Malossi Large Spline Over Range Info

Feb 24, 2012 23:48:40 GMT -5

Corrosion, Clank, and 1 more like this

Post by 90GTVert on Feb 24, 2012 23:48:40 GMT -5

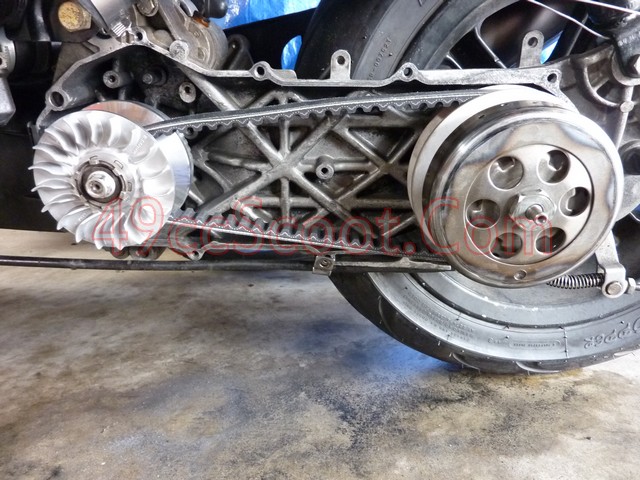

Time for the next mod! A Malossi OverRange CVT. This one is sold by G-Force Powersports. It seems there are no good kits out there for large spline cranks, so G-Force put one together.

All of the goodies I ordered from G-Force Powersports. This is more than what's included in the overrange kit. Extra belts, different torque springs, and more roller weights.

The overrange kit that I ordered, the "OEM large taper"kit on their site, includes :

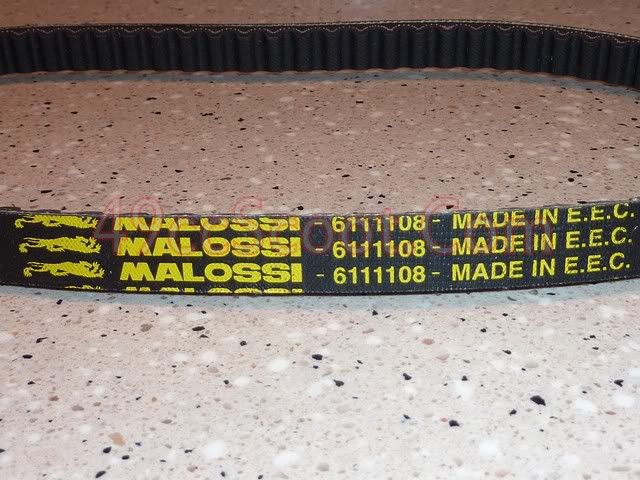

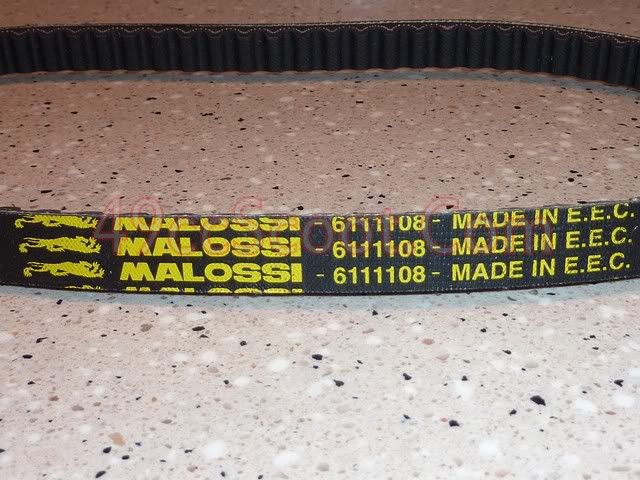

Malossi 6111108 Kevlar Belt (816 17.5 30). They do offer other belts to suit most applications, this is the proper belt for my scoot that normally uses a 788 17 28 drive belt.

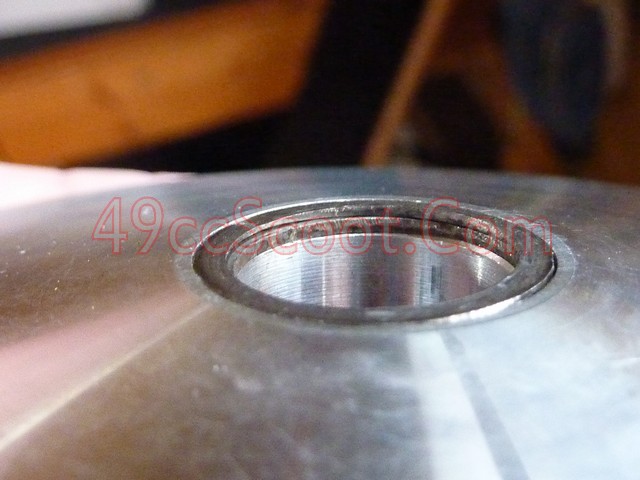

Malossi 61 7151 finned variator pulley. This is the fixed half of the variator, and the star washer that goes along with it for large spline cranks.

Mallosi OverRange variator. The only number I see on this is 12801, stamped inside of it. I believe this is Malossi part number 6112801B, but I'm not 100% sure of that.

Malossi 2512807B variator ramp plate with bushings.

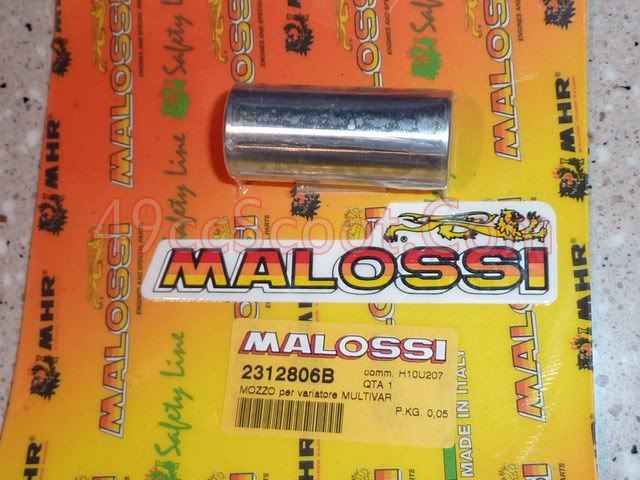

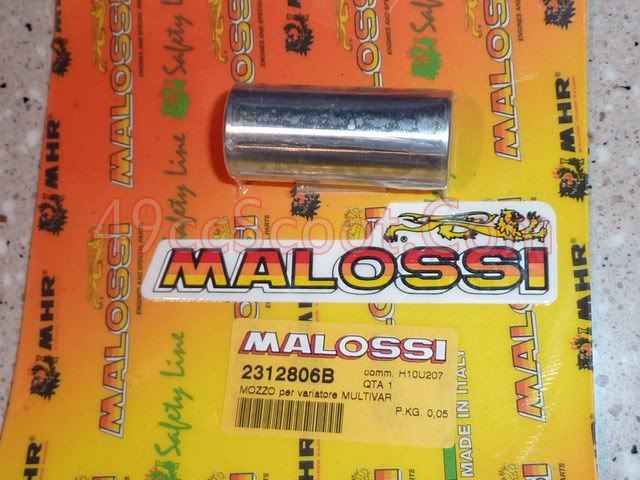

Malossi 2312806B Multivar drive boss.

Malossi 0812805B Multivar rear bushing.

4 spacers for the drive boss.

Malossi 19x15.5mm 3.8g and 3.5g roller weights.

Malossi 6111121 OverRange rear pulley system.

Malossi 7611882B grease. Malossi recommends this to lubricate the torque driver and a very thin coating on each roller weight.

2000RPM torque spring. G-Force Powersports may let you choose a different spring rate if you speak with them.

*I think this is the correct number, but I am not completely sure. It seems to match up with the number stamped inside the variator (12801B). I suggest speaking with someone who knows for sure before ordering this part.

All of the goodies I ordered from G-Force Powersports. This is more than what's included in the overrange kit. Extra belts, different torque springs, and more roller weights.

The overrange kit that I ordered, the "OEM large taper"kit on their site, includes :

Malossi 6111108 Kevlar Belt (816 17.5 30). They do offer other belts to suit most applications, this is the proper belt for my scoot that normally uses a 788 17 28 drive belt.

Malossi 61 7151 finned variator pulley. This is the fixed half of the variator, and the star washer that goes along with it for large spline cranks.

Mallosi OverRange variator. The only number I see on this is 12801, stamped inside of it. I believe this is Malossi part number 6112801B, but I'm not 100% sure of that.

Malossi 2512807B variator ramp plate with bushings.

Malossi 2312806B Multivar drive boss.

Malossi 0812805B Multivar rear bushing.

4 spacers for the drive boss.

Malossi 19x15.5mm 3.8g and 3.5g roller weights.

Malossi 6111121 OverRange rear pulley system.

Malossi 7611882B grease. Malossi recommends this to lubricate the torque driver and a very thin coating on each roller weight.

2000RPM torque spring. G-Force Powersports may let you choose a different spring rate if you speak with them.

Part Description | Part Number |

Kevlar Belt (816 17.5 30) | 6111108 |

Multivar Variator* | 6112801B |

Multivar Ramp Plate | 2512807B |

Finned Variator Pulley | 61 7151 |

Drive Boss | 2312806B |

Rear Bushing | 0812805B |

OverRange Rear Pulley | 6111121 |

MRG Grease | 7611882B |

*I think this is the correct number, but I am not completely sure. It seems to match up with the number stamped inside the variator (12801B). I suggest speaking with someone who knows for sure before ordering this part.

! In fact i think the mina engine is the only one ive seen with splines in the drive ramp now that i think about it more (again). It didnt make sense to me when i first discovered this in GY6,s and most if not all other 2T vari set-ups ive worked with. My Cobra (aka Work Truck) has no splines on that style either...I pondered that one for awhile when i worked on my uncles Cobra a couple years ago and saw how it was. I suppose it works with more centrifugal force and friction?? It works thats all i know

! In fact i think the mina engine is the only one ive seen with splines in the drive ramp now that i think about it more (again). It didnt make sense to me when i first discovered this in GY6,s and most if not all other 2T vari set-ups ive worked with. My Cobra (aka Work Truck) has no splines on that style either...I pondered that one for awhile when i worked on my uncles Cobra a couple years ago and saw how it was. I suppose it works with more centrifugal force and friction?? It works thats all i know

. No playing around with shims and files! Just put it in, tune the spring and weights and let-er-rip

. No playing around with shims and files! Just put it in, tune the spring and weights and let-er-rip  .

.