|

|

Post by 90GTVert on Apr 1, 2010 13:15:50 GMT -5

I read that it should be 27mm x 1.0 LH thread, but I have that puller and it doesn't work. I ordered a multi-puller along with the stator the scoot needs so hopefully it will cover it, but does anyone know what the GY6 150s could be other than 27mmx1.0 LH? It's real close to 27mmx1.0, maybe RH? Just trying to be sure because this is for a customer and if I don't have the right puller ordered, I need to get one here. Thanks.

|

|

|

|

Post by Fox on Apr 1, 2010 14:38:57 GMT -5

I used that cross type puller I got off eBay just yesterday to pull off a 157QMJ 150cc flywheel and it worked fine using the 27X1 Left hand thread.

|

|

|

|

Post by shiftless on Apr 1, 2010 15:02:49 GMT -5

|

|

|

|

Post by Fox on Apr 1, 2010 15:56:08 GMT -5

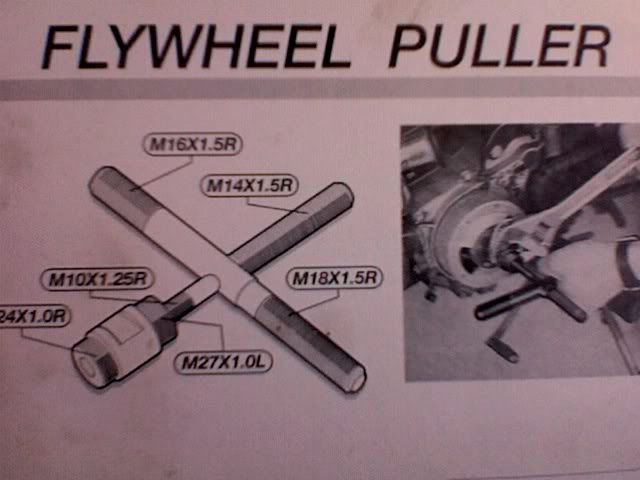

I have the same type puller and I went ahead and removed the flywheel from the QMJ again and it screws in to the left. It's 27X1 Left hand threaded.Maybe they have both left and right flywheels?  This first pic is the back of the flywheel puller package:  This is the puller in the flywheel after screwing in to the left.  |

|

|

|

Post by 90GTVert on Apr 1, 2010 16:32:38 GMT -5

Thanks. The PFS puller is the one I ordered with the stator. I had the LH already (works on minarellis). I hope something works. I really don't wanna have to call someone and say sorry, I can't even get your flywheel off.  |

|

|

|

Post by shiftless on Apr 1, 2010 18:17:31 GMT -5

I have the same type puller and I went ahead and removed the flywheel from the QMJ again and it screws in to the left. It's 27X1 Left hand threaded.Maybe they have both left and right flywheels?  JM is correct, I just checked on one of my engines, and the threads are LEFT handed The pfs puller you ordered is the right one though My bad  |

|

|

|

Post by Goosey on Apr 1, 2010 18:20:59 GMT -5

This is a steering wheel puller. $10, Autozone. Buy 2 6mm thread bolts seperate. The flywheel has two 6mm threaded holes on the front. You screw in the 2 bolts into those. You then tighten the center bolt to pull the flywheel. Works like a charm. |

|

|

|

Post by 90GTVert on Apr 1, 2010 19:42:30 GMT -5

Nice tip. I've already got a steering wheel puller too. I've got 3 jaw pullers and all that stuff. Hopefully I'll get it off of there somehow. Kinda odd though that everyone states 27x1.0 LH and my puller doesn't work. I'm just lucky I guess.

|

|

|

|

Post by 90GTVert on Apr 6, 2010 16:02:45 GMT -5

I got the Pit Posse puller in with the 2 stators that could be under the flywheel. The Pit Posse puller is 27mmx1.0 LH just like my other puller. I was really hoping it was RH or 28mm or something stupid, but it's not. The threads were screwed up from the factory. I've got a 1.0 pitch thread file, but theres really no way to get it into the flywheel the way it's setup. I tried the 2 jaw puller that would fit the flywheel well and the hooks on it aren't long enough to get a good grip. I tried my steering wheel puller with 6mm bolts and it is stuck on there so well that it stripped the 6mm bolts (luckily the bolts not the flywheel) and still didn't budge. I bought 2 more pullers at Advanced today. A 2 jaw puller with a little longer hooks and a kinda flimsy 2 jaw puller with real long hooks that grip well. The flimsy one can't take the force required and bends. It's not that flimsy really, but I think this flywheel is seized onto the crank much tighter than it should be. It's not even 100% on the crank, like it was manufactured too tight in tolerance and never could be pressed on right. If it was much farther off it wouldn't even be positioned to work with the pickup coil. The other puller gets tight to the point that I can't turn it by hand anymore. I'm not a tiny dude, and it ain't just me being wimpy. I could hit it with an impact, but the last thing I need is to damage the crank. I thought about trying to heat the flywheel, but if it doesn't come off I'm risking damaging a stator that does let the bike run and does run the lights still so it can be driven with a charged battery for him to take it home and to a different shop to become their headache. It puts out about 13.3V peak, enough to keep the battery from dying quick but it's not gonna charge it. I even called in my father, a carreer auto mechanic for 45 years of his life. He agreed that it was to a point where with any tools we have it is more of a risk than it's worth at this point and time to cut my losses. After buying 2 stators (not sure if it's 6 or 8 pole behind the flywheel), 4 hours of labor to diagnose and mostly fiddling with it because I was sure it should come off but trying to be very careful not to damage anything, and $70 worth of pullers I called the customer this afternoon and told him his flywheel was damaged by a previous mechanic or most likely from the factory. He said no one ever worked on it, it's only got 1,000 miles and been trouble free. I told him the deal and said I'm just not willing to take the risk of ruining something and owing you a crankshaft or something like that and apologized. I told him just to come get it and I won't even charge him a penny. He said he'd pick it up tomorrow and nothing more. I think he's a bit upset. Kinda sucks because if you aren't a mechanic or don't have a good understanding of how things work, you'll never understand it and probably just assume the guy trying to fix it has no idea what he's doing. The next shop he takes it to will gladly stick to that story if they can get it off to make them look better. This has not been my day. Best of all, this guy rides with a whole big group of potential customers and they all share their experiences. I kinda think if one likes you you're golden, and if one doesn't your nothing. Guess what I'll be.  Sorry for the rant, but gee thanks China! |

|

|

|

Post by Goosey on Apr 6, 2010 20:06:03 GMT -5

You did the right thing. I had to use the stearing wheel puller on 2 different flywheels to do a swap, should of gone easy.

|

|

|

|

Post by 90GTVert on Apr 6, 2010 21:02:05 GMT -5

Thanks for the backup, I could use it. I still wonder if I should have tried heating the flywheel, but then I imagine calling the customer to say I couldn't get the flywheel off and apparently the heat damaged your stator so now your scoot doesn't even run. I'll probably always second guess this one.

|

|

|

|

Post by Fox on Apr 6, 2010 22:27:48 GMT -5

That sucks!  |

|

|

|

Post by 2strokd on Apr 7, 2010 9:01:40 GMT -5

I think you did the right thing. A bad day could have been worse if you would have done further damage. If the guy dosnt get it, oh well! At least your not tearing his whole engine down to replace the crank because the guy needed a stator(maybe?). Good idea talking to your pop too! Never hurts to get a second opinion. From a seasoned pro at that! There will be better days  ! We wouldnt even know what a good day was if we didnt have bad ones  . |

|

|

|

Post by Fox on Jan 1, 2013 22:03:26 GMT -5

I know this is an old thread but as I was revisiting it I felt that have to ask the question: Why left hand thread on the 150's? :confused: Right hand thread seems to be the standard so why? WTF?  |

|

|

|

Post by reveeen on Jan 2, 2013 9:40:51 GMT -5

I know this is an old thread but as I was revisiting it I felt that have to ask the question: Why left hand thread on the 150's?  Right hand thread seems to be the standard so why? WTF?  No idea......... maybe to sell more tools? In my "bag of tricks" I have an OTC 4742 www.otctools.com/newcatalog/products/4742_4945.jpgThough usually: when I encounter one of these things seemingly stuck on, I find they pop off with a slight nudge with a hammer (on the end of the puller), and if you care to look the ends are designed for just such a "nudge". I know this is twice now I have suggested to you to "have at it" with a hammer, and it seems to be some kind of a "bad habit", but "in the real world" where mechanics have to serve a 5 year apprenticeship they learn the "in's and out's" of BFH application. |

|