|

|

Post by 90GTVert on Apr 25, 2011 13:58:48 GMT -5

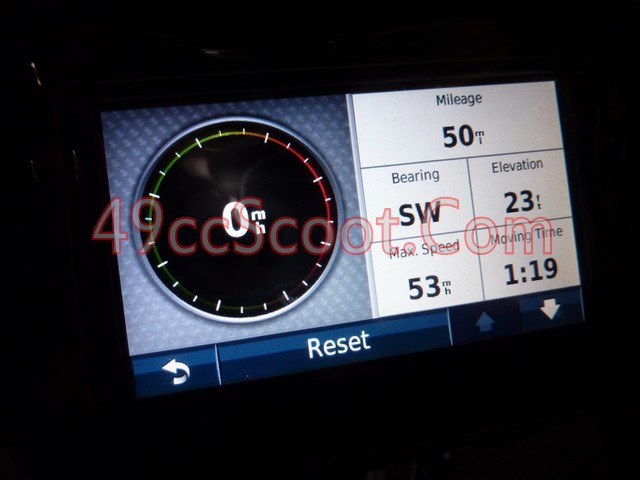

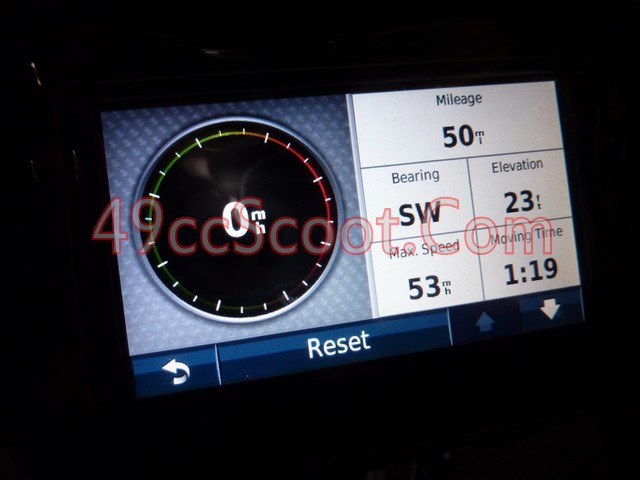

This is a condensed version of a thread in the builds section with just the info. Check out the other thread HERE. Project 90"Project 90" is or is going to be the testing and modification of a 90cc engine. I will be trying to document the tuning and modifications from bone stock and beyond in an attempt to help others that have chosen to swap up to a 90cc Minarelli engine. While the information will hopefully be useful to the 90cc crowd, I hope it will at least be somewhat relevant for the little brother of that engine, the 49cc Minarelli/Jog/1E40QMB. I'm sure I'll forget to document some things I should, and there will be problems here and there as always. I know I could just bolt on a big bore kit and throw in a stroker crank and get the wildest pipe and so on to take the "easy" route to max performance, but that's not what this is about. This project may never be anything that special in terms of performance, but if those reading this and I can learn from it, I feel it would be a success. Perhaps when I'm done with it, I can condense this thread into a smaller thread with just the facts and figures so to speak, that may prove useful for 2T scooter enthusiasts. We'll have to see how it goes. Those are my basic goals though. I must say, it feels strange to start a build with this sort of goal. I'm more accustomed to shooting for a performance figure. Let me start the project off by showing you exactly what "Project 90" is starting out as. I picked up this engine cheap on eBay. It is a 49cc Minarelli that has been machined and fitted with a 52mm bore and a 42mm stroke, to make it 89cc just like most engines advertised and sold as 90s.  I went through the engine and discovered that the manner in which it was done would allow me to get it into stock trim. Only the necessary porting had been done, the crank is a stock style crank, and the cylinder is a stock setup. Anything that was not on par with a stock 90cc engine was swapped out for appropriate parts. Stock gaskets and clearances were used to the best of my abilities. The CVT was setup as commonly found stock on 90cc engines as well.  Specifications Specifications(As The Project Begins) Bore : 52mm  Stroke : 42mm Note : This shows the travel from BDC to deck as the engine came to me, not the full stroke.  Displacement : 89.2cc Cranking Compression : 150psi  Squish Clearance : 1.49mm Note : The stock cylinder head is not a squish band design, as illustrated in the images below. The squish clearance stated is the minimum clearance from piston to head.   Exhaust Duration : 172°  Transfer/Boost Duration : 118°  Carburetor : Stock 49cc/90cc Note : Most of the Minarelli engines from 49cc to 90cc or so use the same style of carburetors stock. There are some slight variations in styles, and jetting may vary from one scoot to another. UPDATE : You will see me call this a 14mm carburetor throughout the project. I have since learned that most stock carbs are actually 16 - 16.5mm. Main Jet : 78 Pilot Jet : Unknown size, stock. Needle : Stock. Clip in center of 5 positions. Air Filter : Stock airbox Intake : Stock Reed Block and Reeds : Stock Fuel System : Stock tank, 1/4" hose, 1/4" fuel filter, manual petcock. Exhaust : Stock 49cc.  Oil Delivery : Pre-mix. I removed the stock oil injection system in favor of pre-mix in order to provide consistent oiling with any modification. I am using AMSOil Sabre Professional 100:1 Premix, mixed at 50:1. Ignition System : Stock CDI, stock stator/flywheel, Bando coil, NGK BR8HS spark plug. While the coil and plug are not stock, the plug is a stock replacement. The coil should have little to no effect on performance. The only time I've really seen much change with aftermarket coils or spark plugs is on much racier engines, and even then the difference tends to be small. The main benefit tends to be easier starting and more resistance to spark plug fouling. CVT Belt : 788 17 28 Bando Roller Weight : 6g Contra Spring : Stock 90cc The image below shows a 49cc contra spring (also called a torque spring or main spring) vs a 90cc contra spring. 49cc on the left, 90cc on the right.  Clutch Springs : Stock Final Drive Ratio : Approximately 10.125:1 Note : I measured the final drive ratio by counting the revolutions of the clutch bell vs one revolution of the rear tire. It rotated roughly 10 1/8 times. That should cover most of the specs. To sum it up, it's pretty much all stock. The exceptions being pre-mix instead of oil injection, a manual fuel petcock instead of a vacuum fuel petcock, an NGK spark plug, and a Bando ignition coil. I chose the stock carburetor setup from a typical 49cc Chinese scooter as well as the stock exhaust from a Chinese 49cc scooter, because I have had many people ask me if it's O.K. to use these components on a 90cc engine. This engine has been installed in my stripped down Triton, that most of us here know as T2. The lack of fairings allows for much easier access for repair and adjustments, which is an incredible benefit for this particular project.   Other Info For Reference Other Info For ReferenceElevation : ~40ft Above Sea Level Rider Weight : 260lbs Fuel : 91-93 Octane (Premium) I have more info to share, but I'm going to take a little break from typing and uploading. I may go out and gather more data? ;D |

|

|

|

Post by 90GTVert on Apr 25, 2011 13:59:23 GMT -5

For the first try, I wanted to leave the carb just as I got it. I was definitely thinking the 78 main jet was too small, but it seemed like a good idea to see just how close it may be by doing nothing but transferring the 49cc carb and exhaust onto a 90cc engine. Again, thinking this may be useful for folks attempting a swap of their own. Besides, I knew I had someone to call with a truck for the worst case scenario. As the video and pic will show, I got it up to 51MPH GPS. I believe it could have gone just slightly faster, maybe 1-2MPH, but it was too lean and would begin to drop off after WOT or close for much time. One cool thing is that I did get a soft seize on video for the folks that have never experienced this, or have but didn't know what it was. It was very mild and restarted easily. Sorry the camera gets kinda wild at times, I hang it from the zipper of my jacket so you can see the gauges a bit.  I should also note, I realize it's not the best idea to push it after even a very mild soft seize. As I said though, I knew there was someone with a truck if I needed it, and I never gave it much gas till I was very near my house. I also tried to keep it as brief as I could. For those that don't know, you are likely to have at least some scarring of the piston, rings, and cylinder walls every time the engine seizes, even when it seems so minor like in the video. Heat is causing the aluminum piston to expand more than the iron cylinder, and with enough heat and expansion the friction is just too much and the engine will die out as you saw there. For comparison, a seize or hard seize is when the piston won't budge in the cylinder again, even after the engine completely cools. A hard seize will require engine disassembly and inspection. At very least, you will usually see rather severe scarring. Here's a pic of this cylinder after soft seizing.  Max RPM on that ride was 8,160. I was pleasantly surprised that the CVT setup was reasonably well in tune for stock. |

|

|

|

Post by 90GTVert on Apr 25, 2011 14:00:31 GMT -5

After the first ride, I decided to take a very simple approach to the initial tune. I looked at the plug and used my experience and feel on the first 5 mile ride to simply guess at a main jet size. After seeing so many people having trouble with 90cc swaps, I wanted to attempt to show that it really shouldn't be all that difficult to get into some sort of ridable state. Not likely to be a great tune, but something able to get you down the road. I decided to go with an 85 main jet and left everything else the same. I went out for a 33 mile ride that night. Power output at WOT felt similar, possibly less. After all, engines do tend to run a little harder when they're lean. With the larger jet, anything much below WOT was noticeably rich. This was very obvious in town having to stop and start a lot and maintaining lower speeds. It took more throttle than I felt it should have to get the RPM up and get moving. Riding on long stretches out of town was done at around 40MPH most of the time. In town I tried to go relatively easy on it as well. I stopped to fill up before I got home so I could calculate fuel economy. I used 0.741 gallons of gas in 30.41 miles, which comes out to 41.04MPG. That number was less than thrilling to me. I was really hoping it would be much more fuel efficient with the small carburetor, stock setup, and normal riding. I had hope though, knowing it was not quite in tune yet.  |

|

|

|

Post by 90GTVert on Apr 25, 2011 14:00:31 GMT -5

My project for the next day was to get the carburetor in a better state of tune, rather than just guessing at it. I started out by swapping over to a new spark plug. Here's how the previous plug looked after riding. Very oily. I noticed that the gas in my fuel filter was darker that normal, appearing to be more saturated with 2T oil than it should be. I assume some of the oil settled to the bottom after I mixed at the pump, not a problem I normally have with this oil. Just to be sure the mix ratio is correct, I drained the tank and then mixed that with a little over 3 gallons of pre-mixed fuel. Other than the little bit from the filter, the color of the rest of the fuel looked about right, so I believe it should be very close to normal.  After installing the new spark plug, I made a WOT pass up and down a stretch that's maybe 1/2 mile long and killed the ignition just before the driveway. Max speed was 48.49MPH and max RPM was 8,240RPM. Again, this is the 85 main jet. For these test runs, I am using the onbard Sigma speedometer, rather than GPS. It's very close to the GPS and easier to use for tuning runs. The TTO tach flashes the max RPM after the engine is shutdown, which is quite handy for this stuff. All runs were made sitting up. Here's the plug from that run. Notice the mixture ring (the bottom of the porcelain insulator, where it meets the steel part of the plug) is a deep caramel color. I should also note for this and future photos, the flash of my camera tends to make spark plugs look lighter than they really are. Without the flash, you can't really see what you need to see.  I then moved up to a 90 main jet for a pass. Max speed over the same distance was 48.02MPH and max RPM was 8,020RPM. When looking at the spark plug from this pass, it appears to be lean at a quick glance. However, knowing the condition of the plug with the previous smaller jet, noting the pattern of coloring on the plug, and noting the excess fuel/oil on the end of the plug, I believe it to actually be rich but lighter due to excess fuel cleaning the plug.  Just to be sure, I stepped up to a 95 main jet. The first thing I noticed was very hard starting after the installation of the larger jet. Once it fired up, the sound of the engine was deep and "sputtery" for lack of a better term. In fact, it was so ric that I never even took it on the road. I had a hard time even getting it moving. I ran it WOT through the yard, and it felt like it took forever to hit it's max speed of 12.97MPH at about 5,000RPM. If the horrid performance wasn't enough, the amount of raw fuel on the plug makes it very apparent that the engine is running incredibly rich at this point.  I went back to the 85 main. I never tried below the 85. I know the 78 main that was originally in it was so lean that it soft seized after only a brief run. That, coupled with the 85's reading, made me feel safer sticking with the 85. Farther tuning could be done if looking for max performance with in-between jet sizes, such as 87-88, but I did not have those size to try. I feel that there would be a very minimal change in performance at best, if any. |

|

|

|

Post by 90GTVert on Apr 25, 2011 14:01:45 GMT -5

After dialing in the main jet, I addressed part throttle and idle tuning. I knew the part throttle tune was way rich, but I did a plug chop from 1/2 throttle anyway. I did this on the center stand, while slightly applying the rear brake to provide some load. This would be best done riding under load however. This is quite obviously rich.  I moved the needle clip from the center position to the uppermost position, to move the needle down and make it leaner. When I fired the engine up again, my idle had went from the previously set 2,000RPM to about 4,000RPM with the rear tire spinning quite fast. I knew it was rich before, but I didn't have enough adjustment in the mixture screw to get it right without swapping pilot jets. Leaning out the mix with the needle did the trick without needing a new pilot jet. I adjusted the idle RPM, then adjusted the mixture screw until the engine was running smoothly at the highest RPM achievable through adjustment. Then I turned the screw back in about 1/8 of a turn to leave it slightly on the rich side. With that set, I readjusted the idlle to right around 2,000RPM. With all of that complete, I repeated the part throttle plug chop. Still looks rich, but again it's not under full load.  After one last check to make sure the throttle response was good and the engine ran smooth in different throttle positions, I was ready for another test ride. I took a 31 mile ride last night. It was obvious that, even with the main jet the same, the part throttle and idle tuning had done a lot of good. I needed to use less throttle to get going, since the engine was not loaded up with fuel so much. It was easier to regulate speed with less throttle. Throttle response was much improved. Overall, the additional tuning made it a lot more enjoyable to ride. This made me eager to see what sort of gas mileage I would get. Riding basically the same way and with more wind (the previous night was calm, winds were about 15MPH last night) I got 45.09MPG. That's a 4.05MPG increase, just from getting in a better state of tune. Since it was windy, I don't know that the speed is good for anything. I made sure to cruise easy when I happened to have a tailwind. I tucked down on a short straight that goes through some trees, so I was protected from a crosswind. The max speed shown by the GPS was 51MPH once again. No pic this time. I thought you'd get tired of seeing 51, 51, 51,.... I wanted to note, you probably won't see me giving all of those details every time I have to tune for a change. I just wanted to give some illustration of the process I use for tuning at least once during the project though. Again, I felt it may be helpful for someone. |

|

|

|

Post by 90GTVert on Apr 25, 2011 14:03:15 GMT -5

With the carburetor in tune, of course the CVT should be the next focus for getting a scooter dialed in. Even though I didn't expect any real gain, there was one thing bugging me on every ride so far. The stock clutch springs are so weak that the clutch engages as soon as I touch the throttle. Once it heats up, at times the clutch doesn't even fully disengage at stops. I hate that feeling, so the first step for me in CVT tuning is to swap out the clutch springs. I only had 1,500RPM and 2,000RPM clutch springs. I chose the 1,500RPM springs since the stock 90cc makes so much torque. I don't really need to rev it high just to get going. It may jump off the line slightly faster with stiffer springs, but it's slightly more street friendly and less attention getting the less you need to rev to move.  I also decided to vent the CVT cover in order to keep the clutch, and CVT in general, cooler. The cooler it stays, the less things tend to wear and the better the springs and clutch act after some riding time.  I took it out for a ride this morning to make sure the venting and springs were working well after a chance to get some heat in them and took the GoPro along. The first little bit shows that even after 12 miles or so everything's still functioning well. Later, you'll see me pull out and head to a red light. The acceleration you see there is faster than normal. It was really windy today. I was fighting 20MPH headwinds for 10 miles to town. It would maintain upper 30s and just squeak into the 40s with a dead on headwind. That's the first time I've rode a scoot lately and really felt slowwww. Still, it's a heck of a lot better than a 260lb rider would be doing with a 50cc. As you see in the video, when I left a light the throttle snapped. I haven't looked at it yet, but I'm pretty sure I know what it was. I bought a Motion Pro throttle cable since the price was about the same as stock. I had to mod the cable, because the Motion Pro wouldn't work with the stock carb. Thought it was supposed to. I had a hell of a job getting the carb end of the cable to stay soldered on after I had to mod it. I finally got it secure, but now approaching 100 miles later I think it's popped off again. I did this to the Venus and have had 0 problems once I figured out the process. This cable just really didn't seem to like solder. If I can't get it to stay well, I may need to mod the stock carb or get a new cap if that's possible. I had to rethread the stock carb to accept M6x1.0 thread instead of whatever it was stock in order to use it with the Motion Pro cable. At any rate, the clutch springs and cover vents were welcome additions. I also noted the amount of travel I'm missing on the stock variator faces. Once the throttle setup is repaired/replaced, I'll be looking into the CVT some more.  |

|

|

|

Post by 90GTVert on Apr 25, 2011 14:04:05 GMT -5

The CVT seems pretty well in tune, as far as weights and the contra spring. That doesn't mean I can't still try to improve the way it feels and acts though. In particular, I had belt travel on my mind for this next mod. This first picture shows how much marker is left on the variator after running the scoot at it's max speed of 51MPH. 5.81mm is a good bit of variator being put to no use on the top end of the gearing.  This next image shows how close the two halves of the front pulley could potentially get, assuming the rest of the CVT tune and engine power allows it. Just shy of 16mm. If you are thinking, "but my belt is 17mm stock", you don't actually have to grab the whole belt when it's at full travel for max performance. On some of my other scoots I've had the outer edge of the belt beyond the outer edge of the variator. Also, in reality most 17mm belts are shy of that be 0.5mm or more sometimes when new. After the belt is worn it can easily get to 15mm, less if you allow it. For these, you should be replacing the belt around 15mm however.  The other side of gearing is your "first gear", or the initial position of the belt that gets you off the line. The easiest way I know of to show you where the belt is at that point is to show you how far up it rides in the rear pulley. Showing how far down the belt travels in the front would be nice, but it's harder to get a picture of. Here's the belt in the rear pulley with everything stock. I've seen worse, but there is definitely room for improvement.  Here's a look at the front pulley in stock form, all the way open.  My first plan of attack involves this little lip built into the variator fan, or fixed half of the variator. As you can see it's roughly 1mm deep.   My thought is that by removing this lip the front pulley can not only open wider, but also close roughly 1mm tighter than before. In theory, that should allow for the belt to ride lower in the front pulley and therefor higher in the rear pulley for an improved "first gear". One would also think that closing the front pulley a little more should allow the belt to ride farther out in it's max "high gear" to increase potential for top speed. The lip can be easily filed off and then sanded to remove deep gouges if you use very rough files. You could also use sandpaper and glass ( as described here) to accomplish the same thing. A lathe, a belt sander, there are all sorts of ways to do it. Just be sure to keep it even so your pulley isn't lopsided. I cheated and used another stock fixed half that I had done in the past... kinda like how the TV chefs pull a dish already cooked from the oven. ;D  Here's a shot of the pulley all the way open after filing the lip off. A little more room now for the belt to start off lower, closer to the drive boss.  Once it was all installed, you can see that the belt is riding higher in the rear pulley.  This image shows that the front pulley will close roughly 1mm more than before for it's max top gear. From 16mm initially, to 15mm now.  Here's a video of the first test pass. Initial launch is slightly improved. It seemed to be struggling a little more with the speed above 43-44 though. The leftover marker now shows 6.6mm of unused space on the front pulley, more than before, but I was not that concerned. For max speed and belt travel, I usually tuck down as far as I can and give the scooter plenty of time to stretch it's legs on flat ground. During the day, when there's usually no one else around to watch my grandmother, I won't go very far at all on a test pass so if I do breakdown I can get back fairly quickly pushing the scooter. I generally get out at night when there's no traffic and no time limit to stretch it out as much as it will go.  Even without any increase in top speed yet, I still felt like I was on the right track and I did see some improvement in acceleration from a stop. The fixed half is not the only part of the front pulley with a little excess material that can keep the belt from getting all the way down in the front pulley or from closing as tight as possible. As you can see here, the movable half has roughly 2mm of aluminum protruding past the brass guide for the drive boss.  I began by filing the center down.  Before filing and periodically during filing, I kept check on the ramp plate and guides on the rear of the variator. You can sit the variator face down on a flat surface. Then put the drive boss in place and sit the ramp plate on top of that. You want to make sure that you don't file so much of the variator's face away that the ramp plate will clear the guides. Try to leave a little extra room, not just right on the edge, to be safe. If the variator and ramp plate separate so much that they are able to move freely from one another, they may not line back up on deceleration easily or at all. I've done this before and ended up with variators that constantly break the plastic guides on the ramp plate and damage rollers and at times even stuck in high gear.  I went a little farther than just filing the face flat. When the center of the face is flattened out, sometimes you end up with an odd spot in early acceleration. Flat filing creates a very abrupt transition from flat to angled surfaces. I sanded and filed to smooth out that transition better so there's less of an obvious ridge on the face.  I left a bit of a lip, but not much. As I noted earlier, trying to stay on the safe side and keep the vari and ramp plate in line with each other.  While I was at it, I opted to smooth out the transition on the fixed half as well.  You can see there is even more room for the belt to get low in the front pulley.  This is even more clearly demonstrated by how far out the belt can ride now in the rear pulley.  Now the two halves can close up within a bit over 14mm of each other.  With the variator marked again, I went for a second quick test pass. The video didn't turn out so great, but you aren't missing much vs the first one here. Takeoff was improved slightly more. Top speed was 48MPH this time. Upon disassembly, I found that I had still less belt travel than last time, even though I was going a little over 1MPH faster. Seems a little counterintuitive, but that's the result.  Once I could get out for a few minutes more, I took a very brief ride so I could try full tuck for a slightly longer distance. Once again, I saw the 51MPH top speed that I'm getting very accustomed to. Max RPM showed 8,800.  Belt travel increased a bit from my shorter run, but it's still a little over 1mm less travel that I got before modding.  When I took the last ride, I placed the GPS and the GoPro under the seat together. I thought maybe I could get a video of the GPS recording the speed to show you, and I for that matter (can't see my speedometer at night), how it was doing. Seemed like a good idea, but the video turned out to be horrible. The camera was moving all over the place, probably because I hung it from that "rubber band" that attaches to the bottom side of the seat so it bounced and such. Definitely not good enough that I wanted to post it. It did at least allow me to see, in a bouncy blur, my speeds creeping up. It's not terrible, but it has lost a little acceleration from about 45MPH to max.  To sum this modding segment up, if you go back and look at the pics of the belt in the rear pulley at start and finish, you can clearly see that I made an improvement in the "first gear" ratio for the better. The more free feeling caused by the belt not binding as much at a stop or on launch also makes it feel a little better to pilot. You can also see that I clearly have made the front pulley's potential for closing greater, however I have not recognized this potential. In fact, I have made the actual belt travel less in top gear. Even given that, I managed to retain the exact same top speed. The only unfortunate part being that the last few MPH are a little harder to come by. For real world riding, most people won't be full tuck for very long, so I feel this to be only a minor setback. Even though the results don't show any great progress, I do feel like this mod is a good one. I have done this same type of mod, mostly on aftermarket variators however, in the past with much better results. I believe the reason I have not seen really positive results on the top end in comparison to past endeavors is the difference in engine power of this project and final drive gearing vs the others I have tried. I generally have started off by getting the engine tuned where I want it, and then moving on to fine tuning the CVT. For my own projects, I know where I want to be and I take the fastest path there. In this project I am trying to take some steps as I feel others may and wanted to try this early on because it is a free mod assuming you have a file and some sandpaper. My theory is that the scooter in stock form simply doesn't have the power to pull these gears with my weight significantly faster on flat ground. I do believe it's possible to go faster with the stock horsepower and gearing, but not by a great margin. The potential is there to go faster based on what we've seen here. One bright point is that I did the same top speed with 1mm less of belt travel. The CVT is operating in the proper RPM range for the stock engine. I think those facts support my thoughts. |

|

|

|

Post by 90GTVert on Apr 25, 2011 14:05:03 GMT -5

Before I even get started, I am sorry for the sound in some of the videos. It is out of sync in certain vids. I spent a lot of time on them and really wanted a good product. I'm disappointed to say the least. I viewed them numerous times before exporting the files. It seems PowerDirector9 has some sort of output issues with synchronizing sound and video. Again, I apologize. I have swapped out the audio on the worst of them. Rollers, Sliders, And ModsIn this segment, I'm testing roller weights against slider weights as well as seeing how the stock variator stacks up against the previously modded one. I did all of the swaps below and made all of the test rides in a very short time period on exactly the same stretch of road. This was done in an effort to keep results as accurate as I could by reducing variances in ambient temperature, wind speed, etc... Hope it helps! The videos in this segment are edited in the best way I could think of to really show the effects of each weight change or modification. It's sort of like watching the scooter race itself. Take note of landmarks along the way for an even better idea of which setups work best. You may notice that some of the quicker or faster setups at the end aren't winning the race all the way through. Roller Weight ComparisonThese runs were made to show the differences in light and heavy roller weights. I actually did these runs last, after realizing it won't do much good to show sliding weights with nothing to compare to. I only tried 5g and 7g rollers, because I was flat out of time to work and ride at that point. The lighter 5g rollers clearly have an advantage in early acceleration, but as you can see, the heavier rollers do start to catch up a little, exhibiting the same max speed over the distance, and I feel that they would prevail in a longer race over a flat surface if I stayed tucked down. I have been using 6g rollers, which I feel was the right choice. They provided good upper MPH performance as well as good starting acceleration. Sliding Weight ComparisonFor these tests, I'm using Dr Pulley sliding roller weights (sliders). Other manufacturer's do make sliders. I have a set of non-Dr Pulley sliders and they function much the same. The main difference I have witnessed is longevity. Dr Pulley sliders seem to be more resilient to abuse than the off-brand units. The image below shows the difference in a roller (left) and a slider (right). The specialized shape of the slider allows it to provide both increased acceleration and top speed potential.  For those of you unfamiliar with installing sliders, these pictures should show you how they are to be installed. It is very important to install sliders properly. Degraded performance or possibly even damage to the sliders or other components could occur if they are not correctly installed.    I only have 5 gram and 7 gram sliders at this point. The weights were staggered, as shown below, to achieve the effect of 6 gram sliders.   The testing... The 5g and 6g sliders are pretty clear winners here. Excellent acceleration and the same top speed. Again, as with the rollers, I feel that the heaviest sliders may show a slight advantage over a long flat stretch. The lighter sliders will function much better for daily use, providing quicker starts and more ability to maintain speed on hills and against the wind. Rollers vs SlidersNow that we have an idea of which sliders and rollers perform the best, we can compare their performance. It seems to me that you can make rollers accelerate off the line as well as sliders or perform at speed as well as sliders, but not both at the same time. The design of slider weights give them a definite advantage. There's not a huge difference in the two, but I'd say that's a decent difference for the cost of sliders. I paid about $25 shipped per set on eBay for these 15x12 sliders. To their benefit, roller weights can be had at much lower prices. Due to the lower cost of rollers, they can be a great tuning tool. Rather than buy many sets of sliders at $25 or so a set, you can usually find a "tuning set" of roller for just a little more that includes a wide range of weights. Once you get the weight dialed in with rollers, the slider you'll want to use will probably be the same weight or possibly up to 20% heavier I'd guess. The great advantage that sliders have over rollers that you can't see in these vids is that they tend to greatly outlast roller weights. I've used the smae sliders seemingly forever in some of my scoots without issue. Rollers tend to flat spot over time, which severely degrades performance. If you ask me, sliders are a clear winner. Variator ModsWhile I was testing, I wanted to sort of revisit the previous mods that I did to the variator and fan. For more detail on the variator mods shown and tested, see my previous update. I marked the variator with a Sharpie before every test. Below are the results of how much belt travel was left on the variator after each pass as well as the MPH achieved as shown on my GPS. Fixed face = variator fan. Movable face = variator. Description | Remaining Marker | Max Speed | Stock Fixed + Movable, 5g Rollers | 6.97mm | 49MPH | Stock Fixed + Movable, 7g Rollers | 6.50mm | 49MPH | Stock Fixed + Movable, 5g Sliders | 6.33mm | 50MPH | Stock Fixed + Movable, 6g Sliders | 5.44mm | 50MPH | Stock Fixed + Movable, 7g Sliders | 5.30mm | 50MPH | Filed Fixed + Stock Movable, 5g Sliders | 5.81mm | 50MPH | Stock Fixed + Filed Movable, 5g Sliders | 5.49mm | 51MPH | Filed Fixed + Filed Movable, 5g Sliders | 5.39mm | 51MPH |

One thing that the vid or the numbers don't illustrate is belt slip. I found that using the better performing 5 or 6 gram sliders along with the modified drive faces added belt slip. This did not appear to be a problem with the roller weights. In addition to the videos show here, I tried 6g and 7g sliders with the modified parts as well. It was less apparent with the 7g sliders, but belt slip was present with all of them at certain points. You can actually see right where it happens in the image below. Notice the area polished by the belt slipping as it transitioned from the flatter center section into the outer portion of the face. I believe this could be remedied with more time and effort exerted in blending the angles of the fixed and movable halves.  Here is a quick video where you can clearly hear the afore mentioned belt slip. This was with 6g sliders and both filed faces. Another thing that you can't see in the videos or the figures is the feel of the transmission with the modified faces. At idle and lower RPM, until the clutch engages, the engine is free revving with the modified drive faces. With the stock parts, the belt sort of binds in the variator so you don't get the full feeling of effect of later engaging clutch springs. Conclusion / My ChoiceSo out of all of the things tested, which did I decide to stick with? I chose to go with the stock variator and fan and 6 gram Dr Pulley sliders. Yes, a couple of setups showed a 1MPH gain over this one. Yes, I recorded more belt travel with a few other setups. Overall though, the 6g sliders coupled with the stock front pulley parts were as quick as any other setup under the tested conditions. Also remember that I took a 7 mile ride with each of those setups. All over the exact same course. The 6g sliding weights and stock parts performed on par with any other setup under those conditions. It was a very close call between the 5g and 6g sliders though. As you can see in the mod video, I was initially planning on using the 5g sliders. I feel that the 5g sliders would be a good choice if I were in a hillier area. The 5g sliders also show a benefit against the wind. The 6g sliders keep the cruise and max RPM just a tiny bit lower though. I felt like that may translate to very slightly improved fuel economy and engine life as well as possibly a higher max speed if I were to stay tucked for a long time or catch a tailwind while riding. If I had the option, I'd go with 5.5g sliders. The main deciding factor for choosing the stock parts vs filed was belt slip. While not drastic, I felt it may have a negative effect on drive belt life without showing any significant gains. Of course each rider must choose the combination that works best for them. Some riders will sacrifice more top speed for more top end. Others will be willing to give up some acceleration if it nets another MPH or two. Rider weight, engine horsepower and torque, CVT setup, gearing, tire size, and other variables will all change what works best for each scooter. I can show you how these things work for me, but only time tuning and learning what you like will allow you to choose the best setup for you. After swapping back to the stock variator and 6g sliders, I took the scooter for a ride to get a gas mileage figure. I filled up at 32.31 miles with 0.793 gallons of fuel, which is 40.74MPG. I have seen 45MPG in the past. I was riding just before a storm blew in and I believe fighting wind associated with the storm led to the drop in economy. It should be about the same as before, around 45MPH if I had to use less throttle without the wind. It reached 51MPH with me tucked, once again. I feel like I just need more power and it will easily give me more speed at this point. This seems like a good time to make a note about RPM. Unfortunately I kept forgetting to read the max RPM that the tach displays after the ignition is shut off to provide that data. What I can tell you after making so many trips with all sorts of weights is where the engine performs the best. With my current setup, best power is found from 6,000-8,000RPM with the absolute peak being from 6,800-7,800RPM. It will make power over 8,000RPM to help reach higher speeds, but those are the peak figures as best I can tell without the use of a dyno. |

|

|

|

Post by 90GTVert on Apr 26, 2011 22:21:51 GMT -5

Modified Stock ExhaustNext up, I'm gonna try out a few exhausts. I'm starting with a modified stock pipe. This is the exhaust that came on my 90cc Triton, that I modified as shown HERE.  I had some hope for this pipe, mostly because I noticed the 49cc stock pipe that has been on Project 90 was discoloring from heat. I thought perhaps that could be a sign that it was too restrictive.  I installed the exhaust and immediately did a plug chop, then took a short ride to see if anything seemed off. No tuning was necessary. I went for a longer ride that night. Fuel mileage was 38.6MPG, the lowest to date with this project. I was pretty easy on the throttle, but I did have to fight some fairly strong winds at times. Max speed was 51MPH. I tried to avoid getting help from a tailwind, but I may have had some assistance.  It appeared to me that power may have actually dropped slightly at higher RPM slightly. I'm not sure if it could be header length, internal design, better matching of the port to the pipe, or what for sure. All I know is that I would greatly prefer the ever so slightly better performing, quieter, unmodified pipe. |

|

|

|

Post by 90GTVert on May 13, 2011 8:11:02 GMT -5

The stock carburetor that I was using had some sort of malfunction. I tried multiple cleanings and looking into other possible issues, but no matter what I did it ran rich at all times with any reasonable jetting. 190mech was kind enough to send me an old stock carburetor from his 49cc minarelli powered CPI scooter. It is the other common style of stock carburetor on Chinese scoots and a genuine Mikuni. Even in rough condition, it works OK. The easiest way to identify the differentiate the two styles of carburetors at a glance is the cap. The cheaper carbs have a round top with a little tab for a screw to go through. This style has a flat and oddly shaped top as you can see below.   I cleaned it up and then added a new fitting to the cap to work with my throttle cable.  I was using an 85 main in the last stock carb before it's problems started. A 78 was the previous carb's stock jet and it seized with that as shown at the beginning of this project. I was quite surprised to see this carburetor working well with only a 75 main jet. I went with a 78 just to stay a little more on the safe side, still in disbelief that my jet size was changing this much. Needle clip in the center position. On a ride, I did discover that the midrange had a lean spot that was kind of dead, so I think the needle should have been raised a bit more. This is with the stock exhaust and airbox again to get a good idea if this carb changed anything. I went for a 28 mile ride and got 44.7MPG. Max speed was 50MPH. I think I could have squeezed out the extra MPH to equal what the other carb did with the same setup otherwise, but I had traffic to deal with when I tried to stretch it out. At any rate, it appears that the carb is not going to change performance so it should be fine for future comparisons. I would have liked to stay with the other carb and jetting that was working so my results for upjetting and other tuning for different mods would have been most relevant, but what can you do? |

|

|

|

Post by 90GTVert on May 13, 2011 19:08:37 GMT -5

Airbox Snorkel RemovalThe original plan was to test a series of exhausts. That was rudely interrupted by carburetor issues. Now that those problems have been ironed out, I decided to see if there is any benefit from removing the stock airbox snorkel. Removal is very easy. In some cases it may be sealed in. If your airbox is, you just need to use a screwdriver or sharp tool to free it up. If the snorkel isn't sealed in place, it should pull out pretty easily.   Here you can see the difference in size of the inlet with and without the snorkel. This snorkel on;y has roughly a 14mm opening. Without the snorkel it's around 22mm.  You'll get a throatier sound after removing the snorkel. It's not loud, but it is definitely louder. Nowhere near as loud as an open filter. I had to upjet from a 78 main to an 85. I also had to adjust the idle mixture. Be prepared to re-tune your carburetor completely if you do this mod. So was it worth the effort? I went for a 19 mile ride. Fuel economy stayed similar at 43.3MPG, riding a little more aggressively than the previous ride. It did feel like there was a slight power increase across the board. Nothing major, but any improvement from a free modification is a good one IMO. Max speed was 52MPH on GPS, my fastest speed to date with this project. I'm not sure that this mod would work so well on smaller displacement minarelli powered scooters, but it seems to work for the 90cc. All future mods will be done with the snorkel removed. |

|

|

|

Post by 90GTVert on May 14, 2011 22:38:50 GMT -5

Phongeer Exhaust [/b] For this installment, I tried a Phongeer pipe. The pipe was purchased for another of my scooters and meant to fit a Jog style short case engine. This caused a couple of problems on this long case minarelli. First off, I couldn't get the exhaust to bolt up properly because it hit this tab on the bottom of the engine case.  I noticed that the short case engine does not have this. I have no use for it, so I chopped it off and filed the edges smooth.  Now the exhaust would fit, but once I had it lined up and bolted to the cylinder it wouldn't fit up to the mounts properly.  I ended up making a bracket to bolt the pipe up securely while keeping it aligned with the cylinder's flange. I had to do the same thing, although the bracket is slightly different, for the short case engine this pipe was on.  With that out of the way, I finished up the installation. Nice looking piece.  Here's a sound clip. The pipe is very quiet. Not much different than stock. A good choice if you don't want to attract attention. I increased the main jet size from 85 to 90 and made a slight adjustment to the idle mixture setting. On test rides for the jetting, I noticed that there wasn't as much of an increase in acceleration as I was hoping for. I swapped to 5 gram sliders, from 6g, and acceleration was greatly improved. I went on a 37 mile ride with the new pipe and tune. The acceleration is a welcomed change. After about 7,000RPM the power increase is really noticeable. Power extends up to the mid 8,000RPM range, seeming to max right around 8,500-8,600RPM. Cruising speeds greatly increased. With all past mods, reliable cruising speeds have been in the lower to mid 40MPH range for me. With the addition of the Phongeer pipe, cruising speeds increased to mid 40s up to about 50MPH depending on conditions. Max speed was 53MPH, only a 1MPH increase. Fuel economy was the best to date for this project at 48.9MPG. That surprised me since I was actually pretty hard on the throttle on this ride.  The max RPM was around 8,850RPM to achieve 53MPH. That's definitely above what the pipe and engine combo likes at this stage, so I thought perhaps I could squeeze out a little more speed with heavier sliders. I swapped in 6g Dr Pulley sliders again and took a quick ride. Once again acceleration decreased dramatically, and top speed stayed the same. 5g sliders would definitely be a better choice for this setup for improved acceleration and responsiveness. So, the Phongeer exhaust didn't show great increases in top speed. 1MPH doesn't sound very impressive. However, the pipe gives a very nice boost to usable power to increase acceleration and cruising speeds. I believe it to be an excellent stealthy street pipe. Nothing flashy to make most folks think anything of it, but nice gains in the right areas to make riding much more fun than before. [/center] |

|

|

|

Post by 90GTVert on May 15, 2011 22:25:27 GMT -5

Leo Vince ZXNext up, I installed my Leo Vince ZX exhaust. This pipe was purchased for a 100cc Yamaha Aerox. It is not the more common 50-70cc version. I have removed all restrictions, and then some. Details on the modifications to this pipe can be seen HERE.  This exhaust only needed a few washers stacked up to space it out. Otherwise installation is pretty simple.  Here's a vid with the sound revving and riding. The silencer has been repacked, but it's pretty similar to original in sound right now. The volume level is much louder than stock or the Phongeer, but not obnoxious. It definitely attracts more attention though, which can be good and bad. I increased the main jet to a 92, just one size up from what the Phongeer exhaust liked. Otherwise it was good to go. I kept the 5g sliders in place, knowing this exhaust has a higher powerband. I went for a 50 mile ride to evaluate the change and enjoy a bit of nice weather this afternoon. Acceleration is noticeably slower than with the Phongeer pipe, but still greatly improved over stock. Normally I would try to fix that with lighter rollers or sliders, but read on. Cruising speeds are good, in the upper 40s. Here's the bit that surprised me. Max speed was 53MPH. That's right, exactly the same as with the Phongeer pipe. Unlike the PG pipe, I had to wait a little longer for the last 3MPH. It got to 50MPH easily and would even cruise right around there at times. Max RPM was somewhere around 8,700-8,800. I know that this pipe makes it's max power nearly 1,000RPM higher. The reason that I didn't try to get the revs up is that I just don't think this engine likes to rev that high. The stock port durations are so mild that I don't believe it can make the best use of what the ZX exhaust has to offer at this point. With any exhaust, the power drops off above 8,500-8,600RPM. Unfortunately this mismatch and the higher powerband of the ZX makes it less pleasant to use than the Phongeer pipe which has a much broader range and is better suited to the mild cylinder. I have used this pipe on other motors, so I know it's got potential, but I think we're just seeing the importance of matched components rather than random part swapping for what is the "better" part. Fuel economy on this ride was 41.5MPG. I was quite hard on the throttle and dealing with crosswinds for a bit though.  So, disappointing as it may be, this pipe didn't function as well as the Phongeer. On top of falling short on power, the additional noise seems unnecessary when you don't have the horsepower to back it up. This can be a good pipe, but it's not if the cylinder is as mild as this one. That said, it's still a great improvement over stock. |

|

|

|

Post by 90GTVert on May 16, 2011 15:29:22 GMT -5

Leo Vince SP3 [/b] The last exhaust that I have around to try out on Project 90 in this phase is a Leo Vince SP3. It was supposed to fit an Aprilia Scarabeo 50 up to 70cc, so it's not exactly intended for the big 89cc minarelli.  The header and outlets are close in size to the stock 49cc exhaust. The outlet is just slightly larger on the SP3 though. SP3 is on the left in each pic.   The brackets on the pipe were already setup to work on a Chinese minarelli engine, because I've used it before on a 70cc.  This exhaust really hugs the wheel. So much so that I had to use spacers or it would be pressing into the tire.    Here's a sound clip and quick riding shot. Even a little tire spin thanks to some water on the garage floor. lol This pipe is very quiet. Most similar to stock, slightly quieter than the Phongeer. Jetting was moved to a 90 main with the needle set next to the richest position. I used the same 5g sliders just as I have with the other performance pipes. On a 17 mile ride, I saw 46.2MPG. Low and midrange power is quite similar to the Phongeer exhaust. Power at a little higher revs is not bad, but not as good as the PG and ZX pipes. Cruising speeds were in the mid 40s for the most part, while I saw upper 40s with the PG and ZX. Top speed once again fell right in line. 53MPH. That surprised me, seeing how it lacked the power at revs that the other pipes had. It seemed like once I tucked down it did alright though. I think I may have had a little boost from a tailwind, but regardless it was very similar to the pipes intended for a 90cc for max speed. Overall, I'd say it did quite well for a 50-70cc pipe on a 90cc. Well enough to make me wonder what a Leo Vince SP3 that's meant for this displacement would do. That said, I'd still take the Phongeer over every pipe tested at this stage. [/center] |

|

|

|

Post by 90GTVert on May 16, 2011 21:26:16 GMT -5

Free Flow Air Filter [/color] With all of the exhausts I have tested, I went back to the stock exhaust and stuck on a free flowing air filter. This is a UNI filter with a pre-filter from a cheap eBay purchased filter. From past experience, it flows the same as a UNI or close enough that I can't tell a difference.  I had to swap all the way up to a 100 main jet. The stock airbox used an 85 main with the snorkel removed and a 78 main with the snorkel in place. That's one heck of a change. I kept the needle in the same position as before (one from the richest), but I think it may have benefited from being set all the way rich. The biggest change is the volume level. Open filters are loud on two-strokes! This open filter is louder than any of the exhausts by quite a bit. I find it to be annoyingly loud. HERE is a video I did in the past showing an airbox vs a free flowing air filter. I went for a 27 mile ride, on which I got 44.4MPG being liberal with the throttle. I expected that number to drop with the addition of the large main jet. Power seemed about the same as stock with perhaps a slight improvement in cruising speeds which were low to mid 40s. I think maybe averaging a MPH or so above the stock airbox with snorkel. Top speed was unimpressive. Back to 51MPH. It almost seemed like the mild setup didn't know what to do with all of the air and fuel it could suck in.  This mod is really not for me.There would have to be a much more of an increase in performance to be worth all of the noise that an open filter makes. [/center] |

|