|

|

Post by gsx600racer on Jun 4, 2017 19:34:08 GMT -5

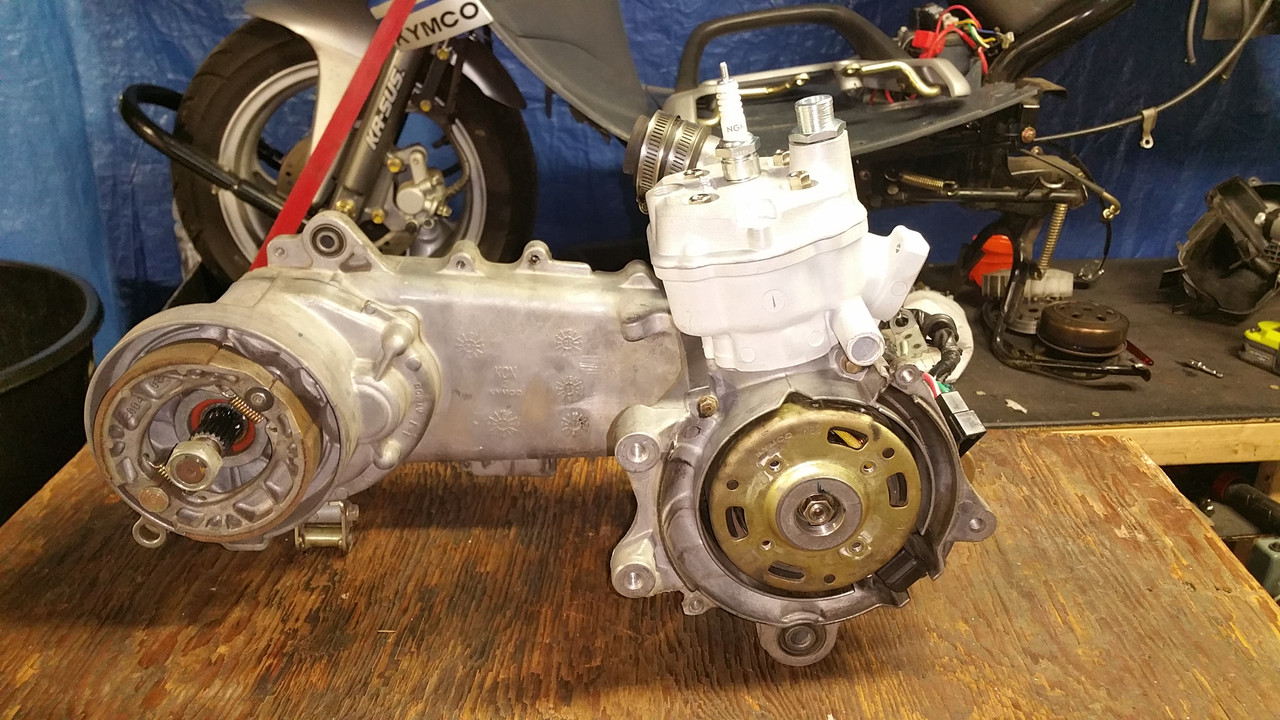

Recently I finally broke down and purchased this. Taking advantage of Treatland the 17% off www.treatland.tv/peugeot-speedfight-airsal-70cc-47-6mm-cylinder-kit-p/airsal-peugeot-010243476.htmThere has been some discussions in the past with this cyl being plug and play on a Honda AF16/Kymco SC10 engine and I argued there were some difference but could not verify seeing I could not find any Peugeot Speedfight engine specs so the next best thing was to buy it and reverse engineer it. So here what iv found so far.  The cyl overall lengths are almost the same. Thats where it stops. LOL The Airsal bolt hole circle(cylinder studs locations) were a larger diameter, the base to head length is longer(.070"), Case surface to bottom of cyl skirt was shorter, The center of cyl to exhaust flange(furthest point away) was .301" longer. What does this all mean, I dont know, yet.... LOL What I do know as that the stock stroke length for Honda/Kymco are 41.4mm(1.630"). A mini stroker length is 44.0mm(1.732") with a difference of 2.6mm(.102') between the two crankshafts. So now with the taller Airsal cyl (1.77mm or .070") and the difference from the stroker/stock crank lengths gets you (.81mm or .032"). I think the best way to go is with a stroker crank(and a little base shim) to correct this issue. I plan on port mapping this cyl so I can compare it as well. Maybe the stroker crank will make the port timing worse. As for the exhaust, I don't think a direct bolt up would be possible, the "longer" exhaust flang location would move the exhaust side case mounting holes forwards and into the fan cover. Fix's could be to cut and re-weld the case mount bracket or cut and shorten the exhaust flange mount and re-weld. This sorta sucks because now that pipe is specific to that built and swapping with other engines is no longer an option without reworking the pipe. Port map added. Dimensions in (mm)  More to come. |

|

|

|

Post by Lucass2T on Jun 5, 2017 16:28:09 GMT -5

I have a peugeot sv cylinder laying around which is the same as the ac speedfight, vivacity, buxy, speedake and zenith. What specs you need.

|

|

|

|

Post by gsx600racer on Jun 5, 2017 19:30:07 GMT -5

I have a peugeot sv cylinder laying around which is the same as the ac speedfight, vivacity, buxy, speedake and zenith. What specs you need. Thanks Lucass2T. I have the Airsal 70cc listed above for specs which is for the Speedfight. What I would REALLY like to get my hands on is the water pump cover. I don't want to buy a new one and take the chance of it not fitting up seeing there is no market for one here in the USA. I wouldn't have a problem buying a used/leaking/broken one for cheap and seeing if it would bolt up. So if you have any buddies on your side of the pond with one let me know. Maybe we can get it here. Thanks  |

|

|

|

Post by gsx600racer on Jun 5, 2017 21:01:15 GMT -5

|

|

|

|

Post by gsx600racer on Jan 10, 2018 0:39:04 GMT -5

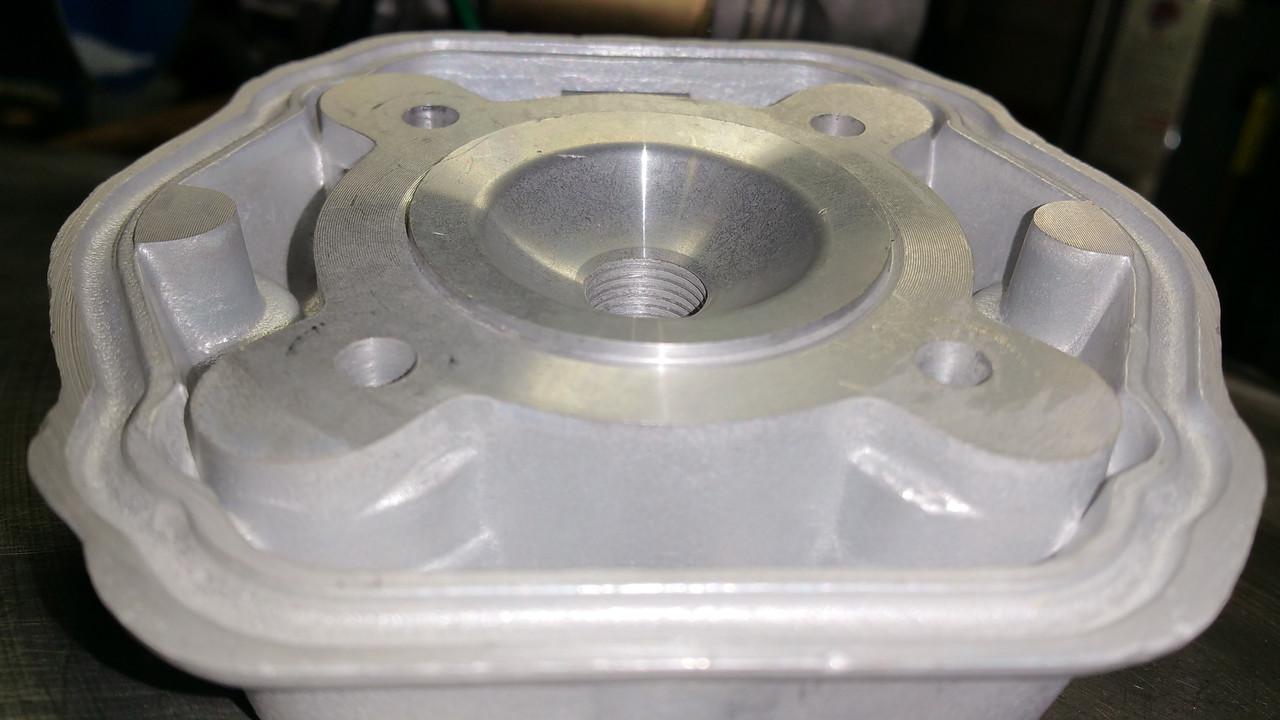

Well I had some time to revisit this project. I got on of the ZX50's on the bench and pulled the engine. Took off the Polini Corsa(which looked in good shape, very little carbon on the piston top and cyl looked good with no scoring.  So I installed the new cylinder studs and dropped the cylinder on. It fit with no issues(cylinder skirt did not hit case)  Unfortunately that's where the fun ends. The new piston skirt is longer and hits at almost BDC. The piston is also taller too. Airsal on left / Polini Corsa on right. (Note: I aligned both pistons on the pin)    Some piston #'s PoliniOveral all height 1.92" Center of pin to bottom of skirt .851" Top of piston(outside diameter not dome) to center of pin .932" AirsalOveral all height 2.225" Center of pin to bottom of skirt 1.025" Top of piston(outside diameter not dome) to center of pin 1.039" DifferencesOveral all height .305" Center of pin to bottom of skirt .174" Top of piston(outside diameter not dome) to center of pin .107" Guess next move is throw on the degree wheel and see how close I am to BDC an where(degree)the piston hits the crankshaft. I have a feeling I am going to need to raise the cylinder some. I also had this crazy thought of machining the dome of the piston and loosing the top ring. More pictures to come. |

|

|

|

Post by 190mech on Jan 10, 2018 7:01:07 GMT -5

Looks like a 2.5mm cyl base spacer will be needed and some skirt trimming.Lifting the cylinder will help unshroud the transfer ducts too..Oughta run strong!

|

|

|

|

Post by 90GTVert on Jan 10, 2018 8:13:41 GMT -5

I also had this crazy thought of machining the dome of the piston and loosing the top ring. I would think you'd want to exhaust other options, like raising the cylinder and trimming the skirt as 190mech said or searching piston catalogs before going there... at least not as the total fix. Sounds like you have more machining experience than me by far from past posts, so you've likely already thought of this, but you could end up with a crown that's too thin if you're cutting off much. www.macdizzy.com/update19.html |

|

|

|

Post by gsx600racer on Jan 11, 2018 2:18:31 GMT -5

Looks like a 2.5mm cyl base spacer will be needed and some skirt trimming.Lifting the cylinder will help unshroud the transfer ducts too..Oughta run strong! I was hoping you would chime in. LOL Can you elaborate on the "unshroud" thing ? |

|

|

|

Post by gsx600racer on Jan 11, 2018 2:20:01 GMT -5

I also had this crazy thought of machining the dome of the piston and loosing the top ring. I would think you'd want to exhaust other options, like raising the cylinder and trimming the skirt as 190mech said or searching piston catalogs before going there... at least not as the total fix. Sounds like you have more machining experience than me by far from past posts, so you've likely already thought of this, but you could end up with a crown that's too thin if you're cutting off much. www.macdizzy.com/update19.htmlLike I said, it was a "crazy thought". The whole idea of a one ring piston(race) sorta like adding stickers. LOL |

|

|

|

Post by gsx600racer on Jan 11, 2018 2:41:42 GMT -5

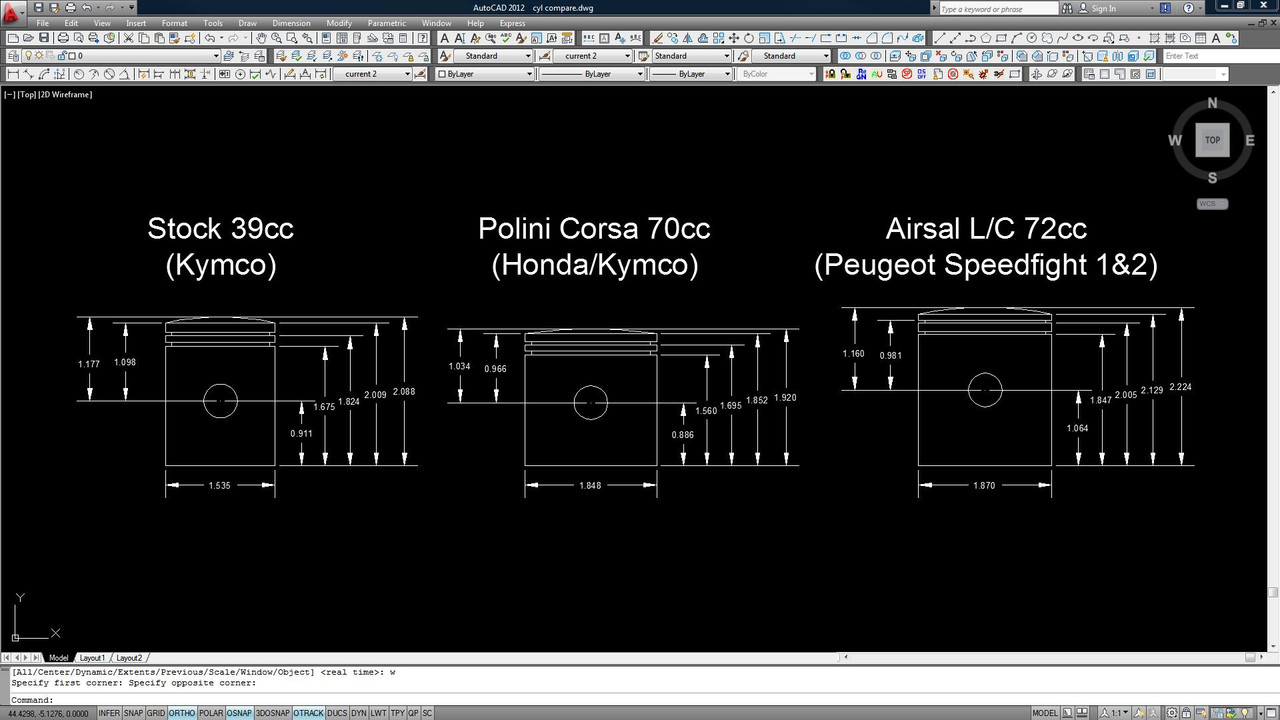

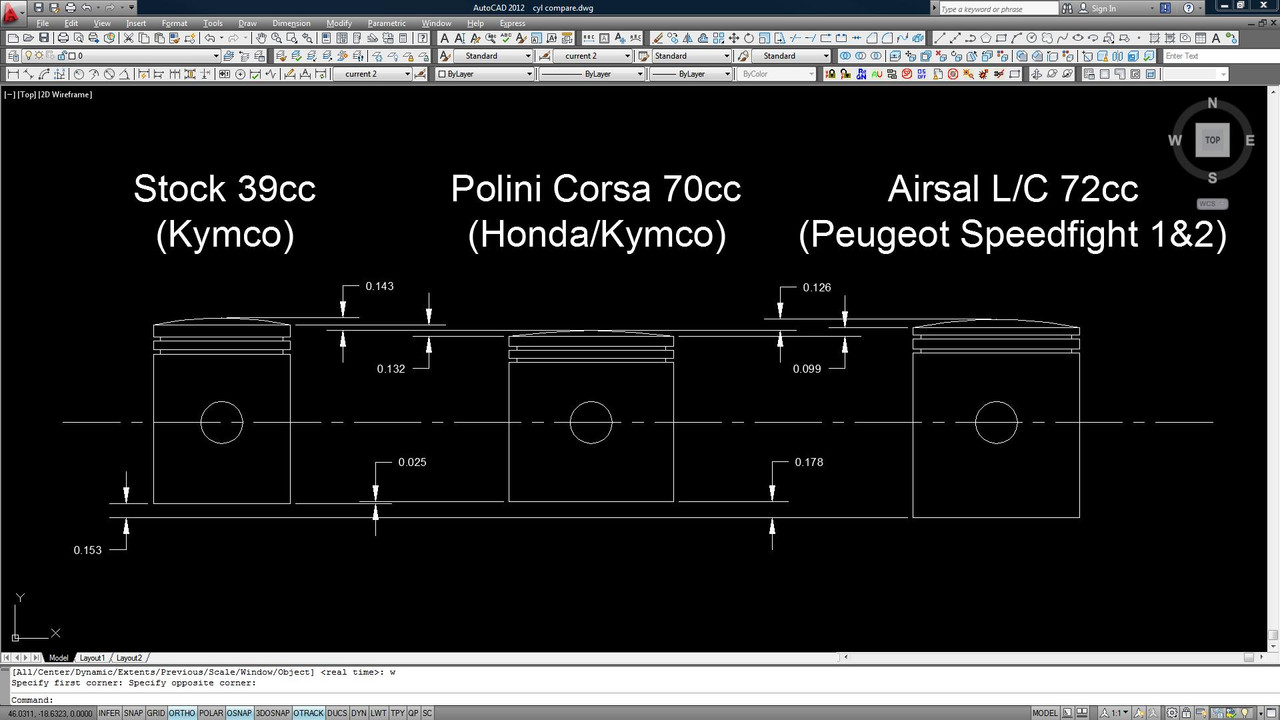

I borrowed my friends height gauge and measured several pistons,(kymco stock, polini corsa & airsal)  This is what I was able to document.(sketches)  The is the comparison between them all(based on wrist pin location as datum)  I think my first plan of attack is to shorten the skirt of the Airsal piston either by .178"(polini) or .153"(stock). Its clear by the #s that the Peugeot has a longer rod length hence the taller piston. Once the piston(skirt)is modified then I can get the degree wheel out and start dialing in the spacer thickness. |

|

|

|

Post by 190mech on Jan 11, 2018 5:00:43 GMT -5

I doubt if it will be a problem,but lightly scribe a line on the piston skirt across the bottom of the ex port with the piston at TDC,that'll show you how much skirt is below the port before cutting..

Unshrouding just means picking up the cylinder will move the cyl skirts and transfer ducts out of the way a bit more to allow the mixture an easier path..

|

|

|

|

Post by gsx600racer on Jan 12, 2018 16:27:31 GMT -5

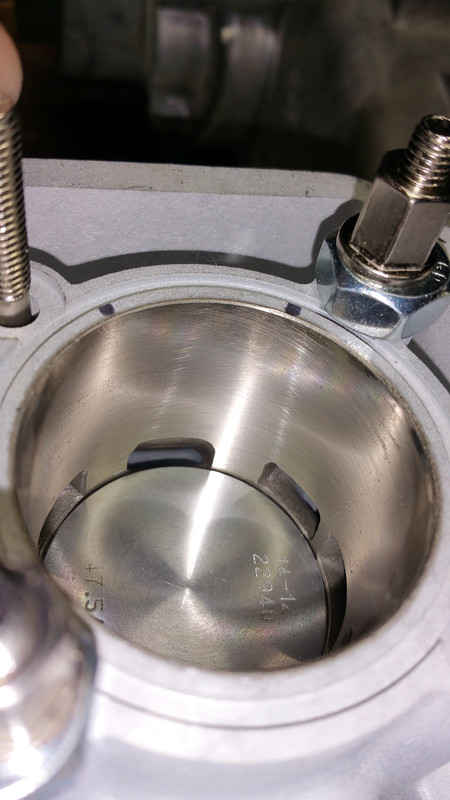

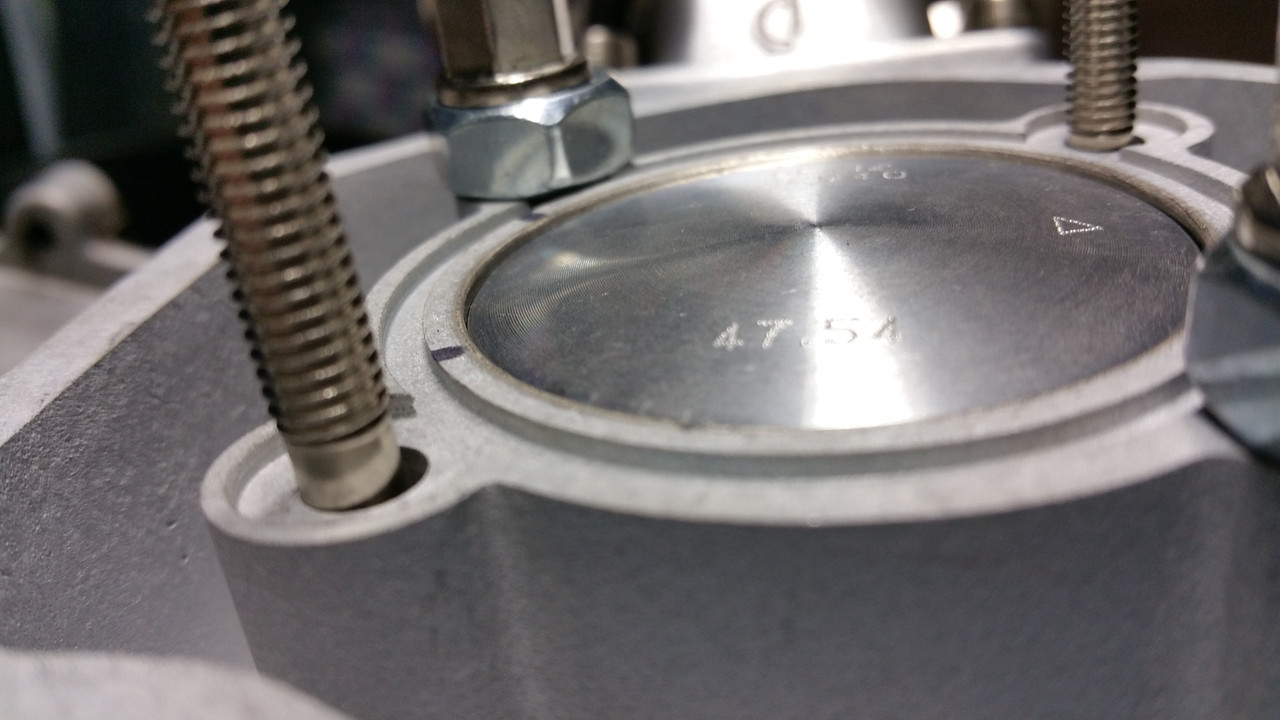

I was able to make some progress. I machined .160" from the bottom of the piston. I set up the degree wheel and got some #'s(without gasket) Exhaust: Open 88° Closed 268° Duration 180° Transfer: Open 113° Closed 243° Duration 130° Boost: Open 116° Closed 239° Duration 123° Here are views of the ports @ BDC    Here are view of the piston @ TDC. The distance from the top of cylinder to top of piston(outside) is -.028"  The cylinder head squish feature extends .062" into the cylinder. So there is .034" of interference. Note this is without any squish calculated yet.

I'd like to shoot for at least .034" or a tad bigger squish. So if my math correct I will need to raise the cylinder a minimum .068-.070". |

|

|

|

Post by 190mech on Jan 12, 2018 17:56:32 GMT -5

I hate to see transfer durations above 130 degrees,,also lifting the cylinder will get the bottom of the transfer ducts above the piston dome at BDC and will decrease piston cooling greatly..Ideal numbers would be 130 Tr,190/195 Ex..Only way I see that happening is raise the Ex port,but cutting Nikasil is a dicey operation..The head squish could be easily adjusted on a lathe after the port work is solved.Stacking thin flat washers on the studs under the jug is a good way to simulate a spacer height..

|

|

|

|

Post by gsx600racer on Jan 12, 2018 18:53:07 GMT -5

I hate to see transfer durations above 130 degrees,,also lifting the cylinder will get the bottom of the transfer ducts above the piston dome at BDC and will decrease piston cooling greatly..Ideal numbers would be 130 Tr,190/195 Ex..Only way I see that happening is raise the Ex port,but cutting Nikasil is a dicey operation..The head squish could be easily adjusted on a lathe after the port work is solved.Stacking thin flat washers on the studs under the jug is a good way to simulate a spacer height.. Thanks 190. Its almost a catch 22. I like how the pics look @ bdc (piston cooling). Sadly this is with no base gasket. I think the trick is to work this problem from the bottom up. I did raise the cyl with flat washer(.068"), #'s and more pictures comming shortly. I think using just a thin base gasket to keep bdc purdy. My concerns is with coolant leaks if I start shimming up the head. I'm thinking of splitting the difference with some machining and shims. There is only so much the outer o-rings is going to seal. Can always use larger o-ring material is an option too. |

|

|

|

Post by 190mech on Jan 12, 2018 19:22:10 GMT -5

I wouldnt try to lift the head,lathe cutting the squish and combustion chamber to match the cylinder setup will keep the water jacket at the designed height..

|

|