|

|

Post by 2strokd on Feb 21, 2010 12:14:15 GMT -5

I bought a couple sheets of carbon fiber reed material. One is .30mm and the other is .35mm. Anybody ever cut their own reeds? Just looking for any tips or tricks as i have never cut them before... Thanks  |

|

|

|

Post by 90GTVert on Feb 21, 2010 12:25:45 GMT -5

From THIS page... "Yes the carbon sheet can be cut with sharp scissors and the edges sanded with some 600 grit wet & dry sand paper . With drilling the holes I just put an old set of tin reeds over the top and use a pointed grinding stone on the dremel to drill the holes using the tin ones as a guide." |

|

|

|

Post by drawkward on Feb 21, 2010 15:50:57 GMT -5

Hey 2strokd, if you have any material left over I'd be willing to buy it off of you.

Let me know how well it works, very interesting. Is it cheaper than buying the premade CF reeds?

|

|

|

|

Post by 2strokd on Feb 22, 2010 10:42:09 GMT -5

|

|

|

|

Post by 2strokd on Feb 23, 2010 13:41:26 GMT -5

Cut some for my Uncles Kymco this morning. Its time consuming but worth it in savings. I ended up cutting the first petal with a hobby knife (exacto?, whatever ya wanna call it)and the second with some good scissors. They both turned out the same after sanding them with 1000grit for awhile. But the scissors are loads faster to cut with, just make sure they are good and sharp    I cut the screw holes with a small grinding stone and it worked well, they line up great. Do you guys think i should cut a slot in the center like the stock reeds are? These are for the stock cage.....And they are a bit stiff w/out it  |

|

|

|

Post by 90GTVert on Feb 23, 2010 14:58:45 GMT -5

Looks good, nice work. What about cutting the stock reed cage's separator to get more flow? Just an idea. Might be a bad one?

|

|

|

|

Post by drawkward on Feb 23, 2010 15:01:22 GMT -5

Oh I figured you would have gone the full nine and cut them exactly to size and shape.

Is that not necessary?

|

|

|

|

Post by 90GTVert on Feb 23, 2010 15:04:57 GMT -5

Shouldn't be necessary to cut them exactly as stock. As long as they cover the ports in the reed block and you don't cut 'em so big that there are clearance issues. Cutting them different ways, as 2strokd was saying, can affect how stiff they are. A little extra stiffness may not be a bad thing.

|

|

|

|

Post by drawkward on Feb 23, 2010 15:09:03 GMT -5

|

|

|

|

Post by 2strokd on Feb 23, 2010 15:14:19 GMT -5

Yep. The stiffer or thicker they are the less likely they are to flutter at higher

RPM,s. Kinda like a valve "floats" in a fourstroke...

|

|

|

|

Post by 2strokd on Feb 23, 2010 15:15:03 GMT -5

Looks good, nice work. What about cutting the stock reed cage's separator to get more flow? Just an idea. Might be a bad one? Good idea! I will have to look into that  |

|

Greg

Scoot Enthusiast

Posts: 218

|

Post by Greg on Feb 23, 2010 18:01:57 GMT -5

That is awesome.

I can't wait to hear how they work.

Do you have enough material to try them split and not split?

|

|

|

|

Post by 2strokd on Feb 25, 2010 9:06:54 GMT -5

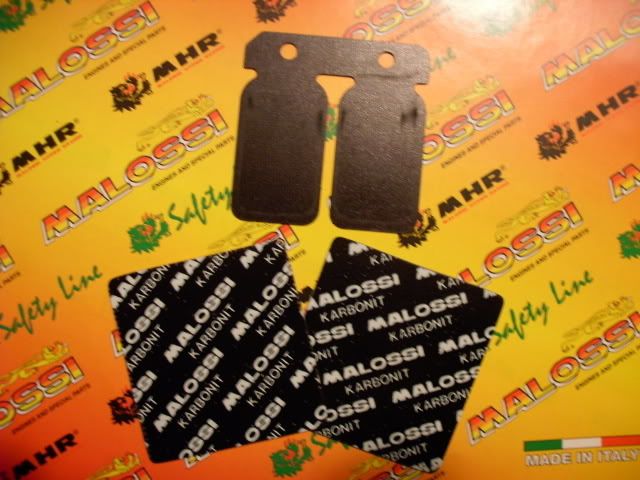

Yea i do, good idea  . Heres a pic of the finished product. Not perfect, but they make a good seal.  |

|

|

|

Post by 90GTVert on Feb 25, 2010 9:16:20 GMT -5

Looks like you bought 'em pre-cut. Very nice.

|

|

|

|

Post by drawkward on Feb 25, 2010 14:02:19 GMT -5

Wow - that looks really good. Nice work.

|

|