Post by 90GTVert on Feb 14, 2010 17:41:54 GMT -5

CVT Cooling

CVT transmissions create a lot of heat, yet many stock CVT covers offer little to no ventilation to allow this heat to escape. High temperatures can cause premature belt wear or failure, belt slippage, roller weight glazing or sticking, clutch slippage, early clutch engagement, and more. Luckily venting the CVT cover is a pretty simple task. Ther is lots of room for creativity here. I encourage you to use the images and explanations here for ideas, but do something to make your scooter unique. You may notice that clutch ventilation seems the most extreme. That is because the clutch is a major source of heat in your CVT. Venting near the clutch makes the most difference from my experience. Please be careful to take your specific CVT setup into consideration before settling on a method of ventilation. Some CVT covers have bearings in them to support the rear pulley that needs to remain intact. If you wish to use a kick start, leave plenty of material around it to support the stress of kick starting. If you plan to ride in wet weather or through standing water you may wish to choose a style of venting that would let little water in or make an air inlet to draw "dry" air into the CVT. Getting the belt wet could cause belt slip and poor performance.

Here's a really easy method of CVT ventilation. I just drilled a lot of holes to keep the basic structure of my CVT cover, while leaving it open to airflow. This method does a decent job of cooling the transmission, but it doesn't look very nice in my opinion.

I did some mild clutch venting on this CVT cover. Even though there isn't a lot of open surface area, it seems to get the job done. Before adding these vents I couldn't hold my hand on the CVT cover after a ride because it was so hot. I can usually touch the clutch bell itself now. I marked a pattern on the CVT cover and then drilled holes to fill up as much of the pattern as possible. Ofter drilling all of the holes I used a file to fisnish shaping the vents. A Dremel or other small grinder could work well for shaping, but be careful with power grinders. Aluminum shapes quickly so it's easy to overdo it if you aren't careful.

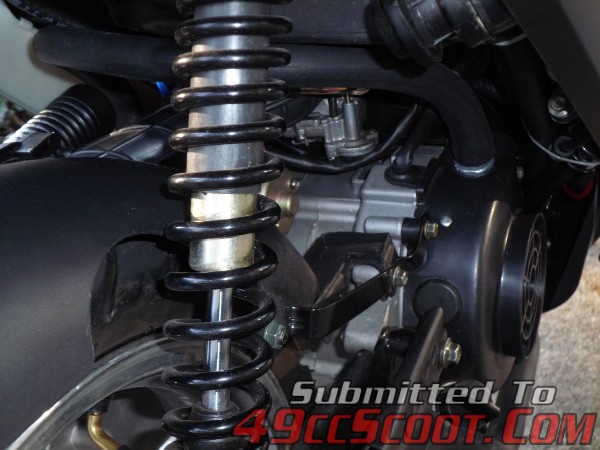

Here is a stealthy way to increase CVT cooling. Drilling large holes in spots that cannot easily be seen. I didn't notice much improvement using only these holes, but at least it appears stock.

Some people use hole saws to completely remove the metal in front of their clutch. Make sure your scooter doesn't use a bearing to stablilze the rear pulley and primary drive gear before cutting out that much material. Others have sawed the entire rear off of their CVT covers to retain the kick starter but keep the transmission very open to fresh air.

CVT transmissions create a lot of heat, yet many stock CVT covers offer little to no ventilation to allow this heat to escape. High temperatures can cause premature belt wear or failure, belt slippage, roller weight glazing or sticking, clutch slippage, early clutch engagement, and more. Luckily venting the CVT cover is a pretty simple task. Ther is lots of room for creativity here. I encourage you to use the images and explanations here for ideas, but do something to make your scooter unique. You may notice that clutch ventilation seems the most extreme. That is because the clutch is a major source of heat in your CVT. Venting near the clutch makes the most difference from my experience. Please be careful to take your specific CVT setup into consideration before settling on a method of ventilation. Some CVT covers have bearings in them to support the rear pulley that needs to remain intact. If you wish to use a kick start, leave plenty of material around it to support the stress of kick starting. If you plan to ride in wet weather or through standing water you may wish to choose a style of venting that would let little water in or make an air inlet to draw "dry" air into the CVT. Getting the belt wet could cause belt slip and poor performance.

Here's a really easy method of CVT ventilation. I just drilled a lot of holes to keep the basic structure of my CVT cover, while leaving it open to airflow. This method does a decent job of cooling the transmission, but it doesn't look very nice in my opinion.

I did some mild clutch venting on this CVT cover. Even though there isn't a lot of open surface area, it seems to get the job done. Before adding these vents I couldn't hold my hand on the CVT cover after a ride because it was so hot. I can usually touch the clutch bell itself now. I marked a pattern on the CVT cover and then drilled holes to fill up as much of the pattern as possible. Ofter drilling all of the holes I used a file to fisnish shaping the vents. A Dremel or other small grinder could work well for shaping, but be careful with power grinders. Aluminum shapes quickly so it's easy to overdo it if you aren't careful.

Here is a stealthy way to increase CVT cooling. Drilling large holes in spots that cannot easily be seen. I didn't notice much improvement using only these holes, but at least it appears stock.

Some people use hole saws to completely remove the metal in front of their clutch. Make sure your scooter doesn't use a bearing to stablilze the rear pulley and primary drive gear before cutting out that much material. Others have sawed the entire rear off of their CVT covers to retain the kick starter but keep the transmission very open to fresh air.