|

|

Post by gsx600racer on Aug 26, 2018 23:28:27 GMT -5

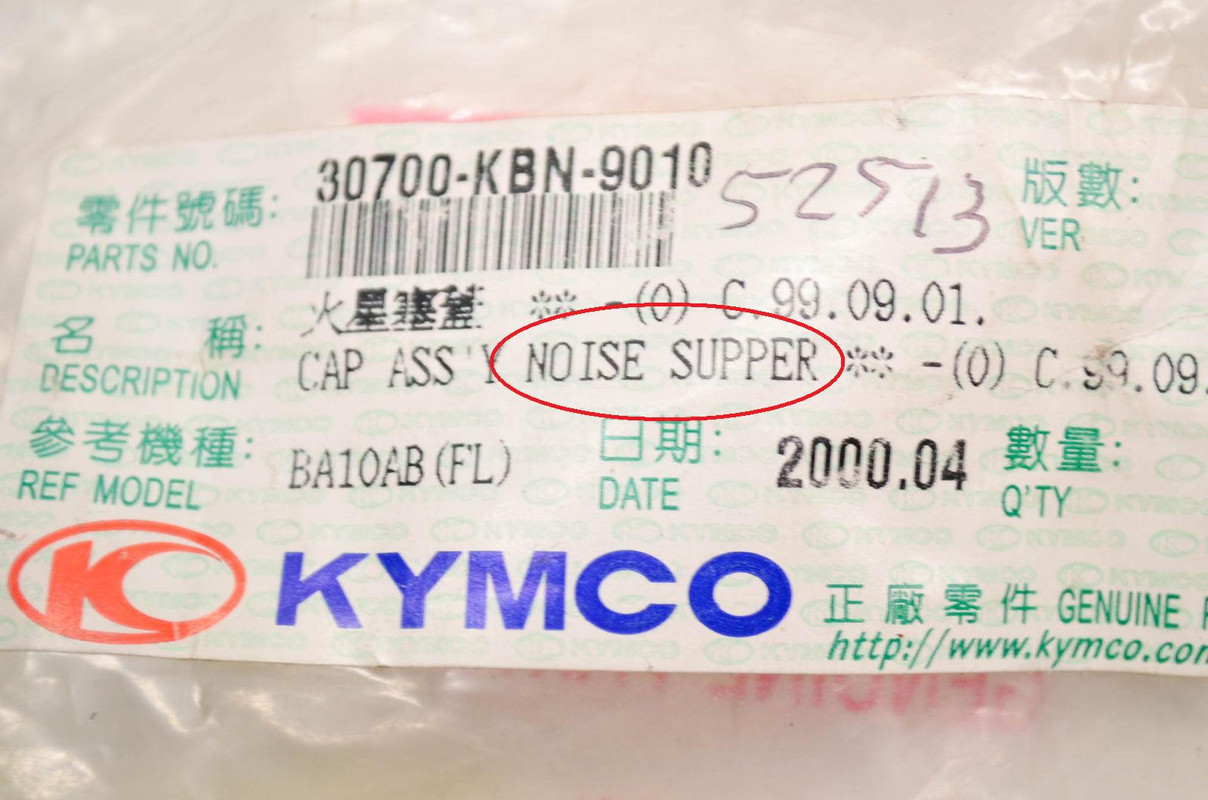

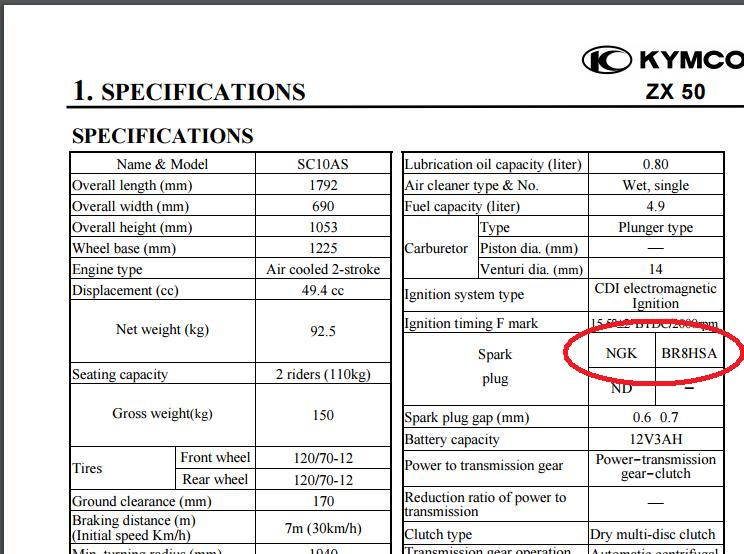

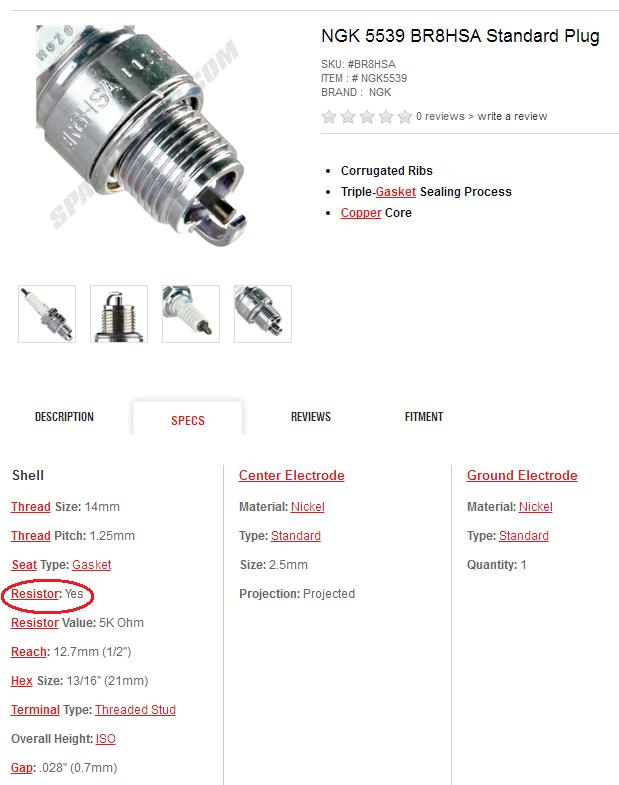

I wouldn't run resistor plugs or cap unless it was called for. Was the CDI originally a resistor cap? IIRC you can frizzle a CDI running resistors if they weren't meant for it. Good point. ZX 50's original spec's OEM # 30700-KBN-9010 spark plug boot  I going to assume that "noise supper(essor)" means resistor cap. I did tear down my broken one and there was a small resistor pill in it. The manual for the spark plug spec's is NGK BR8HSA, I am pretty sure the "R" is for resistor type.   I have a feeling with these 2 pieces of information Iv solved the problem. Right now I have a non-resistor spark plug and a resistor plug cap installed. Factory specs for both.  |

|

|

|

Post by tsimi on Aug 27, 2018 8:02:42 GMT -5

Have you ever tried a ES plug instead? BR9ES (5722) or BR10ES (4832)? Pig is running a 95cc LC setup and Ryan used to run the Airsal 77cc kit and both say they used the longer ES spark plugs and not HS for the LC builds. Could a too short spark plug be the cause of the rev limit? We both have a similar problem and if the ES plug would solve yours then it could also be the reason for my failure.

|

|

|

|

Post by gsx600racer on Aug 27, 2018 19:42:02 GMT -5

Have you ever tried a ES plug instead? BR9ES (5722) or BR10ES (4832)? Pig is running a 95cc LC setup and Ryan used to run the Airsal 77cc kit and both say they used the longer ES spark plugs and not HS for the LC builds. Could a too short spark plug be the cause of the rev limit? We both have a similar problem and if the ES plug would solve yours then it could also be the reason for my failure.

, I was only referencing the stock plug to verify that it was a resistor type and the plug cap/boot was resistor type as well. I am running the correct reach plug. I might not have the correct heat range though. I tried looking for a Peugot Speedflight manual with the correct info with not much luck. I based my choice on web sites that sold parts for that model. I started with the one on the left(non resistor) I am currently running the one on the right(box)  |

|

|

|

Post by gsx600racer on Aug 27, 2018 20:06:11 GMT -5

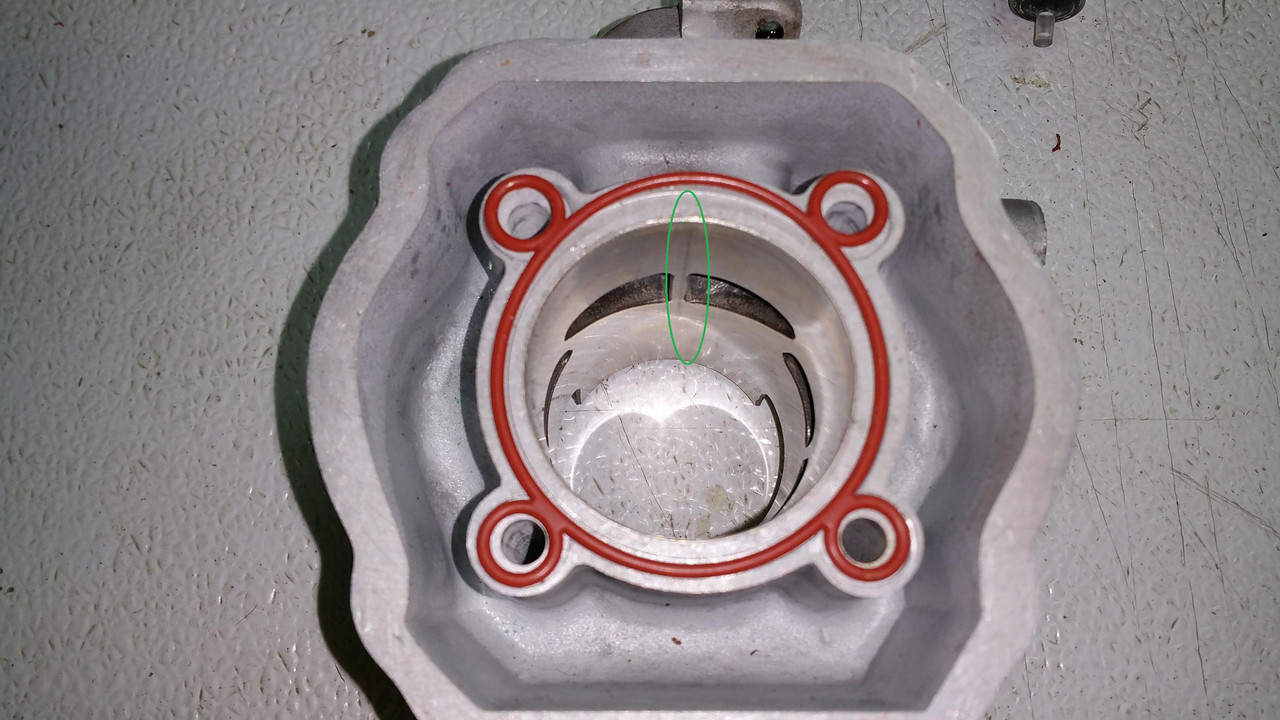

I took a short post-maiden voyage video. Things to listen to. @ 33 sec, stumbling a little at take off. @ 1:06 , stumbling when giving more throttle(was going up a decent hill) with non resistor plug, I could not do this hill. @ 1:26, stumbling when wot @ 2:07, wot takeoff stumbling @ 2:13, backed off wot and slowly rolled back to almost wot, stumbling went away almost. @ 3:06, total loss of power for a sec.(at top of the hill) I took a peek into the cylinder and seen this. I had a feeling this was happening.   I need to come up with a better way to seal the head with the shim, or have the head's squish/dome re-machined so I can eliminate the shim all together. |

|

|

|

Post by tsimi on Aug 27, 2018 20:19:32 GMT -5

You have coolant going into your cylinder?

Looks we don't have the same issue. You at least move forward where mine won't barely get to 3-10 mph.

|

|

|

|

Post by 190mech on Aug 28, 2018 3:55:43 GMT -5

That water is tough on the con rod bearings,another 'fun' fact with liquid cooling!!  |

|

|

|

Post by fly on Aug 28, 2018 8:19:17 GMT -5

What's your airbox/filter situation like? Wondering about float height as well.

The reason I ask is if you back off wot and and then wot again and it runs mo betta: I'm wondering if it's because the engine is upping the vacuum. With the throttle closed it'll still pull off the main, but it'll pull more air than the normal air/fuel mixture. Leans you out. So when you get back on the throttle it seems better for a bit.

If your floats are too high you're going to be rich, so more air could seem to alleviate the problem. And if the floats are not too high, maybe you need more air if you're still running the stock airbox.

Just a couple farthings

|

|

|

|

Post by gsx600racer on Aug 29, 2018 0:16:48 GMT -5

That water is tough on the con rod bearings,another 'fun' fact with liquid cooling!!  Yup, so much fun. LOL |

|

|

|

Post by gsx600racer on Aug 29, 2018 0:20:21 GMT -5

What's your airbox/filter situation like? Wondering about float height as well. The reason I ask is if you back off wot and and then wot again and it runs mo betta: I'm wondering if it's because the engine is upping the vacuum. With the throttle closed it'll still pull off the main, but it'll pull more air than the normal air/fuel mixture. Leans you out. So when you get back on the throttle it seems better for a bit. If your floats are too high you're going to be rich, so more air could seem to alleviate the problem. And if the floats are not too high, maybe you need more air if you're still running the stock airbox. Just a couple farthings Iv ordered a smaller carb, 24mm. I use a UNI air filter. My biggest issue at the moment is dealing with the coolant leaking into cylinder. |

|

|

|

Post by SMALL CC TEK on Aug 30, 2018 14:32:04 GMT -5

Nice build , you try a thicker o ring yet ? Or is that head flat ? Bet you cant go much thicker on the o ring Hmmm

how much pressure is in the system when running ?

|

|

|

|

Post by gsx600racer on Aug 31, 2018 17:37:57 GMT -5

Nice build , you try a thicker o ring yet ? Or is that head flat ? Bet you cant go much thicker on the o ring Hmmm how much pressure is in the system when running ? The o-ring is 2mm in diameter, maybe a scooch smaller. I cant find anything close locally. I run no pressure, I keep the fill cap cracked open, I have a small leak from the reservoir to the radiator fitting. |

|

|

|

Post by 190mech on Aug 31, 2018 18:01:32 GMT -5

|

|

|

|

Post by gsx600racer on Aug 31, 2018 20:45:26 GMT -5

Iv torn the top of the engine down and I am having the squish & dome re-machined. Going to push everything back the thickness of the shim so I can eliminate it.  I measured the CC volume of the head.  Dome volume(up to squish): 4.5cc Dome and squish(full): 6cc So hopefully I have a reference to follow after the head is machined for verification. Seems the cylinder o-ring grew a bit. Not sure if it was the heat, coolant, oil/fuel that made it swell.  I also noticed this mark on the cylinder wall and piston. I'm guessing it might be from the exhaust bridge expanding.   |

|

|

|

Post by ryan_ott on Aug 31, 2018 21:41:55 GMT -5

|

|

|

|

Post by Lucass2T on Sept 1, 2018 0:53:01 GMT -5

That would be a real flaw if that bridge bulged up...manufacturers should cut them back a few hundreds of a mm from the factory. Never had this problem with the my metrakit sp3 aka athena evo. Havent drilled oiling holes in the bottom of the piston at the bridge area.

When my cr500 cylinder (iron sleeve) got a hone the dude had manually cut back the bridge...to prevent the scuffing you found on your piston.

|

|