|

|

Post by 90GTVert on May 18, 2011 22:44:18 GMT -5

Reed SpacerReed block spacers seem to get very mixed reviews. Some opinions I've read feel like it serves no purpose. Others believe it works. I think, like most other mods, the effectiveness depends on the application. The best I can do is give you an honest review and let you decide for yourself if you wanna go for it. The reed spacer I'm using is a simple homemade version, made from an old spare reed block. With an extra gasket it ends up being about 4mm thick. You can find all of the details to make your own HERE. They are also available from many sellers for around $15-$25 in varying thicknesses and made from different materials.  The spacer is placed under the reed block to raise the reed assembly out of the intake tract a little more. This is said to increase throttle response and low end power. This mod will increase the volume of the crankcase and therefor lower primary compression. One effect that can easily be seen is unblocking the boost port. Well, it's easily seen if you just happen to have an extra set of engine cases around. ;D Notice the reeds protruding into the boost tunnel in the first pic with no spacer, then clear when the spacer is used in the second pic. The boost port on the cases shown here has been modified, so the intrusion may not be as drastic on stock cases and cylinders.   Here's another view of what's happening inside the cases.   Installation is simple. Just make sure there are no air leaks. The reed blocks on Minarelli/Jog motors is a common spot for sealing problems. I use an RTV sealant to avoid problems when installing reeds. You may need longer bolts depending on the thickness of the spacer.  No jetting change was necessary. It worked fine with the 85 main jet and the needle set in the next to richest position. I went for a 36 mile test ride to evaluate the change. On the trip I had a max speed of 51MPH. Fuel economy was 45.9MPG. It didn't seem like it was as willing to rev out as without the reed spacer. It felt like the powerband may have moved down just ever so slightly to me. I can't honestly say I noticed any difference in low end power output. Any changes in peak power would be very slight. I did notice two good things with the reed spacer in place. The throttle response improved. That was the most obvious change. Nothing crazy, but there was definitely a difference. I also believe the engine ran a little more smoothly. It felt like more of a smooth transition throughout the rev range or throttle position than before. I would gladly do this mod to any of my Minarelli powered scooters. It may not make any big improvements, but it's cheap, simple, and just feels right to me. Who can't use a little more throttle response? I think with ported cylinders and cases moving the reeds up might have a slightly more pronounced effect than on the small ported stock setup. |

|

|

|

Post by 90GTVert on May 20, 2011 20:15:36 GMT -5

Carbon Fiber ReedsThis engine came with a set of carbon fiber Malossi reeds when I picked it up on eBay. Of course I promptly removed those performance parts to go stock (that still sounds wrong even this far into the project). Now that I am trying out some other intake/reed related stuff, it's time to see if putting them back on will show any benefit vs the stock metal reeds. The install is easy enough. Just remove the screws, stops, stock reeds, and backing plate to start.   Here's a pic to sorta show you the order it goes together.  Stock steel reeds vs Malossi reeds.  Assembled.  You may notice that I have the words out on one side and in on the other. It really doesn't matter unless the reed is curved. Sometimes aftermarket reeds are made curved slightly so they naturally press into the reed cage to promote sealing. In those cases I believe the writing should be facing out. For these, I just tried each read on both sides and mounted however they appeared to seal the best. The easiest way to see if they are sealing is to look for sunlight coming through the reeds.  No jetting change was necessary so the setup is using an 85 main jet with the needle in the position next to the richest. I took a 19 mile test ride and observed 45.9MPG. My max speed was once again 51MPH on the GPS. It appears to me that the reeds are making no difference. Cruising speeds were the same as the stock benchmark again, low to mid 40s. There may have been a slight change in throttle response and smoothness, much like the reed spacer, but very slight. One common reason for swapping to carbon fiber reeds is that they put your engine at less risk if they break compared to the stock steel reeds. Perhaps they would be worth adding for that reason, but if you are looking for more performance from your stock 90cc I think you'd be quite disappointed in this mod. |

|

|

|

Post by 90GTVert on May 20, 2011 20:37:27 GMT -5

Polini Reed CageEven though I didn't have much hope for improvement after the other reed related mods, I thought I might as well finish it off and try out the Polini reed block with carbon fiber reeds that I have on hand.  Here's the difference in port area of the Polini (left) vs stock.  I installed the reed block with the stuffers thinking that would be the best setup for the stock setup with it's small carb and small ports.  With the reed out, you can see how the stuffers smooth out airflow through the reed block.  As with all of the other reed mods, no change in jetting was necessary. 85 main jet, needle clip next to the richest position. On a 38 mile ride I got 46.8MPG. Max speed was 51MPH. This mod felt similar to stock and the carbon fiber reeds in the stock block. Little to no changes. Possibly a change in throttle response. It didn't even seem like it ran as smooth as with the reed spacer or the Malossi reeds. I'd probably only do this mod in preparation for bigger things to come or if there were a problem with the stock setup and I could get a good deal on an aftermarket cage. I will also note that the Malossi blocks I have in other scoots are better quality than the Polini block. |

|

|

|

Post by 90GTVert on May 24, 2011 21:03:19 GMT -5

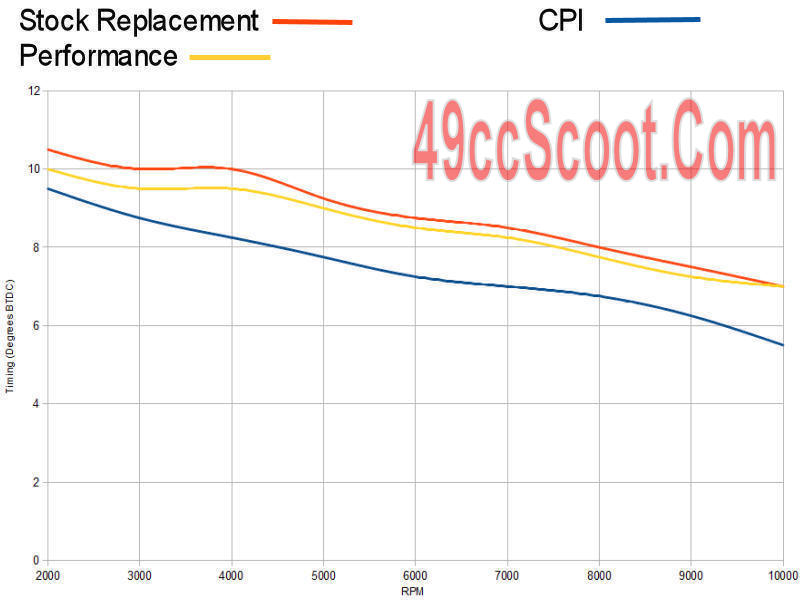

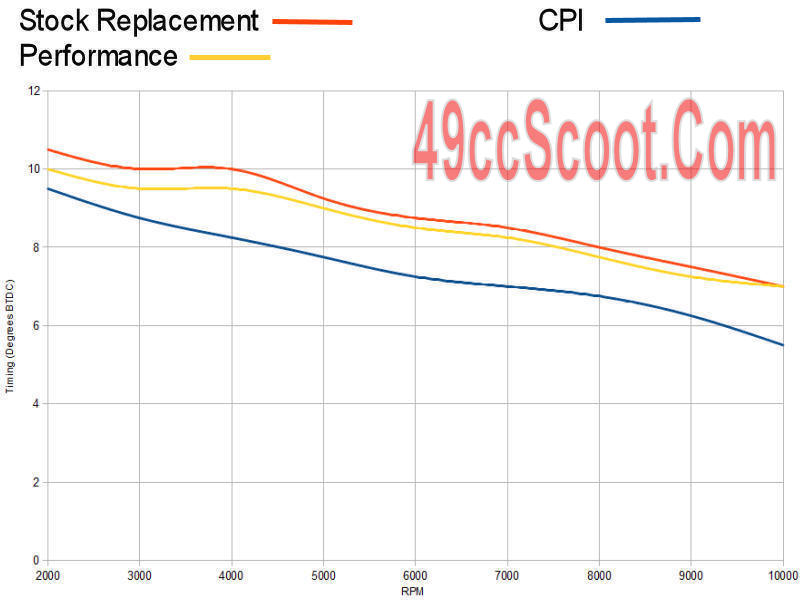

CDI TestingI decided to test a few CDIs and see what kind of timing figures I got. I know some folks believe they are all the same. I have three to test, so let's see if they really are all the same.  I tested each by using a degree wheel to mark 0° TDC on the flywheel relative to a timing pointer that I made up and bolted on. I used my digital adjustable timing light to measure advance in 500-1,000RPM increments and recorded those readings. I tested from 2,000 to 10,000RPM. I don't believe any of the CDIs have a rev limit. I only tested to 10,000RPM because the stock engine just doesn't want to go much higher, even on the center stand.

The CDI that has been on the scooter since day 1 of the project is a stock replacement CDI that I got from Scrappy Dog Scooters. I picked it up a while ago just because it was cheap.  It's labeled with "1E40QMB".  All of the CDIs I'm using have 3 loose wires (2 male bullet connectors, 1 female bullet connecter) and a 2 wire connector. Here are the connections for this one. Wire colors on your scooter could vary. [/color][/center][/td][td] Dark Green [/td][/tr][tr][td] Red / Black [/td][td] Black / Red [/td][/tr][tr][td] Blue / White [/td][td] Blue / White [/td][/tr][tr][td] Orange [/td][td] White / Black [/td][/tr][tr][td] Black [/td][td] Black [/td][/tr][/table] Maximum Advance : 10.5° BTDC Minimum Advance : 7° BTDC

The next CDI I tested is a stock CPI CDI that came on one of my Vento Tritons.   [/color][/center][/td][td] Dark Green [/td][/tr][tr][td] Black / Red [/td][td] Black / Red [/td][/tr][tr][td] Blue / White [/td][td] Blue / White [/td][/tr][tr][td] Black / White [/td][td] White / Black [/td][/tr][tr][td] Black [/td][td] Black [/td][/tr][/table] Maximum Advance : 9.5° BTDC Minimum Advance : 5.5° BTDC

Finally, I picked up the cheapest performance CDI I could find on eBay. It looks just like the common blue racing CDIs, but it's got an orange heat sink instead.  [/color][/center][/td][td] Dark Green [/td][/tr][tr][td] Red / Black [/td][td] Black / Red [/td][/tr][tr][td] Red / White [/td][td] Blue / White [/td][/tr][tr][td] Orange [/td][td] White / Black [/td][/tr][tr][td] Black [/td][td] Black [/td][/tr][/table] Maximum Advance : 10° BTDC Minimum Advance : 7° BTDC

Here's a graph that I made up showing all of the timing curves.  I never road tested any of the CDIs. The CDI with the most advance (the stock replacement) is already on the scooter so I wouldn't expect to see any gains. All of the timing curves are fairly similar. I think a base timing adjustment (accomplished by moving the flywheel or pickup relative to each other) could make each of the CDIs perform basically like the other. One thing that I noticed is that I got different readings with the CPI CDI on this engine than I did with it on another engine some time ago. On that engine it started at 12° BTDC. Perhaps some flywheels or stators are built different or tolerances are poor? [/center] |

|

|

|

Post by 90GTVert on May 30, 2011 22:18:57 GMT -5

19mm Arreche CarburetorNext up, a larger carburetor. The stock carburetor is 14mm, so the Arreche 19mm is a pretty good upsize. Here's a look at the Arreche carburetor beside the stocker.  Stock  Arreche  Connections   Inside the bowl.  Pilot jet, main jet, atomizer, needle, throttle vavle.  Amal/Arreche jets can be hard to come by. If you choose this carburetor, I would suggest picking up a selection of jets when you order the carb. Here is the Arreche jet (left) beside a Keihin hex main jet. The Keihin jets are very similar, but cannot be used because they won't fit in the bowl of the Arreche carburetor.  These Keihin 6mm jets could work in a pinch.  A nut on the bottom of the bowl allows for quick main jet changes.   A 6mm socket, the same size as most bit drivers, can be used to remove the Arreche jet easily.  If you have to get to the bowl, be careful not to strip the screw that's partially blocked by the enricher.  Needle clip position changes are made easy by the large clip.  One of the things that makes an Arreche swap easier than most is how it hooks up. It works with the stock airbox and installs in the stock intake with locater tabs just like a stock carburetor. It is available with an automatic enricher that connects to the stock wiring. I believe they are available in different configurations, so if you want the easiest connection be sure to choose the right options.  It can connect to the stock throttle cable with ease, but I am using an aftermarket throttle and cable so I had to use a slightly different setup.  I used a 90 main jet, 15 pilot, and the needle was set in the center position. I took a 21 mile ride, where I observed 39.5MPG. I was being quite liberal with the throttle, but that's the worst gas mileage I've seen so far with this project. Maximum speed was once again 51MPH. Cruising speeds were the same as stock, in the low to mid 40s. I noticed two changes. First, it seemed like power from 7,500RPM and above increased slightly. The problem being that this engine configuration really doesn't like to rev far beyond that point. The other change I noticed is a lack of spark knock on deceleration. From the time project started, I've had spark knock when I let off of the throttle. The only way to get rid of it with the stock carb was to keep the needle high and jet richer than it should be. It's brief and seems to be of little concern, but it was non-existent with this carburetor. I believe that shows the Arreche is keeping the cylinder cooler and/or delivering a more appropriate amount of fuel at part throttle positions. I was surprised at the lack of performance increase witnessed with this modification. I can't call it a bust though, due to the positive points made above. I was planning on testing other and larger carburetors, but the lack of gains with this 19mm Arreche leads me to believe that farther carburetor testing would be futile at this stage. |

|

|

|

Post by 90GTVert on May 31, 2011 8:47:12 GMT -5

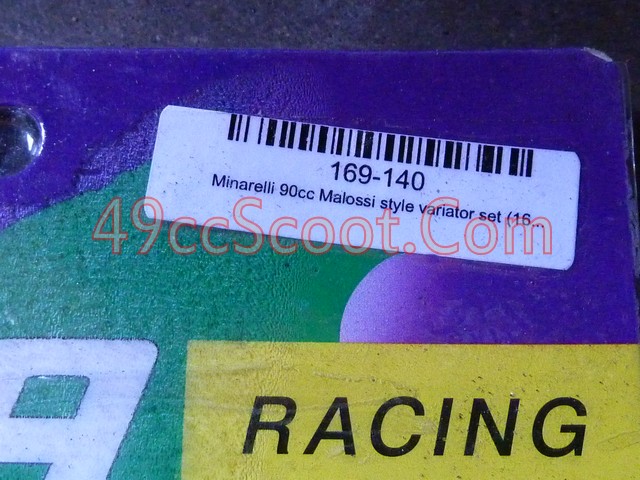

Hoca Performance VariatorThis test involves the Hoca performance variator (Part number 169-140 for the large spline crank) sold by Parts For Scooters.  As the tag right on the product indicates, it's a clone of one of the Malossi MultiVars.  The kit comes with the variator, ramp plate and guides, drive boss, and a set of 4g roller weights. This variator uses 16x13mm rollers or sliders, while the stock setup uses 15x12mm. The bushings or guides on the ramp plate can be replaced with those from a 139QMB/GY6 50 stock variator if you ever lose or break them.  The Hoca variator offers increased roller travel with longer tracks and the angles of the tracks are optimized for better performance.  The angle of the drive face is similar to stock.  Outside diameter of the variator is just barely larger. The stocker measures roughly 95mm and the Hoca measures just over 97mm.  The drive boss that fits over the crankshaft's splines is made with a smaller outer diameter. This can allow the belt to travel slightly farther down in the front pulley for the strongest takeoff or "1st gear" if properly setup. The Hoca's drive boss is a couple of millimeters shorter than the stock drive boss.  For the first attempt, I installed the variator with only what comes in the kit. As you can see, the drive boss is on the short side.  Since the drive boss is shorter, I couldn't get everything secured properly without adding a washer to the outside.  The short drive boss also means the belt doesn't travel very far down in the front pulley, which can cause a major change in initial acceleration. I show the belt in the rear pulley, because the position of the belt in the rear pulley and front pulley are directly related and it's much easier to get a shot of the belt's location in the rear pulley at rest.  I ditched the 4g rollers that came with the variator in favor of a set of heavier 5g sliders to start with. I have shown the benefit of sliders in previous tests, and sliders are what I've been using in the stock variator. The 5g sliders were too light, and I eventually ended up finding 7g sliders to be the best choice for this setup. I immediately noticed a bad bog from 0-20MPH and an effect similar to using no clutch springs. The belt riding so high and binding up in the front pulley at low speed and RPM causes the slow takeoff and lack of transmission disengagement. Once past 20MPH, with the variator then working as it should, acceleration was greatly improved vs stock. I would say the increase in acceleration is comparable to what some of the aftermarket exhausts did, and that's a pretty impressive change IMO. Not only did acceleration increase, but top speed improved 3MPH to 54MPH. That's the highest speed of the project to date with any mod. The variator does an excellent job of keeping in the proper rev range longer, which also upped cruising speeds to the mid 40s reliably, up from the low to mid 40s with the stock setup. The ability to handle headwinds and inclines was also improved.  Here you can see the belt travel achieved in stock form.  For the next try, I added 1.5mm worth of spacers to effectively lengthen the drive boss and get the belt a little farther down in the front pulley. It actually needs more spacers than that to get the belt all the way down, but I wanted to do a safe test. The spacers (actually shimming washers found at McMaster-Carr) were ground down to be small enough that the variator could travel over them without hanging up. Since the variator can travel farther, you should always check to see if the ramp plate will pass the guides in the variator. If it does, you will break the plastic bushings at speed and you can cause all sorts of other troubles like damaged rollers and getting stuck in "high gear" and snapping belts. Test by sticking the spacers you plan to use on the end of the drive boss while it's in the variator as shown. Then put the ramp plate on and make sure it can't turn. Leave a little room for error.   It's not a huge difference to look at, but the 1.5mm definitely helps.   I found that being setup that way, top speed remained the same. The bog on acceleration now only lasted from 0-10MPH instead of 0-20MPH as before and was much more bearable. I have a modded version of this variator sitting around from one of my other scooters, so I thought I'd try that setup as well just to see what could possibly be expected from this variator with some work. It's filed down in the center to allow it to open wider at rest and to close tighter at speed.  I coupled it with a similarly modified fixed face, as shown in a previous update to this project.  I added spacers to this setup as well to get the belt down deep in the front pulley.   That attempt was not so successful. I ended up with slip on takeoff that later turned to a bog. The slip is from the altered drive face angles coupled with the acceleration rate of the sliders on takeoff. The bog is from the pulley getting into a "higher gear" than usual with the mods I did. I've seen this work well on other scooters with more power, but the stock setup just can't handle the gearing this provides. I did manage 53MPH, but the RPM was nearly 1,000 below where it was before at that speed. I didn't want to move to lighter sliders because the slip on takeoff would increase. The extreme RPM drop with modding shows that this could increase speed if you have enough engine to pull it. I would definitely not recommend doing all of this at the stock power level though. This turned out to be an excellent mod. The best so far with an acceleration increase rivaling the performance pipes and a max speed surpassing all other mods to date. At a price of only around $50, (plus the cost of larger rollers or sliders if you don't have them already) this one's hard to beat. |

|

|

|

Post by 90GTVert on May 31, 2011 15:27:55 GMT -5

Hoca Performance Torque DriverI haven't tested a performance torque driver yet, and T1's transmission is all apart at the moment, so it seemed like the perfect opportunity. The torque driver I'm using is a Hoca piece sold as part of a complete performance rear pulley package by PFS . It's part number 169-126 there. The clutch and bell that it includes are nice pieces as well. They seem to have a little more grip than the stocker and hold up well in other engines that I have them in. You can also find these from other sellers sold separately. The top torque driver in the image below is the stocker. The lower one is the Hoca unit. As you can see, the stock torque driver has a pair of grooves, and the Hoca has multiple pairs. The Hoca torque driver allows you to choose different pairs of grooves for fine tuning if necessary.   The stock unit uses a dual-angle groove. This allows the pulley to begin it's travel in a groove with say a 45 degree angle. I don't actually know what the exact angles are, just making a rough guess. With the guide having to travel at that angle, it resists change more than if the groove were just straight up and down at a 90 degree angle. Resisting the change translates to higher RPM. Once the pulley is about halfway open, it moves into the second angle of the groove. That's about 60 degrees, so closer to being straight up and down. Again just a very rough guess on the angle. Once in the second part of the groove, the pulley is less resistant to change and RPM will decrease as it transitions to a higher "gear" with greater ease. You can usually clearly feel that "shift". The single angle grooves of a performance torque driver allow the CVT to operate at a much more constant RPM. Where the dual-angle groove may have you revving at your peak power RPM initially, when it "shifts" it will drop below peak power to allow for lower RPM cruising. A pair of grooves with one angle means no shift. That means your CVT has a much easier time staying within peak power RPM from the rear pulley's fully open and fully closed positions. The real downside here is that cruise RPM will increase compared to the dual-angle grooves. I went for a test ride and maximum speed stayed the same as stock at 51MPH with the addition of heavier sliders. Acceleration however was much improved. Keeping within the powerband makes a very nice improvement. The acceleration increase was not as prevalent as it was with the Hoca variator, but still quite nice. Cruise speeds did increase slightly to the mid 40s, a little better than stock but not quite as effective as the variator. Hill climbing and riding into the wind were also improved. This is a good mod for someone looking for max acceleration and not so concerned with max speed gains or low cruise RPM. The installation and setup is pretty simple. If you buy the whole rear pulley set it's a very fast bolt on mod. |

|

|

|

Post by 90GTVert on Jun 1, 2011 22:00:05 GMT -5

Squish Style Cylinder HeadThis time around I'm swapping the stock style cylinder head with a squish band style cylinder head. My main hope is that the improved design will be more resistant to detonation. This engine has had detonation from the beginning if I let off of the throttle from wide open. Nothing too serious, but I was still curious to see if the combustion chamber design would have any effect.  Stock.  52mm, high compression, squish style, cylinder head. I looked for a 52mm head that had a recessed combustion chamber, to no avail. This one actually measures 49mm across the combustion chamber. That's OK though, the stock head measures about the same and then it's flat as well.  Before removing the stock head, I took a measurement of the compression. 152psi.  I set the squish head up with 5 head gaskets to get 150psi. I know it's not exact, but I think 2psi is a fair comparison.  Squish clearance is 2.15mm. I was going to try to set the squish the same as the stock head, but compression figures would be crazy if I set them to the minimum clearances. The minimum clearance for the stock head was around 1.5mm. At just 1.79mm on the new head, compression went up to 170psi. The max clearance on the outer edge of stock was about 2mm, so this is close enough to matching that for me. I took the scooter on about a 20 mile ride, being hard on it to make sure it was hot of course. I saw no power or speed gains. What I did notice is that the crackle of detonation upon releasing from WOT was much less. If I just cut the throttle off or released it normally, I didn't hear any spark knock. To hear the crackle, I had to roll off of the throttle slowly. Even then, I only heard it right around 1/4 to 1/2 throttle for a moment. A definite improvement. My initial thought with this mod was that perhaps I could increase compression to the point where I found the detonation again to see if it was enough to see any improvement in performance. Seeing that I still didn't completely relieve detonation, I didn't feel it worth all of the time trying to figure out where that point is. I feel like it would still be very close and gains would be minimal. That's not to say this isn't a good thing to do, but it's more of a fine tuning mod if you're looking for the most from a particular setup I believe. |

|

|

|

Post by 90GTVert on Jun 2, 2011 9:53:43 GMT -5

Torque Driver ModificationI've tried an aftermarket torque driver, but what about working with the stock unit? Here's a picture of the groove that the pin rides in on the stock torque driver. Notice how the groove goes very near the seal at the top, but not so close to the seal on the bottom.  The pin starts in the top of that groove and gradually moves to the bottom. When at the top, the pulley would be fully closed. When at the bottom, the pulley would be all the way open. The problem is, the short stock groove won't allow the rear pulley to open quite as far as it possibly could. The picture below shows a stock torque driver that has been modified by elongating the groove to allow the pulley to open farther. I used a torque driver that was previously modified so I can go back to stock for future tests in this project. You can see all of the details about the modification and changes in pulley opening by clicking HERE. There's also a thread by another member about this modification HERE.  I went out for a brief ride to test the mod, which somehow turned into 57 miles on an 80 degree night. Max speed did increase to 52MPH, up by 1 over stock. Cruising speed increased just slightly, maybe 1MPH average. Both are the result of keeping the engine in it's powerband just slightly longer I believe. Otherwise, no perceivable changes. While it's not much of a gain, it's still a gain and it's completely free if you have the tools and are willing to do it. It may show even greater gains on an engine with more power. I wanted to note, this is not the only modification you could do to the stock torque driver. This is the easiest, but you could go as far as to cut a set of completely new grooves if you have the time, tools, and patience. Notice that there's plenty of room left for a new set of grooves on the stock torque driver.  Just as an example and a learning experience, I cut one groove in the stocker to mimic the straight grooves in the aftermarket unit. I started out by measuring the pin that rides in the groove in a drill bit gauge.  Once I knew that, I drew a line at 90 degrees as a centerline and a 45 degree line to guide the new groove. I marked a few holes with a punch, and drilled them out with a 15/64" bit.  After plenty of time with a dremel and files, my stock torque driver has a groove much like that of the aftermarket unit. If you do this, be very sure that all edges are smooth. Test the movement assembled before moving on to the next groove.  The even tricker part is to do the exact same thing at 180 degrees on the torque driver. If both grooves aren't properly aligned at all points, it won't work. I never went that far. I have a perfectly good aftermarket unit for now. You can see though, that if you are willing to invest the time and effort you can save yourself a lot of money. Test everything on the bench for proper motion and make sure nothing binds before ever attempting to use it on the scooter. As long as you don't mess up and pass the seals or something catastrophic, if the mod doesn't work as planned you can simply go back to using the stock grooves. |

|

|

|

Post by 90GTVert on Jun 10, 2011 19:36:02 GMT -5

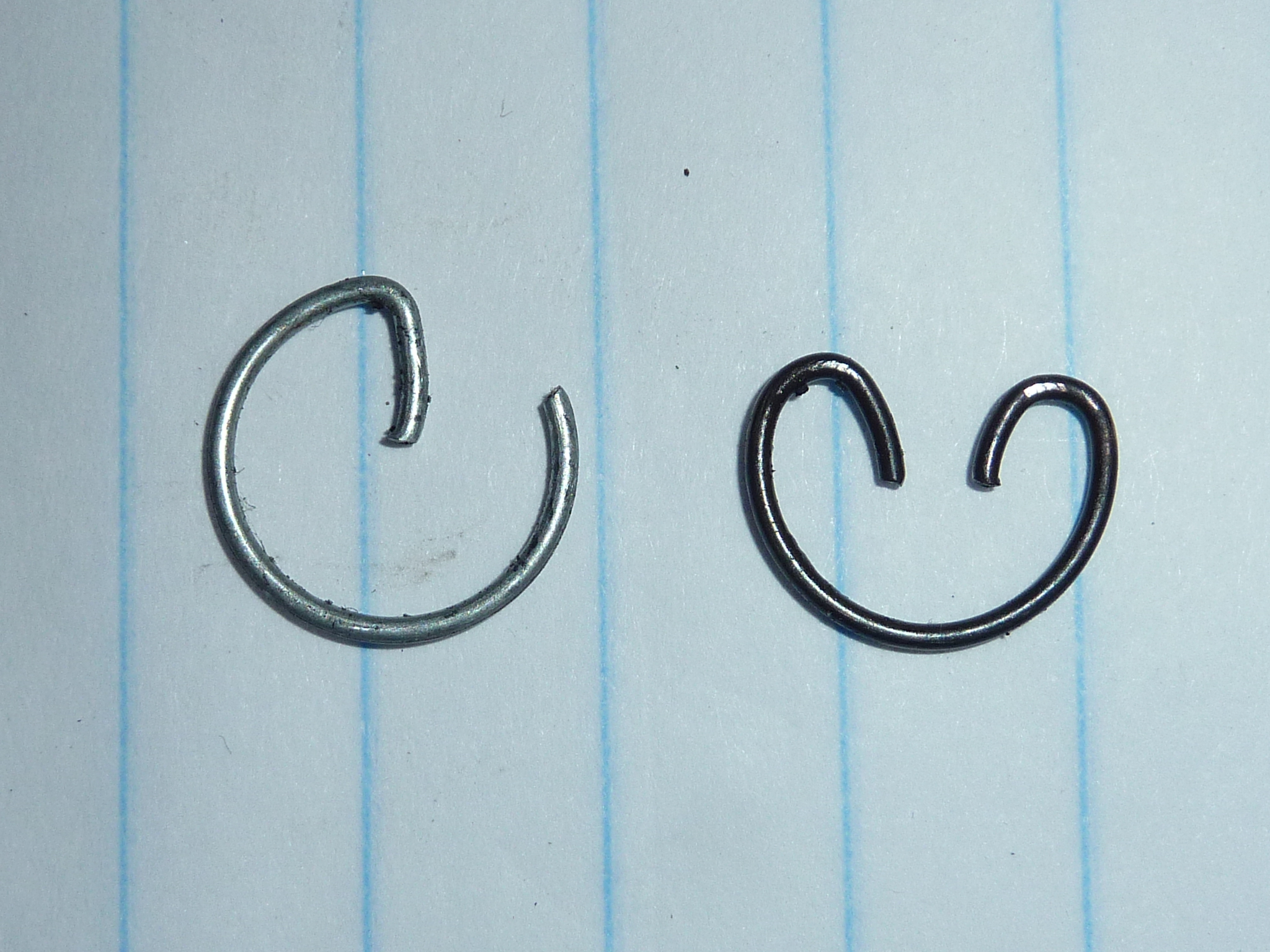

Circlip Failure...And now for the bad news about that last ride. 57 miles wasn't actually the distance back to my house. That was about 6 miles short. I was cruising along (at WOT as usual) and I started to hear a rattle. Moments later, the engined died. I gave it a minute, but it wouldn't restart. I ended up going home in the back of a truck. The next morning I went out to see what happened. I hooked up the compression tester and got a reading of only 80psi. Upon trying the kick starter, it was obvious that the reading is correct. I just tested yesterday for the cylinder head mod and had over 150psi. I pulled the cylinder head off and noticed a couple little indentations at the very edge of the crown, but nothing too alarming. Upon pulling the cylinder off, I realized that one of the circlips was missing. Oh nevermind, I see where it is...    The piston is done, but I believe the cylinder will be OK with a quick hone. It has fairly severe scarring by the transfers on one side. I think it can be usable and work well enough to continue the project with it.  Here are the 2 types of circlips common for these engines. The one that just came loose was like the right circlip. The ones on the left are a little harder to install, but a little harder to get 'em out.  I've gotta get a 52mm piston kit, do a little work to the cylinder, and hopefully I can get it back to it's original specs to maintain accuracy. In the meantime, I'll keep testing with a big bore kit. |

|

|

|

Post by 90GTVert on Jun 10, 2011 20:29:54 GMT -5

Hoca 54mm Cylinder KitI love to recommend big bore kits as the best bang for the buck mod for most 49cc scooters, but how much difference might one see by moving up from a 52mm stock cylinder to a 54mm cylinder? It's time to find out. I'm using the Hoca 54mm cylinder kit (Part # 169-154) from Parts For Scooters for this test. As you can see, it includes pretty much everything you'll need to increase your displacement. Of course you still have to supply your own tuning and installation supplies, but it include a cylinder, head, piston, piston rings, wrist pin, circlips, as well as a head, base, and exhaust gasket.  The Hoca kit is the only one I've seen (that doesn't cost a small fortune) that offers auxiliary exhaust ports in a 50+mm cylinder kit.  Here's a closer look at the exhaust port layout. The auxiliary ports help to increase the exhaust port area at the right time. Using this style of ports as opposed to a larger single port can also be easier on the piston rings. A very large port can allow the rings to pass farther into the port and potentially cause the rings to snap. The little auxiliary windows add a lot of width to the top of the port without that unfortunate side effect.   I did no port matching to the case.  The Hoca kit works quite well with the stock 42mm crankshaft. As this image shows, the piston travels all the way to the top of the bore. (These pics were taken after testing, so that's why the piston is suddenly dirty.  )  The piston is just shy of clearing the ports at BDC when using the base gasket that comes with the kit.  Port Durations Exhaust : 178° Transfer : 124° Boost : 132°  I installed the kit with just the supplied gaskets. The head gasket supplied is 0.7mm uncompressed. The suppled base gasket is 0.45mm uncompressed.  Once everything was installed, I checked the squish clearance and did a compression test. Squish clearance was 1.7mm. A compression test showed 185psi. 185psi seemed like too much to me, but I wanted to try the kit as it would be if simply bolted on as supplied.  I ended up swapping up from an 85 to a 90 main jet and moving the needle to the richest position, from the next to richest position. The needle setting is actually a bit rich, but I was attempting to increase cylinder cooling with a little more fuel since compression readings are so high. I also swapped up to 7g sliders. The increase in power output was immediately obvious. The small increase in displacement (from 89cc to 96cc) coupled with high compression and a better port layout makes a nice difference. The engine feels like it has much more torque at lower revs, and that added torque allows for lower throttle cruising and better response from any speed. It's not just low end grunt though, the power increase is steady throughout the revs. Cruising speeds increased to the very upper 40s and as much as a shade over 50MPH at times. 50MPH cruising was at roughly 8,500RPM. Max speed was 54MPH at about 9,000RPM. It felt like the power was there and it would have the ability to go faster, but the rest of the stock setup just won't support higher revs and the stock CVT just won't let me tune it to go faster.  I purchased a set of 9g sliders to see if I could drop the revs farther and find more speed to no avail. All the very heavy sliders did was make acceleration more sluggish and drop the lower speed cruising RPM. One thing the heavy sliders did show me is that this setup is comfortable at pretty low revs. Even revving at only 4,000RPM in town cruising, acceleration wasn't bad and the engine seemed "comfortable". Once I hit somewhere in the neighborhood of 40MPH, the stock CVT seems to be allowing the belt to travel as far as it wants to as configured. That's why even heavy sliders can't gain me top speed. At that point you are limited by engine RPM and final drive gears. The biggest problem that I noticed was detonation when operating at high revs. The additional power and timing pushes the engine to RPM that it previously didn't visit regularly. Couple that with an increase of heat from higher compression and you end up with plenty of excess heat, which leads to detonation. When cruising at lower revs I heard no detonation other than when decelerating, similar to what the stock setup has been doing. No big deal. As long as you have the sense to back out of the throttle a bit here and there, the scooter can easily be operated as-is. Of course adding one extra head or base gasket would likely provide enough of a compression drop that negative symptoms would decrease substantially. Adding an extra base gasket would also increase port durations, which may prove useful if you use an aftermarket exhaust that will support higher RPM. An aftermarket exhaust designed for a 90-100cc engine may also help to keep the engine running a little cooler. One other issue, albeit minor, is the large cylinder head provided with the kit. The larger head should help to dissipate heat better, but it is a bit big to fit the shroud just right. As the second image shows, it did burn through the shroud a bit, but I noticed no ill effects from this. It's not something I would be too concerned with.   All in all, I'd say this is a great mod. Even without adjustment I rode about 100 miles total while this kit was installed, because my other scooters were out of order. Just keeping out of the throttle a little while cruising kept the detonation at bay. The increase in torque was very much welcomed. Being able to accelerate and cruise into the 40s at lower throttle positions lead to improved fuel economy of 52.2MPG, the best to date. I could have been easier on it than that in town and probably saw even farther improved mileage. One issue that I have with this kit, or perhaps it's just my nature, but it leaves me wanting more. Yes, it increased max and cruising MPH as much as any other modification to date. Yes, it increased torque and acceleration as much as any modification to date as well. Here's the problem though... It made me want more. This modification, more so than any other I've done to date on this project, made me want to do more to the scooter. For example, when I installed the Hoca variator and saw the same max speed and a great increase in acceleration, I was content. The setup felt like it was "right". After installing and riding with this big bore kit, I feel like the setup is not reaching it's potential and it leaves me really wanting to see how much more it's got in it with a new variator, pipe, carb, etc... I think it would be very hard to leave it alone after installing this big bore kit, even though it offers performance as good as or better than any single mod I've tried on Project 90 to date. You have been warned, this mod might get you addicted and turn a simple project into a real build. |

|

|

|

Post by 90GTVert on Jun 12, 2011 12:00:05 GMT -5

Lightened FlywheelLet me start by saying I cheated and tested this modification while the 54mm cylinder was installed. I don't feel it matters much for this particular mod whether it's the stock cylinder or the 54mm. A lighter flywheel removes weight from the crankshaft and is said to help throttle response because the engine has to fight the flywheel weight less. You can have a flywheel lightened by a machine shop and there are places that offer flywheel lightening services by mail order. If you are handy with a lathe, you could even do this yourself. The lightened flywheel that I'm using is a stocker that has had 0.060" removed from the outer edge as shown below. I have seen people machine the face down as well to remove even more weight. I'm really not sure exactly what the limits are, because the last thing you want is to weaken the flywheel to a point where it may come apart. That could cause serious injuries. I do know that I have a few flywheels lightened as shown, and they have all held up well for me. I've only tested them on engines revving up to about 12,000RPM max.  In stock form the flywheel weighs in at 755 grams.  After lightening, 675 grams or about 10% lighter.  I took the scooter for a brief ride and I can't really say I see much difference. I believe throttle response to be slightly improved, but if didn't know there was a change, I'm not sure I'd notice a difference. No MPH increase. I made a video so perhaps you can judge for yourself. Looking at the tach really is of little use, as the Trail Tech doesn't respond fast enough, so you'll have to use sound more than anything. :itshere: :itshere: |

|

|

|

Post by 90GTVert on Jun 15, 2011 10:22:38 GMT -5

Additional Base GasketsI got the stock cylinder setup again on the workbench with a new piston. The pistons are both about the same, with all the important bits in the right spots.  I did a quick hone of the cylinder. I can't even feel most scratches, other than the most severe in the second pic. It should be fine though.   I put it back together and the specs are right on, so it should be fine to move on with more mods. For this update, I wanted to increase the port durations in a simple manner that anyone comfortable with installing a cylinder can do to see what benefit that may offer. After a little trial and error and checking with the degree wheel, I decided to use 3 base gaskets that had a combined uncompressed thickness of 2.1mm. The three gaskets were just enough to get the piston below the ports at BDC.  Setup as stock with a single base gasket the timings were 172° exhaust, 118° transfer. With three base gaskets the timings moved to 180° Exhaust, 130° transfer. That's +8° of exhaust duration and +12° of transfer duration by raising the cylinder. The down side to this is that the piston is farther from deck at TDC, which is bound to drop compression. I used only copper spray and no head gasket to try and offset the change a little and still ended up with 3mm of squish clearance.  Sure enough, compression dropped from about 150psi stock to 128psi. 128psi is lower than I'd like to see, but I wanted to try this mod in it's simplest form.  No carburetor adjustment was necessary. I left the slider weight alone as well, although .5-1g lighter sliders may have been beneficial to acceleration. The loss of compression was apparent. The crispness and response of the throttle was just not there as it has been. Initial takeoff and acceleration in general suffered. The effects weren't terrible, but I could easily tell that the engine didn't have the same "grunt". Cruising speeds did increase just slightly, by 1-2MPH over stock on flat ground. The engine felt a little more comfortable at slightly higher revs, so I believe that's where the cruise speed change came from. The overall lack of torque from the compression change made inclines and headwinds drop cruising speeds more than usual however. MPH still maintained as high as it would stock, but there was a greater difference than normal. The bright side here being that I was also able to see a little more speed than normal when I had a tailwind on my side or a decline. Max MPH did not improve, which surprised me a bit, but the engine really isn't running to it's peak with 128psi of cranking compression. Even with the minor gain in cruise RPM, I would prefer the stock setup over this one. The loss of torque makes the scooter less fun to ride in town or anywhere where you'll be stopping and starting a lot. The 1-2MPH increase in cruising speeds in ideal conditions just isn't worth that loss in my opinion. I didn't want to call the test done there, because I felt like more could be gained fairly easily by simply increasing compression. The easiest way to do this would be to buy a 52mm squish style cylinder head. They tend to have smaller combustion chambers and the only one's I could find were high compression setups. I tested this modification earlier in the project and I had to add multiple head gaskets to drop compression to a reasonable level. The other option, and the one that I chose, is to mill down the stock cylinder head to increase compression. I did this using sandpaper and glass as described HERE. If you aren't comfortable doing it yourself, a machinist should be able to handle this easily and for a very reasonable price. I almost completely removed the lip from the stock head, as you can see in the photo below with an untouched head on the left and the modded one on the right.  Without a head gasket, that upped compression to just over 160psi.  I wanted compression to be similar to stock, so I added a 0.3mm thick head gasket and compression moved to 150psi. Squish clearance was about 1.6mm.  Upon starting the engine and twisting the throttle a little, I could tell that things were more back to normal. Throttle response improved back to the level I am more accustomed to. On a test ride I saw cruising speeds increase to the mid to upper 40MPH range. Resistance to inclines and winds improved over the previous setup, to be more similar to stock. Acceleration also came back to normal. I was hoping to see more of an increase in acceleration, but gains were minimal. Max speed was 51MPH once again, which surprised me. I really thought I was going to pick up some top speed with this mod. It feels smoother revving out, but it doesn't want to rev out any farther. With supporting mods like a more rev friendly exhaust and carburetor, more improvement may be seen. Using the first setup with the lowest compression, I never heard a bit of detonation as I had been with everything stock. I did notice a little spark knock with the compression raised to the stock level, but not quite as much. I would say that this mod is worth doing when the compression is raised, simply to see an improvement in cruising speeds. Otherwise, I didn't see big improvements. It's hard to argue with any gains when the costs involved can be as low as additional gaskets and some cheap supplies to remole material from the cylinder head. |

|

|

|

Post by 90GTVert on Jun 15, 2011 18:13:45 GMT -5

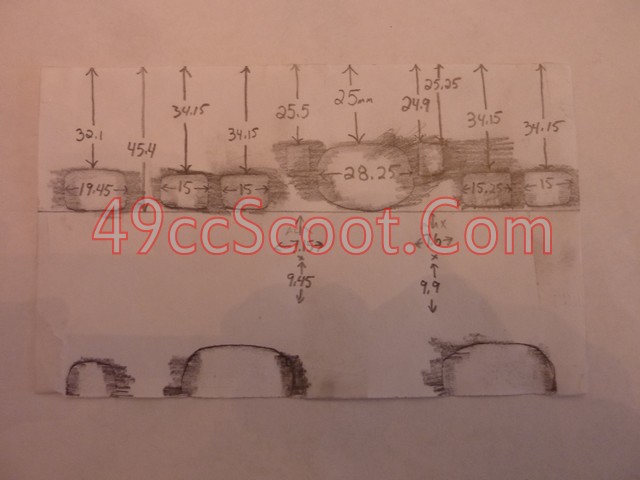

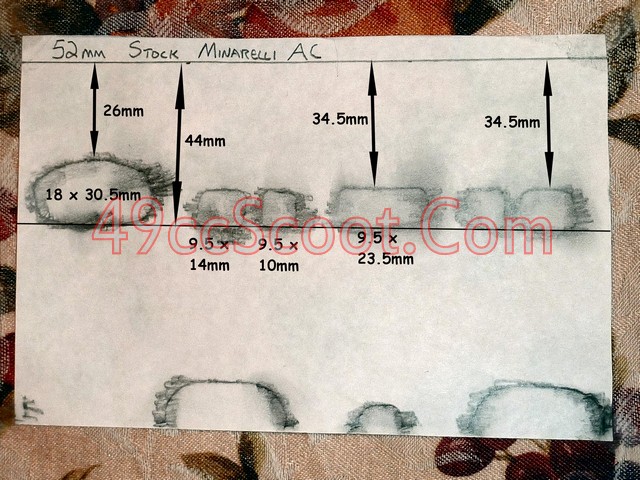

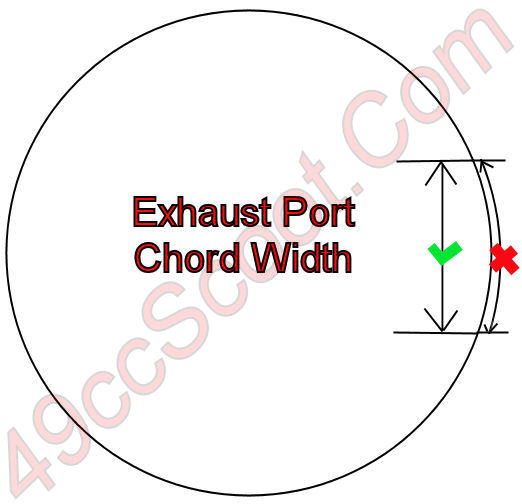

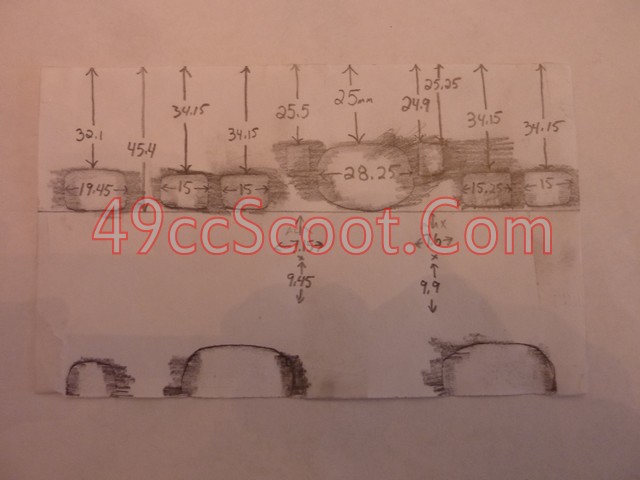

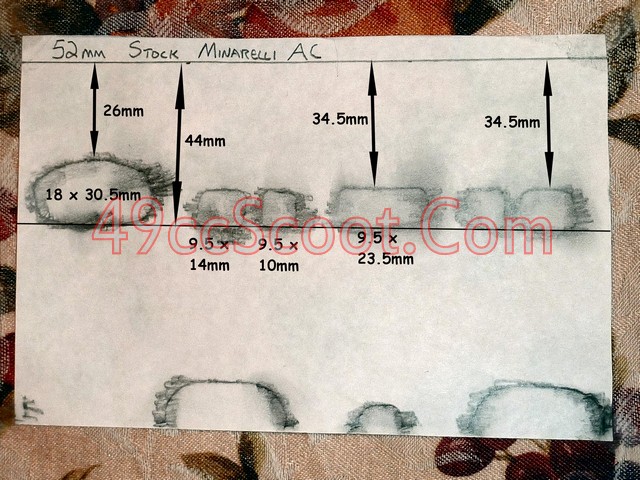

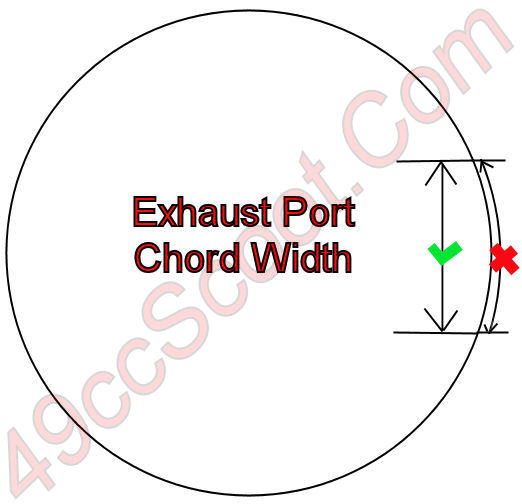

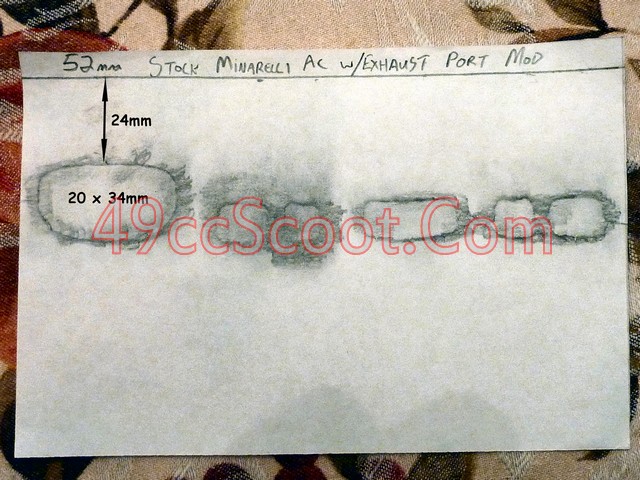

Porting And AdjustmentFinally, I got to move on to the mod I've wanted to do since the day the project started. Watching most of the modifications that have been tested do very little, I have been assuming that the port setup is a major factor in their failure. I made a port map of the stock cylinder. As setup stock, it had 172° of exhaust duration and 118° of transfer open time.  My next step was to determine what my goals were and what I needed to do to reach them. I wanted to try to set the cylinder up to work well with aftermarket pipes in the future, and to have a strong powerband. I needed to know the port durations I was shooting for, consider exhaust port shape, and determine the width I wanted to make the exhaust port. Modifying the transfer port shapes is out for me, because I don't have the proper tools. You need a Dremel or Foredom style rotary tool and small angled handpieces to reach the transfer and boost ports. Once you can reach them, you have to be very careful how you modify them. They are designed at a certain angle to aim the mixture upwards as it enters the cylinder. Blindly changing this angle could lead to a poor performing cylinder. I started out by determining the width I wanted to make the exhaust port. I wanted to go as wide as I felt would be a safe setup to try and get the most from the cylinder. Going too wide will have your piston rings traveling deep into the port and snapping or at least wearing quickly. For a standard single port exhaust, the figures most used for maximum exhaust port width tend to be from 60-75% of the cylinder bore. 60% usually being considered very safe and 75% generally being for max performance where longevity is of very little concern. I chose to go with 65% to stay on the safe side. 52mm x 0.65 = 33.8mm. The number I have just came up with is the chord width of the exhaust port. That means the width as measured across the curve, rather than around the curve. I'm not sure if just stating it that way makes sense, so here's an image that may help.  Next, I moved on to determining the exhaust port shape that I wanted to use. Exhaust port shape can have dramatic effects on the powerband and piston ring wear. To keep piston ring wear to a minimum the exhaust port would have gentle curves, especially the port roof. An oval shape is generally considered to be the easiest on piston rings, because the rings travel gradually into and out of the port, rather than abruptly meeting up with the port roof or floor. When considering the shape of the exhaust port for power output, look to the roof. The flatter and wider a port is at the roof, the better it's output will be in the rev range that it's setup for. A flat roof tends to create great peak power, but makes power peaky. That means that power below the intended range tends to drop off, but power in the intended range is usually very good. CVT tuning must be more precise, keeping within a narrow range, for the best results. Of course the other downside to a very flat roof is that it's harder on rings as mentioned previously. A port that takes a more gradual curve to reach it's peak height has the opposite effect. Maximum power output will be lower than the wide, flat, roof, but the cylinder will have a much broader powerband. A wide powerband can be very nice for a street ridden scooter. It makes the CVT easier to tune, because you don't have to keep the RPM in a very specific range. As stated earlier, a gradual curve is also easier on the piston rings. The best street setup in most instances, especially with an otherwise stock engine and CVT, is the oval port that provides a nice wide powerband and minimal piston ring wear. I wanted to see a little more peak power, but I wanted to keep the ring wear down. For those reasons, I decided to shoot for a mix of both ideas. A fairly wide roof that isn't completely flat. Now that I know basically how I want my port to look, I need to determine how tall it will be by deciding what duration I want to achieve. In order to choose a duration figure, I need to know what RPM I am hoping to see peak power at. My goal is to make the cylinder work with any of my aftermarket pipes reasonably well. Of course they don't all operate at the same peak RPM, so that makes life a little harder for me. For those of you that won't be using a slew of exhausts, this will be much easier. The pipes I plan to use claim peak power anywhere from 8,500 to 9,500RPM. I decided I wanted to look for peak power in the 9,000-9,500RPM range. I believe any of the pipes I have will respond pretty well to this. To determine the durations I need to shoot for, I use past experience and the experience of others online and in books. These guidelines are from A. Graham Bell's book, Two-Stroke Performance Tuning. He lays out most of this info, I'm just dumbing it down a bit and made slight adjustments with the table below and trying to make it easier to read. I'm not a pro tuner, so I still advise doing your own research, but this may help for a starting point. RPM | Exhaust Duration | Transfer Duration | 7,000 | 172-176 | 118-120 | 7,500 | 176-178 | 120-122 | 8,000 | 180-182 | 122-124 | 8,500 | 182-184 | 124-126 | 9,000 | 184-186 | 126-128 | 9,500 | 186-188 | 128-130 | 10,000 | 190-192 | 130-132 | 10,500 | 194-196 | 132-134 | 11,000 | 196-199 | 134-136 | 11,500 | 199-202 | 136-138 | 12,000 | 202-204 | 138-140 |

EDIT : 190° exhaust and 130° is often a great spec to aim for with many builds. I would suggest using this as a cutoff point if you aren't sure what to do. Now many years past this article, I have used a 190/130 aftermarket cylinder that runs very well even with an exhaust making peak power at near 14,000RPM. The same setup worked very well for me with another exhaust at closer to 10,000RPM.

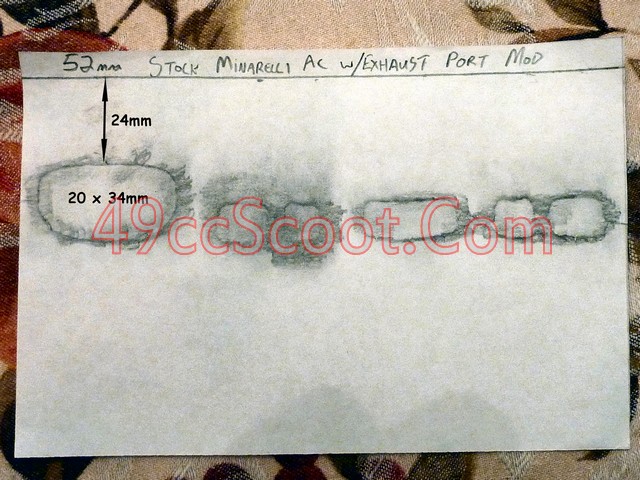

I chose 186° exhaust and 130° transfer as my target durations. 186° is right in the range above for the exhaust. 130° is on the higher end, but still in the above range for the transfers. Myself and other members here have found a little more transfer duration to have good effects. With those things determined, it was time to get to work. I started out by using multiple base gaskets to raise the cylinder about 2.1mm so the piston would clear the ports at BDC. This upped the durations to 180° exhaust and 130° transfer. The exhaust will still need work, but the transfer duration is right where I was hoping to be. If you need to increase the transfer duration more, you may consider filing the piston. CLICK HERE for more info.  Now I needed to get the exhaust port to the specs I was hoping for. Here's a look at the exhaust port pre-op.  I used a black permanent marker and colored in an area above the exhaust port. Then I used the degree wheel to set the piston at 87° from TDC, where the roof needs to be to achieve 186° of open duration. I used a razor knife to score a fine line at the top of the piston. You can really see how curved the roof is in relation to the straight line.  I wanted to open up the outlet of the exhaust port as well, and doing this first can help you get tools in to the exhaust port easier. If you're lucky, you'll have an exhaust with a detachable header flange so that you can bolt it up and port match. I'm not that lucky, and I would be attempting to match to multiple exhausts for this project. I used the outline from the stock exhaust being ran on the cylinder as a rough guideline and got to work.  It's sure not the best port job, but it'll work. I didn't spend a whole lot of time here since I don't know exactly what exhaust I'm hoping to match.  After some time with a Dremel and a drill with a carbide burr, the exhaust port took shape. Looking at the photos, I didn't do a great job getting the port roof as smooth as I would have liked and I can see a little more work that could be done inside the port, but it's still a big improvement and the size and shape ended up where I wanted it. I always notice more flaws in photos than I see at the time. Perhaps reviewing pictures before finishing up or using a lighted magnifying glass would help.   I made a port map after I finished and cleaned the cylinder.  Here's a before and after look at the exhaust port so you can easily see the change. These are laid side by side, not edited together, so the difference is in scale.  I re-installed the cylinder. Since I moved the cylinder up with additional base gaskets the piston is farther down in the bore at TDC. Making the exhaust port so much larger also makes healthy compression figures are harder to come by.  I ended up using the high compression squish band head, tested earlier in the project, with one 0.3mm uncompressed head gasket to get 158psi on a compression check with squish at 1.4mm.  I swapped to a 90 main jet, from an 85. The needle remained in the same position, next to richest, and I made a minor adjustment to the idle mixture. The engine now seemed less responsive revving from idle. On initial test passes I noticed a lack of power at low revs. Anything below 6,000RPM was pretty dead. Once RPM raised to 7,500 though, it really started kicking in. I tired going to lighter 5g sliders, but the revs would raise so much while shifting that I found it unpleasant. I ended up with the same 6g sliders I've been using and stiffer clutch springs. Unfortunately, the clutch springs have less affect than they should, because the belt is hung up in the front pulley at rest as the CVT is setup stock. As it stands, there is a very brief bog, then the RPM raises quickly and the scoot accelerates well to 25-30MPH, then the RPM drops down to 5,800 or so when the torque driver shifts to the second angle. Acceleration slows until about 7,000RPM and then it comes to life again and pulls very well. When above 7,500RPM, power feels like it is significantly increased. The maximum RPM that I have seen is 9,550. I went for a 50 mile ride to really see what the porting would do. On this ride, I got 44.7MPG. Again on par with most past results. Max speed was 54MPH. Cruising speeds increased to the upper 40s to 50MPH, with RPM hovering around 8,500RPM most of the time.  I didn't notice much detonation when I was riding. The only time I heard any was rolling out of the throttle very slowly once I reached 1/2 throttle or so. That would probably make for a very good tune if I needed to use a lower octane fuel, but I've been sticking with premium to get a little more from the engine so I wanted to up the compression a bit. I switched from a thin head gasket to no head gasket and ended up with 180psi with 1.15mm squish.  I didn't see a whole lot of improvement in power, but there was some improvement. It seemed like keeping speed on inclines and against wind improved more than anything. It's still pretty dead at low revs. I did once again bring back the rattle of detonation, but it isn't really any worse than stock. I hear it when i let off of the throttle a bit and I get some spark knock when the engine is under much load, like at low RPM. Otherwise it's alright. I don't have any desire to push it farther, but it's OK where it is. I did manage to make the highest speed so far in the project, at 55MPH. To be fair, it was very close to that speed without the increased compression. My speedometer was reading 54.5MPH on the previous test.  To sum it all up, this is absolutely a good mod to do if you feel comfortable with it. I saw the best MPH of any mod I've tried, and it's one of the cheapest to do if you have the tools. Acceleration isn't that impressive in my case, but you can always opt to tailor the setup to what you want. I think that this cylinder will start to shine with more tuning like a CVT that can keep within the powerband better and and exhaust better suited for more revs for example. Using a less aggressive exhaust port shape and duration should allow you to see good gains all around and not lose the low end power as I did. I use 184/130 durations with a less aggressive port shape on my Venus' 96cc and it makes excellent power from 4,500 to just over 9,000RPM. If you do your homework, take your time, and properly execute a porting mod, you can see some very impressive gains without spending much money at all. The Hoca big bore kit that I tried definitely had a wider powerband, but it did not pull any harder at higher revs than this cylinder. Of course it had the benefit of adding 7cc of displacement. It also had a lot of detonation as I tried it and would have needed the compression lowered to make it a really good street setup. You can make and/or buy the gaskets you need for this mod under $20 and the Hoca or other big bore kits will cost you around $150. |

|

|

|

Post by 90GTVert on Jun 16, 2011 18:28:37 GMT -5

Here are a couple of tables that I've made up to compress a lot of data into a smaller space. Results : Stock With A Single ModificationStock carburetor jetting and adjustment as well as CVT tuning with rollers or sliders and clutch springs considered "Stock" baseline. Prices are rough estimates. Brand, retailer, shipping charges, and tuning supplies may make prices vary greatly in some cases. Prices assume you do the installation and tuning. Modification | Max Speed | Comments | Price | Stock Tuned w/Roller Weights | 51MPH | Main Jet Selection, Carburetor Adjustment, Roller Weight Selection | $30 | Stock Tuned w/Sliding Weights | 51MPH | Main Jet Selection, Carburetor Adjustment, Sliding Weight Selection

Faster Acceleration Than Roller Weights | $45 | Clutch Springs | 51MPH | Improved acceleration from a stop or low RPM. I chose 1,500 RPM springs and kept them in for all future modifications. | $10 | Hoca Malossi Style Variator | 54MPH | Excellent increase in top speed and acceleration. Some decrease in initial takeoff power without a little setup work. May require slightly heavier rollers or sliders. | $50 | Performance Torque Driver | 51MPH | Nice improvement in acceleration. Expect to use heavier rollers or sliders to maintain the same max speed. | $50 | Torque Driver Modification | 52MPH | Small gains on the high end due to keeping within the powerband slightly longer. | $0 | Airbox Snorkel Removal | 52MPH | The MPH increase was a fluke on that test run. Power did feel slightly better. Carburetor tuning required. | $0 | Free Flow Air Filter (UNI) | 51MPH | Very slight increase in power, not worth the noise increase IMO. Carburetor tuning required. | $20 | Reed Block Spacer | 51MPH | No noticeable power gain. Some improvement in throttle response and smoothness. | $20 | Carbon Fiber Reeds | 51MPH | No noticeable power gain. Some improvement in throttle response and smoothness. | $20 | Polini Reed Block | 51MPH | No noticeable power gain. Some improvement in throttle response and smoothness. | $60 | 19mm Arreche Carburetor | 51MPH | Possible increase in cylinder cooling ability and better fine tuning. Stock configuration too mild to take advantage of the larger carburetor. Decrease in fuel economy. | $125 | Modified Stock Exhaust | 51MPH | Restricted stock exhausts will show gains. Little gain to be had with unrestricted stock pipes. | $0 | Phongeer 100cc Exhaust | 53MPH | Increased power and acceleration throughout the rev range.

Stiffer clutch springs, lighter rollers/sliders, and carburetor tuning may be beneficial or required. | $150 | Leo Vince ZX 100cc Exhaust | 53MPH | Increased power at mid to upper RPM. Needs more RPM than this 90cc's stock cylinder can support. Stiffer clutch springs, lighter rollers/sliders, and carburetor tuning may be beneficial or required. | $250 | Leo Vince SP3 50-70cc Exhaust | 53MPH | Increased power and acceleration throughout the rev range. Not quite as good as the 100cc specific pipes, but still not a bad choice at this stage. Stiffer clutch springs, lighter rollers/sliders, and carburetor tuning may be beneficial or required. | $150 | Performance CDI | N/A | Excellent upgrade if your current CDI has a rev limiter that cannot be removed. Otherwise expect minimal to no perceivable gains in most cases. | $20 | Aftermarket Ignition Coil | N/A | Expect no gains in performance. | $25 | Iridium Spark Plug | N/A | Improved starting. More reliable spark. Expect no gains in performance. | $10 | Lightened Flywheel | 51MPH | Slight increase in throttle response with 10% weight reduction. Greater weight reduction should have more effect. | $50 | Squish Style Cylinder Head | 51MPH | Slighty more resistant to detonation. Expect no gains in performance. | $30 | Additional Base Gaskets | 51MPH | Gains were minimal, but present. Power increased in the upper RPM range enough to boost cruising speed a little. | $20 | Porting And Adjustments | 55MPH | Depending what you do, you can see great gains. This one can be tailored to your setup. Read up and do it right and I don't think you'll be disappointed. Possible jetting and CVT adjustments. Some configurations may require a high compression head for proper compression. | $20 | Hoca 54mm Big Bore Kit | 54MPH | Improved torque and power all the way to max speed. Slightly improved fuel economy by allowing lower throttle acceleration and cruising. May require upjetting and roller weight adjustment. | $150 |

Modification | % Change | # Change | Airbox Snorkel Removal | +9% | +7 | UNI Air Filter | +18% | +15 | Phongeer Exhaust | +6% | +5 | Leo Vince SP3 Exhaust | +6% | +5 | Leo Vince ZX Exhaust | +8% | +7 | Hoca 54mm Big Bore Kit | +6% | +5 | Ported Stock Cylinder | +6% | +5 |

|

|

)

)