Post by 90GTVert on Jun 16, 2012 11:16:57 GMT -5

"Project 49" is a 49cc two-stroke scooter performance project, based on the Minarelli / Jog / 1E40QMB engine. It is the most common 2T that I have seen in Chinese scooters. My intention with Project 49 is to show performance of the engine from stock and beyond and to provide useful information to help the reader achieve their performance goals. I have already done a "Project 90", similar to this Project, but starting out with the 90cc version of the Minarelli horizontal two-stroke. You can see that HERE.

I picked up a 49cc long case motor from a Vento Triton, missing a few bits and pieces some time ago. The major missing parts were the cylinder and piston.

I pulled the 49cc engine off the shelf this afternoon to start tearing it down a bit to be cleaned up. Here's some stuff that won't be going back on. I will pre-mix my fuel 50:1 with AMSOil Sabre Professional 100:1 2T oil. I only use 50:1 because it is an oil intended for lean mix ratios. Even with synthetics, you generally don't want to go beyond 40:1 if you pre-mix.

I checked the crank and bearings and such over to be sure the bottom end was sound and that all looks good. One thing I noticed while looking the engine over was the poorly aligned and matched transfer and boost port areas. You can see in the pic below that the gasket/cylinder wasn't matching the case well at all (notice the brownish areas).

I dug out a stock 49cc gasket that I got from Vento years ago and used it to verify that this case is mismatched with a typical 49cc cylinder.

I suppose for a true stock test I should leave the case alone. However, looking at this just annoyed me and I'm sure some scoots come with cases machined properly. None of mine have, but there have to be some out there. lol I used a carbide burr and files to match the cases to the gasket.

Once that was finished, I cleaned up the cases and CVT cover.

Next, I started trying to figure out what I wanted to do for the top end. I bought this stock replacement cylinder kit from Scrappy Dog Scooters shortly after I bought the engine, with the intention of it being used for Project 49.

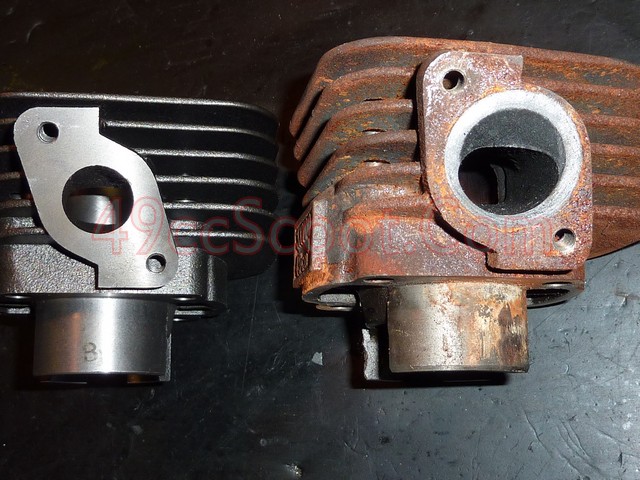

I noticed the boost port seemed really small on the cylinder though. After some searching, I found the cylinder that came stock on my Keeway Venus and compared the two. As you can see, the stock Keeway cylinder has a much larger boost port. It matches up to a 49cc gasket and case well.

I started looking over the two cylinders a bit more and found other variances. In the photo below you can see the Scrappy cylinder has a very small circular exhaust port and a small flange. The stock cylinder has a half circle port, but it appears to be similar in size to the small full circle. The stock cylinder has a larger flange. You may also notice the stock cylinder is a little taller.

Inside the cylinders, the Scrappy kit has smaller ports than the stocker. You should be able to tell by their conditions, but the top is stock and the second pic is the Scrappy cylinder.

After looking at both cylinders, I decided to make a top end out of new and leftover parts. I'll be using the Keeway stock 49cc cylinder, the Scrappy Dog piston kit, a stock head, and of course stock gaskets.

I cleaned the stock head and then drilled and tapped it to accept a cylinder head temperature gauge sending unit. I'll be using a CHT to help speed tuning and to look for any major swings in temp when modding.

The stock cylinder had very low mileage so it's main problem was rust from sitting around so long.

I cleaned, painted, and honed the cylinder and it was ready for use.

I installed the cylinder using 1 stock base gasket.

Even though the deck is pretty good, looking at the head and gasket it's obvious this engine's gonna have a lot of room between the piston crown and head.

Sure enough, a check showed a minimum clearance of 1.85mm.

I installed the stock reeds and intake and then proceeded to do a pressure test. The intake/reeds are leaking at the gaskets. I'm not sure why I ever bother to try just gaskets for the reeds? Every time it leaks unless I use RTV.

I sealed up the intake and reeds and did another pressure test. Still leaking. This time it was the stator side crank seal.

I replaced the seal and then everything seemed fine.

Then I moved on to cleaning all of the CVT and starter clutch components.

Even the "restrictor" was included with this motor. From the looks of the variator, it was working.

On closer inspection, I'm not sure if this will prove to be really restrictive or not. The worst restrictors are larger than the diameter of the drive boss, so they'll prevent the variator from closing all the way. This one is the same diameter, so it's more of a spacer. It could limit speed by making it harder for the halves to close, but it shouldn't be as severe as the ones that absolutely will not let the variator halves close.

The stock 4 gram rollers were mildly flat spotted, so I replaced them with another set of stock 4g rollers I had around.

There's a slightly worn area in the torque driver that indicates either slow cruising speeds or the inability to max out the CVT. Either or matches up to the poor markings on the variator.

I'm starting out with the "restrictor" in place so we can see what difference it really makes in or out of the transmission.

Below are looks at the rear pulley (easier to see the difference there than in the front) with and without the spacer/restrictor. The top pic shows without the spacer. The lower pic shows with it. Even if it does limit top speed, the initial "gearing" should be better with the restrictor/spacer in place. That means it should have a stronger launch.

All together.

I did a bit of simple CVT cooling mods to the cover before installing it. Just a series of holes to let some heat out around the clutch mostly. The clutch seems to be the single largest heat source in the CVT. Once again I'm deviating from stock I suppose, but this is a mod that I feel every scooter should have. It won't affect performance when the scooter is first started and ran, but it helps to eliminate the decline in performance as the CVT heats up and springs stop working like they should as well as keeping the belt cooler to perhaps increase it's life.

With the CVT and kick start stuff installed, I could finally do a compression test. Turns out the electric starter and a good battery cranked the 49cc to max compression without needing to kick it. I suggest that you always kick the engine over to look for an increase vs the electric starter though. I got way more compression than I expected after seeing the wide squish clearance. Just over 180psi. On the 90cc builds I've been more accustomed to, 175-180 is about where I need to stop if I want to run on pump gas. I'm thinking that won't apply here and the cranking compression max target may be higher for a 49cc. Time will tell.

I pulled the 103cc out of T2 and got the center stand, brake shoes, rear wheel, and fan shroud off of it to use on Project 49. The fan shroud is the one from this 49cc, I just had to use it on the other engine for a bit.

While I was transferring stuff, I remembered that I had not checked the durations of the cylinder setup like stock. I stripped some parts back off of it and got out the degree wheel to see what we've got.

Exhaust Duration : 171°

Transfer Duration : 125°

Very mild. Suitable for peak somewhere between 7,000-8,500RPM I'd guess.

After hooking up the bare necessities, I fired the engine up long enough to get some heat in it so I could re-torque the cylinder nuts. The vid below is actually the second start. First start required two hands. Since there's no airbox and no enricher hooked up yet, I had to manually choke it. I didn't have a stock airbox at that point. You will notice there are no shrouds. NEVER run your engine without the shrouds. I only do this on the first start and let it run long enough to warm up. If you ride like this it will overheat quickly. If you run it on the stand long it will overheat. Use your shrouds!

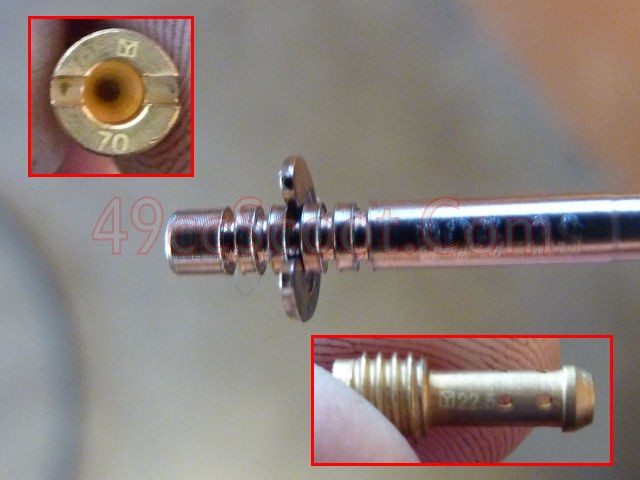

The carb being used is a "Leader", pretty common on Chinese Minarellis.

I'm using the cap from another stock carb that had already been modified to work with my aftermarket throttle.

I checked the jetting, but the only change I made was to the idle speed. The main jet is a 70. The pilot is a 22.5. The needle clip is set in the center position.

The enricher will be powered by an on/off switch attached to the battery instead of being wired into the scooter's charging system. This scooter's wiring harness (custom made) has no provision for the enricher.

I'll be using a completely stock airbox and filter.

When everything was together and all the loose ends were tied up, I went for a ride. No tuning or checking anything. I wanted to ride just as if the scooter was fresh out of a crate. It ended up, appropriately, being a 49 mile ride.

Acceleration is certainly sluggish. I didn't mind it terribly though, aside from the times I forgot how slow I was and pulled out in front of cars. I did put a foot down for a push start leaving one light in hopes of keeping with traffic. The initial launch is quite slow with the stock clutch engaging around 2,900RPM. The engine doesn't seem to start picking up a lot of steam until closer to 6,500RPM, so it has to work it's way through a few thousand RPM to really get moving.

Once RPM got to 6,500 it pulled pretty well for a stock motor, up to a max of 7,600RPM. Wide open throttle cruising, sitting up, kept speeds most often in the 37-40MPH range at 6,900-7,200RPM. Max cruising speed was 44MPH, but I was sitting up, going down a decline, and had a tailwind for that. My max speed tucked was only 43MPH. It seems I generated more power by sitting up and acting as a sail than I did by tucking down and trying to let 49cc horsepower work.

I got 59.29MPG. The problem is I ride wide open most of the time. I have to in order to keep up with traffic in town or to cruise 40MPH on open roads. The CHT gauge was showing 340° or so peak at WOT.

Here's a video of the 0-35MPH acceleration in stock form. Just shy of 18 seconds. I need to note here that you will see some inconsistencies in early 0-35MPH runs in this project. I started out using a couple of different locations that seemed to be flat, but times varied between them slightly. I also found some issues with the transmission's torque driver later that changed things a bit.

Project 49 : Baseline Specifications

Bore : 40mm

Stroke : 39.2mm

Displacement : 49.26cc

Cylinder : Stock

Exhaust Duration : 171°

Boost/Transfer Duration : 125°

Cranking Compression : 182psi

Squish Clearance : 1.85mm

Cases : Stock

Carburetor : Stock "Leader" 16-16.5mm

Main Jet : 70

Pilot Jet : 22.5

Needle : Stock. Clip set in center position.

Air Filter : Stock Airbox

Fuel System : Stock tank, 1/4" hose, 1/4" fuel filter, manual petcock.

Oil Delivery : Pre-mix. I removed the stock oil injection system in favor of pre-mix in order to provide consistent oiling with any modification. I am using AMSOil Sabre Professional 100:1 Premix, mixed at 50:1.

Intake : Stock

Reed Block & Reeds : Stock

Exhaust : Stock

Ignition System : Stock CDI, stock stator/flywheel, Bando coil, NGK BR8HS spark plug.

CVT Belt : 788 17 28 Bando

Variator : Stock

Roller Weights : 4g

Clutch & Bell : Stock

Contra Spring : Stock

Clutch Springs : Stock

Final Drive Ratio : Approximately 10.125:1

Max Speed : 43MPH

Cruise Speed : 37-40MPH

Fuel Economy : 59.29MPG

Other Info For Reference

Elevation : ~40ft Above Sea Level

Rider Weight : 300lbs

Fuel : 91-93 Octane (Premium)

The engine is in the scooter I call T2. It's a 2004 Vento Triton that I have stripped down and modified. It allows for easier access to do the work necessary for a project like this.