|

|

Post by 90GTVert on Jul 11, 2012 6:54:45 GMT -5

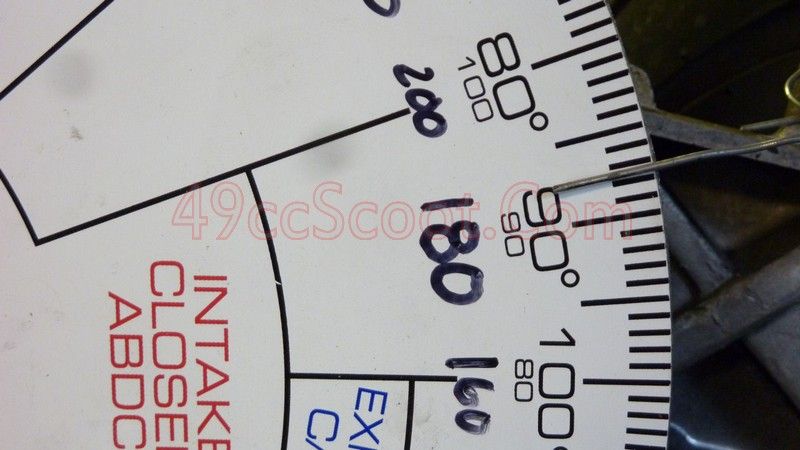

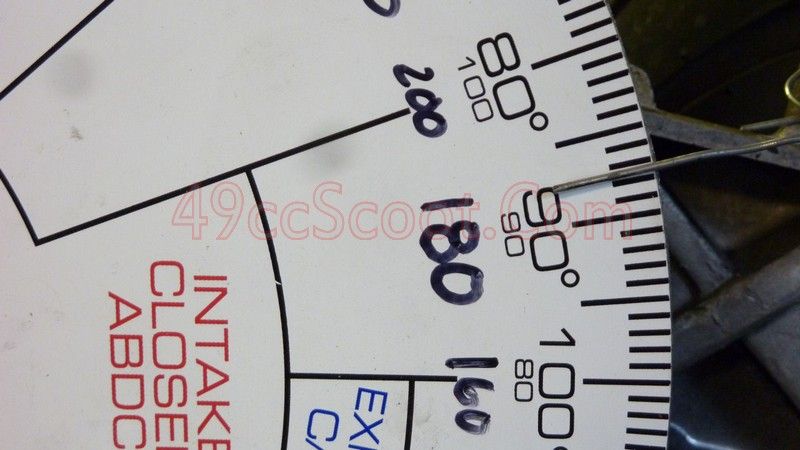

I've been doing more measuring and math to get some numbers to go along with the cranking psi numbers that I had found.

180psi = Stock Head #1 w/Head Gasket

195psi = Stock Head # 1 w/o Head Gasket

225psi = Stock Head # 2 w/o Head Gasket

Measured Volumes

Stock Head #1 (1.4mm recessed) = 5.1cc

Stock Head #2 (1.12mm recessed) = 4.5cc

Piston Crown Displacement = 1.1cc

Formulae

Cylinder Volume = ( (Bore Radius Squared x 3.14159) x Stroke ) / 1000

Trapped Volume = Combustion Chamber Volume + Head Gasket Volume + Volume Above Piston To Deck - Piston Crown Displacement

Uncorrected Compression Ratio = (Cylinder Volume + Trapped Volume) / Trapped Volume

Corrected / Effective Compression Ratio = (Cylinder Volume Above Exhaust Port + Trapped Volume) / Trapped Volume

Head Gasket Volume

Head Gasket Bore Diameter = 40.68mm

Head Gasket Thickness = 0.28mm

HG Volume = ( (20.34 Squared x 3.14159) x 0.28 ) / 1000 = 0.4cc

Trapped Volume

180psi Setup Trapped Volume = 5.1 + 0.4 + 0.5 - 1.1 = 4.9cc

195psi Setup Trapped Volume = 5.1 + 0.5 - 1.1 = 4.5cc

225psi Setup Trapped Volume = 4.5 + 0.5 - 1.1 = 3.9cc

Cylinder Volume / Displacement

Cylinder Bore Diameter = 40.02mm

Stroke = 39.2mm

Cylinder Volume = ( (20.01 Squared x 3.14159) x 39.2 ) / 1000 = 49.3cc

Uncorrected Compression Ratio

180psi UCCR = (49.3 + 4.9) / 4.9 = 11.1:1

195psi UCCR = (49.3 + 4.5) / 4.5 = 12.0:1

225psi UCCR = (49.3 + 3.9) / 3.9 = 13.6:1

Corrected Compression Ratio

Exhaust Port Depth Below Deck = 23.9mm

Corrected Cylinder Volume = ( (20.01 Squared x 3.14159) x 23.9 ) / 1000 = 30.1cc

180psi CCR = (30.1 + 4.9) / 4.9 = 7.1:1

195psi CCR = (30.1 + 4.5) / 4.5 = 7.7:1

225psi CCR = (30.1 + 3.9) / 3.9 = 8.7:1 |

|

|

|

Post by 90GTVert on Jul 11, 2012 21:20:02 GMT -5

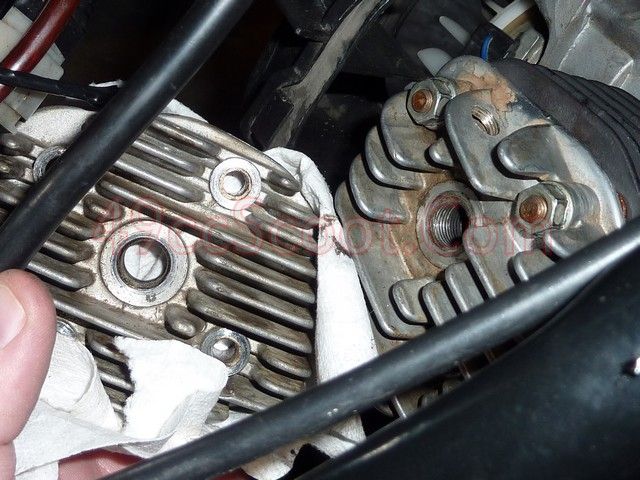

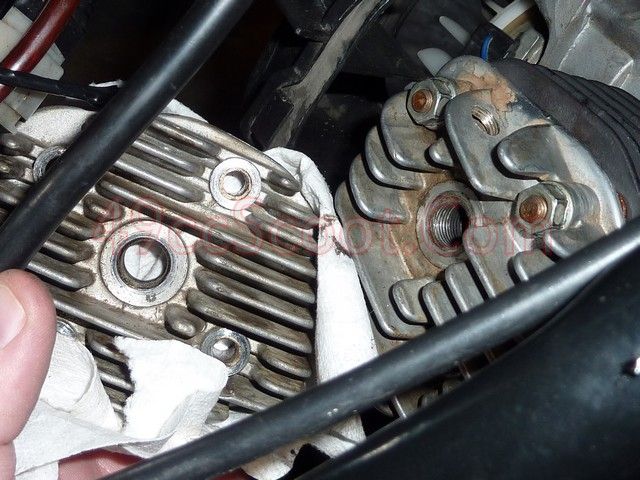

I re-tried the compression tests, and got results more like I'd expect this time without the torque driver malfunctioning. No flat feeling top end. Any increases were felt across the board. Note that times are slow in the video because of a headwind. So really no big gain with just removing the head gasket. On my 3ish mile test rides I couldn't really tell a difference in temperature between stock and stock minus the gasket. I would expect an increase in temperature on a longer ride. At 225psi the temperature difference was significant, but as I showed in the video the heads have different cooling setups. Here's a better look with the stock head I've been using off the engine on the left....  It may be a different story with the same cooling fin layouts. Hard to say. As tested, I wouldn't sacrifice the cooler temps for the added performance. Increasing timing gave similar results, but without as much of a temperature increase. I had planned to set timing back to 16 or 20 degrees for future tests, but I think I have a different plan that makes more sense, to me at least. I believe I'm going to set timing and compression as stock. Then the only difference will be the modified clutch, which could for the most part be replicated with stiffer springs. I'll try some parts out and see how they do on a tuned stock layout. Then I can play with the cylinder and perhaps advance timing again. Time will tell exactly how it goes beyond that. I may open the exhaust port up to a full circle before moving on. That's something I think I would always do if I were spending the cash on a pipe. I don't really expect a gain without other changes, but I'm sorta interested to see rather than guess. What do you all think? Try it as-is or open it up before testing pipes? If I don't open it up now, I'm not going back to test a bunch of stuff with it rounded. Next time I test pipes and such would be after the cylinder is ported, not just the rounded outlet. I'll be testing more than just pipes BTW, but I don't know that a variator for example will care too much if the exhaust port is round. |

|

|

|

Post by 90GTVert on Jul 12, 2012 11:43:41 GMT -5

I went ahead and opened up the port. Can't hurt, it'll be done at some point anyway, and we can see if there's a point to it without other cylinder work. Once the engine has been ran for a while, it's not exactly hard to see the area you need to cut for a better match. It wouldn't hurt to scribe I guess, but in this case even below the carbon is a discolored circle to follow.   I put the cylinder in a vise and used an electric drill with a carbide cutting bit to start out. I like the big bit and the drill because it gets work done quickly and the drill has a lot more torque than my Dremel does. It could be used in a die grinder, but then I have to listen to the compressor run all the time with the setup I have.  I followed the carbon outline until I ended up with a circle. Not perfect, not terrible. I blended the new shape into the port just enough to make a smooth transistion. Not enough to change the inside of the port much.  I switched over to a sandpaper roll to smooth it out just a bit more. Nothing fancy, just removing bumps and such.   Once I was finished with the porting I cleaned the cylinder and all ports thoroughly to get rid of any metal dust or debris. I stuck it all back together with the original head and a head gasket. I took a 10 mile ride to make some observations. I noticed no difference in power, RPM, sound, or temperature. If I didn't know that I had done it, I wouldn't have known that I did it. lol It seemed to neither help nor hinder anything as far as I can tell. I still think I'd always want to open up the half circle port if I were buying an exhaust. If for nothing other than my satisfaction in knowing it's done. I see no point in doing this to an otherwise stock engine though. |

|

|

|

Post by 90GTVert on Jul 12, 2012 21:28:14 GMT -5

I tried out the first exhaust today, the Leo Vince GP. Just to be clear, the GP does not come polished. It's mostly made of stainless steel though, and isn't hard to polish if you like that better than a more plain look. I picked this pipe up used, with no exhaust bracket included. I started out by mounting the header to the cylinder to see where it needed to be. For the header to be lined up just right, the pipe sits right up against the rear tire.  This GP was intended for a Yamaha Zuma and I have a bracket from a Leo Vince ZX for a Yamaha Zuma, so I tried that. I had to open up the mounting holes in the bracket a bit and use spacers, but it ended up fitting pretty well. I spaced the bracket out just far enough that there is a little over 1/8" of clearance between the pipe and the tire at the closest point.  For my taste, if I had to pick a pipe by looks alone, there would be no reason to look any farther.   The GP sounds so much better than my stock exhaust that rattles. It's got a good note at idle, but it's basically the same volume as the stock pipe otherwise. In this case it's quieter since it doesn't always rattle. I had to swap from a 75 main up to an 85 main and I adjusted the idle mixture screw again. Otherwise I didn't have to change anything. The GP seems to start kicking in at 7,000RPM. Below 7,000RPM I can't really tell any difference, good or bad. Above 7,000RPM it pulls quite a bit harder than the stock pipe. Power seems to peak at 7,900 - 8,000RPM. Peak came at 7,500RPM with the stock exhaust. I saw as much as 8,500RPM with the help of a wind gust at one point. Cruising speed was pretty much dead on 41MPH most of the time on flat ground. It didn't slow down nearly as much for wind or hills. I think it could cruise faster, and it would creep up a little more at times, but 41MPH is 7,900RPM. I had tuned the CVT for 40MPH at 7,500RPM at one point to go along with the peak output with the stock exhaust. After the troubles with the torque driver and it's more severe shift, I've had it tuned a couple hundred RPM higher than normal to make the drop off at the shift a little better. I think if I went heavier on roller/slider weight it could pull at least a couple more MPH worth of cruise speed. Since there's no gain below 7,000RPM though, I don't want to go heavier and make the drop off at shift worse. When I take off the scooter reaches somewhere over 7,500RPM before the torque driver shifts. Once it shifts RPM drops into the mid 6,000RPM range and struggles until it reaches at least 7,000RPM again. So with the GP it accelerates much more quickly to 25MPH, then it struggles to 35MPH. AAt 35MPH RPM is around 7,000 and it gets up to cruise speed pretty quickly. The 0-25MPH improvement makes it much better for short bursts in town and the additional power at 35+MPH makes cruising faster and more steady. I'm pretty pleased with the results. No crazy speed gains as I have it setup, but it's a very obvious power difference when it's in the right range. Looks great, but doesn't draw attention with the sound. I feel the stock porting is holding it back a bit, but it still did pretty well. With a CVT more capable of keeping a steady RPM it would be a big performance gain vs the stock exhaust. |

|

|

|

Post by 90GTVert on Jul 13, 2012 7:02:31 GMT -5

No, no, no... maybe. :laugh: Na, I've done that already. I did look at the sound clip of the GP on Project 90 though and without any times or other info, it's quite obvious there's a huge difference. lol Watch the take off in the one above, and then watch this one...

|

|

|

|

Post by 90GTVert on Jul 13, 2012 9:08:33 GMT -5

Thanks.  I've seen that it does start to yellow in the hot spots, but just going over it quickly with a metal polish and a rag will remove it. Not sure it would be so easy if neglected for a while, but after the initial effort of buffing it's not difficult to maintain. |

|

|

|

Post by 90GTVert on Jul 13, 2012 10:35:32 GMT -5

I swapped out the Leo Vince GP for the Leo Vince SP3 this morning. This SP3 was intended for an Aprilia Scarabeo 50-70 with a Minarelli 2T. I bolted up the header, and much like the GP for a Zuma, the pipe hugged the rear tire. In this case there was a tiny bit of clearance though. I used the bracket that came with this pipe, that I modified long ago, and a spacer to secure the exhaust and provide adequate clearance.   It's not a bad looking pipe, and has a more stealthy appearance than the GP. If you know scooters you can spot the SP3, but I think most people that know very little about scoots wouldn't notice that it's not a stock exhaust at a glance.   The SP3 also has a very mild tone to keep people in the dark about your performance pipe. It's quite quiet. Riding along you'll hear more wind noise than sound from the exhaust. It has a better sound at idle than stock, but it's not loud at all. On the 90cc I really couldn't tell much of a difference in the sound of the GP and SP3 exhausts, but with less engine to listen to, I can hear the difference a bit more on the 49cc. The SP3 is the quietest of the two. The GP is only very slightly louder, with a bit sharper sound. It could be the design on their internals, but I also think the steel vs stainless steel construction or perhaps just the difference in material thickness plays some role. I used an 85 main jet with the SP3, just as I did with the GP. No change from the idle mixture that I used with the GP. I saw no need to change needle settings either. Below 7,000RPM I can tell no difference in the SP3 and the stock pipe as far as performance is concerned. Above 7,000RPM the SP3 starts doing it's job, and there is a definite power increase over stock. I had expected the SP3 and GP to perform as twins, but this was not the case. The SP3 does not pull as hard as the GP did. Not only that, but it seems to peak at 7,700RPM, 200RPM less than the GP. That put cruising speeds at 39-40MPH. Another indicator of the power difference in the two exhausts is that the GP cruised at 41MPH and hardly swayed from that speed. The SP3 moved back and forth a lot more, showing it's not creating as much power to overcome slight changes wind or grade as the GP. It would find it's way to 8,000RPM or so at times with a little assistance from a slight wind or decline, but then level back out to 7,700RPM again. I went as fast as 45MPH sitting up, but that was going down a hill and with a little tailwind. I really didn't expect the GP and SP3 to be any different. From all the things I've read here and elsewhere, I would have expected the SP3 to be the better of the 2 if there was a difference. When tested on Project 90, I really thought they were just the same pipe with 2 different skins. Now I'm wondering what we'll see with more port duration and when a 70cc kit comes along. |

|

|

|

Post by 90GTVert on Jul 13, 2012 16:25:23 GMT -5

I'm testing pipes so fast you aren't even replying yet. :help: I swapped on the last of the Leo Vince 50-70cc exhausts I have today, the ZX. My neighbors have to be wondering why I keep going back and forth with so many test runs and rides of the different pipes.  lol This is another pipe intended for a Zuma. I have been able to find deals on the Zuma stuff the easiest. One thing I failed to note with the GP is that the Zuma pipes have dents in them to be able to clear their center stands. I have tried this 50-70cc ZX on my 90cc Project in the past, and to try and get a fair result I froze the dents out of it for the most part. You can read more about that process at the link below. There are also links showing how to remove the header pipe restriction common in some Leo Vince pipes as well as some baffles in the convergent cone. I even accidentally tested the exhaust with the restrictor, so you can see that result as well. Check it out... 49ccscoot.proboards.com/index.cgi?board=yamajog&action=display&thread=1712&page=4Once again I bolted the pipe to the cylinder before worrying about the bracket. This is a good practice anytime you install a new pipe IMO. It allows you to set the pipe up in a manner that provides the best alignment and seal. Having a pipe mounted just how you like it is worthless if it leaks at the header or the port is way out of alignment. Like the other Leo Vince pipes I've used so far, it sits very close to (against) the rear tire. I used just enough spacers to make the bracket work and allow for a small clearance at the tire.    I used an 85 main jet with the Leo Vince ZX, just as I have with the others. The ZX certainly has a much more aggressive sound than the other Leo Vince models tested. I like the idle sound. I still think it's quieter than the rattling stock pipe I have.  <- Perhaps this guy's in my stock exhaust? I think I prefer the more stealthy pipes for street riding. It's not that the ZX doesn't sound good, but rather at this stage I'm just not getting anywhere fast... so why draw attention to me taking off fairly slowly? The ZX feels more dead below 7,000RPM than stock or the GP or SP3 exhausts did. It wakes up around 7,000, but never really starts working until about 7,500RPM. It goes until it peaks at 7,900 - 8,000RPM. It's power output feels more similar the the SP3, not as strong as the GP. It will cruise as high as 41-42MPH, but speeds vary more than with the GP. I switched from 5g to 4.5g and ultimately to 4g sliders. No matter which weights I used, it did not want to rev over 8,000RPM and it still cruised at the same speed. What the lighter weights accomplished was higher revs before the shift, and higher revs just after the shift. It revved just a tad too much with 4g sliders taking off, but they stayed very near the power after the shift so they were my choice for this pipe. Keeping in, or much nearer. the powerband made this my best test to date for acceleration. I have to wonder if I couldn't have gotten a similar effect with a the SP3 or GP. I never tried with those because the SP3 seemed to obviously not want to rev any farther and the GP appeared as it if had the power to rev higher, but just didn't. I never really expected cruise to stay the same, while everything else increased RPM. I have the MRP 50-70cc exhaust still hanging on the wall and that's my last small displacement pipe I think. The Phongeer and V8 stuff is all intended for 90-100cc IIRC. I had really wanted to try out a Stage 6 Pro Replica after hearing such good remarks from other members, but I just can't afford it. I don't really think it would have shined with the stock porting either. |

|

|

|

Post by 90GTVert on Jul 13, 2012 20:15:56 GMT -5

The worst part of all of this is I don't think all stock stuff is created equal. Not sure if it's crappy tolerances, intentional variations, or what. This thing doesn't even hit 8,500RPM where I expect it to be with a stock pipe. The 90cc stock would outrev this thing. I'm hoping we'll see bigger gains once the exhaust port gets a little work done. 171 degrees duration really isn't something I'd expect to see a ton of RPM out of. The right pipe might push it up more than these, but if it sees 12,000RPM with that timing I'll have whatever pipe does it gold plated... that sounds expensive... gold leafed? I still have the MRP that has a small stinger that may be useful for the 49cc.  |

|

|

|

Post by 190mech on Jul 14, 2012 5:01:43 GMT -5

I think you are right Brent!That mild port timing will act as an RPM limiter,likely done that way to make engine life longer...

|

|

|

|

Post by 90GTVert on Jul 14, 2012 19:22:26 GMT -5

In between thunderstorms, I bolted up the MRP exhaust to see if it could do any better than the Leo Vince lineup. This is the first aftermarket pipe I bought, and it's been through a lot. One crash, the silencer support is gone and the stinger and silencer have broken off twice, lots of installs, etc... Still going though. I really should put a support for the silencer on here somehow. One thing I like about the MRP is the 2 piece design. The header is a few inches long and then there's a slip fit joint to attach the bulk of the pipe. It makes mounting easier and gives the pipe a little more adjustability. The bracket also swivels to make installation easier. Of all pipes tested, the MRP was the quickest installation.   It's a good thing the install was faster, because tuning was more time consuming than the rest of the exhausts. It started out feeling rich with an 85 main jet, as the other pipes have used. I swapped to an 80 and it started performing better. With the lightest sliders I have, 4g, it still seemed like it needed to rev more. I swapped to a 2000RPM contra spring and finally ended up with 5g sliders to get the revs right. Once the pipe got into it's operating range, then it was lean with the 80 main, so I moved back to an 85 main for best results. The MRP pipe is pretty dead at low revs. It never started waking up until just over 8,000RPM, and the best power was above 8,500RPM. It peaked at 8,900RPM, cruising at 41MPH most of the time, swaying up or down just slightly. Even with all the extra RPM, the power was similar to the Leo Vince ZX or SP3, and not as good as the Leo Vince GP. The one good thing about the higher revs is that it seems the higher I make the stock CVT rev, the less drastic the shifts become. Otherwise, the additional revs won't do much but make more noise and more wear on parts. The MRP is the loudest of the bunch. It sounds good, but it will get attention. It seems to me that the stock porting limits power output and RPM on all of the pipes. Meanwhile the stock variator with the spacer in place limits speed. Being heavy, I really can't remove the spacer from the variator if I want decent acceleration. I looked around and the other pipes I have are really not intended for 50s. I may try the YMS V8 and/or Phongeer once this project is a 70cc. I covered a lot of things in Project 90 that I don't see a need to redo for the 49cc. For example, if I didn't see power gains with a big carb on a stock 90cc that revs higher than this, I see no reason to test a larger carb. I would have to think cylinder cooling would be the only expected benefit. I've been over CDIs, intake and reed mods, and airbox/air filter changes with Project 90 as well. None of which showed any great improvements. Most likely I'll try a variator and perhaps a straight groove torque driver before moving on to farther cylinder work. |

|

|

|

Post by 90GTVert on Jul 16, 2012 18:25:24 GMT -5

I've been fiddling with the Hoca variator for the last couple of days. I think the video will get the point across better than anything I can type here.

It's not a big gain mod. The seamless shifts are sure nice. It runs much more consistently that way. I can do without the bog that it gets with some setups. Having used the Hoca on many setups, I know it will shine when more power is involved. It's not a must have at this point, but it's not a bad addition either.

|

|

|

|

Post by 90GTVert on Jul 18, 2012 19:41:47 GMT -5

Here's another test covered by a video. This time it's a straight groove torque driver.

|

|

|

|

Post by 90GTVert on Jul 20, 2012 14:55:37 GMT -5

190mech sent me a suggestion a little while back for Project 49... I happed to have an extra piston around, after my mistake with the hole in the crown.  Not much to lose by giving it a shot. I think it would be good if we could find an alternative method that is easier or requires less (or less expensive) tools than the traditional cylinder porting. The piston crown can be modified with a file. You can pick up a single file for $2-3 or a whole set of files for $5-10 at Harbor Freight. That's certainly cheaper than a carbide burr to make quick work of a porting job. It would require a similar amount of time, if not more, but it's also a little harder to mess up when you are using a file vs power tools. Worth looking into for sure. I took the engine out today to start checking over some things. To start with, he's right on the port's width. It has a chord width of 27mm, which puts it at roughly 68% chord width. Not bad. As he said, the transfer duration is pretty good at 125°. I wouldn't mind seeing it slightly higher, depending where the exhaust duration ends up. Exhaust duration is only 171°. Good for power around 7,000RPM. I'd really like to see durations good for around 9,000RPM. I think that would work with the stock pipe and all the aftermarket pipes. I'd really like to be able to get 185° of duration for that reason. I removed the piston and cleaned it up.   I reinstalled it and the cylinder and set the degree wheel up. I set the piston to where it just covers the cylinder, checked my duration on the degree wheel again to be sure, and then measured the depth in the bore at roughly 24mm.  Then I set the degree wheel where it needs to be for 185 degrees of duration and measured the piston's depth at roughly 21.5mm.   Before removing the cylinder and piston, I marked the crown where the exhaust port lines up.  Then I measured the amount of material above the top ring land at basically 3mm.  This is a bit of a problem for me. I really don't know the limits of the average piston to remain safe. In the past I had assumed that I should remove half of this area as a maximum. I would need to remove 2.5mm of 3 to get 185°. If I remove only the half maximum I have previously guessed at, I could squeeze in 180° of exhaust duration at least. I have a selection of cylinder shims in various thicknesses, which can be picked up fairly cheap.  I was considering using these to add on another 0.3mm. The reason being, the head gasket is about 0.3mm thick, so not using the head gasket could offset any compression difference caused by the addition of the shim. My concerns there are that it could make sealing slightly more difficult and if you buy a $10 set of shims, it's a big increase in cost vs possibly just a $2 file an a base gasket for what will amount to about 1 degree of exhaust duration and 2 degrees of transfer duration (181/127 as opposed to 180/125). I could double up on base gaskets for about .5mm more cylinder height, but then a head gasket can't be removed to completely offset the difference in height, and remember we'll already be losing some compression to the reduced displacement of the piston crown. The head could be milled at home for cheap with sandpaper and glass, but that's once again getting away from the point of this being the easiest mod possible. Right now it looks like my best bet is just to shoot for 180° exhaust by removing 1.5mm from the piston's crown in that area, and leave the transfer duration at 125°. Those should both be good for at least a 500RPM increase of peak power in theory vs my current 7,500RPM observed peak. Not where I was hoping to be, but that sounds like it could be a nice gain for the cost of a file and a base gasket. Of course on paper I would have thought my current peak would be a little lower, so I may see even more that a 500RPM increase. That's my plan as of now, but I thought I'd see how this sounded to you guys before I did anything. So how does that sound? Better ideas? |

|

|

|

Post by lshigham on Jul 20, 2012 15:43:03 GMT -5

A quick rifle through my piston collection and I can't find a piston with less than 2mm to the top ring, a distance they try to minimise in performance kits as the gas trapped there won't burn, wasting potential power. Too small a gap would expose the top ring to too much heat from combustion, which isn't going to end well. Just some food for thought.

|

|

I've seen that it does start to yellow in the hot spots, but just going over it quickly with a metal polish and a rag will remove it. Not sure it would be so easy if neglected for a while, but after the initial effort of buffing it's not difficult to maintain.

I've seen that it does start to yellow in the hot spots, but just going over it quickly with a metal polish and a rag will remove it. Not sure it would be so easy if neglected for a while, but after the initial effort of buffing it's not difficult to maintain.

lol

lol

<- Perhaps this guy's in my stock exhaust? I think I prefer the more stealthy pipes for street riding. It's not that the ZX doesn't sound good, but rather at this stage I'm just not getting anywhere fast... so why draw attention to me taking off fairly slowly?

<- Perhaps this guy's in my stock exhaust? I think I prefer the more stealthy pipes for street riding. It's not that the ZX doesn't sound good, but rather at this stage I'm just not getting anywhere fast... so why draw attention to me taking off fairly slowly?

Not much to lose by giving it a shot. I think it would be good if we could find an alternative method that is easier or requires less (or less expensive) tools than the traditional cylinder porting. The piston crown can be modified with a file. You can pick up a single file for $2-3 or a whole set of files for $5-10 at Harbor Freight. That's certainly cheaper than a carbide burr to make quick work of a porting job. It would require a similar amount of time, if not more, but it's also a little harder to mess up when you are using a file vs power tools. Worth looking into for sure.

Not much to lose by giving it a shot. I think it would be good if we could find an alternative method that is easier or requires less (or less expensive) tools than the traditional cylinder porting. The piston crown can be modified with a file. You can pick up a single file for $2-3 or a whole set of files for $5-10 at Harbor Freight. That's certainly cheaper than a carbide burr to make quick work of a porting job. It would require a similar amount of time, if not more, but it's also a little harder to mess up when you are using a file vs power tools. Worth looking into for sure.