GY6 / 139QMB Oil Cooler Information & Installation Help

Jun 19, 2016 9:57:48 GMT -5

190mech, spaz12, and 5 more like this

Post by 90GTVert on Jun 19, 2016 9:57:48 GMT -5

My GY6 150 had some serious cooling issues based on the cylinder head temperatures (CHT) that I observed. I saw CHT reach beyond 500°F on hot days with much wide open throttle (WOT). In case you're wondering; yes, I was using the cooling fan shrouds. I even made an air scoop from PVC that stuck out far enough to catch cold air. That helped a little, but I still saw over 500 degree temps with the air scoop. I used a larger main jet that robbed the engine of a little bit of power from running rich to increase fuel cooling. That controlled temperatures better, but it still ran hot and I hoped to find another way to cool the engine so I could keep in closer to a peak power tune.

Click here to see how the scoop was made.

Oil cooler kits were available for the GY6 125/150 and the 139QMB/GY6 50 for roughly $100 and up. A power steering fluid cooler or other small cooler from an automobile could work for a cheaper alternative, but I wouldn't have any easy way to hook one up. I'd need an adapter, and I have only seen adapters as part of complete oil cooler kits. Some GY6 engines have provisions for oil cooler connections built into the case, but mine did not.

I bought an oil cooler kit from ScrappyDogScooters for around $100 shipped that included the adapter, cooler, hoses, and hardware that seems like it should cover most installations. The pics below show the kit that I received and include some measurements of the cooler. Most kits should be a similar design with different cooler dimensions and they may use a different style of hoses. The hoses in my kit had the fittings crimped on, while others will use barbs and standard hose.

Installation on most scooters will probably need to start with removing body panels so you can access the frame to mount the cooler and route hoses. Once I had my panels off, I started mocking up the system to make sure the hoses would reach from the engine to the location that I had in mind for the oil cooler. The scooter I was working on is a Roketa Cayman, similar to the Vento Triton and other B-series designs. It's a somewhat large frame for a 50-150cc, and the hoses had room to spare to reach to the front of the scoot.

This scooter, and others like it, have a triangular panel above the headlight assembly. It's normally just a decoration, but I thought it could be of some use to me. The panel is secured with plastic tabs and it can be removed from the large front fairing. That leaves an opening right in the front of the scooter where plenty of fresh air is available.

The area was mostly clear, but the rectifier/regulator and an aftermarket horn that I installed were in the way. I unbolted them and set them aside until later.

Then I needed to come up with a bracket that would position the oil cooler behind the opening in the front fairing. I took a few measurements from the front mount bolt hole in the fairing to the opening. Then I used some steel strap to hang the cooler where I thought I wanted it. I used the bolts that hold the screen on the filter to hold the strap.

Then I could put the front on and verify that the measurements I made were correct or make adjustments as needed so I had the info to make a more permanent bracket.

The oil cooler kit did include a bracket, but it didn't work well for my plan.

I chose to make a bracket out of steel flat bar, using all four bolts that secure the screen to hold the bracket and cooler together. This required welding, but you could probably come up with something similar using L brackets that you can find and hardware and home improvement stores if you wish to do something similar without welding.

This location also left free space behind the oil cooler. This is important. You never want to place the oil cooler right up against a surface. Air needs to be able to move through the cooler front to rear without getting trapped or blocked by a wall directly behind it.

Once my bracket was finished, I mounted the rectifier/regulator and horn in ways that would work with the oil cooler in place.

The way I chose to mount the oil cooler is just one of many. Whatever you can come up with that will allow plenty of airflow through the cooler could work. Many people mount it closer to the engine, especially when the kit they use comes with standard hoses that can be cut shorter. Some mount the cooler over the cooling fan shroud's inlet, so the fan is drawing air though the cooler. My only concern with that design is that you would be sort of pre-heating the air that is being blown across the engine for cooling. Allowing the cooler and fan to have their own sources of cool fresh air may be beneficial. Perhaps I have it all wrong and the amount of air that the fan draws through the cooler would make it work very well. I've never tried it, so those are nothing more than thoughts. You may be able to look to scooters like the Genuine Buddy 170i that is stock with an oil cooler mounted under the scoot. If you are lacking an idea, try doing a little image searching or picking our brains on the forum.

With the cooler mounted, I moved on to running the hoses to the engine. The return line, that's the hose that takes the cooled oil back to the engine, is a simple straight hose. The feed line, that transports hot oil from the engine to the cooler, required some assembly because it includes an oil filter inline.

The oil filter in this kit is a serviceable unit, so it comes apart. It's actually the same style of screening unit that is inside of the engine which will be replaced by the adapter for the oil cooler. Take it apart and make sure everything goes together as it should, and then reassemble it. The assembly order is shown below. You may want to smear a little bit of oil on the o-ring prior to assembly. Use the 2-pronged spanner tool if your kit included it to tighten the filter sections together.

When you assemble the feed hose with the oil filter, make sure you install the filter so that it is catching particles as they flow through. You want it to be setup so that the filter screen's opening is toward the engine. Pay attention to the fittings on each section of the hose, because you may find that the fitting on one end is smaller than the other so they must be used in the appropriate spot. In my case the larger end's banjo fitting matches up to the oil cooler and the smaller banjo fitting needs to go to the adapter.

I used a bit of teflon tape on the threads going into the oil cooler to promote better sealing.

When installing banjo fittings, each bolt should have two special washers with rubber inner sections. The banjo fitting should be sandwiched between two washers as shown. Leave the bolts a little bit loose so they can move until all routing is complete.

Avoid routing hoses anywhere where they will be pinched if the suspension moves and keep them away from anything sharp. Braided hoses can chafe anything that they rub against, and they will be hot. Route carefully to avoid unnecessary contact with wiring or sensitive components. You can use tubing that withstands heat to protect the hoses and anything they are near if you see fit. I used heat shielding near the engine to prevent my cooler lines from soaking up some of the exhaust heat.

Once the lines were routed, I began the process of installing the oil cooler adapter in the engine. Before I began, I drained the engine oil using the drain plug on the CVT side and then reinstalled the drain plug.

Then I removed the plug and filter assembly on the other side of the engine, keeping slight pressure on the plug as it was removed since there is a spring behind it. This is the plug that the adapter will replace.

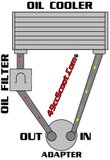

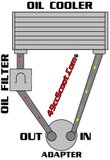

The adapter has spots for two fittings. One is the inlet and the other is the outlet. If you look into each hole, you can see that one leads to the outer section of the adapter and the other leads to it's center. The one leading to the center is the inlet, where cooled oil enters the engine. The one leading to the outer section is the outlet where hot oil exits the engine. I marked my adapter prior to installation to make it easy to tell which is which once it was on the engine.

Now the adapter can be screwed into the engine in place of the plug/screen assembly that you removed. You should have a rubbery cap with the adapter that helps to seal the inlet and outlet sections. Use the supplied spanner tool to tighten the adapter.

After that, the lines can be installed. Again, the outlet hose is the one with the oil filter inline. Leave these slightly loose for now as well.

I finished up most of the final hose routing, securing it all, up till near the oil cooler. Then I tightened the fittings on the adapter and one of the fittings on the oil cooler. Get them tight, but don't overdo it, especially on the aluminum adapter.

I removed one fitting from the oil cooler. Instructions with other oil cooler kits mention priming the system by using a syringe to push oil in one hose until it comes out of the other. Since the hoses in my kit used pre-installed banjo fittings, that would be tough to do. I filled a container with 750ml of the motor oil that I normally use. This is the standard oil capacity for this engine. Then I filled a large syringe with 100ml of oil. The kit included a syringe, but I thought it would be easier with a larger one that I had. I used the syringe to fill the cooler with as much oil as I could get it to hold and then installed the last fitting, tightened it, and finished securing all hoses.

I put the remaining 650ml of oil into the engine to complete the 750ml of a normal oil change. I checked the fill level on the dipstick and added 100ml to reach the full mark.

I looked around to make sure nothing was leaking, then started the engine and let it idle for about 30 seconds. I watched over it to see if anything leaked. I checked the dipstick again and added another 100ml to reach the full mark. Then I started then engine and let it run around one minute, blipping the throttle occasionally. I had to add another 100ml to reach the full mark on the dipstick after that. I started the engine again and rand it for a few minutes, revving it a bit. By then, I could feel heat at both sides of the cooler and my oil temp gauge read 115°F. I shut it down and the dipstick still showed full, so it took the usual 750ml plus 300ml to total 1050ml to get everything primed and full.

I let the engine warm up till the oil temp was at 140°F while watching for leaks and the whole cooler felt hot. I had no leaks and everything appeared to be working so I put the scooter back together and went for a ride. After the ride, I checked the oil level again and it was still full.

I recorded some data from before and after the oil cooler installation so I could see if the cooler worked and how well.

There's a 26°F difference in the highest oil temps before and after, and the cooler helps consistently with each run. Cylinder head temps also dropped with the addition of the oil cooler, staying in the mid-300's.

Click here to see how the scoop was made.

Oil cooler kits were available for the GY6 125/150 and the 139QMB/GY6 50 for roughly $100 and up. A power steering fluid cooler or other small cooler from an automobile could work for a cheaper alternative, but I wouldn't have any easy way to hook one up. I'd need an adapter, and I have only seen adapters as part of complete oil cooler kits. Some GY6 engines have provisions for oil cooler connections built into the case, but mine did not.

I bought an oil cooler kit from ScrappyDogScooters for around $100 shipped that included the adapter, cooler, hoses, and hardware that seems like it should cover most installations. The pics below show the kit that I received and include some measurements of the cooler. Most kits should be a similar design with different cooler dimensions and they may use a different style of hoses. The hoses in my kit had the fittings crimped on, while others will use barbs and standard hose.

Installation on most scooters will probably need to start with removing body panels so you can access the frame to mount the cooler and route hoses. Once I had my panels off, I started mocking up the system to make sure the hoses would reach from the engine to the location that I had in mind for the oil cooler. The scooter I was working on is a Roketa Cayman, similar to the Vento Triton and other B-series designs. It's a somewhat large frame for a 50-150cc, and the hoses had room to spare to reach to the front of the scoot.

This scooter, and others like it, have a triangular panel above the headlight assembly. It's normally just a decoration, but I thought it could be of some use to me. The panel is secured with plastic tabs and it can be removed from the large front fairing. That leaves an opening right in the front of the scooter where plenty of fresh air is available.

The area was mostly clear, but the rectifier/regulator and an aftermarket horn that I installed were in the way. I unbolted them and set them aside until later.

Then I needed to come up with a bracket that would position the oil cooler behind the opening in the front fairing. I took a few measurements from the front mount bolt hole in the fairing to the opening. Then I used some steel strap to hang the cooler where I thought I wanted it. I used the bolts that hold the screen on the filter to hold the strap.

Then I could put the front on and verify that the measurements I made were correct or make adjustments as needed so I had the info to make a more permanent bracket.

The oil cooler kit did include a bracket, but it didn't work well for my plan.

I chose to make a bracket out of steel flat bar, using all four bolts that secure the screen to hold the bracket and cooler together. This required welding, but you could probably come up with something similar using L brackets that you can find and hardware and home improvement stores if you wish to do something similar without welding.

This location also left free space behind the oil cooler. This is important. You never want to place the oil cooler right up against a surface. Air needs to be able to move through the cooler front to rear without getting trapped or blocked by a wall directly behind it.

Once my bracket was finished, I mounted the rectifier/regulator and horn in ways that would work with the oil cooler in place.

The way I chose to mount the oil cooler is just one of many. Whatever you can come up with that will allow plenty of airflow through the cooler could work. Many people mount it closer to the engine, especially when the kit they use comes with standard hoses that can be cut shorter. Some mount the cooler over the cooling fan shroud's inlet, so the fan is drawing air though the cooler. My only concern with that design is that you would be sort of pre-heating the air that is being blown across the engine for cooling. Allowing the cooler and fan to have their own sources of cool fresh air may be beneficial. Perhaps I have it all wrong and the amount of air that the fan draws through the cooler would make it work very well. I've never tried it, so those are nothing more than thoughts. You may be able to look to scooters like the Genuine Buddy 170i that is stock with an oil cooler mounted under the scoot. If you are lacking an idea, try doing a little image searching or picking our brains on the forum.

With the cooler mounted, I moved on to running the hoses to the engine. The return line, that's the hose that takes the cooled oil back to the engine, is a simple straight hose. The feed line, that transports hot oil from the engine to the cooler, required some assembly because it includes an oil filter inline.

The oil filter in this kit is a serviceable unit, so it comes apart. It's actually the same style of screening unit that is inside of the engine which will be replaced by the adapter for the oil cooler. Take it apart and make sure everything goes together as it should, and then reassemble it. The assembly order is shown below. You may want to smear a little bit of oil on the o-ring prior to assembly. Use the 2-pronged spanner tool if your kit included it to tighten the filter sections together.

When you assemble the feed hose with the oil filter, make sure you install the filter so that it is catching particles as they flow through. You want it to be setup so that the filter screen's opening is toward the engine. Pay attention to the fittings on each section of the hose, because you may find that the fitting on one end is smaller than the other so they must be used in the appropriate spot. In my case the larger end's banjo fitting matches up to the oil cooler and the smaller banjo fitting needs to go to the adapter.

I used a bit of teflon tape on the threads going into the oil cooler to promote better sealing.

When installing banjo fittings, each bolt should have two special washers with rubber inner sections. The banjo fitting should be sandwiched between two washers as shown. Leave the bolts a little bit loose so they can move until all routing is complete.

Avoid routing hoses anywhere where they will be pinched if the suspension moves and keep them away from anything sharp. Braided hoses can chafe anything that they rub against, and they will be hot. Route carefully to avoid unnecessary contact with wiring or sensitive components. You can use tubing that withstands heat to protect the hoses and anything they are near if you see fit. I used heat shielding near the engine to prevent my cooler lines from soaking up some of the exhaust heat.

Once the lines were routed, I began the process of installing the oil cooler adapter in the engine. Before I began, I drained the engine oil using the drain plug on the CVT side and then reinstalled the drain plug.

Then I removed the plug and filter assembly on the other side of the engine, keeping slight pressure on the plug as it was removed since there is a spring behind it. This is the plug that the adapter will replace.

The adapter has spots for two fittings. One is the inlet and the other is the outlet. If you look into each hole, you can see that one leads to the outer section of the adapter and the other leads to it's center. The one leading to the center is the inlet, where cooled oil enters the engine. The one leading to the outer section is the outlet where hot oil exits the engine. I marked my adapter prior to installation to make it easy to tell which is which once it was on the engine.

Now the adapter can be screwed into the engine in place of the plug/screen assembly that you removed. You should have a rubbery cap with the adapter that helps to seal the inlet and outlet sections. Use the supplied spanner tool to tighten the adapter.

After that, the lines can be installed. Again, the outlet hose is the one with the oil filter inline. Leave these slightly loose for now as well.

I finished up most of the final hose routing, securing it all, up till near the oil cooler. Then I tightened the fittings on the adapter and one of the fittings on the oil cooler. Get them tight, but don't overdo it, especially on the aluminum adapter.

I removed one fitting from the oil cooler. Instructions with other oil cooler kits mention priming the system by using a syringe to push oil in one hose until it comes out of the other. Since the hoses in my kit used pre-installed banjo fittings, that would be tough to do. I filled a container with 750ml of the motor oil that I normally use. This is the standard oil capacity for this engine. Then I filled a large syringe with 100ml of oil. The kit included a syringe, but I thought it would be easier with a larger one that I had. I used the syringe to fill the cooler with as much oil as I could get it to hold and then installed the last fitting, tightened it, and finished securing all hoses.

I put the remaining 650ml of oil into the engine to complete the 750ml of a normal oil change. I checked the fill level on the dipstick and added 100ml to reach the full mark.

I looked around to make sure nothing was leaking, then started the engine and let it idle for about 30 seconds. I watched over it to see if anything leaked. I checked the dipstick again and added another 100ml to reach the full mark. Then I started then engine and let it run around one minute, blipping the throttle occasionally. I had to add another 100ml to reach the full mark on the dipstick after that. I started the engine again and rand it for a few minutes, revving it a bit. By then, I could feel heat at both sides of the cooler and my oil temp gauge read 115°F. I shut it down and the dipstick still showed full, so it took the usual 750ml plus 300ml to total 1050ml to get everything primed and full.

I let the engine warm up till the oil temp was at 140°F while watching for leaks and the whole cooler felt hot. I had no leaks and everything appeared to be working so I put the scooter back together and went for a ride. After the ride, I checked the oil level again and it was still full.

I recorded some data from before and after the oil cooler installation so I could see if the cooler worked and how well.

| Without Oil Cooler | ||||

| Ambient Temp | Humidity | Max Observed Oil Temp | Max CHT | Miles & Riding Style |

| 68°F Night | 68% | 241°F | 381°F | 29 Miles; Mixed riding. |

| 78°F Night | 65% | 231°F | 368°F | 25 Miles; Mixed riding. No long WOT runs. |

| 78°F Day Sunny/Sunset | 52% | 243°F | 380°F | 59 Miles; Mixed riding. Lots of WOT. |

| 79°F Day Sunny | 65% | 247°F | 376°F | 52 Miles; Mixed riding. 5 miles WOT. |

| 85°F Day Cloudy | 48% | 250°F | 395°F | 45 Miles; 50-55MPH roads. Long WOT runs. |

| 86°F Day Sunny | 41% | 254°F | 441°F | 44 Miles; Mixed riding. |

| With Oil Cooler | ||||

| 69°F Night | 75% | 208°F | 348°F | 25 Miles; Lots of WOT. |

| 72°F Night | 85% | 213°F | 355°F | 29 Miles; Mixed riding. Long WOT runs. |

| 75°F Day Partly Cloudy | 66% | 217°F | 360°F | 39 Miles; Mixed riding. Lots of WOT. |

| 80°F Day Cloudy | 79% | 216°F | 358°F | 32 Miles; Mixed riding. No long WOT. |

| 84°F Day Sunny | 53% | 228°F | 369°F | 86 Miles; Mixed riding. Lots of WOT. |

| 85°F Day Sunny | 51% | 221°F | 369°F | 31 Miles; Mostly WOT. |

There's a 26°F difference in the highest oil temps before and after, and the cooler helps consistently with each run. Cylinder head temps also dropped with the addition of the oil cooler, staying in the mid-300's.