|

|

Post by 190mech on Dec 15, 2015 18:26:12 GMT -5

|

|

|

|

Post by 90GTVert on Mar 25, 2016 6:58:19 GMT -5

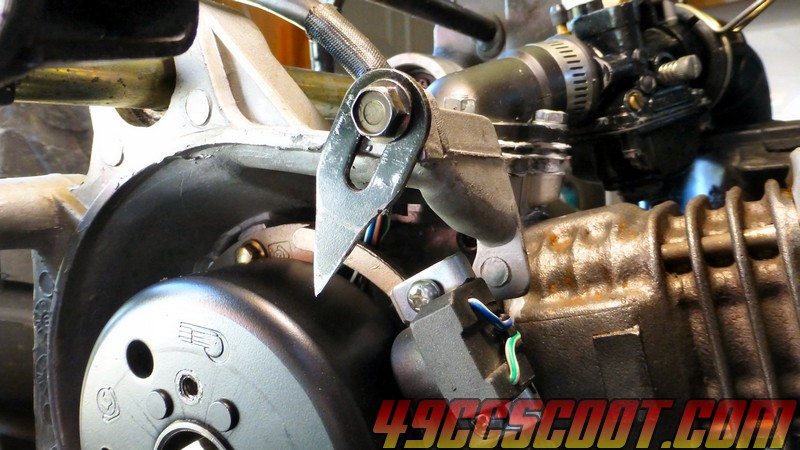

I always use an adjustable advance timing light that allows me to dial in the advance on the light so that I can work with just a TDC mark. If you're working with a light with no adjustment, you will need something like John showed or to make a series of marks some other way, graduated at least as far as 20 degrees BTDC every 1-5 degrees. What John posted is very nice, I've just been too lazy to make one I guess. I usually setup a pointer. Can be an arrow type or just a piece of wire/paperclip. Needs to be sturdy enough not to jiggle around when the engine is running though. This was a piece of a slotted bracket (I think for a license plate) just ground to a point.  Then I use either a degree wheel and piston stop or dial indicator to find TDC. For a degree wheel you 0 it to TDC the same way you would if checking port timing. For a dial indicator you put it through the spark plug hole so it's perpendicular to the deck/crown. You can make a bracket, use a base, or there are specialty indicators that thread into the plug hole.   Here's a link to the degree wheel/piston stop TDC method : 49ccscoot.proboards.com/thread/353/port-durations-degree-wheel-methodsWhen using a dial indicator, you can find the highest point of travel (highest reading on indicator) and mark that as TDC. That leaves a small amount of room for error though. To find true TDC with a dial indicator, you would mark the flywheel when the piston travels a specific distance from wherever you've zeroed the indicator near TDC. Usually something like 0.040" is used. Then rotate the piston the opposite way and make another mark when the piston reaches the number you initially chose. So if you marked the flywheel at 0.040" before, mark it at exactly 0.040" again. That should leave 2 marks on the flywheel, and TDC is directly in between them. Basically the same idea as using a piston stop. I'm prob confusing people with this. Most people seem to look at my stuff about the degree wheel and find it hard to understand, so I'm not sure why I suck at explaining it, but I doubt this is any better. You can find more info on finding TDC with your favorite search engine if necessary. Make a mark that corresponds with the pointer once you've figured out where TDC is.  Connect the timing light, usually just an inductive pickup that goes over the plug wire and clips for the battery terminals to provide power. Make sure no wires are near moving or hot parts and start the engine. Aim the light at the flywheel and pointer and you should see the mark on the flywheel as the light flashes. If you only have a standard light with no adjustment, or when your adjustable light hasn't been dialed in, you'll see that the mark and pointer don't align (unless your timing is right on TDC, which it shouldn't be). If you have something like John made that is marked at multiple points, then you can read the timing.  If you're using an adjustable light, you'll need to dial it in until the mark on the flywheel and the pointer are aligned the best that you can align them.  Once the marks are aligned, you can read the timing light to see where your ignition timing is currently set. You should either have a digital readout or a dial to read. In this case, my marks aligned at 15.5 degrees, so my timing was set at 15.5°BTDC.  This is just a base timing check and you'll want the engine at idle speed, hopefully not above 2000RPM. You can continue to note timing this way while revving the engine to map your timing curve. Plot RPM and advance on a graph if you'd like a visual representation of the curve, which is easy to do with most office software (Open Office is free and works well). Hopefully I haven't totally confused everyone with how it's explained. If I did, maybe at least the pics will be of some use. I need to note that if you test without the fan and shrouds as I've shown, you need to keep ignition checks brief and monitor temps if you have a CHT or other temp gauge.Here's a video of timing being checking on a Minarelli 2T engine. |

|

|

|

Post by 90GTVert on Mar 25, 2016 7:44:34 GMT -5

If you have a four-stroke, the process is much easier because their flywheels are generally marked from the factory with a pointer built into the case.  You can use a degree wheel or dial indicator to verify that TDC it correct on your four-stroke engine if you'd like. Sometimes flywheels, especially on Chinese scooters, are found to be machined improperly and that can throw off not only ignition timing, but also valve timing. Here's an example of a timing light being used on a 139QMB. |

|