|

|

Post by dexameth on Jun 20, 2021 9:14:19 GMT -5

Alrighty folks, I need some help finding a torque driver with the absolute steepest angle for Dio/ZX/QMB engines.

I've seen the best performance with my ZX when my angled driver gets steeper... it pulls much harder.

My Hoca Minarelli TD had three different angles, and I always used the steepest possible. I like the spring to do all the contra work, not the friction of the pins.

The NCY does look the best so far, but I haven't been able to find any info on the two angles except they are both straight. SSP-G, Naraku, TWH all have that straight drop at the end in one groove, and then another straight groove is too angled, I need it straighter up and down.

If anyone knows of any, please let me know!

|

|

|

|

Post by captincvmn on Jun 20, 2021 9:42:28 GMT -5

I’m thinking the angle of the slot helps with up/downshifting and the straight slot parallel to the shaft would not cause the umph of the engine and load of the driveline to affect the shifting. The dual angle sucks. No argument there.

|

|

|

|

Post by dexameth on Jun 20, 2021 10:34:40 GMT -5

I’m thinking the angle of the slot helps with up/downshifting and the straight slot parallel to the shaft would not cause the umph of the engine and load of the driveline to affect the shifting. The dual angle sucks. No argument there. So when my clutch drops into that straight section at the end is when it pulls REAL hard. Even with the rpms dropping slightly, the spring then comes into action and it works amazing to hold the rpms where I want. It basically revvs up to 8500 off the line and gets up to 38/40mph when you fell it lurch forward and pull hard all while the rpms fall to like 7800. But, this allows the engine to now rev back up and get back on the powerband and pull again. 2 speed! It literally feels like a 2 speed setup. I just hate the slow launch. |

|

|

|

Post by Zino on Jun 25, 2021 23:26:21 GMT -5

Here is a picture of my ncy pulley I cannot find my protractor to measure the angles  |

|

|

|

Post by dexameth on Jun 26, 2021 6:05:43 GMT -5

Yeah, it looks like NCY is the only one with 2 straight angles. I've been looking everywhere...

SSP-G, Naraku and TWH all use the same groove designs. Then NCY has the double straight groove, and looks VERY similar to the SSP-G driver I installed for GY6 yesterday. to the naked eye they look the same but after studying I could tell one groove was steeper than the other.

Good thing my shop is an NCY dealer... Hehe.

|

|

|

|

Post by dexameth on Jun 26, 2021 6:20:44 GMT -5

A few days ago I popped out the NCY 1000rpm spring and installed a stock QMB (softer) spring. It was instantly better! Harder pulling for sure, it spun out like a mad man when I took off in the dirt, then wanted to pop the front wheel up easier!

Seems these ramps are so angled that it creates too much friction and in turn a softer spring is needed. This kind of setup will slow down the shifting of the belt, coming on and off the throttle like banging corners or even hilly areas.

A super steep angle requires the spring to do the variator's contradiction, and should allow the pulleys to open and close MUCH smoother and quicker; using spring force and not friction.

I'll get the NCY driver soon, hopefully it's steeper than what I have!

|

|

|

|

Post by 90GTVert on Jun 26, 2021 16:37:12 GMT -5

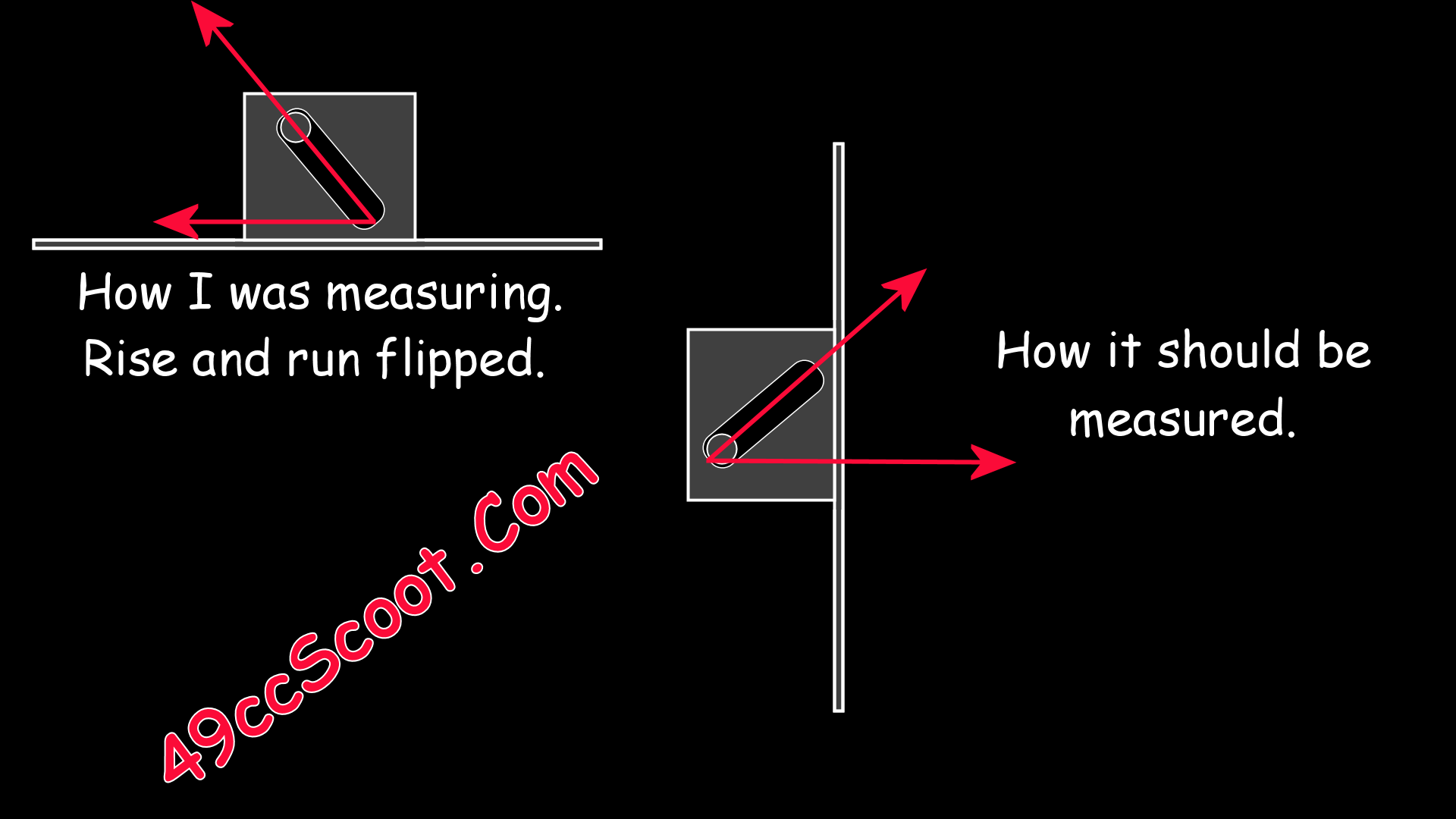

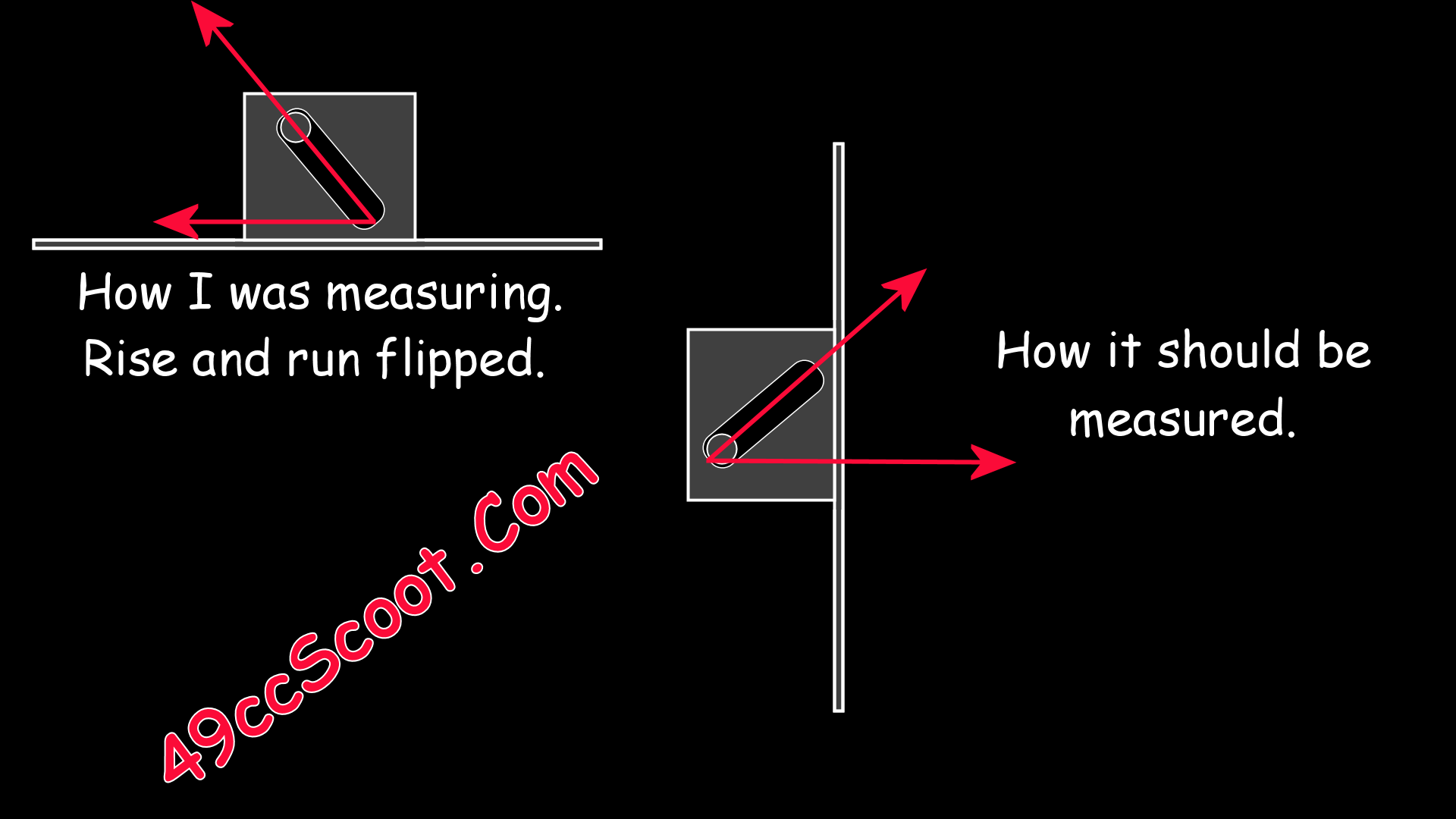

Here's an old post in case it's of any use. The NCY TD that I had said "FOR DIO" on it. It was from when I had my SunL, which was probably ~12 years ago, so the product could have changed since. I just realized I've been measuring my torque driver groove angles wrong. I was looking at a Malossi torque driver for a minarelli engine, and saw it quoted at 36 and 38 degree grooves. I'm looking at it thinking, "no way, those are more like 50 something degrees". So then I start thinking about it and realize I've been getting it bass ackwards.  The way I measured made sense to me at first, just because that's how it's easy to set the TD on a flat surface and measure. Looking and thinking a little more, it actually makes way more sense the other way. The way I now believe it should be done is more correct in the perspective of the motion of the pin through the path of the TD groove. The rise and run would be correct from it's perspective. The way I did it was switching the rise and run around. So, new figures for my torque drivers are as follows : Tao Tao Stock : 41° SunL Stock : 41° NCY Groove Set 1 : 40° NCY Groove Set 2 : 37° |

|

|

|

Post by dexameth on Jun 26, 2021 17:31:53 GMT -5

Here's an old post in case it's of any use. The NCY TD that I had said "FOR DIO" on it. It was from when I had my SunL, which was probably ~12 years ago, so the product could have changed since. I just realized I've been measuring my torque driver groove angles wrong. I was looking at a Malossi torque driver for a minarelli engine, and saw it quoted at 36 and 38 degree grooves. I'm looking at it thinking, "no way, those are more like 50 something degrees". So then I start thinking about it and realize I've been getting it bass ackwards.  The way I measured made sense to me at first, just because that's how it's easy to set the TD on a flat surface and measure. Looking and thinking a little more, it actually makes way more sense the other way. The way I now believe it should be done is more correct in the perspective of the motion of the pin through the path of the TD groove. The rise and run would be correct from it's perspective. The way I did it was switching the rise and run around. So, new figures for my torque drivers are as follows : Tao Tao Stock : 41° SunL Stock : 41° NCY Groove Set 1 : 40° NCY Groove Set 2 : 37° Thanks for that info, Brent. I never did the math and measured the true angles, just went by the naked eye. This proves the NCY is the TD I need to install. |

|

|

|

Post by Zino on Jun 26, 2021 18:28:32 GMT -5

40 degrees and 37 degrees are the angles for the current dio/genuine roughouse ncy torque driver

I just used a online protactor and uploaded the image.

|

|