Post by 90GTVert on Nov 5, 2011 22:41:38 GMT -5

Clutch Modifications And Upgrades

Before getting into any modifications, I'd like to explain a little bit about the operation of the clutch. If you understand how something works, it's usually easier to understand how and why modifications and upgrades work or don't work.

Most of us already know what a clutch accomplishes, but simply put, it lets our scooters operate at idle or low RPM without driving the rear tire so we can start and stop without the engine stalling or the scooter trying to pull us forward at all times. It does this all automatically, without any rider input, helping to keep CVT equipped scooters easy to ride and truly twist and go.

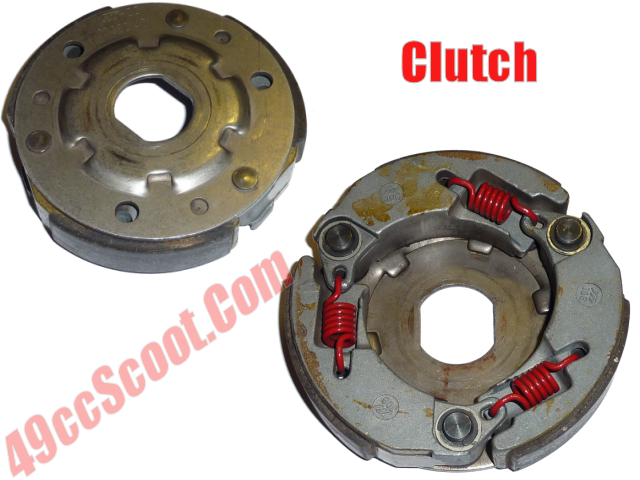

The clutch system on most CVT scooters is made up of 2 major components, the clutch and the clutch bell. The clutch bell is pretty simple. It's a piece of metal, usually steel on stock scooters, that attaches to the primary drive shaft, which turns the gears in the final drive transmission, and ultimately the rear tire. The bell is formed to create a housing for the clutch.

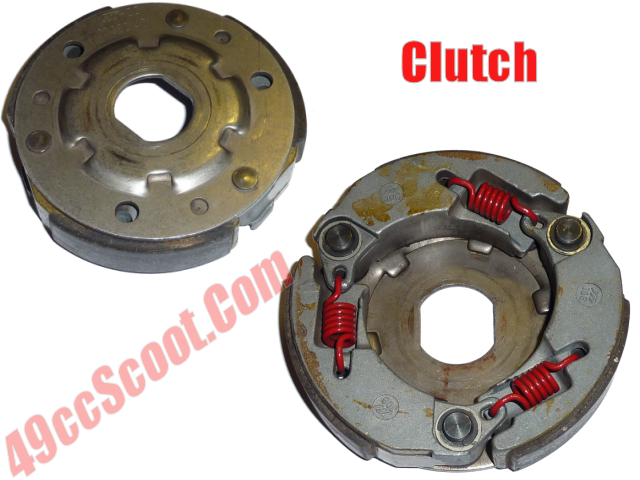

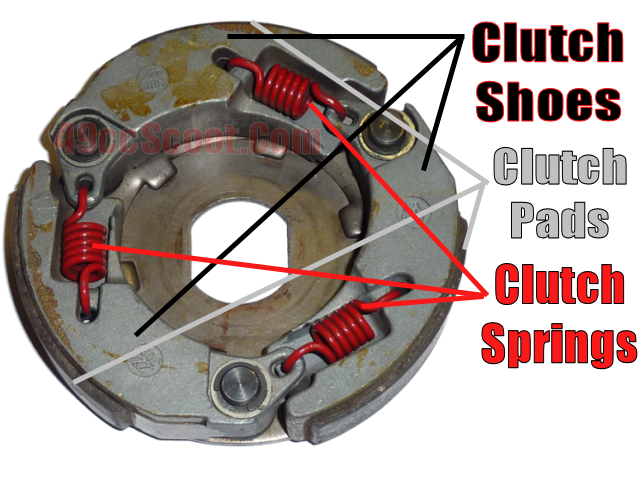

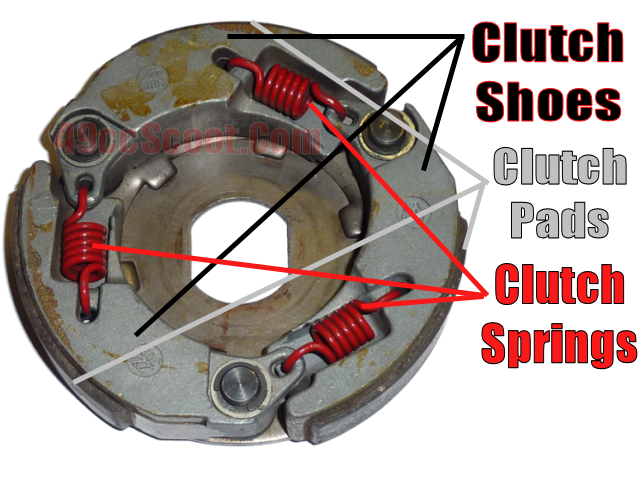

The clutch typically has 3 shoes, each with a pad on it's outer edge, and a clutch spring. The pads are a friction material that will grip against the inner surface of the clutch bell, but they have to overcome the tension of the clutch springs to do so.

The clutch is positioned inside of the clutch bell, as shown below. The clutch is slightly smaller than the inside of the clutch bell.

As the rear pulley and clutch rotate, centrifugal force will try to push the clutch shoes outward. Centrifugal force increases with RPM. Eventually the force will be great enough to overcome the tension of the clutch springs trying to hold the shoes in place and cause the pads to contact the inner surface of the clutch bell. The pads will slip a little, until RPM is great enough that the clutch can fully engage.

Once engaged, the clutch allows the CVT to drive the final drive transmission, and ultimately the rear wheel. If RPM decreases, the clutch will lose grip and disengage.

Hopefully you understand basically what the clutch does and how it does it at this point, so we can start talking about modifications or upgrades. The most common upgrade is definitely aftermarket clutch springs. Aftermarket springs are stiffer, and they cause the clutch to engage later, at a higher RPM. The stiffer the spring, the higher the engagement RPM. They can be great for more aggressive acceleration from a stop, to get the engine into it's peak power faster. This is especially helpful when cylinder porting or expansion chamber exhausts cause a drop in low RPM power. Stiffer springs can allow you to bypass that dead area, and get right to the power.

You don't always want to install the stiffest clutch springs though. Like anything else, for best performance they need to be matched to the rest of your setup. If you use clutch springs that are too stiff, you can miss out on part of your powerband and end up with a scooter that has to rev very high just to move.

Clutch springs commonly come in 3 denominations. 1,000RPM, 1,500RPM and 2,000RPM. The numbers don't indicate the engagement RPM, but rather the estimated RPM increase. For example, if your scooter's clutch engages at 2,000RPM stock and then you add 2000RPM clutch springs, it should engage around 4,000RPM. Unfortunately, it seems that the actual stiffness of both stock and aftermarket springs from one manufacturer to the next can vary, so these are just rough estimates of the increase in engagement RPM.

Springs sold as a certain RPM gain are usually color coded. 1,000RPM srpings are blue, 1,500RPM are yellow, and 2,000RPM are red. The same color coding applies to some contra springs.

Not all springs are coded this way. Some manufacturers like Malossi and Polini use their own unique color coding to designate spring stiffness. Some label them like the Koso 2,000RPM spring shown below. All companies don't name them using RPM either. Some are just arranged by spring stiffness like this Stage 6 clutch spring set.

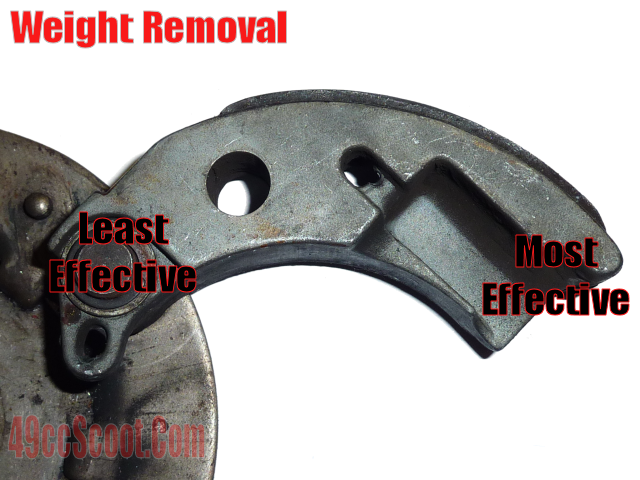

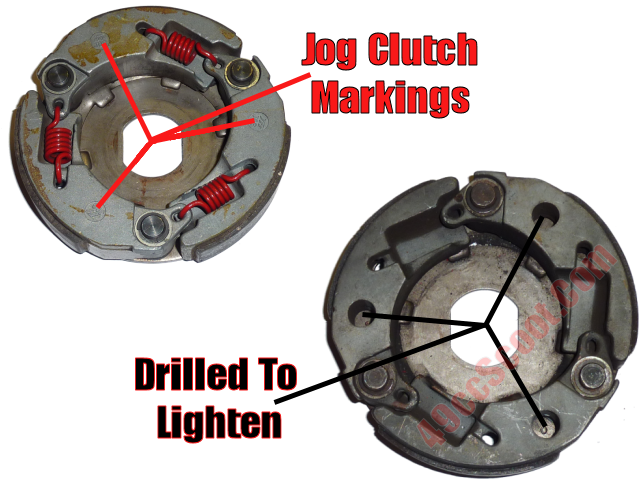

Another way to make your engine rev higher before the clutch engages is to lighten the clutch shoes. The lighter the clutch shoes are, the later they will engage. This can be helpful if you are on a tight budget or if you wish to fine tune your clutch engagement a little more than just swapping springs. I've lightened a few clutches just using a drill and different bits. You could find other ways to remove material as well.

There are a couple of things you must keep in mind. First, do not lighten the clutch to the point that it is not structurally sound and may come apart at speed. I tend to remove a small amount of material only from a section of each shoe that has plenty of material left around it. Remember, the clutch and rear pulley could be traveling at speeds much greater than even engine RPM. Lighten clutch shoes at your own risk, and err on the side of caution if you have any doubts about what is safe.

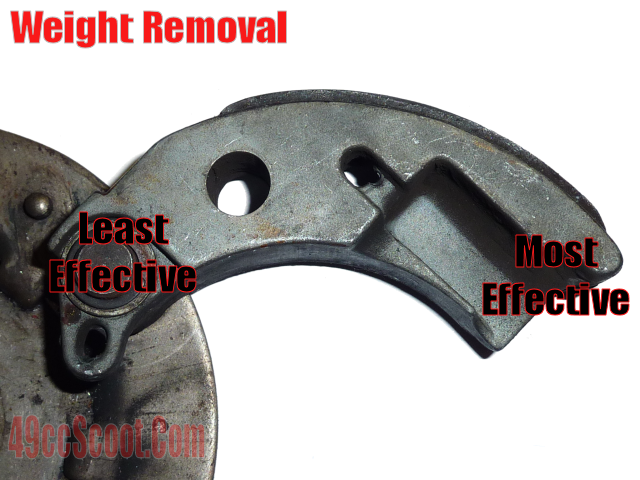

Next, remember to keep the shoes balanced. You can remove the shoes and weigh them to assure that they are all equal weights. You must also remove weight in the same area on each shoe. Removing weight farther from the pivot point of the clutch shoe has a much greater effect than removing weight close to the pivot point.

An easy way to understand the idea might be to try swinging a hammer holding it as you normally would, so the greatest amount of weight is farthest from your hand, the pivot point. Then hold the hammer by the other end and do the same thing. You should see that when the weight is farthest from your hand, the hammer feels much heavier. That's why both weight and location of material removed needs to remain as similar as possible for all of the clutch shoes.

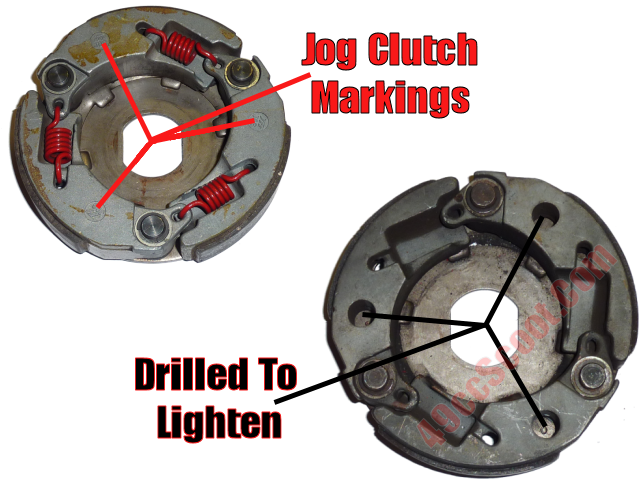

Minarelli clutch shoes have a round marking on the same spot on each. I use these as my drilling point to keep the weight removed in the same spots and because there is plenty of material left around this area. However you choose to do it, take your time and make everything as balanced as you can for the best results.

Stiffer clutch springs and or lightening the clutch shoes will get the results most of us are looking for, and both are very affordable options. If you've got a lot of power and the stock clutch just isn't cutting it, or if you just like shiny new parts, there are lots of aftermarket clutches and clutch bells on the market. They can achieve later engagement, and greater adjustability. Some are made a lot stronger by design and use of different materials. Some provide easy access to the clutch springs and adjustments to really speed up clutch tuning. Take a look around at your favorite performance parts retailer and see what's right for you and your budget.

Some engines use multiple clutch sizes, depending on specific make or model. Minarelli engines have a few different sizes, 105, 107, 110, and 112mm. You can usually change sizes, but the new clutch and bell must be the same size. If your scooter has multiple options, do your research before buying anything to be sure it fits.

That should wrap up the basics of the clutch system and it's modifications and upgrades.

Related Info

Lightening A Stock Clutch

49ccscoot.proboards.com/index.cgi?board=transtech&action=display&thread=359

Malossi Clutch Spring Coding

49ccscoot.proboards.com/index.cgi?board=transtech&action=display&thread=2283

Before getting into any modifications, I'd like to explain a little bit about the operation of the clutch. If you understand how something works, it's usually easier to understand how and why modifications and upgrades work or don't work.

Most of us already know what a clutch accomplishes, but simply put, it lets our scooters operate at idle or low RPM without driving the rear tire so we can start and stop without the engine stalling or the scooter trying to pull us forward at all times. It does this all automatically, without any rider input, helping to keep CVT equipped scooters easy to ride and truly twist and go.

The clutch system on most CVT scooters is made up of 2 major components, the clutch and the clutch bell. The clutch bell is pretty simple. It's a piece of metal, usually steel on stock scooters, that attaches to the primary drive shaft, which turns the gears in the final drive transmission, and ultimately the rear tire. The bell is formed to create a housing for the clutch.

The clutch typically has 3 shoes, each with a pad on it's outer edge, and a clutch spring. The pads are a friction material that will grip against the inner surface of the clutch bell, but they have to overcome the tension of the clutch springs to do so.

The clutch is positioned inside of the clutch bell, as shown below. The clutch is slightly smaller than the inside of the clutch bell.

As the rear pulley and clutch rotate, centrifugal force will try to push the clutch shoes outward. Centrifugal force increases with RPM. Eventually the force will be great enough to overcome the tension of the clutch springs trying to hold the shoes in place and cause the pads to contact the inner surface of the clutch bell. The pads will slip a little, until RPM is great enough that the clutch can fully engage.

Once engaged, the clutch allows the CVT to drive the final drive transmission, and ultimately the rear wheel. If RPM decreases, the clutch will lose grip and disengage.

Hopefully you understand basically what the clutch does and how it does it at this point, so we can start talking about modifications or upgrades. The most common upgrade is definitely aftermarket clutch springs. Aftermarket springs are stiffer, and they cause the clutch to engage later, at a higher RPM. The stiffer the spring, the higher the engagement RPM. They can be great for more aggressive acceleration from a stop, to get the engine into it's peak power faster. This is especially helpful when cylinder porting or expansion chamber exhausts cause a drop in low RPM power. Stiffer springs can allow you to bypass that dead area, and get right to the power.

You don't always want to install the stiffest clutch springs though. Like anything else, for best performance they need to be matched to the rest of your setup. If you use clutch springs that are too stiff, you can miss out on part of your powerband and end up with a scooter that has to rev very high just to move.

Clutch springs commonly come in 3 denominations. 1,000RPM, 1,500RPM and 2,000RPM. The numbers don't indicate the engagement RPM, but rather the estimated RPM increase. For example, if your scooter's clutch engages at 2,000RPM stock and then you add 2000RPM clutch springs, it should engage around 4,000RPM. Unfortunately, it seems that the actual stiffness of both stock and aftermarket springs from one manufacturer to the next can vary, so these are just rough estimates of the increase in engagement RPM.

Springs sold as a certain RPM gain are usually color coded. 1,000RPM srpings are blue, 1,500RPM are yellow, and 2,000RPM are red. The same color coding applies to some contra springs.

Not all springs are coded this way. Some manufacturers like Malossi and Polini use their own unique color coding to designate spring stiffness. Some label them like the Koso 2,000RPM spring shown below. All companies don't name them using RPM either. Some are just arranged by spring stiffness like this Stage 6 clutch spring set.

Another way to make your engine rev higher before the clutch engages is to lighten the clutch shoes. The lighter the clutch shoes are, the later they will engage. This can be helpful if you are on a tight budget or if you wish to fine tune your clutch engagement a little more than just swapping springs. I've lightened a few clutches just using a drill and different bits. You could find other ways to remove material as well.

There are a couple of things you must keep in mind. First, do not lighten the clutch to the point that it is not structurally sound and may come apart at speed. I tend to remove a small amount of material only from a section of each shoe that has plenty of material left around it. Remember, the clutch and rear pulley could be traveling at speeds much greater than even engine RPM. Lighten clutch shoes at your own risk, and err on the side of caution if you have any doubts about what is safe.

Next, remember to keep the shoes balanced. You can remove the shoes and weigh them to assure that they are all equal weights. You must also remove weight in the same area on each shoe. Removing weight farther from the pivot point of the clutch shoe has a much greater effect than removing weight close to the pivot point.

An easy way to understand the idea might be to try swinging a hammer holding it as you normally would, so the greatest amount of weight is farthest from your hand, the pivot point. Then hold the hammer by the other end and do the same thing. You should see that when the weight is farthest from your hand, the hammer feels much heavier. That's why both weight and location of material removed needs to remain as similar as possible for all of the clutch shoes.

Minarelli clutch shoes have a round marking on the same spot on each. I use these as my drilling point to keep the weight removed in the same spots and because there is plenty of material left around this area. However you choose to do it, take your time and make everything as balanced as you can for the best results.

Stiffer clutch springs and or lightening the clutch shoes will get the results most of us are looking for, and both are very affordable options. If you've got a lot of power and the stock clutch just isn't cutting it, or if you just like shiny new parts, there are lots of aftermarket clutches and clutch bells on the market. They can achieve later engagement, and greater adjustability. Some are made a lot stronger by design and use of different materials. Some provide easy access to the clutch springs and adjustments to really speed up clutch tuning. Take a look around at your favorite performance parts retailer and see what's right for you and your budget.

Some engines use multiple clutch sizes, depending on specific make or model. Minarelli engines have a few different sizes, 105, 107, 110, and 112mm. You can usually change sizes, but the new clutch and bell must be the same size. If your scooter has multiple options, do your research before buying anything to be sure it fits.

That should wrap up the basics of the clutch system and it's modifications and upgrades.

Related Info

Lightening A Stock Clutch

49ccscoot.proboards.com/index.cgi?board=transtech&action=display&thread=359

Malossi Clutch Spring Coding

49ccscoot.proboards.com/index.cgi?board=transtech&action=display&thread=2283