|

|

Post by lobarrett on Mar 3, 2014 21:24:49 GMT -5

CVT Operational Theory – do I have it right.

I ran across an article several months ago on the Polini official website, titled “VARIATOR WORKBOOK” – It was billed as a first time tuners guild for setting up their automatic transmission. The above “VARIATOR WORKBOOK” is linked to the English translation of the document.

www.polini.com/en/page_415.html

I always have issues reading and understanding translated documents – so I did not pay to much attention to it. After all, I all ready had a ton of information on the subject and there wasn’t any point in trying to understand the “poorly” translated Polini document.

So, after putting all the information together from my other sources and for the most part thinking I had successfully “decoding” the magical world of the CVT into a theory of operation – I decided to compare my “new” knowledge with the “true” but somewhat cryptic knowledge outlined in the Polini document. I thought from this, I could reorganize the Polini document into something more logical and hopefully more understandable. In the end, I wanted to say, “I got it - right.” That’s when the “shit” hit the fan – I didn’t get it - right. My decoding of the mysteries surrounding the CVT appears to be wrong.

At this point in time, I am not is a position to debate the gospels of the CVT according to Polini. They certainly understand it more than I do. In fact, the Polini doctrine agrees with the majority of the information shared by several members of 49ccScoot.com. And, I did believe and I had faith in this information – I understood, it’s just that somewhere along the path – my thinking got screwed up.

Guess you could say, it is time to get back on the path. This time, I thought I would try to put what I think I know into one document and post it to the forum in the hope members would read it and advise me if I am still missing the point - if you got any advise on the subject, I am ready to receive it.

I will start by recapping what I think the Polini “VARIATOR WORKBOOK” is saying.

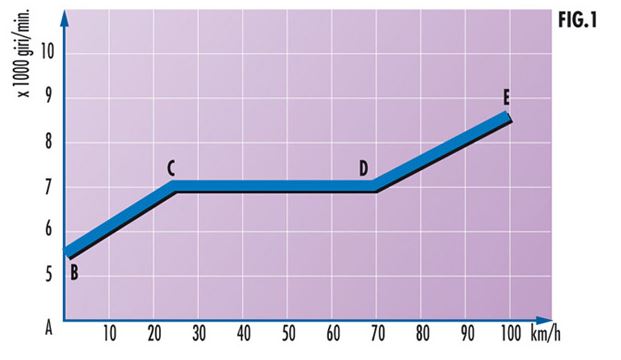

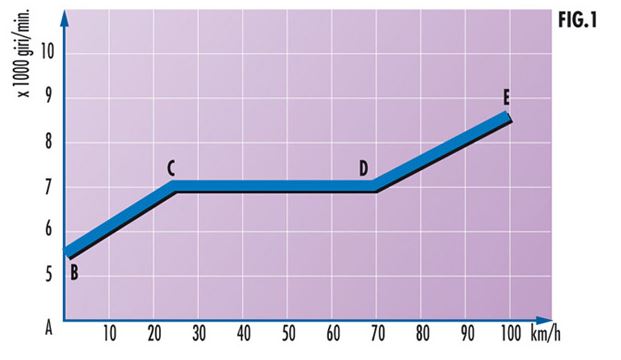

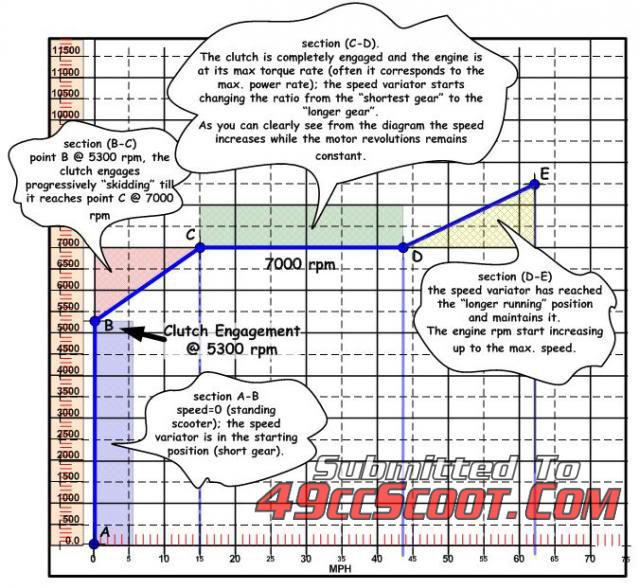

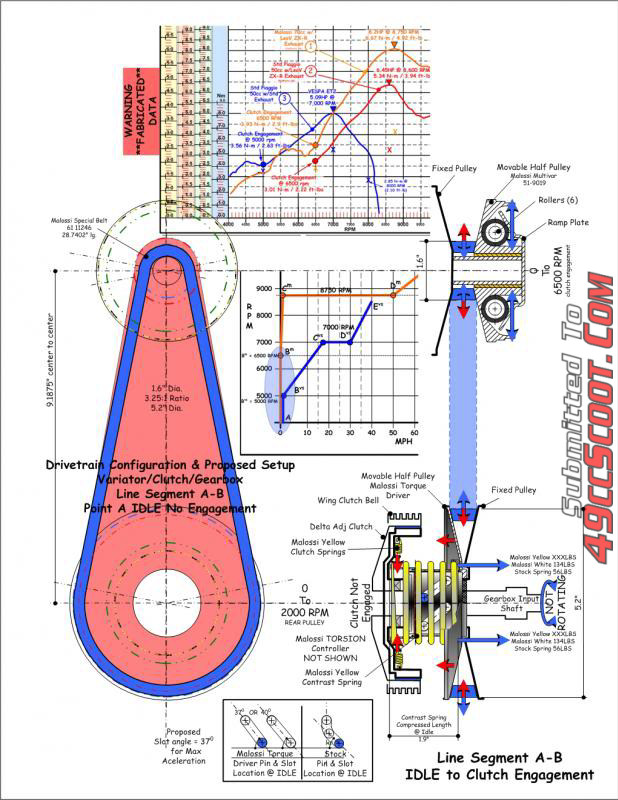

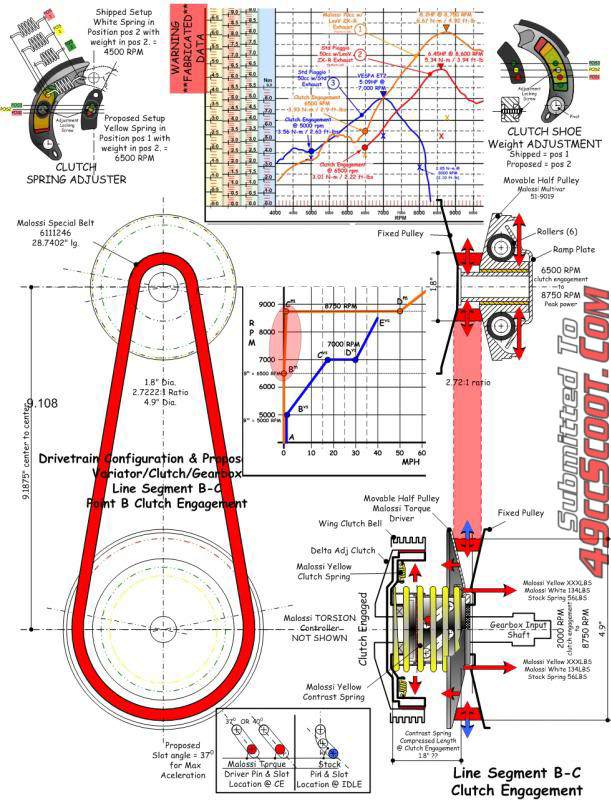

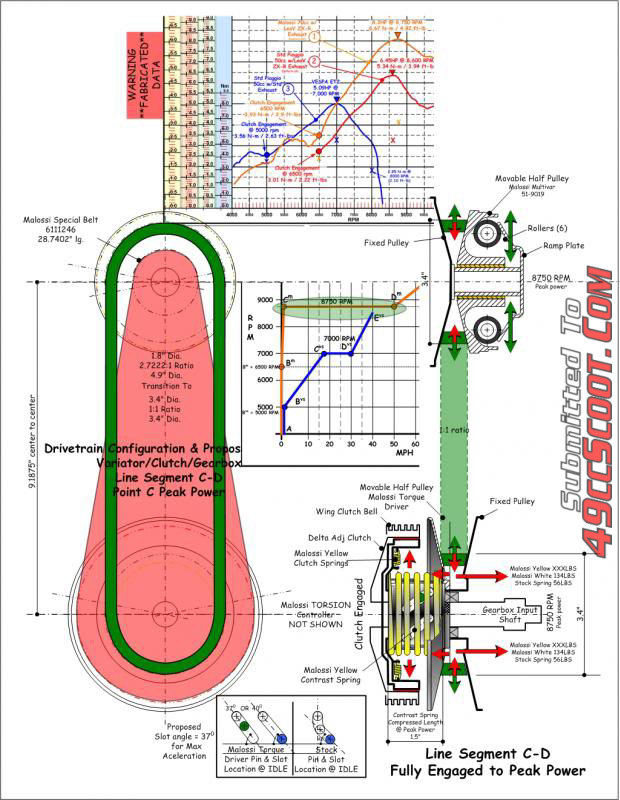

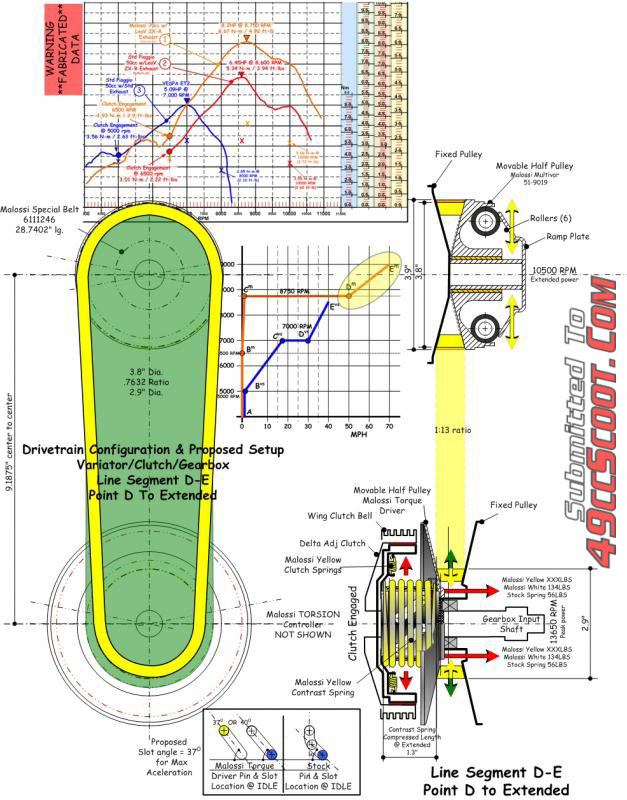

According to Polini, the functioning of a CVT can be theoretically divided in four well defined phases:

1) Section A-B neutral or standing scooter (short gear) phase,

2) Section B-C clutch engagement/skidding (short gear) phase,

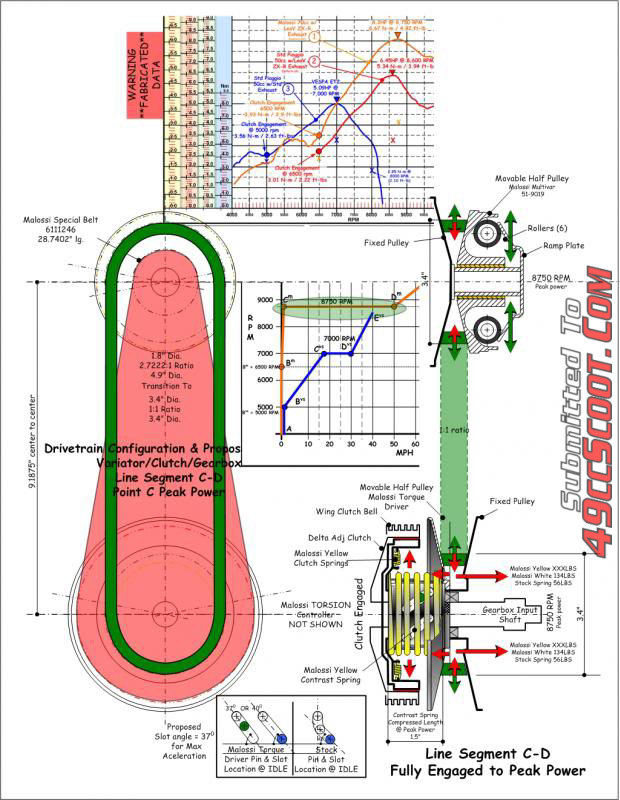

3) Section C-D variator ratio change (shortest gear to the longer gear) phase, and

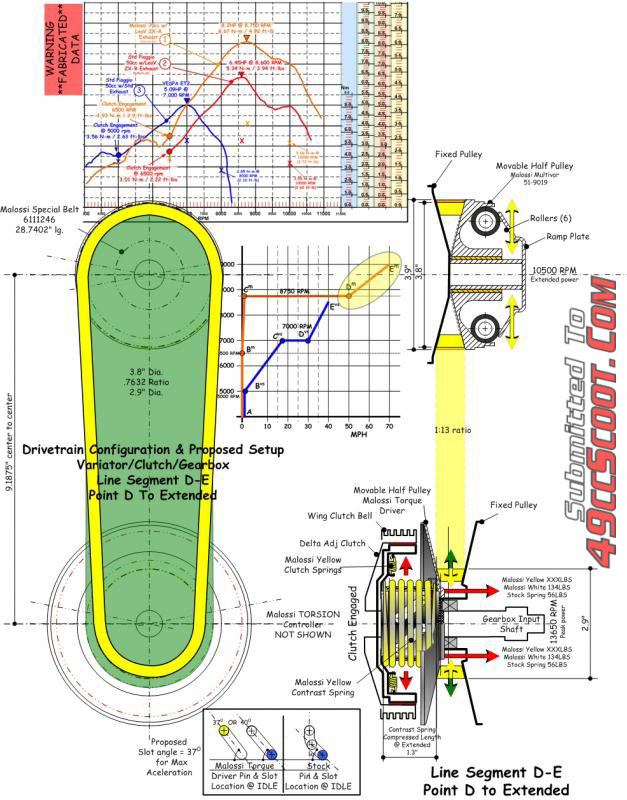

4) Section D-E extension phase.

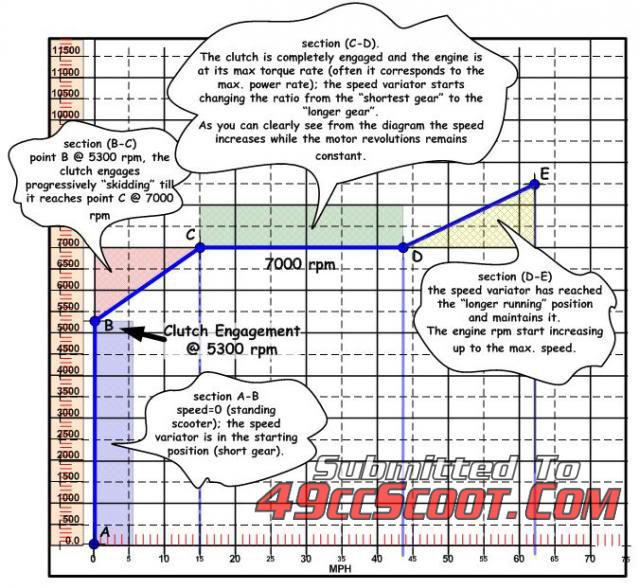

I didn’t feel comfortable copying Polini’s document (copyrights) as part of this posting, but I did copy the primary graphic that has blown my CVT theory all to hell. I than redrew the graphic and added the verbiage Polini had used to describe each phase or sections. Both are copied below.

Polini’s Graphic

My Graphic including Poilin’s Verbiage.

I have a little bit of an issue with section B-C, “the clutch engages progressively “skidding” till it reaches point C @ 7000 rpm.” The word “progressively” doesn’t seem to fit. But that might be a translation issue. And, in fact the clutch may start out “skidding” then progressively decline until it reaches point C @ 7000 rpm. The other issue I have with section B-C is the length of time the clutch “skidding” takes place – 0 to 15mph seems like a long time. However, this maybe a condition that is indicative of a stock clutch like the one that was originally installed on my 50cc Piaggio engine. I would think that a performance clutch like the Malossi Adjustable Delta Clutch could drastically reduce the time it take for the clutch to fully engage.

At this time, I don’t have any issues with section C-D, having the maximum torque available and the CVT in a shortest gear position is a major plus. The front pulley in the lowest position and the rear pulley in the maximum position would ultimately give me more torque at my rear wheels at the time I need it most.

I then compared the above with a document put together by HGT titled, “Rollers and Springs... How to keep the balance” and the accompanying video titled, “Variator transition”.

According to HGT, “To get the best performance from a constant velocity transmission (CVT) based two stroke scooter such as the SR50 DiTech, the optimum RPM band must be maintained throughout the entire transition of the variator as seen in this video”.

www.youtube.com/watch?feature=player_embedded&v=2VcdnM5l5b4

Time sequence of the video:

0 to :17 Malossi Logo,

:17 to :25 Section A-B speed 0, standing scooter, short gear position,

:25 to :26 Section B-C clutch engagement, progressive “skidding” until max rpm,

:26 to :32 Section C-D clutch is fully engaged, the engine is at max torque and the variator starts changing ratios from the shortest gear to the longer gear (1:1 ratio),

:32 to :42 Section D-E the variator has reached the longer running position and maintains it – the engine rpm starts increasing up to max.

There seems to be a correlation between the video and the Polini document. The :25 to :26 Section B-C seems shorter than Polini Section B-C. I am still a little confused about :32 to :42 Section D-E, I thought this was called the Over Revving section.

HGT write up is pretty good – they do not really discuss the video – so I am doing the correlation between the two sources by sight and sound. It sounds like the engine goes to max rpm almost instantly after the clutch engages, and it seems to maintain it.

Anyway, that’s where I am at in my thinking. I will have to go back an run my torque, velocity, and acceleration calculations all over again, but maybe I have it right this time.

If you disagree or have any other comments about all of this, please let me know.

Thank you,

Larry

|

|

|

|

Post by stepthrutuner on Mar 4, 2014 3:46:21 GMT -5

|

|

|

|

Post by 90GTVert on Mar 4, 2014 8:36:47 GMT -5

There's a lot of good info there. Unfortunately I would say you can take that as basically the ideal, but not the norm.

As you can see in the video that stepthrutuner posted above, a good CVT setup on a tuned engine can hardly spend any time in the B-C area. RPM stays essentially constant for C-D, and there's a little increase in RPM at D-E. That is a Malossi over range CVT kit. It's an excellent kit that includes almost everything but the clutch and bell and it's designed to work together. The clutch and bell are Hoca with stiffer springs and clutch lightening to get it just so.

A-B and D-E are about the only things that are pretty consistent in any CVT. For A-B if you are at idle and all is working well you should be in the "shortest" gear ratio, but without the clutch engaged so you're sitting still. You'll often find myself, 2strokd, and others here calling the CVT starting point "first gear", much like 1st gear in the average motorcycle or car transmission is the shortest gear and where you want to be for take-off. The best gear for initial acceleration can be compromised by improper belt width or improper spacing of the variator that causes the belt to be squeezed up away from the center of the variator. Since a CVT is "continuously variable" without many fixed points the level of change depends just how far up the belt is squeezed. It could make a slight difference or a huge difference. It could be hardly distinguishable from the true "first gear" or it could feel like you're starting off in "second gear" for example. If it's really out of whack it could be like taking off in "high gear" and lack any reasonable acceleration or even cause the engine to stall under load at times.

B-C again has a lot of variables. Clutch weight, clutch springs, engine output, and roller weight/contra spring stiffness can all change this as well as rider weight. Rider weight is a simple one so I'll start there. A heavy rider is more likely to experience increased clutch slip. Even at my weight of basically 300lb, it's not a major issue. You can imagine the idea simply by thinking that perhaps the clutch has a gripping force that would allow it to move 200lb without slipping when it engages at let's say 5000RPM. You put a 300lb rider on the scoot and it slips at 5,000RPM because there's more load than gripping force. RPM should increase and the clutch shoes will be thrown outward into the clutch bell with more force and then it should start to grip at some point... assuming the friction capability of the shoes and bell are not exceeded. This is not something a lot will experience, just wanted to throw it out there. It's sort of the same phenomena with belt slip. Even with a proper belt and drive face angles and surfaces and so on, there's a point where the belt just cannot grip with most setups. I have seen this behavior most when messing around doing burnouts or attempting burnouts. Basically there's a contest going on between the tire and the CVT. What we hope happens in a burnout is that the tire loses. It breaks traction and spins and once it spins quickly enough to build up heat it starts smoking and shedding rubber and we rejoice in a cloud of tire bits. If the tire wins the battle and refuses to rotate, then holding the throttle forces something else to give and that will likely either be the front brake, the front tire, or the belt or clutch. Of course if it's the front brake or tire that throws in the towel first, you'll be moving forward awkwardly or struggling to keep the scooter under control. If the brakes and both front and rear tires stand strong, the clutch and belt are left to take the abuse unless the engine decides to die first from the load. The belt tends to be the first to give up for me. You may end up with smoke and rubber bits flying, but unfortunately they're coming from the CVT at that point. One more note regarding slip. It creates a lot of heat and tends to make the whole situation worse.

Some clutch setups will grab hard under normal conditions, so slip in more. A hard grabbing clutch is probably how most think of a clutch. You rev to 5,000RPM, it grabs, and you're on you're way with full engagement... the clutch's job is done. That's a really ideal way to look at it, since any clutch is probably going to slip a little. Sometimes the clutch can't overcome the other forces because of the springs, the weight of the shoes, or friction and it will much more noticeably slip into engagement. For example you hit 5,000RPM and the clutch begins to engage, but it can't fully engage so it's still slipping. RPM will increase until it fully engages and then you're at the mercy of the rest of the CVT for C-D and so on. Sometimes this happens as a steady increase and sometimes you get a "flash" where RPM rises till there's enough grip and then settles down.

To make things even more complicated, you can get a flash or spike of RPM from a slipping belt at launch as well. It can come from poor belt or drive face surfaces, lack of tension from springs and weights, or a really free setup where the belt is thinner than it should be or the drive faced are spaced farther apart than necessary so it takes a second for RPM to rise so the drive faces can move enough to begin squeezing the belt.

While it's nice to think of the clutch finishing it's duty at X speed, the speed at which any event beyond initial launch happens varies by configuration and conditions as well. Tire size, gearing, engine RPM, and the exact CVT configuration can all change MPH relative to a certain phase of CVT operation. For example, my TaoTao 4T's CVT is basically done working at 35MPH where my 2T's over range CVT continues to transition until 60MPH+. You can make generalizations for the average scooter, but don't get too fixed on saying any component works at any certain speed... again other than that the clutch's range starts from 0MPH.

Once the clutch engages, it's not all that likely that you'll be seeing that steady RPM until the CVT runs out of ratios to transition into (C-D). Again that's an ideal more than a norm. That's something you generally expect only of big buck high end setups or CVTs that have been painstakingly scrutinized and modified. There has to be an extremely good balance of a lot of components to achieve this.

What you'll find in most stock scooters, or at least the 50-150cc scoots that I'm accustomed to, is either a steady rise in RPM or sometimes a rise, shift, and rise again. Again it depends on the exact setup. The way the variator is designed such as face size and angles, ramp lengths and angles, ramp plate design, and even what weights you use change a lot. The rear pulley is no different. Changing drive face sizes and angles again alters how the CVT works. There's also a torque driver back there. It's got, usually 2 or 3, grooves in it that pins ride in. Rather than sliding straight open and straight closed, the grooves are angled to modify their resistance to change. The exact configuration of these grooves plays a major role in CVT operation as well.

It's a pretty easy concept to imagine in a basic sense (determining exactly how well changes in the torque driver cooperate with the variator can be a lot more difficult). If you have a straight groove that is perpendicular to the pulley, the pulley would easily (too easily) open and close. The only thing controlling it's rate of opening in that case would be the contra spring and roller weight balance and the way that the variator operates would control the motion of the belt. The torque driver would have no significant affect on CVT operation that way. It's basically just along for the ride. When you start altering the angle(s) of the grooves in the torque driver, then it has some say in how things go down. Call the perpendicular groove mentioned 0°. If you were to make that 90° instead, it would then be parallel with the belt. At that point it would offer the most extreme resistance to change in the rear pulley opening. Then the pulley would be fixed at a certain amount of opening, depending exactly where the groove was machined. 0 and 90 degree grooves are both impractical and not things I've heard of, but that's the best way I can think of to give you some idea of why angles would change how the rear pulley and CVT operate at the moment. Image 0° as the least angle and 90° as the greatest angle. In reality most fall within the 30-60° range. One thing that is kinda screwy about using 90° as the max angle is the fact that it allows no opening or closing of the pulley. This should not be true of any pulley and the range of motion can be made the same for 60° as for a 0° groove. Of course the groove has to be longer to travel the same distance in and out which is just a basic function of rise and run.

To keep it simple, closer to 0° means less resistance to change in pulley opening/closing. Closer to 90° means more resistance to change. I mentioned length of the grooves needing to be altered to get the same total travel. This also has an effect on CVT operation. If you think about it for a second, you should realize that the longer groove would give the pin more possible locations within it. The rate of change in pulley opening would be different not only because of the angle itself, but because of the length of the grooves. The longer grooves may offer a more precise or fine tuned motion.

Now to make it even more complicated, the grooves aren't always straight single-angle grooves. Some torque drivers have multiple angles. Generally two-angle grooves are the most common, but I know there are some with three grooves out there. I've even seen pictures of torque drivers that use curved grooves so the angle would be different all along the path. With the two-angle grooves you could probably say that C-D would be angle one and D-E would be angle two and E-F would become the over-rev portion after belt travel completes. It can at times be a very pronounced "shift" when the CVT moves from one angle to the next and seem very much like a geared transmission shifting.

Here's a video talking about and showing the transitions and their effects a little bit from a 49cc Minarelli/Jog clone project I did (Project 49).

All of that stuff will change just how the C-D section works. That area is the really tricky part of CVT tuning that can make or break a scooter. Exactly how beneficial it is to keep the engine at a steady RPM will vary from engine to engine. If you build an engine with a wide spread of power, and plenty of it, it may not be necessary to get the CVT dialed in all that close to have a pleasant riding experience. Maybe your engine pulls hard from 5,000RPM to 9,000RPM for example, so as long as you stay somewhere in that range you're good to go. If you have an engine with a very narrow peak, then a fine tuned CVT becomes almost a necessity. Two-stroke engines with aggressive tuned pipes that hit hard, but across a narrow RPM range, are a great example of this. Say for example the engine makes excellent power around 10,000RPM, but it's almost dead below 9,000RPM or above 11,000RPM. You will likely find yourself cursing the scooter if the CVT does not keep within that range. The proper CVT in that case can make the difference in a slow accelerating and downright annoying scooter and one that hauls from 0 to wherever HP succumbs to aerodynamic drag.

Here you can see one of my early experiences with a really hard-hitting pipe that had a narrow powerband. It's a burnout in the vid, but I think you can see the point. It struggles and struggles until finally it gets a break so the RPM could rise and then once the pipe hits it blows off the tire with ease. Powerful, but it needs that CVT setup well or it's difficult to deal with.

Now here's a somewhat similar setup with a pipe that hits hard across a sort of narrow range, but this time the CVT is setup in a way that allows peak power essentially from the hit of the throttle.

Hopefully this makes some sort of sense and is not just a jumble of words.

|

|

|

|

Post by lobarrett on Mar 4, 2014 21:51:34 GMT -5

Brent,

Do you ever do “half-assed” work or do you always exceed everyone’s expectation?

Your reply was nothing short of being fantastic. And, I can not thank you enough.

I had watched your video and the HGT video sometime ago. In fact, I had already documented most of what was shown and had put all of the verbiage together that the other members were saying. And, I was very happy with the way it was coming together – only had a handful of questions. But for some reason I made an about-face and went off in another direction. In the end, things just did not add up. All I can say is I screwed up.

It seems that you are somewhat in agreement with the Polini document. So I am going to regroup and go back to my previous documentation and merge your latest information into it. I would imagine that you have answered several of the questions I had.

Also, I am going to post the illustrations I had done earlier on the sections. I will look over your post over the next couple of days and attempt to integrate the data you have shared into it my earlier documentation. I have a feeling it is going to fill in the holes that were in the older stuff.

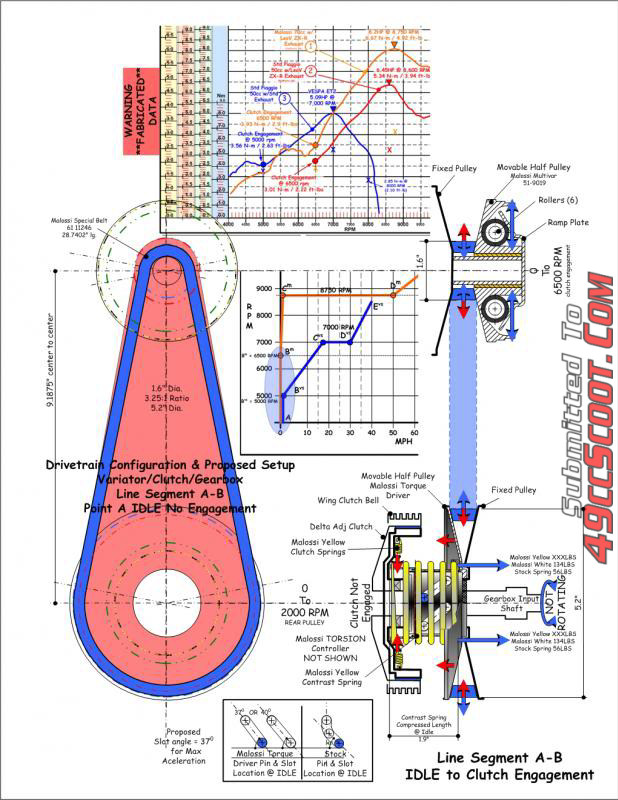

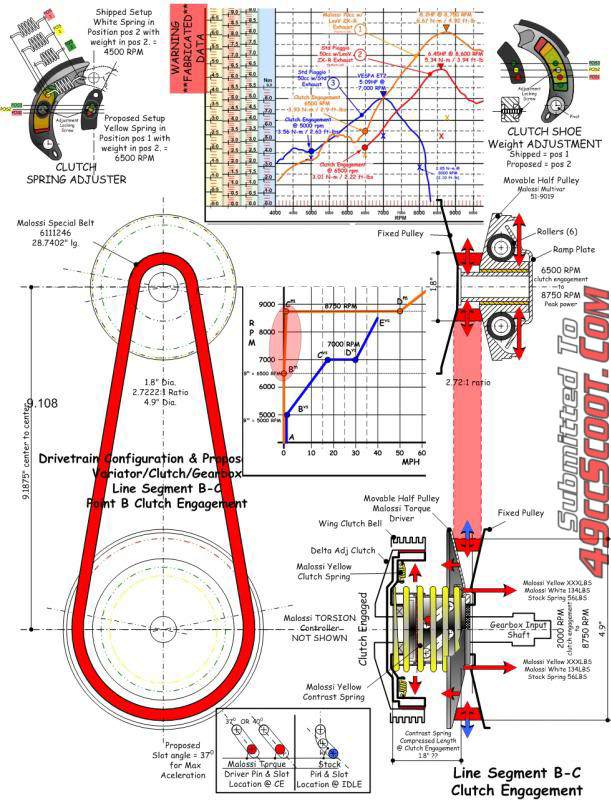

The four illustrations relate to the Malossi gear that will make up my CVT. It does not include any of the Polini up-gearing information. All that I have done with the gearing stuff is now somewhat wasted at least from a calculation standpoint – so I will need to rework it.

I am going to get some rest tonight – it was a cold day at work today. We were in the low 80’s yesterday and it dropped to the mid 50’s today. I had scheduled a lot of work to be done of a boat on the ICW, because it looked like things were staring to warm up a bit. Guess I need to move to south Florida. My blood is to thin for life here in north Florida.

SECTION A-B

SECTION B-C

SECTION C-D

SECTION D-E

Anyway, thank you for the information.

Larry

|

|