|

|

Post by 90GTVert on Feb 21, 2019 12:31:46 GMT -5

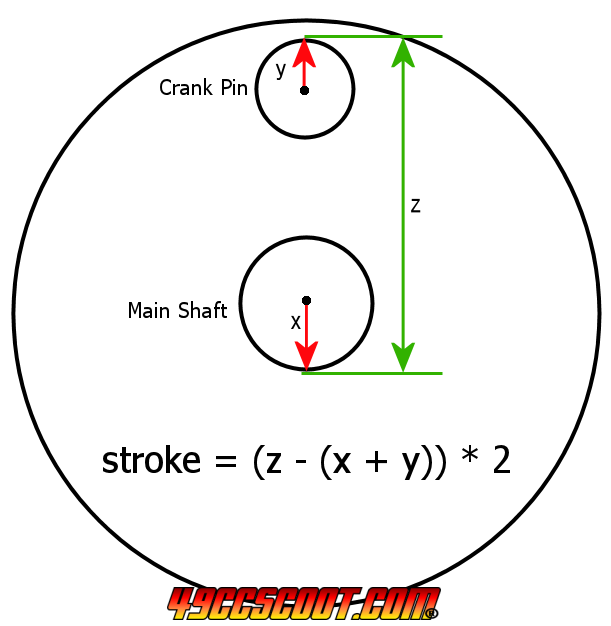

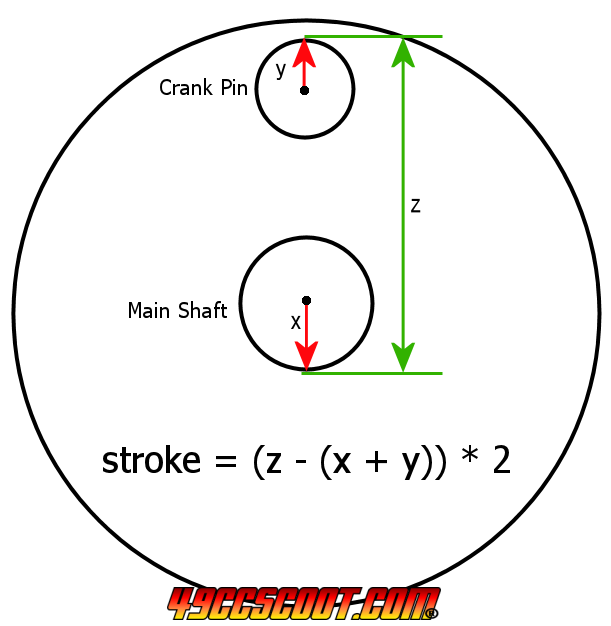

190mech gave me some information about finding the stroke of a crank when it's not installed, so I made up a graphic. (When installed you can measure piston travel from BDC to TDC or TDC to BDC.) Not all cranks seem to have their advertised stroke or maybe you just aren't sure what you've got on the shelf. Either way, a few measurements and this formula will let you check stroke.  stroke = (z - (x + y)) * 2 where; x = main shaft radius (Measure main shaft outside diameter and divide by 2.) y = crank pin radius (Measure crank pin outside diameter and divide by 2.) z = distance from the top of the crank pin to the bottom of the main shaft What you're doing is finding the center to center distance from crank pin to main shaft, which is 1/2 of the stroke or the radius, and multiplying it by 2 to find the working diameter of the crank which is the stroke. You could even do this with a bearing installed on the main shaft if necessary.

|

|