How To : Remove The Oil Injection System

Apr 12, 2010 6:58:56 GMT -5

rxsteve, kilroy, and 5 more like this

Post by 90GTVert on Apr 12, 2010 6:58:56 GMT -5

Removing The Stock Oil Injection System And Switching To Pre-Mix

Before you start removing parts, make sure pre-mixing is right for you. I am a firm believer in pre-mixing oil into fuel. The first mod I've done to the two-stroke scooters I've owned is usually switching to pre-mix, but that doesn't mean it's right for everyone. I'll outline basically what each involves and a few pros and cons of oil injection and pre-mixing to help you make an educated decision.

Oil Injection

Oil injection systems use a pump to inject two-stroke oil into the carburetor or intake. A gear on the crankshaft drives the oil pump. The oil pump pulls oil from a reservoir and feeds it through a line to the intake or carburetor where it's drawn into the engine to provide lubrication. The amount of oil being fed to the engine is controlled by throttle position via cable. The single throttle cable coming from your hand throttle operates one cable that controls the carburetor and one cable that controls the oil pump. The more you open the throttle, the more oil the oil pump should provide.

+Convenience. This is absolutely, bar none, the biggest pro of oil injection and IMO the only reason to keep it. The stock oil injection system could practically be operated by a monkey. Fill the oil tank. Ride and re-fuel normally. When you see a red dummy light come oil with a picture of an oil can, fill the oil tank again. That's all there is too it.

+Fuel Delivery. Because the jets in your carburetor don't have to deliver oil, they can deliver more fuel for the same size of jet compared to a scoot using pre-mix.

-Reliability. Honestly, I can't tell you I've personally seen oil pumps fail. I've heard the horror stories though. If your oil pump or any of the injection system's components fail, your engine won't get oil. No oil = severe engine damage. The gear on the crankshaft that drives the oil pump is made of plastic, so your engine life depends on a plastic drive gear.

-Metering. There's really no easy way to know just how much oil is being delivered through the oil injection system. You can watch for smoke and how much smoke and look for signs of proper wear if you pull the engine apart. It's hard to say if oil is being delivered at a 30:1 ratio or an 80:1 ratio though.

Pre-Mixing

Pre-mixing simply involes adding two-stroke oil to fuel before it enters the carburetor. This is usually done by either by filling a gas can with gas and oil that will be used to fill the fuel tank or by filling the fuel tank and adding oil in the tank.

Pre-mixing must be done at the proper ratio. You can't just put any amount of oil in and expect the engine to operate properly. The amount of oil used is usually stated as a ratio or a percentage. The ratio expresses the amount of fuel relative to the amount of oil. For example, a 32:1 ratio would be 32 parts fuel to 1 part oil. To convert this number to a percentage, simply divide the second number by the first. Using 32:1 again, 1 divided by 32 equals 0.03125 or roughly 3%.

+Metering. Pre-mixing allows you to control how much oil your engine is getting. You decide if you want to mix your fuel and oil at 32:1, 40:1, 50:1, or whatever ratio you desire.

+Reliability. There are no moving parts to fail and prevent oil from getting to your engine when you pre-mix.

+Removing Clutter. When you switch to pre-mix, you can remove the oil pump and it's drive components on the crankshaft, the oil tank, oil lines, oil pump cable, and if you're really ambitious you can even remove the wiring that triggered the low oil indicator. Sometimes you can free up valuable space where you can add things like boost bottles or maybe just gain easier access to your engine or other components. Of course there are less hoses to deal with when you work on the carb as well.

-Inconvenience. Pre-mixing isn't as idiot-proof as oil injection. There's no dummy light to tell you if you forget to add oil to your gas. You have to carry around oil all the time and add a certain amount to the gas tank every time you fill up with fuel.

-Fuel Delivery. Because a percentage of your fuel is now oil, the jets in your carburetor are delivering slightly less fuel. It is a very small percentage though. For example, a mix ratio of 32:1 is 3% oil. If you have a 70 main jet, it will deliver as much fuel as a 68 main jet (3% less) because oil is now passing through the jets along with fuel. This small change may not even be noticed. If you wish to be sure you still have the same amount of fuel, upjet by the percentage of oil you are mixing in. For instance, if you are mixing 3% oil (32:1) and you were using a 70 main jet stock, you'd want to use a 72 main jet to deliver the same amount of fuel as the 70.

Removal

If you've decided pre-mix is the right choice for you, let's get started.

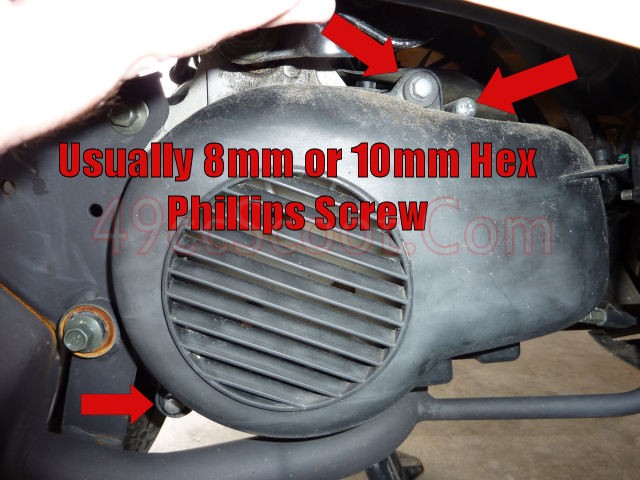

Begin by removing the bolts and screw that holds the cooling fan shroud in place, and removing the shroud.

Remove the three bolts that secure the cooling fan to the flywheel. You can usually just hold the flywheel with your hand to prevent it from moving while you loosen the bolts.

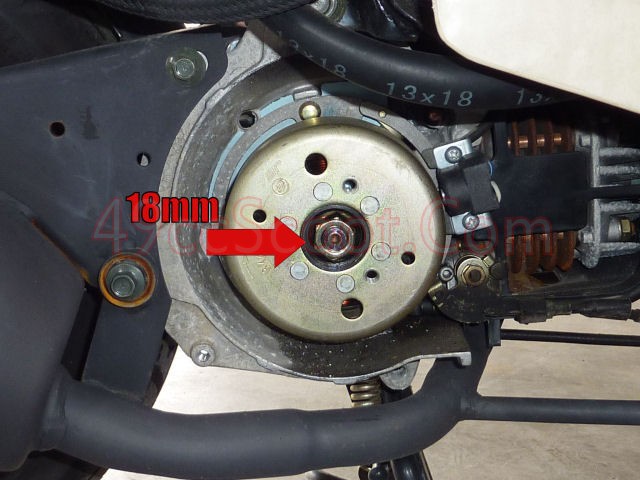

Remove the nut that secures the flywheel to the crankshaft. This is easiest with an impact gun. You can use a socket and ratchet on the nut and a spanner wrench to hold the flywheel.

Remove the washer behind the nut.

You'll need a 27mm x 1.0 left handed thread puller to remove the flywheel.

Screw the puller into the flywheel and then screw the T handle or bolt (depending on your puller) in until it makes contact with the end of the crankshaft and stops turning easily.

Hold the puller with a wrench and give the handle a tap with a rubber mallet. The flywheel should begin to free itself from the crankshaft and you can usually turn the handle by hand until the flywheel pops off.

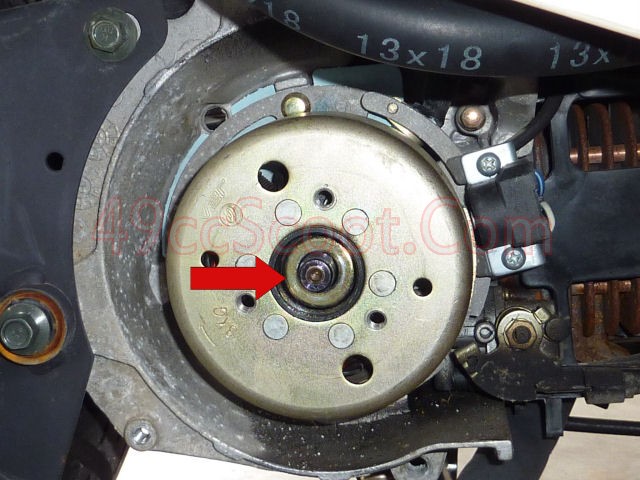

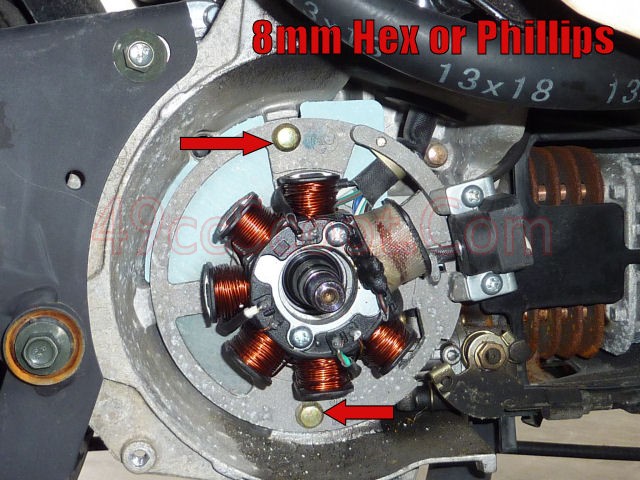

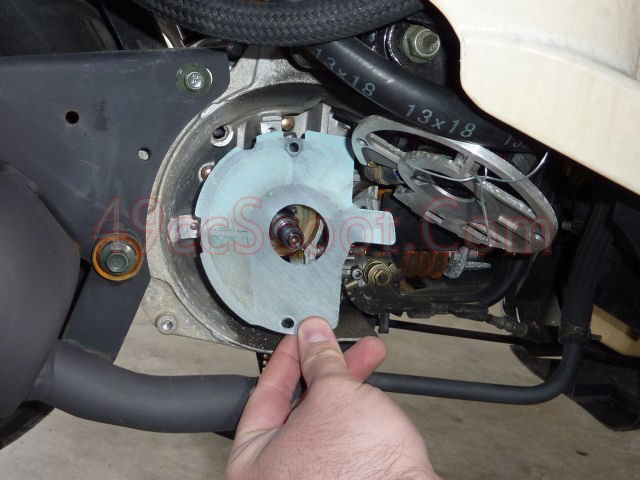

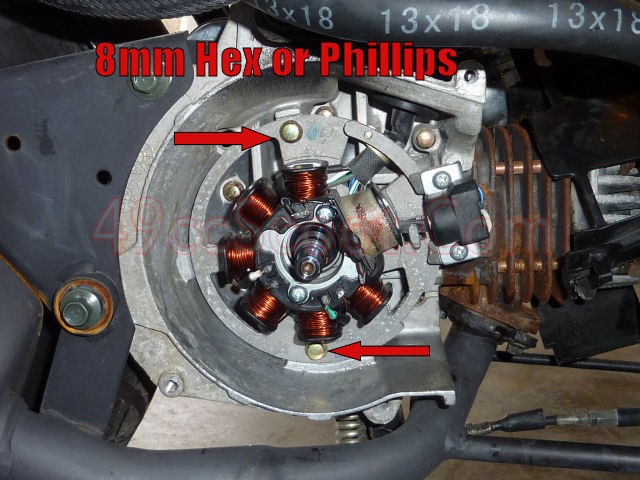

Remove the two bolts that secure the stator and it's plate to the engine case.

I find it helpful to use some mechanic's wire or a wire tie to tie the stator plate up out of the way rather than removing it completely for this job.

Remove this gasket.

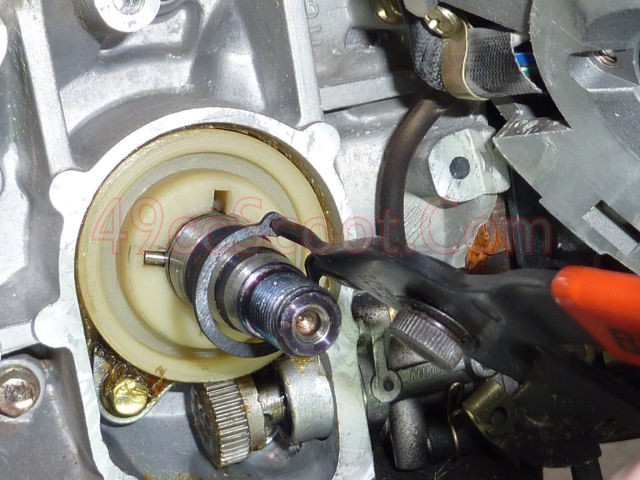

Use a pair of snap ring pliers to remove the snap ring in front of the oil pump drive gear.

Remove the oil pump drive gear.

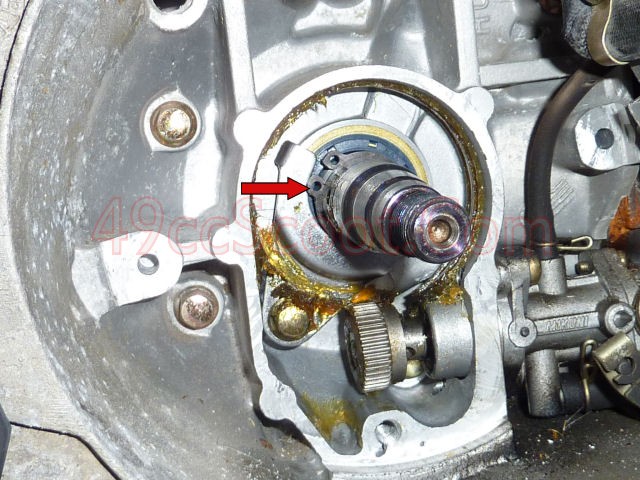

Remove this pin from the crankshaft.

Remove the snap ring that was behind the oil pump drive gear.

Remove the cable from the oil pump as shown.

Remove the oil injection hose from the carburetor. You will need to cap this with a small rubber vacuum cap. I believe 1/8" works.

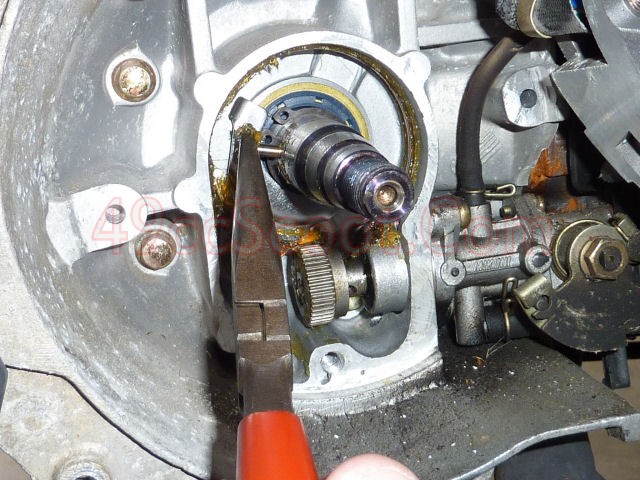

Use a pair of vice grips or line clamps to keep block oil from coming out of this hose and remove the hose from the pump.

Remove this bolt. One of two that secures the oil pump to the case. On small frame scooters you may find a 90 degree screwdriver makes the job easier.

Find the bolt buried in the darkness of the cases and remove it. This one can be a pain. Just take your time and try different screwdrivers until you find the one that works best.

With both bolts removed, pull the oil pump from it's hole. It is shown here with the gear missing, but it is not necessary to remove the gear to pull the pump out.

Locate the oil tank and remove it. Disconnect the low oil indicator wiring.

Clean any grease or dirt from the cases and then re-install the stator.

I forgot to take pictures here, but re-install the flywheel, then the fan, then the cooling shroud.

Now you can move on to removing the oil pump cable from the stock setup. I suppose you could just let the cable stay in a secure area where it won't snag anything, but I prefer removing it.

Trace your throttle cable until you find this box. Most likely it's tucked under your front fairings or front access panel. Remove the screw indicated and the bracket that goes around the box.

Push this dowel out.

Remove the oil pump cable from the "splitter" and pull it from the housing.

Re-install the dowel.

Now is a good time to take up the slack on the carburetor and throttle side adjusters to assure proper cable operation.

Re-install the cover and bolt and tuck the cable back into a safe location.

Once you get the front panels back on, all you have to do is add oil to your fuel tank. It would be a good idea to drain the fuel from the carburetor to assure that your cylinder has oil from the moment you start it.