|

|

Post by pitobread on Feb 7, 2019 2:12:44 GMT -5

www.facebook.com/alfio.vandermuurwww.instagram.com/alfiovandermuur/I don't know if he full times it like HK but hes a nice fella, at least to me.. This is what he said to me about exhausts for the RT95 "found 28.5hp with the rt70kit and 39hp with the oldest rt95 model the new one i gonna teat it i tested al pipes the rd was the only one with serioues more power tested jolly moto roost ps tuning custom pipe stage 6 drag exaust stage 6 rt pipe" HK is also no Joke.. he posts some nutty stuff with 70cc cylinders that would put your stock 95cc to shame. He definitely does S6 stuff but it's an old cylinder at this point, most of the new 2fast stuff puts out better numbers. Most of these guys though you wanna ship them your whole cases and cylinder and let them work their magic.

|

|

|

|

Post by pitobread on Feb 6, 2019 21:46:26 GMT -5

Not sure, He was saying like 38+ HP on his drag bike and he uses R/T cylinders.

I bet even just getting a R&D Italy pipe would really wake the beast up.

|

|

|

|

Post by pitobread on Feb 6, 2019 21:30:39 GMT -5

Send your cylinder to Alfio Van Der Muir. He is the resident R/t95 CC porting Guru. He loves these cylinders. Also the R&D Italy pipe was recommended by him as the highest HP tested pipe he has seen and it was substantially more powerful. That was a year ago though.

Unless you wanna do crank stuff I think your at the biggest displacement you can get to.

I know the 2 fast 100 is the new big thing out there

|

|

|

|

Post by pitobread on Feb 6, 2019 20:29:40 GMT -5

Harleyracer was looking at purchasing this very thing online.

|

|

|

|

Post by pitobread on Feb 3, 2019 0:23:12 GMT -5

Speedfight 1 and 2 are basically the same engine spec wise Speedfight 3 they drastically changed the cylinder... I don't know anything about those. or if anything from those fit.

Also they exhausts kinda fit, but they don't exactly have the same angles.. but close enough you can jam at it and git er done. Roost used to make a Speedfight 2 exhaust.

|

|

|

|

Post by pitobread on Feb 2, 2019 22:43:19 GMT -5

Yep like I mention in the video, that is a pretty mild port. Can definitely go bigger in every direction.

Where it radiuses you can pull that back, but the reed stoppers kinda mean that the reeds on a CT won't open much past that. I think 3d printing a small stuffer to go in there would be ideal.

Yeah the handpiece tool is pretty nice. It does require cleaning and lubrication, but even if I had to replace the drive end every time (25 dollars) I think it would still be worth it. It is so much quieter and my hands don't go as numb as fast.... and I am sure if you got a nice high end one it would be even nicer.

the 90 one is finicky and finding the proper latching d bits is a pain, but I just started super gluing bits in there after grinding a flat on it, you can still pop it out if it needs replacing.

|

|

|

|

Post by pitobread on Feb 2, 2019 15:13:36 GMT -5

|

|

|

|

Post by pitobread on Feb 2, 2019 12:57:45 GMT -5

Yeah and raised the exhaust port.

I used diamond Burrs. I did not notice any chipping at all, the nikasil is extremely tough and seemed to be bonded well to the aluminum. I think using a sharp HSS or Carbide you may see chipping as they bite pretty hard

I could tell when i hit spots of nika in the ports the burrs did remove it albeit slowly

I have 2 long rod cranks built up for just an experiment.....

|

|

|

|

Post by pitobread on Feb 2, 2019 1:55:09 GMT -5

|

|

|

|

Post by pitobread on Feb 1, 2019 20:20:04 GMT -5

|

|

|

|

Post by pitobread on Jan 29, 2019 0:12:00 GMT -5

Things are progressing nicely in the garage.. I have more motors being built than I know what to do with.

|

|

|

|

Post by pitobread on Jan 28, 2019 0:32:36 GMT -5

that's cool you have a guy like that! maybe you can ask if its ok for me to get his info, if it is you could shoot it to me in a PM? theres a few things id love to get my hands on that buyee wont let me buy... lol I really want an af01 motor, ta01 variated gyro 2t motor and someday I want a stream a flush and a dunk.... those are some weird looking scoots I wish they were sold here. but id be down to johnny cash them and build them 1 piece at a time!  I know that there is a large and small crank af18 I have a small crank af18. I also know were there is 10 of those special seals you speak of that are available to me for purchase. there was 12 but I already bought 2 for my future small crank af18 build. 1 for the build and 1 for back up. |

|

|

|

Post by pitobread on Jan 27, 2019 14:23:48 GMT -5

I am Canadian.

I have a buyer, similar to Buyee. He is a home business importer/exporter who lives in Japan.

There are small crank and large crank engine, the small crank ones are not great. It's almost impossible to distinguish the 2 from a distance, there are some casting differences but it's really hard to tell.. It is impossible to get a performance small crank of any type.. only OE replacement.

I now buy only engines that are stripped down, so I can see if it is a large or small. You can tell by the webbing behind the variator, large crank have a larger seal and the casting is larger.

Jiangwayne used to sell a conversion seal so you could run a large crank in a small crank motor. That is really the only thing limiting you from doing so.

I have imported 3-4 engines now... no issues at all.

|

|

|

|

Post by pitobread on Jan 27, 2019 2:47:45 GMT -5

Honestly I do lots of internet, this place is one of a kind. I don't think I've ever met a more well rounded group than here..

|

|

|

|

Post by pitobread on Jan 27, 2019 2:38:23 GMT -5

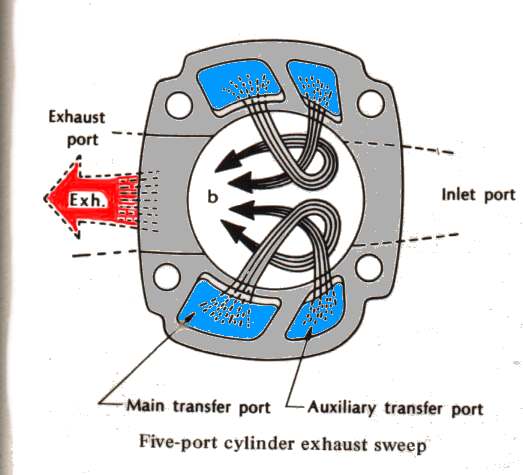

Im going to make a educated guess and say this. The lip will cause turbulence, I Know from reading like 2000 pages of the ESE thread that you want the piston to be dead flush to the bottom of the ports @ BDC for cooling effect. Without being a wizard of math, I will blanket state that the lip will probably be a "low pressure" zone and disrupt your "Schnuerle Loop" at the lower end of the flow. I think that the downsides could be that by opening the port up you would loose some port velocity. Would also have to try and blend and maintain angles a bit. Would any of this matter? Probably not. And I don't have a Dyno (yet) to do some A-B comparisons. But then what is even more confusing? Athena/Stage 6 designed it this way. as the exhaust port goes even lower than the bottoms of the transfers by 2 ish mm. Every other cylinder I have seen they all line up at the bottom of the stroke.. why it was done this way, I don't know. There are people out there much smarter than I about this stuff.  |

|