Post by 90GTVert on Feb 23, 2012 15:26:09 GMT -5

Stock Stator w/Lightened Flywheel vs NCY Racing Alternator

I picked this NCY racing alternator kit up from Parts For Scooters a couple of months ago when they were having a sale. Now I see they carry a Hoca version with what appears to be the same size flywheel, but more coils. These usually go for around $200. They could be a nice alternative to inner rotor ignition kits that usually offer no lighting or charging ability. I wanted to test a few things and see if these are really worth the money and if they can be used on a street scooter without a lot of sacrifice.

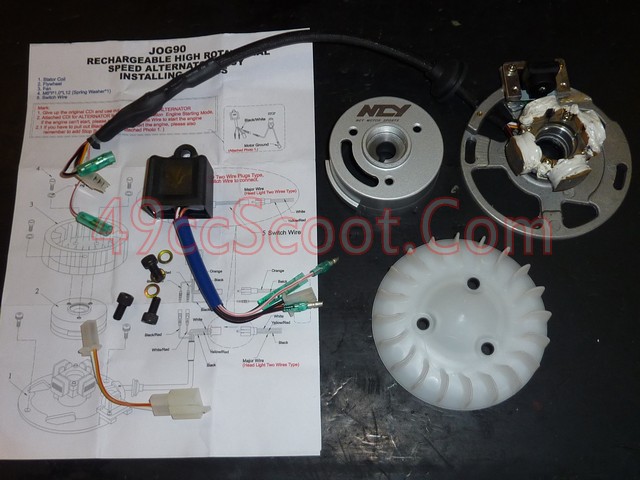

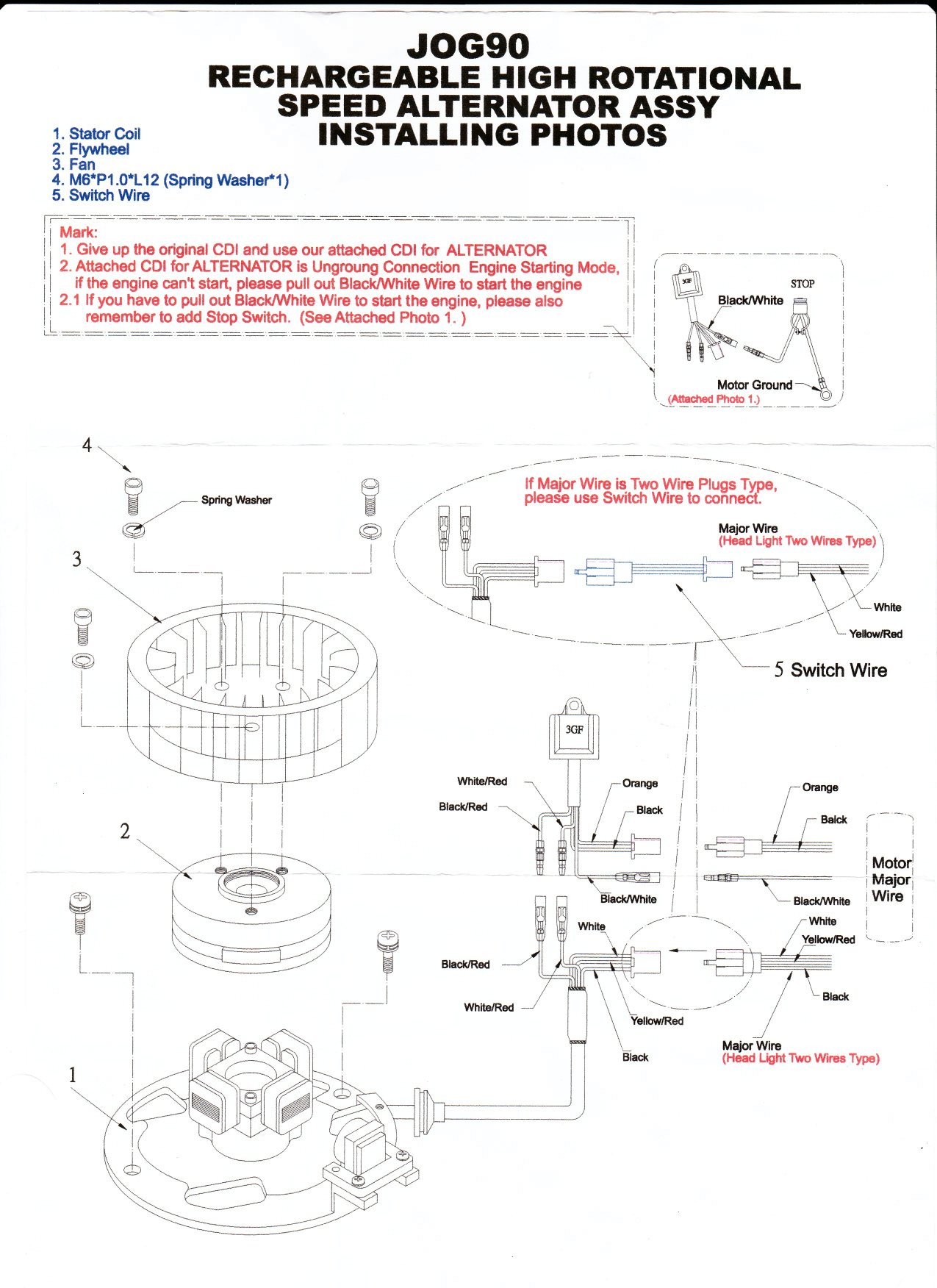

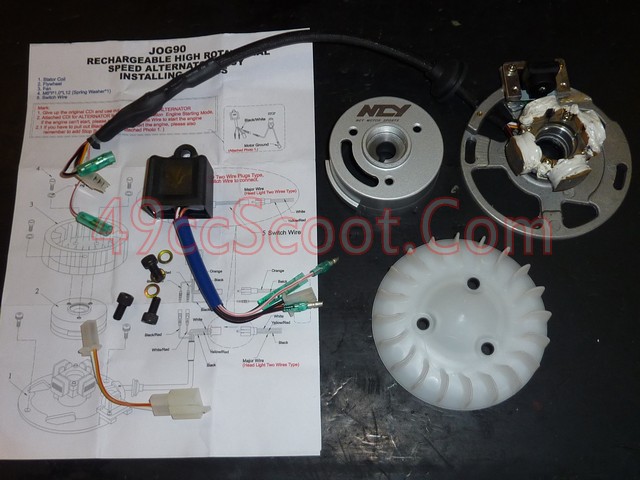

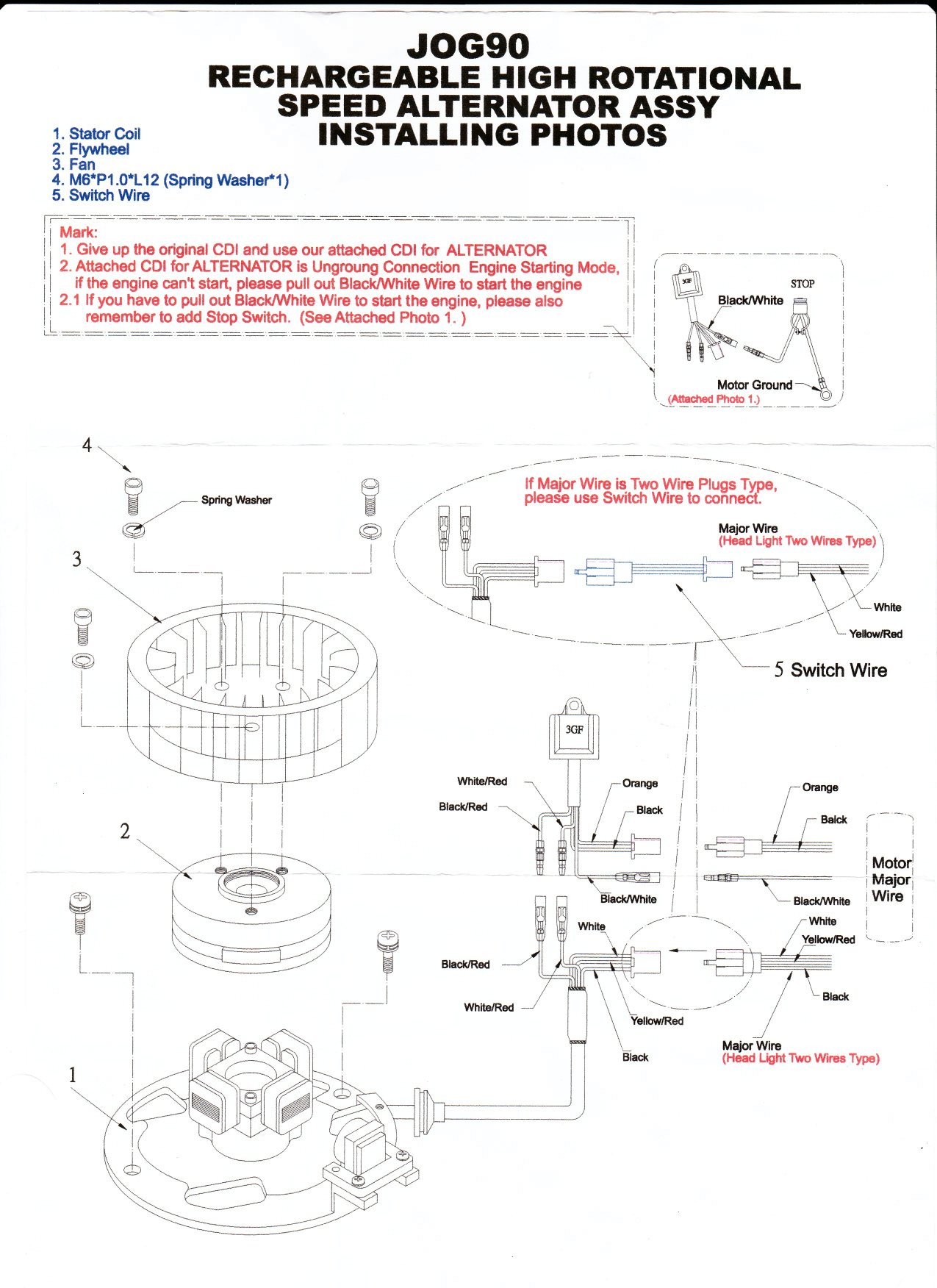

The kit inlcudes a 4 coil stator, smaller flywheel, CDI, stator wiring adapter for 2 and 3 wire harnesses, a standard cooling fan, bolts and washers to mount the fan, and instructions, or really more of a wiring diagram.

I picked this NCY racing alternator kit up from Parts For Scooters a couple of months ago when they were having a sale. Now I see they carry a Hoca version with what appears to be the same size flywheel, but more coils. These usually go for around $200. They could be a nice alternative to inner rotor ignition kits that usually offer no lighting or charging ability. I wanted to test a few things and see if these are really worth the money and if they can be used on a street scooter without a lot of sacrifice.

The kit inlcudes a 4 coil stator, smaller flywheel, CDI, stator wiring adapter for 2 and 3 wire harnesses, a standard cooling fan, bolts and washers to mount the fan, and instructions, or really more of a wiring diagram.

The stator.

Notice the slotted mounts that allow for base timing adjustment by rotating the stator.

Here are the stator's wiring connections, as well as the adapter provided.

A look at the CDI's part number and wiring.

I should note, they call the fan a turbo fan and I call it standard. It's a typical 49cc fan, but it is smaller than the fans a lot of 90cc engines have. It creates less drag on the engine, but it also provides less cooling. I was using a larger 90cc fan, but to make a fair comparison I swapped the smaller fan onto my stock flywheel for testing.

I forgot to take a pic of just the flywheel, but here is a comparison shot of the stock lightened flywheel and the NCY.

For anyone not familiar with it, the stock flywheel is lightened by removing material from it's edges in a lathe.

Here is the NCY 4 coil by the stock 7 coil. You can see how the flywheel can be so much smaller.

I weighed a stock flywheel, lightened flywheel, and the NCY flywheel in both grams and pounds so you can compare whatever is most familiar to you.

Flywheel | Pounds | Grams |

Stock | 1lb 8.6oz | 695g |

Stock Light | 1lb 7.5oz | 665g |

NCY | 14.4oz | 405g |

As you can see, there isn't a huge weight savings with the stock lightened flywheel. All of mine are done conservatively to ensure strength is retained. I have seen them done more aggressively and removing material from the face as well, so I know they can be made much lighter. There is a big difference in the NCY and stock though. Nearly 300g or over 5/8lb. The weight is not the whole story though.

The NCY also has an outside diameter smaller than the stock flywheel. Rotational mass increases dramatically as weight moves outward from the center of the flywheel. It increases by so much that even if the NCY flywheel weighed the same as the stock piece, it would still have much less rotational mass. If this isn't making sense, here's something to imagine or try. Take a small weight and put it on a string that's only a couple of inches long. Swing it around in a circular motion. Then take that same weight and put in on a string that's a couple of feet long and do the same thing. You should notice that it now takes more energy to start and stop the weight on the longer string. You can also try a lighter or heavier weight on the same lengths of string to see how that affects it.

If you did that little string and weight experiment, you should have a good understanding of what the lightweight and smaller diameter flywheel is aiming to achieve. Less mass means the engine can accelerate and slow it quicker. That equates to improved throttle response. Less resistance or hesitation when you apply or release the throttle. Less lag getting the revs up, so less time waiting for the power. That's what this upgrade is all about, so keep reading and we'll see if it really works.

Stock lightened on the engine.

NCY installed.

I installed the NCY stator in the center of it's mounting slots to begin with.

Before I removed the stock setup, I checked the base ignition timing, hoping to be able to set the NCY up the same way. The stock setup was showing 12° BTDC base timing. I marked TDC on the NCY flywheel as well and started checking it out. For some reason I had a hard time even getting my timing light to pick up the signal from the plug wire with the NCY setup installed. RPM readings cut in and out quickly and randomly. Trying to get a read on timing was difficult to say the least. With the stator plate mounted at the center of it's adjustment slot it appeared to be somewhere around 25° BTDC. It's really hard to tell with the light not working well and the timing mark appearing to jump all around. Idle speed was nearly 1,000RPM higher than stock, so I was pretty sure it was advanced a good bit beyond 12°.

I rotated the stator clockwise as far as it would go to retard timing. Rotating counter-clockwise would advance timing. I tried to check the timing again, but I'm not really sure where it was because of how bad the timing mark appeared to be jumping around. As inaccurate as this is, it was somewhere between 10° and 20° BTDC. Idle speed was right at 2,000RPM where it idled with the stock setup. This is where I left the stator set for tests.

I fired it up and went on a very brief test ride. I didn't even need the ride. By the time I was at the end of my driveway the difference was obvious. Before I go on anymore, I'll let you check out some before and after video that I took. Sorry there is a lot of vibration with the GoPro mounted as it was, but I think you'll get the idea.

Hopefully you could tell if from the video, but it made a big difference in throttle response. It's pretty much immediate. I was quite surprised at just how much better the response was with the new stator and flywheel. I expected a small change. Instead, the first time I hit the gas under load and heard and saw it immediately rev I said inside of my helmet, "holy $#!+".

The faster response makes initial acceleration feel a lot better. T1 usually does not feel light on the front tire with the CVT tuned as it is. Now it does. It's not lifting the tire, but it's obvious it's taking the weight off of the front and it would need only the slightest help for wheelies to happen.

Once it gets moving and revved out, it doesn't feel any better or worse to me. If you forget it's there all you have to do is let off and get back on it again to be reminded of the lightweight flywheel's presence.

So, I'm pleased with the performance, but how does it fare on the electrical side. Can it power lights and keep the battery charged? I took a bunch of different readings to try and figure this out. I suppose the easier way would be just to ride, but I haven't got around to more than a test ride at this point and I hope this data may be of some use.

To begin with, I did a simple test of each of the lighting and charging wires from the stator. The yellow/red wire provides AC power to the lighting circuit and the white wire supplies AC power to the rectifier that converts it to DC and regulates it's voltage to power 12VDC accessories and keep the scooter's battery charged.

This chart shows the AC voltage measured from the yellow/red lighting circuit supply wire coming from the stator. The stator was disconnected from the rest of the scooter, other than connections for ignition so it would run. As you can see, the NCY falls way short of the voltage the stock stator puts out.

Stock | NCY | |

RPM | VAC | VAC |

2,000 | 14 | 4 |

4,000 | 25 | 8 |

6,000 | 37 | 11 |

8,000 | 46 | 15 |

10,000 | 56 | 18 |

This chart shows the AC voltage measured from the white charging circuit supply wire coming from the stator. Again, the stator was disconnected from the rest of the scooter, other than connections for ignition to allow it to run. The NCY comes in well behind the stock stator on this test as well.

Stock | NCY | |

RPM | VAC | VAC |

2,000 | 16 | 6 |

4,000 | 30 | 12 |

6,000 | 44 | 17 |

8,000 | 55 | 22 |

10,000 | 67 | 29 |

This table shows the results of testing the yellow/red lighting output with it connected to the scooter, and the headlight switch on. It's powering a 60W headlight bulb, LED tail light, and an LED running light. I believe those lights consume about 65W, so you are probably seeing the numbers max out based on load. In hindsight, I should have tried to create more load on the lighting circuit by using the passing switch perhaps, so both filaments of the bulb would have tried to light. Even without the best data, you can tell the NCY is not keeping up with the stock setup here. The OEM stator is supplying all of the power my lights need by 4,000RPM, while the NCY needs to be ran hard at closer to 10,000RPM to get the most from the 60W headlight. Even without this info, just seeing the headlight at idle it is clear that the stock stator is putting out more power at low revs. The headlight is barely lit with the NCY, but glows pretty well with the stock stator.

Stock | NCY | |||||

RPM | VAC | Amperes | Watts | VAC | Amperes | Watts |

2,000 | 9 | 3.8 | 34.2 | 3 | 1.8 | 5.4 |

4,000 | 14 | 4.6 | 64.4 | 6 | 2.8 | 16.8 |

6,000 | 14 | 4.4 | 61.6 | 9 | 3.5 | 31.5 |

8,000 | 14 | 4.1 | 57.4 | 12 | 4 | 48 |

10,000 | 14 | 4 | 56 | 14 | 4.5 | 63 |

These following tables moves on to testing the white charging wire's output under load. I wasn't really sure what the best way to do this was, so I used two different methods. I don't think either is probably great, but I think they still tell a story. Sorry, I'm no electrical genius, just doing what I can to review this for you. I had an old 1,000CCA car battery around that's had charging and load issues for a long time. I thought it may be able to provide enough load to test out the charging system, so I used jumper cables to connect it to the scooter's battery. I did my best on all tests to keep the starting voltage the same on the batteries.

The first table displays the AC readings that I got while testing this way. I checked AC voltage and amperes out of the white wire, with it connected to the scooter's harness.

Stock | NCY | |||||

RPM | VAC | Amperes | Watts | VAC | Amperes | Watts |

2,000 | 16 | 1.6 | 25.6 | 6 | 0.2 | 1.2 |

4,000 | 14 | 6.3 | 88.2 | 11 | 1.4 | 15.4 |

6,000 | 13.5 | 7.5 | 101.25 | 15 | 2.5 | 37.5 |

8,000 | 13.5 | 8.2 | 110.7 | 20 | 3.2 | 64 |

10,000 | 13.5 | 8.4 | 113.4 | 18 | 4.7 | 84.6 |

This table shows the next way I tried to test the charging output, via DC voltage. I measured voltage at the car battery's terminals and measured amperes on the jumper cables connected from battery to battery.

Stock | NCY | |||||

RPM | VDC | Amperes | Watts | VDC | Amperes | Watts |

2,000 | 12.4 | 0.7 | 8.68 | 12.2 | 0.4 | 4.88 |

4,000 | 13.2 | 1.4 | 18.48 | 12.4 | 0.7 | 8.68 |

6,000 | 13.6 | 1.6 | 21.76 | 13.2 | 1 | 13.2 |

8,000 | 13.8 | 1.6 | 22.08 | 13.9 | 1.4 | 19.46 |

10,000 | 14 | 1.7 | 23.8 | 14.5 | 1.5 | 21.75 |

As I said, the above probably aren't the best tests that could have been done. Some of the data looks a little strange to me. With that said, the stock stator still outperforms the NCY 4 coil on both lighting and charging power for the average street scooter's needs. The NCY seems to be able to keep up with demands at high RPM. It may even outdo the stocker on a very high revving machine. For the average street scooter though, it appears you'll get a lot more electricity out of the stock unit.

I still think the NCY will provide enough for most street riding fun lovers though. A lot of scooters only use 35 watt headlights stock. Even the NCY can get them coming on bright at low speed cruising kind of RPM. If you need bright headlights, plan to rev higher. That may not be an issue though if you're considering a racing alternator. You've probably already got quite a few mods.

While it probably won't be running your stereo, GPS, charging your phone, and charging the battery all at once, it looks like the NCY is capable of keeping the battery charged for the average user as long as you're willing to keep the revs up a bit. By the time you get a racing alternator, you may already have ditched the battery anyway. It'll power your brake lights and turn signals and the typical scooter horn, so it would probably work out fine for that.

To make a long story short, the NCY offers a nice improvement in throttle response and acceleration, at the cost of some electrical power. If you want to run a lot of accessories and bright lights, consider keeping the stock flywheel and maybe having it lightened or look into other aftermarket setups with more coils. If you don't run a lot of accessories and are willing to keep your headlight wattage to reasonable levels, you might just enjoy this kit.

[/center]