|

|

Post by bluegoatwoods on May 25, 2017 8:18:09 GMT -5

Does the circuitry in a typical automotive headlight consist of one ground plus one 12 V DC hot conductor for the low beam plus one more 12 V DC hot conductor for the high beam? That would sound like it's logical.

The reason I ask is this. My low beam burnt out recently and I considered replacing the entire headlight, bucket and all, with an LED motorcycle headlight I have on hand. This would probably be nice if only because it would lessen the load on my stator.

But when testing the LED electrically the results were a bit puzzling.

I could get what appeared to be the low beam from this LED when one of the hot conductors was applied to the positive battery terminal. But I could not get what should have been the high beam using the other hot conductor. Whether conductor A was attached to positive or not, conductor B gave no light at all.

For that matter, I tried this on three different LED headlights. Two of them behaved just like I described above. The third didn't give any light from either conductor. My guess at the moment is that the third one simply isn't working at all.

I'd assumed that basic headlight wiring was something like: if you apply power to one conductor you get the low beam. If you apply power to the second conductor, then you get low beam and high beam both running at once. Have I missed something? Is the circuitry more complex than this?

My remedy for now is to simply buy a new bulb and keep going with the stock headlight. But I wouldn't mind switching to LED sometime in the future. But I'd better be sure I understand just how to wire it first.

|

|

|

|

Post by ryan_ott on May 25, 2017 9:19:50 GMT -5

The headlight in your scoot is typically AC powered from your stator. The led lamps usually only work on DC, some will allow AC. You may have additional wiring required to run leds on your AC as running a relay to the battery or rectify the AC for dc. Typically you have 3 wires for a hi/low beam. One to the base of the lamp for ground and one to each of the high/low beam filaments. I should also add that with most led lamps they need proper polarity, + to + and - to -, I've had some that will work if hooked up backwards but most don't.

|

|

|

|

Post by bluegoatwoods on May 25, 2017 12:36:37 GMT -5

.................Typically you have 3 wires for a hi/low beam. One to the base of the lamp for ground and one to each of the high/low beam filaments. ................

This likely means that none of my LED headlights on hand are working properly. They're a few years old and I don't think they were anything more than cheap-Os. So I guess it's not surprising.

It didn't occur to me that my stock headlight circuit might be delivering alternating current. But it's not surprising. An incandescent bulb wouldn't care. So why go to the expense of rectifying it at the factory? And I'm sure I could do it cheaply enough should I ever convert anyway.

I suppose I could run my own headlight circuit, with an on/off switch, directly from the battery, too. Draw headlight power from the battery and allow the stator to charge that.

|

|

|

|

Post by ThaiGyro on May 25, 2017 23:28:49 GMT -5

The LED issue can be a bit crazy. Ryan offered some of that information. In most newer applications, the LED's come in DC,12 or 24 volt. The true answer to your question depends on a few things. How many LED's are going to be used, say, for just low beam? Are you eventually going LED for high as well?

My experience is not extensive, but I know that DC LED's are in the 2-4 volt range each and require constant current. This current can be in 350mA, 700mA or 1A. In an array, you would need a "driver" to ensure clean, constant power delivery. My friend use Phillips drivers, as they are available here in various voltages. 12V is very common. I don't have one, but recall that they are the general size of a USB device...maybe a bit bigger.

Many pre-built systems have a proper one in place, like those light ribbons and such...Cost? I don't know, but not expensive here in Thailand.

|

|

|

|

Post by bluegoatwoods on May 26, 2017 20:16:06 GMT -5

The LED issue can be a bit crazy. Ryan offered some of that information. In most newer applications, the LED's come in DC,12 or 24 volt. The true answer to your question depends on a few things. How many LED's are going to be used, say, for just low beam? Are you eventually going LED for high as well? My experience is not extensive, but I know that DC LED's are in the 2-4 volt range ....

It sounds like converting to LEDs could be a bit more tricky than I'd anticipated and probably not worth doing unless necessary.

Besides, I don't really like the color of their light.

I suppose I'll just replace the standard incandescent bulbs as needed. |

|

|

|

Post by V90Performance on Jun 7, 2017 13:25:57 GMT -5

I ran some LED headlights on my scooter. If you can change the headlights from AC to DC by changing some wires around, you can swap in a p15d LED bulb and you'll be set. It's brighter than stock but it has no focus. I'm currently running HID's. The brightest of the other two types of bulbs and has real good focus.

|

|

|

|

Post by FrankenMech on Sept 4, 2017 1:47:20 GMT -5

The standard 4 terminal regulators on scoots are a shunt regulator. They shunt (or short) excess positive and negative voltage to ground. They do not rectify the stator output, they just chop it up. What remains from the 'AC' stator windings after all the limitations is a very high ripple DC voltage regulated to about 14VDC with lots of nasty transients from the regulator. It is not 'AC' in that the negative side of the waveform is usually limited to about 1 diode drop below ground. The high ripple and high frequency plays hell with cheap digital meters. A simple 470 or 1000uF 35V electrolytic capacitor across the (yellow or white) +wire to ground will reduce most of the ripple. The battery swamps the ripple on the battery output side.

Many inexpensive LED lights are subject to corrosion in the circuit boards and connections.

LED lamps use different driver circuits. The cheapest use a resistor to limit current and are very sensitive to voltage fluctuations. Better units will work from around 10-30VDC, and some will work either - or + ground with internal rectifiers to protect the circuits. Some will even operate from AC.

A typical HIGH/LOW LED headlamp works the same as an incandescent. One lead is noramlly ground (-) and the other two (+) leads are for HIGH and LOW. The internal circuitry should determine which LED elements are powered for both functions.

|

|

|

|

Post by bluegoatwoods on Sept 4, 2017 22:33:26 GMT -5

Yeah, I can see that this involves electronics that I just don't understand. I'll make sure not to do anything rash.

|

|

|

|

Post by FrankenMech on Sept 4, 2017 23:59:19 GMT -5

Buy some new LED lights. Many LED lights are available without HIGH/LOW options, just two wires, one for ground(-) and one for power(+). Keep it simple.

'Tractor' or utility lights just have two wires and are easy to hook up. Some will say SPOT or FLOOD, there is not a whole lot of difference, they are both mostly FLOOD. That makes them difficult to 'aim'. Look for units that have a wide voltage range like 10-30VDC, 9-24VDC, etc, to get the better power circuits.

|

|

|

|

Post by SMALL CC TEK on Aug 7, 2018 20:56:26 GMT -5

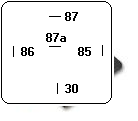

Use a relay in the headlight wiring . You wire in so you can use your rocker switches no external switches . Basically you run a power wire from your battery with a 5 amp fuse in it to the relay then you run a wire to the low bean side if the light then the other spot on the relay to the high beam side of the light so you have tapped into your factory wiring on the low beam side to the relay then ground the relay and you should work .That is a quick overview on how i did it and it has worked for years . Here i did not give you the type of relay in the info SPDT Power fused # 30 Constant power Ground # 86 Low Beam # 87 High Beam # 85  |

|

|

|

Post by lostforawhile on Aug 30, 2018 21:51:09 GMT -5

The issue is the stock stator won't handle you running the lights from the battery, the ac lighting coil runs the lights, the winding to charge the battery can barely do that. You could get a bridge rectifier to put between the AC into the light,and the light, just remember ,you will have some voltage drop across the diodes. The best solution is the 11 pole three phase stator,and then six wire regulator, all that stator does is charge the battery,and then did it's full wave rectification

|

|

|

|

Post by chaoticfury on Dec 4, 2018 4:34:16 GMT -5

That's correct. You won't be able to keep your (stock) battery charged if you run a light. I had a 50 once and the brake light was stuck on. Brake lights are typically DC.

Well, the thing would never electric start. I tested and it was charging properly. When I finally fixed the brake switch, lo and behold the stock stator was able to keep the battery charged.

Maybe if you put in the 8 pole stator, which for gy6 doesn't require a different flywheel or any money business, you'd have a better chance. But I don't know if an "8" is 25 percent better than a "6", or what. Anybody have the specs on stator output?

|

|

|

|

Post by harleyracer59 on Dec 6, 2018 13:47:05 GMT -5

the thing yall got to remember is hes trying to convert to led. on 2 of my scooters im running my headlight with high/ low, all 4 turn signals constant on, dash light, tail light, led under lighting, a 4 channel amp with 3 speakers (back channels are bridged for a 6.5") and a sig lighter/ charge port on 1 of them. all lights have been swapped for LEDs with no starting issues what so ever. all my lighting combined probably draws what my incandescent tail/ brake light did. LEDs use a fraction of the amps a normal bulb does. if you are worried on wiring, search fleebay for motor cycle led headlights (dual polarity?) they are meant to work with DC or AC lighting systems. if youre confident in wiring, the inline bridged rectifier would be easiest, if you wanted to go the relay rout, you can pull power from your ignition switch. its right there in front of scooter, usually 6" away from the head light. in the future I plan to convert my charging system from half wave to full wave. its as simple as resoldering a wire from 1 pole to another on the original stator, replacing the regulator/ rectifier and moving a the headlight circuit wire over to the dc charging circuit. search youtube. theres atleast 6 videos on how to. heres pics of my gyro my blue aero and my beach cruiser. all on LEDS. cant find a pic of my orange aero, it has RGDW multi color ground lighting with a remote control to change colors and effects. the lights can flash strobe fade and switch to music if I so choose (I know its silly but I like it and it makes people smile and shake their heads. lol)     |

|

|

|

Post by harleyracer59 on Dec 6, 2018 13:52:52 GMT -5

|

|