|

|

Post by 90GTVert on Sept 29, 2009 20:36:50 GMT -5

The holes don't go all the way through. I would have to drill the case and hope I hit it dead on.

I told my father about it, and said I wish I had a foot long left-handed drill bit. He said, "just get a drill bit extension." Never knew there was such a thing. lol I'll try that first whenever I can pick one up. Hopefully I can go through the access hole in the case and reach the lower bolt.

Cool link BTW.

|

|

|

|

Post by 2strokd on Oct 1, 2009 9:15:00 GMT -5

hmmmm, thanks for the link 190mech.

I will be getting back on the wagon as soon as my clutch gets out of customs and to my door.

|

|

|

|

Post by 90GTVert on Oct 1, 2009 14:28:03 GMT -5

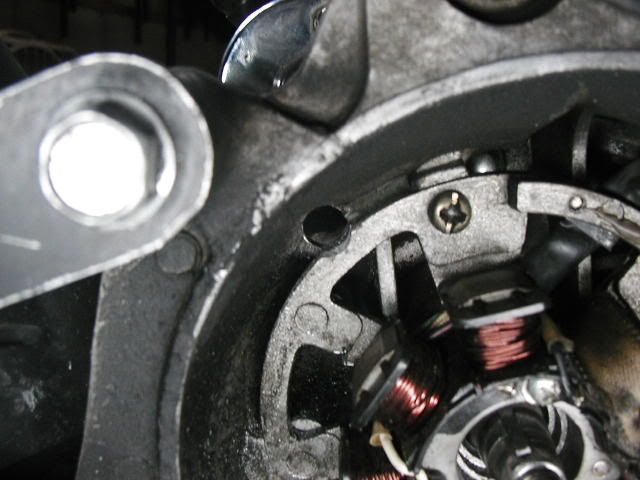

Drill bit extensions and a left handed bit did the trick for getting out those broken bolts. I needed a 6" for the bottom bolt and the 12" for the top bolt. Well worth $5 a pop. Kinda makes me mad that I've went out and spent money on long drill bits in the past. lol  I did have to enlarge the access hole in the case to be able to do the bottom. I just drilled into the stator plate so I didn't have to remove it this time and if it ever does happen again I won't have to do it then either.  I stuck the Powerlink belt on again. You can see that even with the filed variator halves and 2 washers the Gates is too wide to sit down much at all.   Even if I kept spacing it out somehow until the belt could sit all the way inside the front pulley, it would still be too wide to get down in the rear pulley much. I've got 2 Gates belts that are basically brand new and pretty much no good to me unless I need 'em in a pinch or something. I stuck the 15mm worn to hell belt back on because the Gates makes the scoot bog off of the line and it still only tops out around 57-58MPH. I'm sticking with my plain old Bando belts that have worked well for me from now on. |

|

|

|

Post by 2strokd on Oct 1, 2009 15:15:19 GMT -5

So thats what that hole is for lol. Cool, you got it fixed!

I hear ya, i think i will stick with the Bando,s too.

|

|

|

|

Post by 90GTVert on Oct 1, 2009 15:44:26 GMT -5

I was very glad you found that access hole and asked what it was for some time ago. I did use an extension through it to tighten up the lower bolt as well. ...and to think I twisted around in there trying to tighten it up before, moving 1/8 turn at a time.

|

|

|

|

Post by 90GTVert on Oct 4, 2009 10:30:58 GMT -5

Since the Sunl is down and my father can't ride with me, I asked him if he wanted to go out and get a little practice in on my scooter. He was up for it so we went out to an industrial park that sees no traffic (not 1 car in this section in 1hr30min that we were there) and set up some cones. I set up 10 cones 12ft apart to start with for a weave exercise. You need to do 10ft for the motorcycle skills test, and I figured he'd need to start at 12. He went through 12ft with no real problems, but he was a little wobbly at first. After a few passes he was more stable. I moved them to 10ft for a bit, then 9ft. He hit a cone 1 time at 9ft.  I set up a 90 degree turn that is 4 1/2 feet wide. You need to do this in 5ft for the motorcycle skills test. He went through it twice with no issue. Then he stopped and asked what to do with those cones. I told him, "it's a sharp right and you can't touch the cones, just like you've been doing." Then he goes out and hits the cones a few times. lol He got back into it though.  I told him I started hearing a ticking noise and I suspected the belt was getting rough, after all it was below the service limit when I put it on this last time. He wanted to ride it back anyway. I told him I didn't care aboutthe belt, go for it. Oh, and just to be clear he does wear a helmet when riding, but it was a little warm practicing at 5MPH.  The place we were practicing is about 15 miles from my house. We made it 13 3/4 miles when the belt snapped. I pulled the truck over and he was revving up the engine and it was smoking hard. I yelled at him with some colorful language and he shut it off. I apologized, and explained that I really didn't want my engine blown up just because it's sounds cool revving like that. Here's the belt now...   |

|

|

|

Post by erictheviking666 on Oct 4, 2009 17:38:41 GMT -5

Damn, that made a real mess. Looks like you're gonna have too tear it apart again to clean all that junk out of there.

|

|

|

|

Post by 90GTVert on Oct 4, 2009 18:08:04 GMT -5

Oh sure. No worries though. I was thinking about pulling it apart anyway to file a little more off of the variator and maybe taking a look at the rear pulley. Now I have a good excuse. ;D

|

|

|

|

Post by erictheviking666 on Oct 4, 2009 18:39:59 GMT -5

You know watching that video made me wonder. Mine still doesn't launch hard compared to that at all. I have the MRP Clutch and 2000 rpm springs, but I bought a stock new clutch bell. Maybe I should have gotten the High Perf one instead. Also I'm still running a stock contra spring but plan on installing a 1500 RPM spring in a couple of weeks when I'm on vacation. Maybe I'm just expecting too much with my 248lb frame and only 50cc's still. I'm not sure how too tell the difference between the clutch still slipping just a tad or the belt slipping.

|

|

|

|

Post by 90GTVert on Oct 4, 2009 19:21:35 GMT -5

I'm not sure what slips either. The only way I know to tell if the clutch or belt slips is that the belt will leave marks on the pulleys if it slips bad. It will also wear excessively and you should see plenty of dust in the CVT case. The clutch will glaze the bell and the shoes if it slips. I get lots of dust in my CVT cover and my clutch likes to glaze. I don't know that the aftermarket clutch bell does a lot. I do think additional cooling will help, otherwise it doesn't seem much different than the stocker.

|

|

|

|

Post by erictheviking666 on Oct 4, 2009 21:38:11 GMT -5

Yeah I haven't had an excessive amount of belt dust yet. I may try that old trick JR was talking about on Scootdawg. Try putting a little Boric Acid in the bell and on the clutch shoes, to make the shoes seat in the bell. I have some of that Roach Powder here so it's an easy and cheap experiment. I want to cut out a 3-1/2" hole in my cover over the bell when I install the Torque Spring. So that should give me lots of extra cooling.

|

|

|

|

Post by 2strokd on Oct 5, 2009 5:25:50 GMT -5

A broken belt is worth a day of scooter practice with your dad. Looked like fun, my dad woulda revved mine up too lol, whos the dad here dammit?!

Hey, i talked to my pop this weekend and he said he has his eye on a Dio. He asked me if they were any good and if perf parts are out there. I said oh yes, good scooter, the skys the limit.

Hopefully he can get it for the $300 or cheaper they are asking for it.

|

|

|

|

Post by 90GTVert on Oct 5, 2009 5:34:11 GMT -5

Hopefully it's the 2 stroke version.

|

|

|

|

Post by 2strokd on Oct 5, 2009 5:38:17 GMT -5

Hopefully it's the 2 stroke version. Good point, i forgot to mention i asked him if it was a 2 or four, he said its a 2t. He thinks its a 1995 49cc Elite |

|

|

|

Post by 90GTVert on Oct 5, 2009 6:33:21 GMT -5

;D I really hope he gets it now. I wanna see what happens if you get on a 125cc stroker Dio with the transmission set up like Skeedr's.

|

|