Post by 90GTVert on Oct 29, 2010 9:34:53 GMT -5

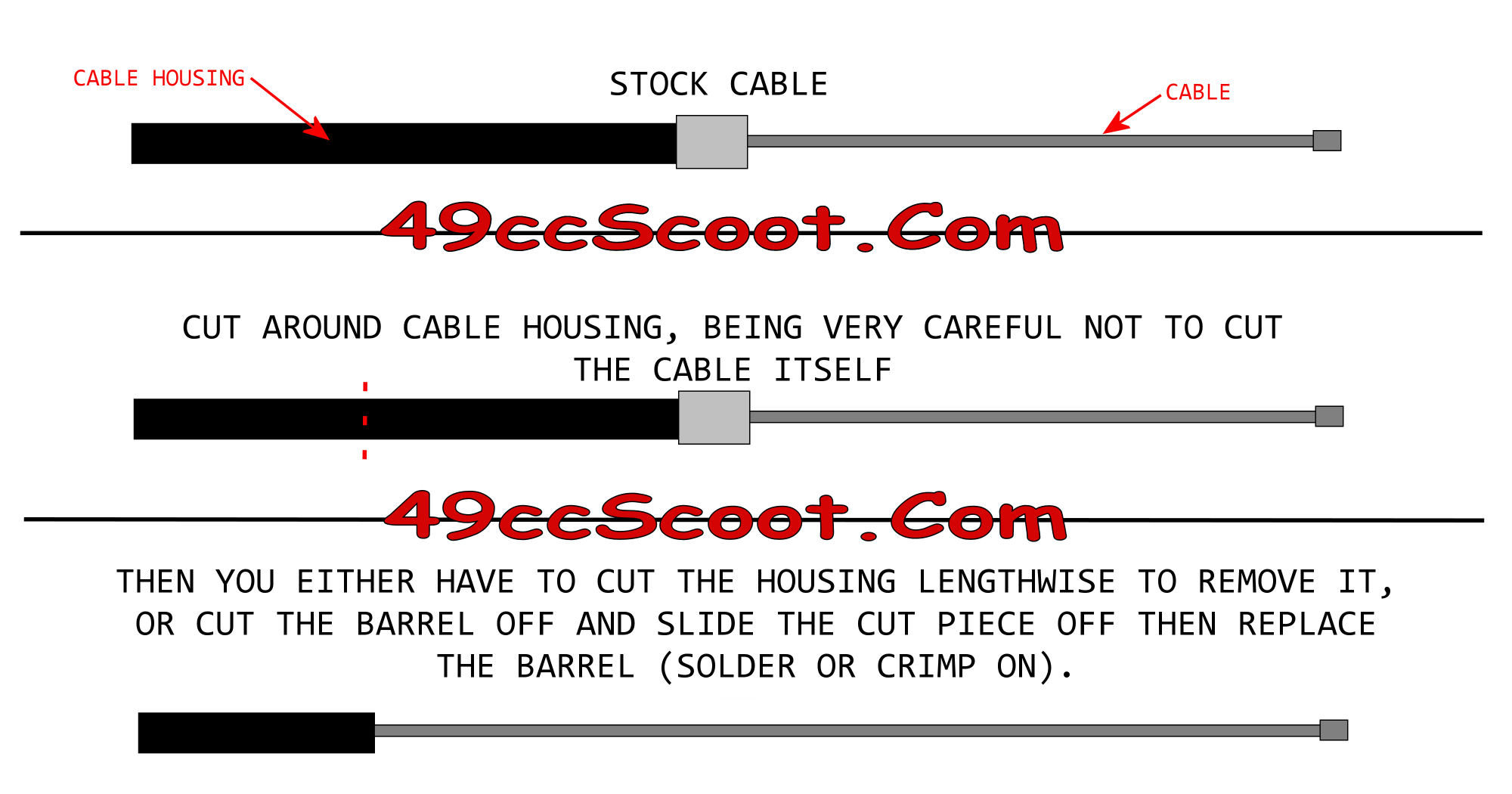

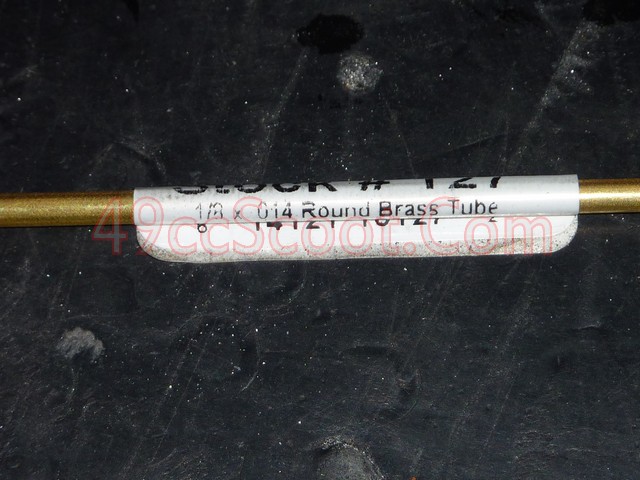

Throttle cable ends can be made from copper or brass tubing if you don't have a premade solder on end. The standard size for the carb end of cables used with the 1E40QMB/minarelli (and many other cables) can be made using 1/8" brass tubing or even 1/8" copper tubing like the stuff the sell for use with mechanical guages at Autozone. I believe those kits are made by Sunpro IIRC. I picked up a foot of 1/8" brass tubing from a hardware store for less than $1.

I'd suggest using a tubing cutter, as shown below, to get a good clean cut of the tubing. A sharp hacksaw could be another option.

Once you get the end cut, hold it in a set of vice grips. Be sure not to clamp down hard and disform the tube. Apply a coating of flux to the inside of the tube. I like liquid flux for this job.

Heat the tube with a propane torch or a big soldering iron/gun. I found a torch to be the easiest.

Once the tubing is hot, beging applying solder until you fill the tube completely. This may take multiple heatings and applications to do it right. I use silver bearing solder.

I was a bit sloppy this time and soldered the brass to the vice grips. No biggie, just heat for a second and it'll come off when you need to remove it (not yet). The solder will either chip off of the grips or you can heat them quickly and remove it.

Now flux the end of the thottle cable. Heat the tubing and it's solder filling again, and it doesn't hurt to heat the tip of the cable a little at the same time. That's much easer with a torch than an iron from my experience. Once the solder is hot, insert the cable into the tubing. You will need to hold it for a few seconds to let it cool enough to hold. Once it's cooled down, you can remove the cable from your grips and your new end should be securely attached.

I would suggest testing to be sure it's a secure hold once it's completely cool. I use a pair of pliers that will close tight enough that the end won't pass through, but allow the cable to move freely. Pull on the cable harder than the throttle would pull it to be sure it's gonna stay. You don't want an end coming off and leaving you stranded or possibly even getting sucked into the engine.

Finally, check to be sure the end fits where it needs to. If not, you may have to grind an end down or knock off some stray solder.