|

|

Post by gsx600racer on Feb 26, 2017 22:02:37 GMT -5

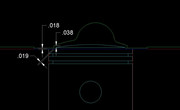

I have an interesting squish situation. The Airsal kit I have has a pop-up piston so you can reuse your 50cc head. This is what the squish solder test looked like.   Surprisingly the measurements of the solder match the sketch dimensions.(.018 & .038) In this sketch, this is basically what I have going on inside my cylinder. Red is the Cylinder, Green is the head, Blue is the head gasket, Piston is Cyan  At the very outside of the cylinder is .018", the corner of the cylinder to the beginning of the mid point of dome is .019" gap, and the actual squish area is .038". So..... what are your thoughts ? Don't sweat the .018 & .019 dimensions or factor them into the .038" ? |

|

|

|

Post by oldgeek on Feb 26, 2017 22:35:17 GMT -5

I dont know, I think the Naraku 70cc head I used on mine may have solved this issue before I even knew I had it.

You could always work the edge of your head just a bit to open it up.

|

|

|

|

Post by oldgeek on Feb 26, 2017 22:40:57 GMT -5

I have a stock Kymco head I could send you for free if you are reluctant to modify your stock Honda head.

|

|

|

|

Post by gsx600racer on Feb 26, 2017 22:54:55 GMT -5

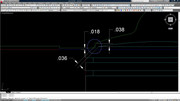

I was thinking of softening the edge like this.  I have a Malossi 70cc o-ring head I can use. I should throw it on and check the squish that way too. |

|