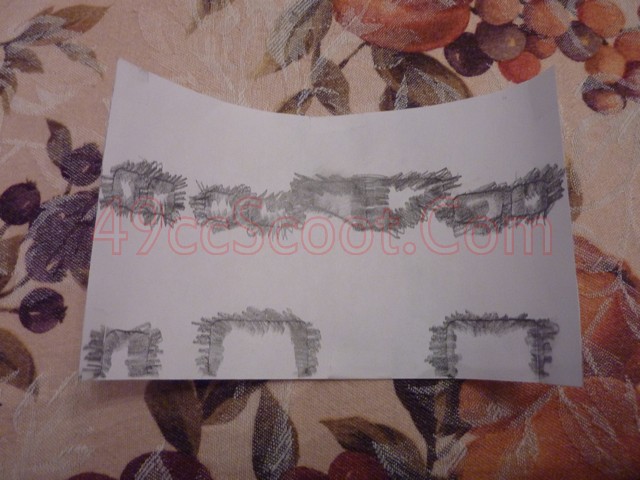

Continue rubbing and outlining all of the ports in your cylinder.

It's not necessary, but I like to trace the section of the cylinder that protrudes into the cylinder. It just seems more complete to me.

Once you've got everything outlined, carefully remove the tape from the cylinder and pull out your paper.

Being careful not to rip the paper, remove or vut away the tape and unroll your new port map.

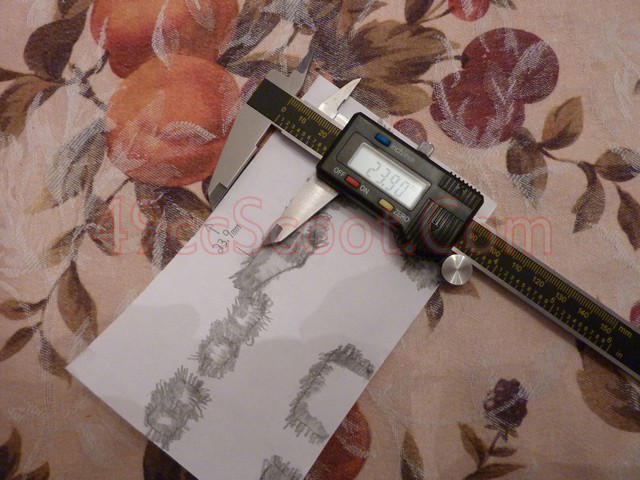

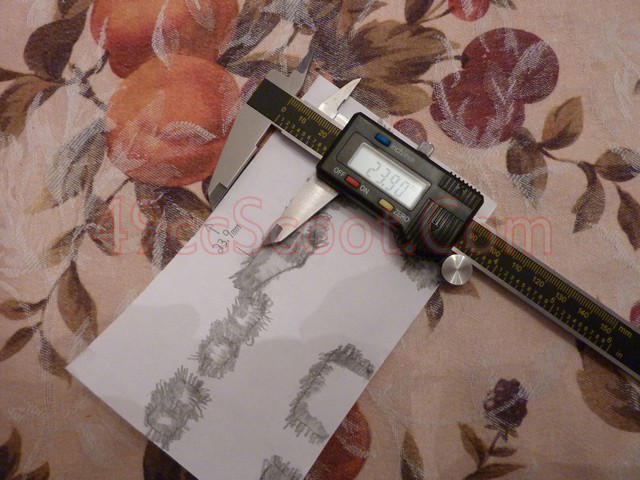

Get your calipers or other measuring tool back out and start taking measurements. I like to measure both the map and the cylinder itself to make sure I haven't got anything way off.

You'll want to measure port heights and widths as well as their distance from the cylinder's deck. You may also want to make a line across the map to represent the cylinder's base (which I forgot to do on this map ). When measuring width, you should actually have the paper still rolled up from the cylinder so you can take a chord width, meaning the width across the curve rather than the width if the paper is flat.

). When measuring width, you should actually have the paper still rolled up from the cylinder so you can take a chord width, meaning the width across the curve rather than the width if the paper is flat.

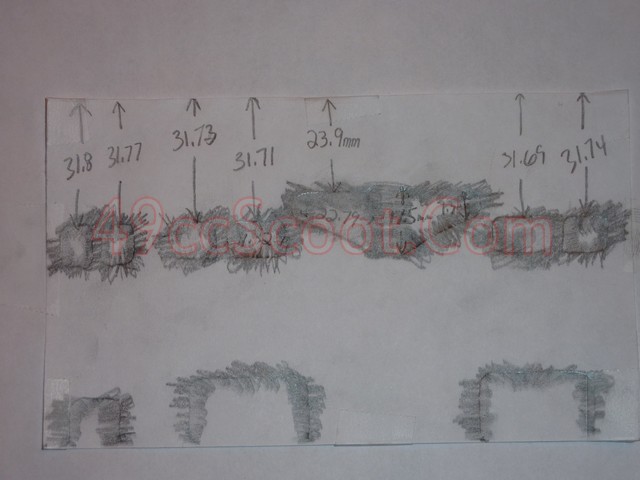

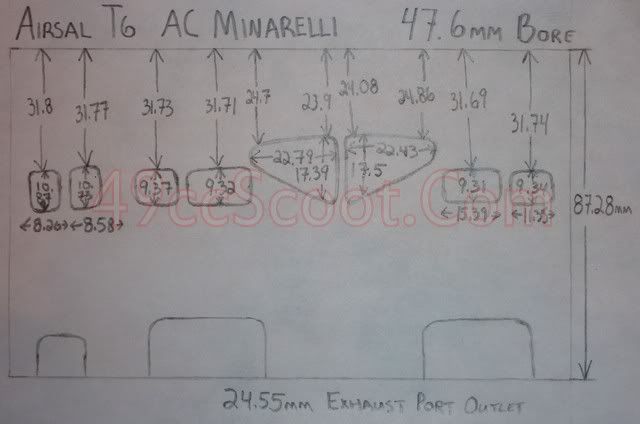

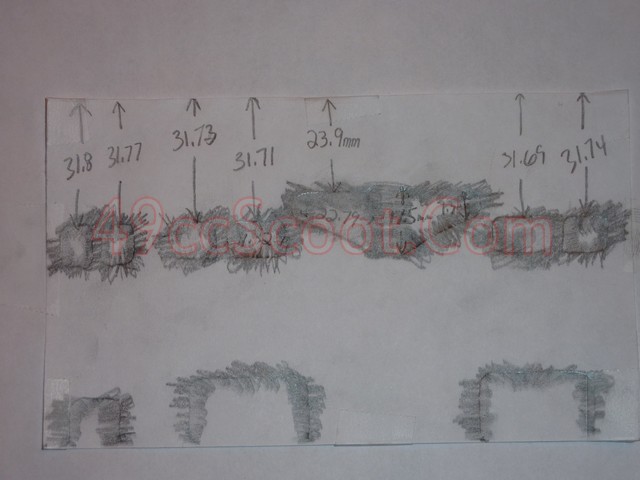

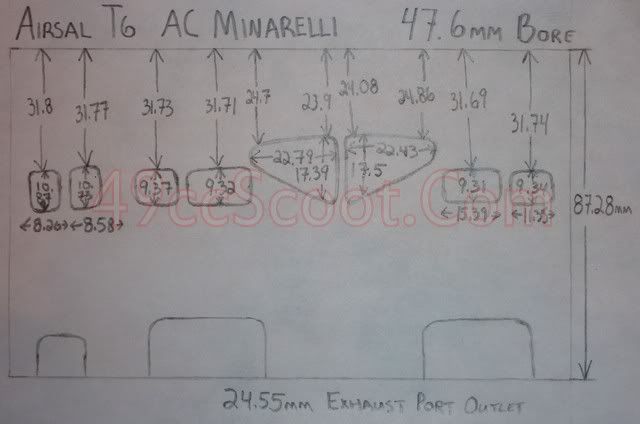

I call the process up to this point the rough map. My maps are usually pretty sloppy looking and hard to see or read, so I create a second map for aesthetic purposes. I tape my rough map to another piece of paper to secure it. Then I tape another piece of paper over it and trace the port outlines onto the fresh paper. I add the measurements a little more neatly and some additional info around the border to create a good port map to share online or for my own personal reference.

If you create a port map, please share it with us in our PORT MAP THREAD. That's also a good place to compare your port map to others.

Start out by placing your cylinder (new or well-cleaned) on a flat surface. If you are using a pair of calipers to take measurements, make sure they are zeroed out before you start.

Measure the cylinder's bore and write down the measurement.

Measure the distance from the cylinders deck to the very bottom and take note of it. It is also a good idea to measure the distance from the cylinder's deck to it's base (where it would sit on the cases).

Get out a piece of plain white paper and create a line across it the same distance from the top as the measurement you just took of the cylinder from top to bottom. Cut the paper on that line.

Wrap the paper into a cylindrical shape and place it inside your cylinder's bore.

Hold the paper against the cylinder walls and keep it flush with the top and bottom of the center. Then mark the paper where it overlaps itself.

Remove the paper from the cylinder and connect the two lines with a ruler.

Cut the paper on that line, and there's your template for your port map.

Take a look inside your cylinder. Find the area(s) with the greatest distance between ports. This is where you will want to put the seam of your paper to make mapping easier and more precise.

Place the paper back into the cylinder, aligning the seam with the area you just identified. Tape the paper to the top and bottom so that it is secure while you are making your map.

Hold your cylinder up so that a light can shine through the ports or use a flashlight to shine through the ports. This will help you find them so you aren't scribbling all over the cylinder.

Once you've found a port, use a pencil to rub the edges of the port. If you are doing it correctly, you should be able to see the outline of your port.

Continue rubbing and outlining all of the ports in your cylinder.

It's not necessary, but I like to trace the section of the cylinder that protrudes into the cylinder. It just seems more complete to me.

Once you've got everything outlined, carefully remove the tape from the cylinder and pull out your paper.

Being careful not to rip the paper, remove or vut away the tape and unroll your new port map.

Get your calipers or other measuring tool back out and start taking measurements. I like to measure both the map and the cylinder itself to make sure I haven't got anything way off.

You'll want to measure port heights and widths as well as their distance from the cylinder's deck. You may also want to make a line across the map to represent the cylinder's base (which I forgot to do on this map

). When measuring width, you should actually have the paper still rolled up from the cylinder so you can take a chord width, meaning the width across the curve rather than the width if the paper is flat.

). When measuring width, you should actually have the paper still rolled up from the cylinder so you can take a chord width, meaning the width across the curve rather than the width if the paper is flat.

I call the process up to this point the rough map. My maps are usually pretty sloppy looking and hard to see or read, so I create a second map for aesthetic purposes. I tape my rough map to another piece of paper to secure it. Then I tape another piece of paper over it and trace the port outlines onto the fresh paper. I add the measurements a little more neatly and some additional info around the border to create a good port map to share online or for my own personal reference.

If you create a port map, please share it with us in our PORT MAP THREAD. That's also a good place to compare your port map to others.