|

|

Post by 190mech on Apr 2, 2016 5:53:03 GMT -5

Its a shame the cam cant be easily advanced or retarded,I guess they dont offer it for fear of crashing a valve into the piston if not set up correctly.. Another design problem I see is this engine has no stator back plate,so the stator AND pickup cant be moved together to alter timing and maintain the proper phase angle between the pickup and stator..  |

|

|

|

Post by 90GTVert on Apr 2, 2016 7:41:36 GMT -5

There is the adjustable cam sprocket that can be pressed on to allow for easy changes. I thought about it, but I've spent too much now on this thing and I figured the cam would be OK out of the box the last time I looked at the sprocket. www.ebay.com/itm/SCOOTER-150CC-GY6-RACING-PERFORMANCE-CAMSHAFT-DEGREE-AJUSTABLE-SPROKET-/182071172899?vxp=mtrA good CDI could solve the ignition timing issue. The question would be, where do you get a good CDI that doesn't advance timing at starting speeds short of buying an MSD or something terribly expensive or that requires you to build it yourself? EDIT : On the topic of desirable improvements... would it be so hard for a cam card to come with performance cams, or at least publish the specs on a company website or something? Actually, it probably is a bad idea when you're pumping out cheap camshafts. If you don't tell the consumer what you intended the timing to be, they can't know it's off.  |

|

|

|

Post by 190mech on Apr 2, 2016 17:28:48 GMT -5

I too am spoiled by having a cam card when a performance cam is bought,too bad CompCams or Crane dont make a GY6-150 cam,,bet they'd have a cam card.. That adjustable cam sprocket has a lot of movement,not for the 'plug-n-play' builder! A DC CDI doesnt rely on a source coil to charge the capacitors,always steady battery voltage,a waay better setup,all the race folks run DC CDI now,yeah,I know ya gotta have a battery to run them..might be worth a look to see if there is anything out there cheap... www.ebay.com/bhp/adjustable-cdi |

|

|

|

Post by 190mech on Apr 3, 2016 19:57:19 GMT -5

More 4T rambling, 4T iggy findings-when working at a race car machine shop as a young man,we studied ignition systems carefully and found great info in a Chevy preformance manual stating an initial advance of 20 degrees,then a steady rise to 38 degrees total advance(42 for forged pistons).I ran with this plan and found a snappy low end(with hot cams) and good top end without melted pistons..Later I got into Datsun cars and used the same setup,good results too..Did the same mods to Honda Xl125's,XR185's & XR200's(dropped back to 35 degrees total due to aircooled)good again..All these motors have centrifugal advance that are modified by welding the slots and filing to get the right combination..I feel the same results could be had if a CDI box has a 15 degree advance range and there was a way to get a 20 degree initial advance(restabbing the flywheel without a key,or,,,)Yeah its old school tech,but it worked well then,why not today???

|

|

|

|

Post by ryan_ott on Apr 3, 2016 20:05:05 GMT -5

Always good advice from the sensei  |

|

|

|

Post by 90GTVert on Apr 3, 2016 20:18:34 GMT -5

I think the stock TaoTao CDI had 12 degrees between base and full advance, but it just shot up and then stayed at full advance. I may try one of those cheap adjustable CDIs. Not sure if I'll switch to DC for it or not. There's an AC unit that cwazywazy bought and said it wasn't a flat curve like the 2 CDIs I tried on the TaoTao. Could be like the stock CDI where it stays low for idle speeds and just jumps up to full advance. Once again, the manufacturers or sellers could be of so much help if they were so inclined, but those cheap parts may vary by shipment so it's probably hard to keep up. EDIT : I just ordered a cheap adjustable AC unit for now from China. Looks like what cwazy linked to at one point, so I'll see what it does. |

|

|

|

Post by cwazywazy on Apr 3, 2016 20:58:05 GMT -5

I think the stock TaoTao CDI had 12 degrees between base and full advance, but it just shot up and then stayed at full advance. I may try one of those cheap adjustable CDIs. Not sure if I'll switch to DC for it or not. There's an AC unit that cwazywazy bought and said it wasn't a flat curve like the 2 CDIs I tried on the TaoTao. Could be like the stock CDI where it stays low for idle speeds and just jumps up to full advance. Once again, the manufacturers or sellers could be of so much help if they were so inclined, but those cheap parts may vary by shipment so it's probably hard to keep up. EDIT : I just ordered a cheap adjustable AC unit for now from China. Looks like what cwazy linked to at one point, so I'll see what it does. Yeah, from what I could tell it had an actual timing curve, but the adjustment screw just changed when the timing advanced in terms of revs. I didn't get any actual degree readings because I was using a 20+ year old basic timing light I found in the back of the garage, which was working intermittently. |

|

|

|

Post by 90GTVert on Apr 4, 2016 9:56:36 GMT -5

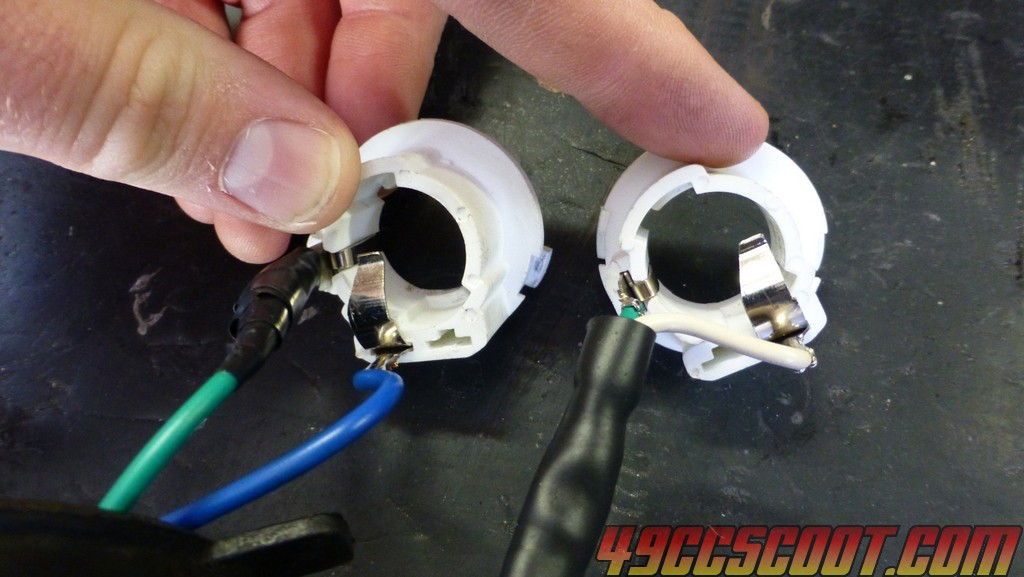

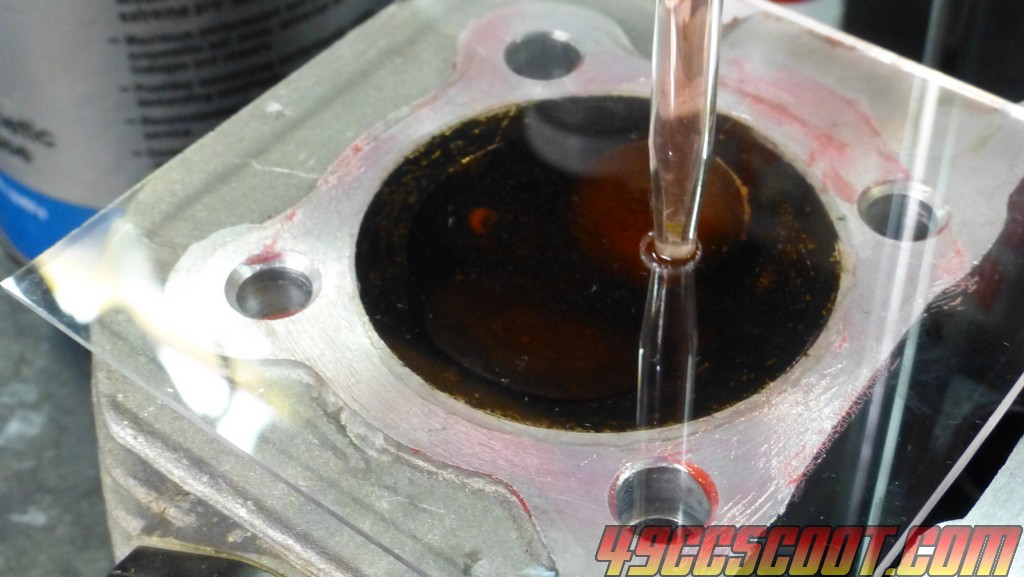

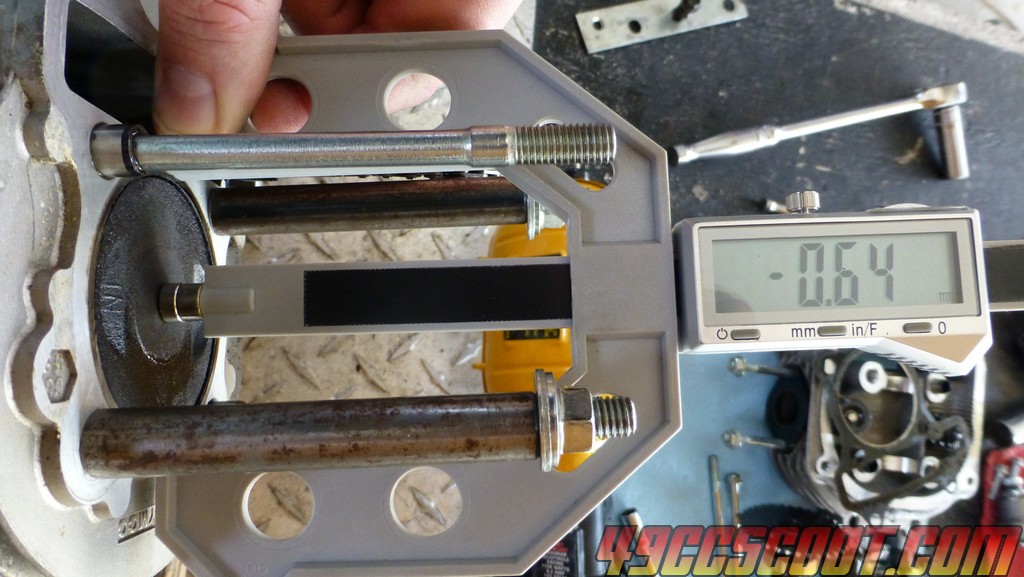

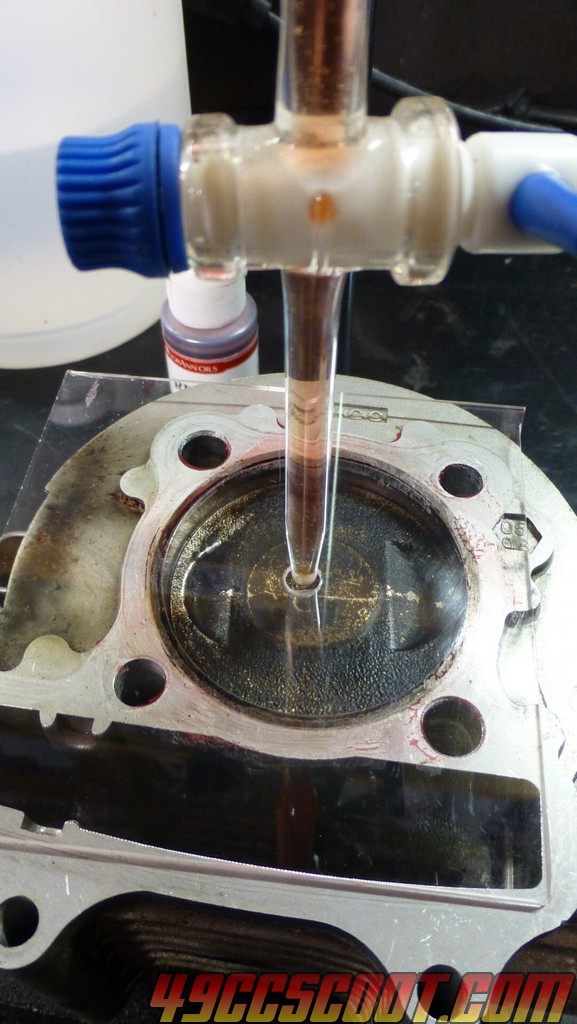

The dual beam socket that I ordered from eBay came in a few days ago, so I used it's wires to switch the existing sockets over so that left and right should both illuminate for high and low beam. The engine is apart so I tested with the multimeter just to make sure all connections were good and the bulb base was grounded when installed. Now the question is, can the stator can light them both bright? I have a feeling the headlights still won't be that great, but I'm crossing my fingers.   Back to the engine. I wanted to find out what the compression ratio is. Compression tests showed over 200psi, so I thought it must be somewhat high compression. I started by setting up a burette and cc'ing the combustion chamber. I checked 3 times and got 13.7 twice and 13.6 once. I'll call it 13.7cc because I think there was some leftover water in the crevices on the lower volume test.   I measured the head gasket thickness (0.29mm) and bore (57.5mm) to calculate displacement (0.75cc). I checked how far the piston sits below deck at TDC. With a bore of 57.4mm and the piston sitting 0.64mm below deck, there's 1.66cc between the top of the crown and the deck at TDC.   Knowing the bore and stroke, displacement was calculated at 149.57cc. That would be enough to get a rough figure, but I wanted to do it more accurately so I removed the piston and cylinder and cc'ed the piston. I found that the piston's crown allows another 1.1cc to be trapped.  With that info, I could find that the total volume trapped above BDC would be 166.78cc, and the total volume trapped at TDC is 17.21cc. Dividing the two yields a static compression ratio of 9.69:1. Lower than I hoped/expected. I was curious to see how bad the A9 dropped dynamic compression ratio. I knew it had to lower it because it closes the intake valve much later after BDC than the stock cam. I used an online calculator and started with the 0.050" lift specs that I recorded. Then I tried it using 0.002" lift points. Some places say to use 0.050" and some say use advertised or seat to seat specs. I think I said it in a previous post, but I don't know if the 0.050" stuff applies well to these small cams. Some motorcycle and even import car companies use 1mm which is 0.039" and some change, or some just use 0.040". I never noted those figures specifically, just every 5 degrees and 0.050" lift and I do have 0.002" of lift for all events on both cams. I used 93.5mm as the conrod length. I couldn't accurately measure it, but I found that spec on one seller's listing for a GY6 rod and it seems like it would match up pretty close to what I'd guess at with the measurements I am able to take. Here's the dynamic compression ratio info :

| IC ABDC @ 0.050"

| DCR @ 0.050"

| IC ABDC @ 0.002"

| DCR @ 0.002"

| Stock Cam

| 20°

| 9.52:1

| 70°

| 7.45:1

| Hoca HB/A9

| 59°

| 8.10:1

| 115°

| 4.06:1

|

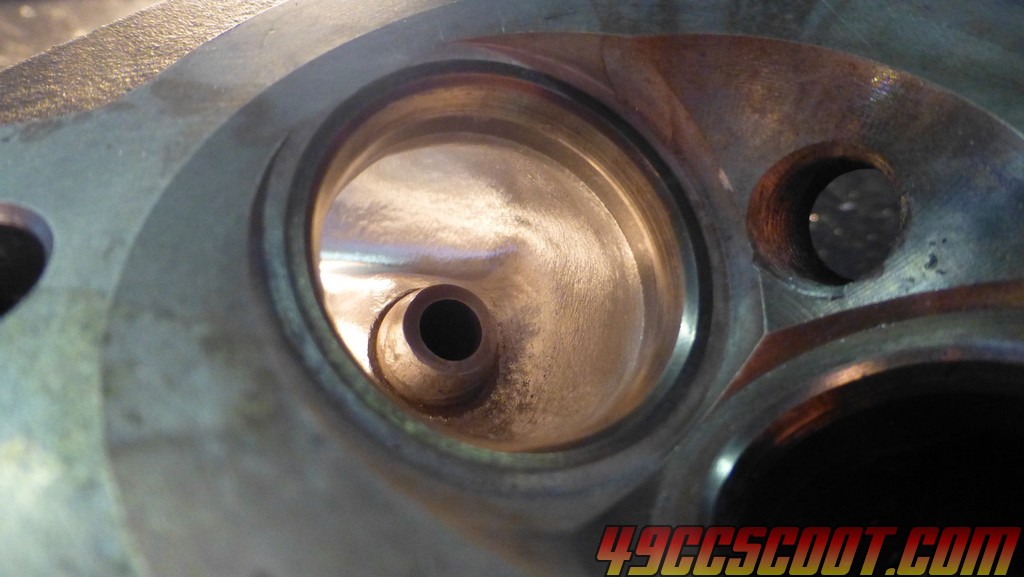

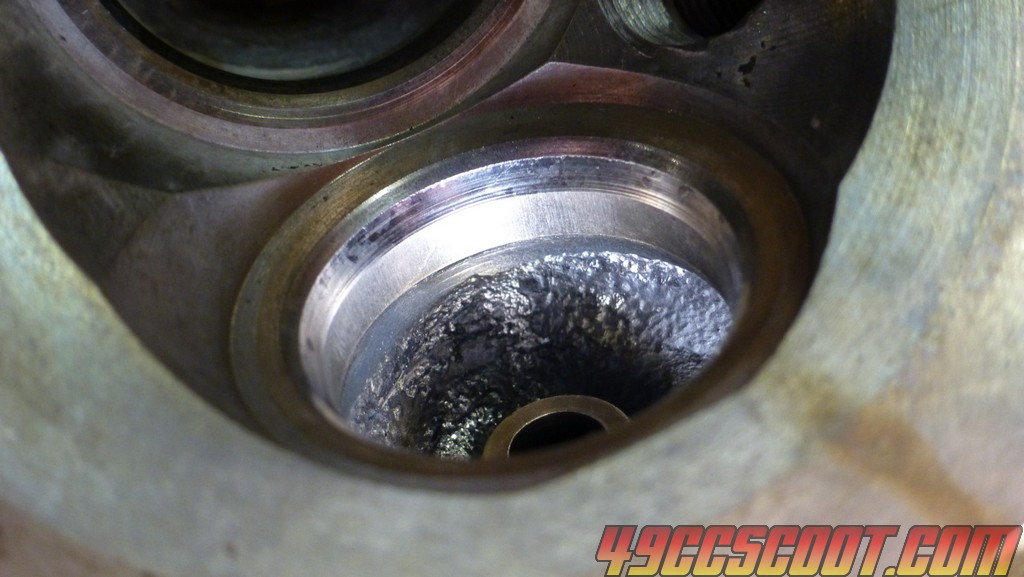

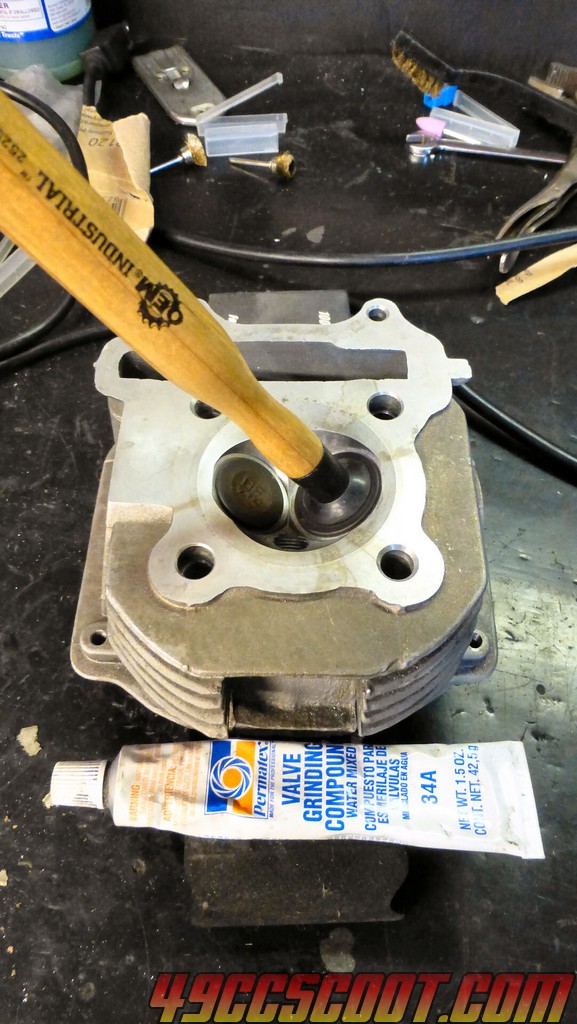

Either way, it's not hard to see the A9 will lose quite a bit of dynamic compression. Just out of curiosity, I checked the A9 numbers at 0.002" advanced 2, 4, and 8 degrees and they were 4.25, 4.4, and 4.68:1 respectively. Big losses vs stock regardless. Before I started looking into increasing compression much, I wanted to change course a bit and work on the cylinder head a little. I cleaned it up and removed the valves so I could get a better look and do a bit of porting.   I had no desire to do a huge port job. I just wanted to clean them up and smooth them out mostly. Here's a look at the intake port in stock form. Lots of rough casting, ledges near the valve seats from cutting, rough transitions.       I cut out the big rough spots and ledges and a little bit around the guide and then tried to blend it all together. You may notice a casting mark on the port floor still leftover. I tried not to muck about in that area or any of the floor too much because the short turn radius is already really abrupt and I didn't want to make it any worse. I only smoothed it and blended a little there. I took small strips of emery cloth in different grits and put them through the port to sand the sharp short turn into a little more of a curve. Looking at the pics, I probably could have cut/blended more around the valve guide, but it's much easier to see looking at a big pic than into the port. It's also much easier to think these things than to get tools in there and do it without messing up seats or digging into areas you don't want to dig into. The finish is just whatever it ended up as after carbide burrs and pink (aluminum oxide) stones.     Before I worked on the port entry to finish up, I checked out the intake and phenolic spacer to see how they matched up. Not exactly the ideal path from carb to port. The carb outlet ID is 24mm. Then in moves into the beginning of the intake where it matches pretty well. Then there's a sharp turn, that is more of a ledge. The turn and the area after are smaller. The outlet of the intake was 22mm. The spacer didn't match up to either the intake or head quite right. The intake port entry in the head was 24mm or a little over. My goal was to make it closer to 24mm all the way from carb outlet to port inlet. I used mostly drum sanders on the Foredom to open the intake up and smooth out the turn the best I could, then matched the spacer to the intake and port.     Here's the exhaust port prior to any work. Again, rough cast areas, poor transitions from the seat/cuts.     Pretty much the same deal as the intake is what I was after, smoothing and blending. It's just a lot harder to do in the little exhaust port. I would like the finish to be a bit more smooth, but essentially none of the bits I have that would work for smoothing it out better wanted to fit in there very well. I had some finer stones, but they disintegrated quickly and left the bare metal shaft to gouge what was just smoothed at times. I didn't enlarge the outlet any more than needed to smooth it a bit because the header ID is less than the port ID in stock form.   I didn't touch the combustion chamber, because I think the loss of compression could be worse than any positive gains from fiddling around in there. I lapped the valves and put the head back together.  I wanted to put the piston and cylinder back on to check squish/quench clearance to see what options there may be for increasing compression. When I went to install the piston, I noticed a problem. The groove for the crirclip is deformed. Pics below show both sides for a pretty much normal and then jacked up view.   The clip seems to fit in there fine and feel as secure as the opposite side that's not damaged. That said, I've had too many circlips that looked fine to me come out in the past and ruin things to trust a setup that appears to be damaged. I looked for a replacement piston and they can be found for roughly $15 in stock form. I tried to find a high compression piston for the stock bore, but didn't have any luck there. While I was searching for a high comp version, a 58.5mm big bore kit with a high compression domed piston was in the results. I had actually done the math for a 58.5mm bore after checking compression, prior to this discovery. I don't really think the jump to 155.36cc will accomplish much, but I thought if a kit were cheap enough it may be an easy way to boost compression. It's kind of hard to know what you'd get with a a new cylinder kit, so I just used all specs from the stock engine and replaced the bore where needed. All else equal, the compression would rise to 9.98:1. At that point it seemed like the BBK would only be worth it if I didn't have many options or if it were cheap. After seeing this, I used those numbers again, but assumed the piston would no longer hold 1.1cc vs a totally flat top piston. Again, I have no idea what the dome actually displaces. Using 0cc instead of 1.1cc, the compression ratio goes up to 10.59:1. That seems like it could be worth it if the price is right. Well, the price was under $54 shipped from gy6racingteam out of Puerto Rico via eBay, so I bought it. I really have not had the intention to spend much on this thing, but I keep finding things that don't look or work right everywhere. I think the $2000 Vespa GTS 300 that I foolishly passed up would have been a solid investment, but then I want to work on a GY6 anyway to learn a little about them so I'll continue to deal with it. It's going to be very sad if a "big" bored, cammed, ported, timing advanced, tuned, GY6 still can't get me to somewhat reliable 50MPH cruising like the mild Minarellis. Meanwhile, everyone else is going faster on their 80cc 139QMBs somehow. |

|

|

|

Post by jkeney on Apr 4, 2016 14:22:29 GMT -5

I have ordered from them and been blown away at the fast shipping, packaging leaves something to be desired... Forks in a dog food bag.

|

|

|

|

Post by niz76 on Apr 4, 2016 20:55:03 GMT -5

Lol must be the same guys I got a flywheel from off ebay- it also came quickly and packaged in a dog food bag!

|

|

|

|

Post by 90GTVert on Apr 4, 2016 22:01:49 GMT -5

I've mentioned that the brakes suck on this thing. I wanted to get the front working a little better and when I searched for a brake hose, a listing for a cheap braided stainless hose came up. Wasn't really sure if it was any good, but I thought it should at least be as good as a stock hose.  Here's what showed up.  I contacted the seller and they said that's all they have, no braided hoses. Seems like you'd take the listing down or change it, but whatever. They told me to keep the hose and gave me a full refund, just don't leave them feedback on amazon. Now I wanted to try a braided hose just out of curiosity to see if it would make any difference that I would notice. I went for big brands searching this time. I ended up going with a Drag Specialties 38" -3AN hose with clear cover. I needed fitting to go with it so I got Russel straight and 35 degree angled chrome -3AN 10mm banjo fittings. It came to about $50 total. I also got a stock replacement master cylinder.   You can find cables from manufacturers like Goodridge and Galfer that are complete with fittings, no assembly required. You can find them in multiple colors and options. I chose what I did because they were the cheapest options I found that I knew I could trust the quality of with the fittings I wanted. Just in case it's of any use, here are pics with part numbers.     Installing AN fittings like these is simple, but just a small amount of info in case anyone goes this route. First, don't treat these like pipe thread fittings and use thread tape or pipe dope on them. They don't need it because they don't seal via the threads. If you look at the ends of the male and female fittings, they have angled bits that correspond to seal.   The fittings screw together, but some (like these) don't have a spot for a wrench to grab them. I wrapped a shop towel around them a few times and put them in a vice somewhat gently. Then I used a line wrench to tighten them together. You can also find specialty AN wrenches, but SAE line wrenches work pretty well. A regular open end wrench works, but you're more likely to damage a fitting.    Ready to use.  I removed the stock ABS unit and then installed the new hose and master cylinder and bled the system.    Another thing I've forgot to post about... a little while back dude posted about JIS screwdrivers. I picked up a set on amazon shortly after. I've found that they really are better at getting screws out of some bits of scooters. One being the master cylinder cap. Those things can be a pain when they get tight, but a #2 JIS screwdriver has worked much better for me.  Once the system was functional, I had one chrome brake lever and one black. I went to swap the old chrome one on, but they are different styles.  |

|

|

|

Post by 90GTVert on Apr 6, 2016 21:22:11 GMT -5

I was going to leave the stock exhaust, but I thought with a cam, more compression, porting, and pod filter; maybe I should try a different pipe. I started by picking up a header. I didn't want to spend a lot so I went with a $30 (+ shipping) header from gy6store2015 on eBay.  It's a little larger than stock. Not huge like some GY6 headers on the market (that carry matching price tags). The stock header is 19mm ID at the inlet and outlet. The new header is 21mm at the inlet and 22.5mm at the outlet.   Unfortunately the bends are low quality and pinch down, but they're still a little larger than stock.    Now I need a muffler. Ah, my muffler kit arrived! *Some assembly required. I didn't want the perforated tube/glasspack muffler that pretty much every other four-stroke scooter uses. Years ago, I built a chambered muffler for this scooter's previous owner. It was a small version of a chambered muffler like you could find on modified cars and trucks. The boxy design was not very appealing, but I loved the sound. It was more deep and mellow than other small engine pipes I've heard. I used to turn around thinking some car or truck was coming up behind me at red lights when we rode together because of the low rumble. I don't think the video did it justice, but this is it : There were 2 issues with it. I already mentioned the appearance. The other problem was that it developed some nasty rattles over time because I struggled to get it all welded with the way I assembled it. The goal here is to have a cylindrical version that I could construct in a way allowing me to weld each piece so it won't rattle apart later. This is the design I used.  I also didn't want to spend forever fabricating it. This stuff always takes time, but I'm not going to build domes so I needed to source those. I used 16 gauge 4" OD exhaust pipe for the casing. The domes were 4" OD post caps that are 0.100" thick. I planned to buy a sheet of 16ga steel to cut the other baffles and use a piece of 1/8" I had for the flange end, but while searching for domes I found an ebay seller offering 4" OD discs in 1/16" and 1/8" thick at a low price. I ordered some of those and a couple of 6" discs in case I had some use for them and the cost wasn't that much worse than if I just bought a big sheet of steel, but it saved a ton of time for me. The ebay seller for the discs was lumberjack1983. The pipe caps came from 114pressman on eBay. Altogether, I spent about $60 for the metal and have spare metal. I traced the header's outlet flange onto the 1/8" steel disc and drilled the bolt holes and a small hole in the center. I matched the flange to the header. Then I made the flange slightly larger than the header so if there's a little mismatch it will open up rather than hitting a lip. I welded nuts to one side of the disc to make bolting it up easy.     The first dome had to be cut down so it could fit inside of the 4" pipe. The rear baffle is a 1/16" disc cut to fit the pipe. Both have just over 1 1/8" holes in their centers. The end piece is a dome with a hole matching the size of the inlet of the muffler. The < baffles are 4" discs that I bent and took a little off to make them fit in the 4" pipe.    Then I cut the 4" pipe into pieces so I could weld 2 things into each, making it possible to weld each thoroughly. Here are the parts laid out in order.  I assembled each section. I welded around each baffle as much as I could to help avoid rattles.   Then I welded all sections together.  Lighter and smaller than stock, even with the thick steel domes and flange.  With the header.   I need to do something for a support bracket, possibly tabs that line up with the stock support bracket locations. I'll have to get the engine together to see how it all fits first. Tons of BBs all over it still from the flux core welding too. Hopefully it'll sound decent. I'm not sure what to think. I definitely don't have the same volume as the big can did and the cylinder may change it up too. |

|

|

|

Post by 49dykon on Apr 6, 2016 22:16:45 GMT -5

DUDE! This is cool as hell! Pardon my french. Im wanting to come up with something like this for my 50cc

|

|

|

|

Post by 49dykon on Apr 6, 2016 22:17:07 GMT -5

Excited to see how this lasts and sounds! All the 50cc performance exhausts i have bought on ebay dont come with brackets and end up braking off at the beggining of the muffler

|

|

|

|

Post by niz76 on Apr 6, 2016 22:35:05 GMT -5

Better order more materials- I have a feeling you may be getting some orders in for those! ;P Very Nice alternative to what's out there!  |

|