|

|

Post by 90GTVert on Jul 20, 2012 15:49:21 GMT -5

Good point. If I stuck with that 2mm minimum, then we're looking at I think 176-177 degrees.

|

|

|

|

Post by 2strokd on Jul 20, 2012 16:06:09 GMT -5

I say go for it. You have another piston and its a great idea. I did a 47mm iron S6 sport kit,s piston just like this. I think i still have it if you are interested in numbers or a pic? Good thinking 190mech  |

|

|

|

Post by 90GTVert on Jul 20, 2012 17:25:29 GMT -5

My concern here isn't so much ruining what I have (not that I want to), but I don't want anyone to follow my lead on something that would have a dramatically shortened life. Even if the piston works out great at 180 or 185, it will see enough miles maybe to know if it's a quick fail, but prob not to know if it fails much earlier than normal. Finding a $2 mod for more power kinda sucks if it ends up costing someone a top end. I've only ever made minor changes to the exhaust area of the crown, I usually just port for ex duration.

If you ran that piston long I'd be interested to see what kind of thickness you had above the ring by the exhaust.

|

|

|

|

Post by 190mech on Jul 20, 2012 19:41:03 GMT -5

Remember the Dykes ring pistons?They have an "L" shaped ring that sits on the top edge of the piston dome,its 'old school' now but worked well in its day..I measured an old Yamaha RD250 piston with a Dykes top ring,it has 1.25mm between the dome and top of ring groove..Just another thought!  |

|

|

|

Post by 2strokd on Jul 20, 2012 20:14:02 GMT -5

My concern here isn't so much ruining what I have (not that I want to), but I don't want anyone to follow my lead on something that would have a dramatically shortened life. Even if the piston works out great at 180 or 185, it will see enough miles maybe to know if it's a quick fail, but prob not to know if it fails much earlier than normal. Finding a $2 mod for more power kinda sucks if it ends up costing someone a top end. I've only ever made minor changes to the exhaust area of the crown, I usually just port for ex duration. If you ran that piston long I'd be interested to see what kind of thickness you had above the ring by the exhaust. I get your point. But at the same time if one is going this far into tuning their engine they should already know the risks they are taking IMO. If not, i dont think they would even get this far :dunno: :zap2: |

|

|

|

Post by 90GTVert on Jul 20, 2012 22:24:11 GMT -5

From Gordon Jennings' Two Stroke Tuner's Handbook :

"with the ring in its usual position, about 0.200-inch below the piston crown, there is a tendency for gases to leak down the side of the piston, and the port-opening process thus becomes more gradual than is desirable. The effect is slight, but it is there, and for that reason ring location always is a matter of juggling the conflicting requirements of keeping the ring cool, and obtaining sharp, clean portopening characteristics. And in most instances, the balance of this compromise will be in favor of the former, for an overheated ring quickly fails. The cause of this failure is twofold: first, excessively high temperatures effectively anneal the ring, and it loses its radial tension; second, an overheated ring warps like a potato chip, and no longer maintains close contact with the bottom of its groove. In both of these cases, the ring's ability to seal is reduced, which allows fire to start leaking down past the ring, and that further raises its temperature -starting a cycle that soon results in outright ring failure.

The single exception to the unpleasantness just described is the L-shaped “Dykes” ring, which also is excepted from the immediate effects of ring-flutter (described elsewhere). A number of engines have been fitted very successfully with Dykes rings located right at the tops of their pistons, and the dire effects of excessive heating are avoided because the Dykes ring's vertical leg has enough area in contact with the cooler cylinder wall to draw away heat faster than it can be added by the ring's contact with high-temperature gases. At least, that's the way the situation can be, if everything is right. On the other hand, it is worth remembering that many users of Dykes-pattern rings have been forced to fabricate them from stainless alloys to overcome temperature related troubles, and even then have experienced problems with oil carbonizing in the ring grooves."

Jennings mentions cutting the crown to increase duration of the exhaust port. He gives no recommendations on height and he also seems to only see that as a way to experiment with duration before porting.

|

|

|

|

Post by 190mech on Jul 21, 2012 5:18:12 GMT -5

I agree reveeen!Having a pile of various porting tools is a nice thing to have..But some folks dont,thats why I thought a simple piston top cut would be a good test.. Brent,you have a good concern about the ring groove to piston top clearance too,,I guess the safest way to get the proper port dimensions is cut the port to the desired height..  |

|

|

|

Post by 90GTVert on Jul 21, 2012 6:42:49 GMT -5

|

|

|

|

Post by tygertung on Jul 21, 2012 15:44:43 GMT -5

In one 2 stroke book, or aticle or something, it said it was important to smooth off the edge of the piston like you have to prevent the sharp edge from scraping off oil from the bore. Also since it is smoother, it won't be a stress riser and therefore less likely to crack. Cracks develop from sharp edges.

You can pick up an electric die grinder set pretty cheap, you can pick them up for about $60 NZD here, so compared with the rest of the money you tend to spend doing up scooters it's not a lot.

|

|

|

|

Post by reveeen on Jul 21, 2012 16:06:46 GMT -5

|

|

|

|

Post by 90GTVert on Jul 22, 2012 10:44:12 GMT -5

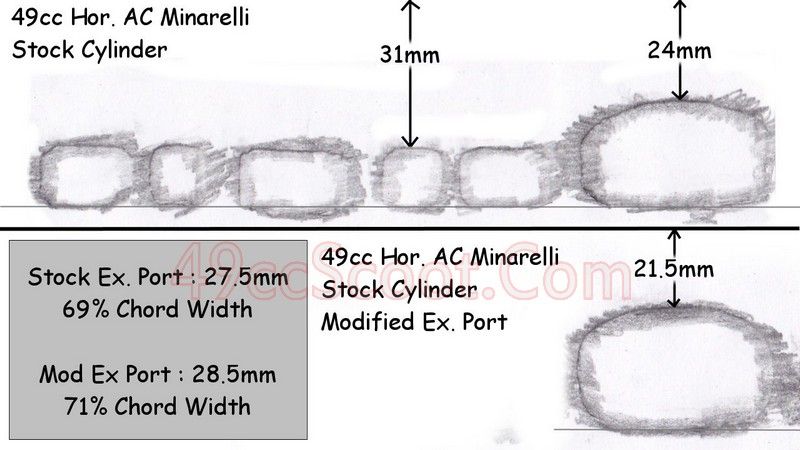

It's sure not a pro port job, but I used a drill, carbide burr, and sanding drums. I used the steel wool at polish just to run through the port once I was finished. Not really any point though, since I left too many imperfections. I used files and a Dremel with a small sanding drum to speed up the chamfering around the cylinder's base.  I started out by using marking the cylinder where the exhaust port needs to be for 185° of duration. I used a degree wheel. You can use formulas or a porting calculator to find the height you want. In this case, it needs to be 2.5mm higher to go from 171° to 185°.  Here's the port after opening it up with the carbide burr. I tried to keep a curved roof. I did the flat port roof on Project 90 and it really woke up the engine at high revs, but it was dead at low revs. The curvier roof should be easier on rings as well.  Here it is after using the sanding drums and steel wool. I guess I need new glasses? It looked smooth to me. Looking at the picture, it appears I had more I could do. It feels smooth at least, and polishing isn't really going to make a difference beyond a smooth feel. (You may notice the cylinder is honed. The pic is from later. I had a hard time getting any decent pics of a lot of steps for some reason.)  I thought it would be a good idea to open up the cylinder skirt a little as well to get more flow through the cases. Below are before and after shots of the cut.   I didn't want to leave all of these sharp edges, so I rounded them out.   Then I rounded out the other areas by the transfers.  Back to the piston. I wanted a little more than 125° duration for the transfers, so I opted to file the piston crow a bit. Started out by marking the transfer/boost locations. Not sure why I marked with such detail, since I just filed the whole area.  I removed about 0.5mm from the crown to get 128° transfer durations.  I cheated on the piston and used my buffer. Really not something that needs to be done anyway. For the crown I've read that smooth is good to reduce carbon and dimpled is better for turbulence. I can't say I've ever seen a difference either way I've done them and 2/3 of the piston was smooth from my mods so I just finished the whole thing.  Here's another look at the ports. I really don't like the one corner of one of the transfers, but there really isn't much I can do about it or at least not easily with what I have. I had no intention of making the port wider, but it had a lip where it entered the cylinder so I knocked it out.  That's as far as I've got. It's still needs to be put back together and so on. |

|

|

|

Post by 90GTVert on Jul 22, 2012 13:37:20 GMT -5

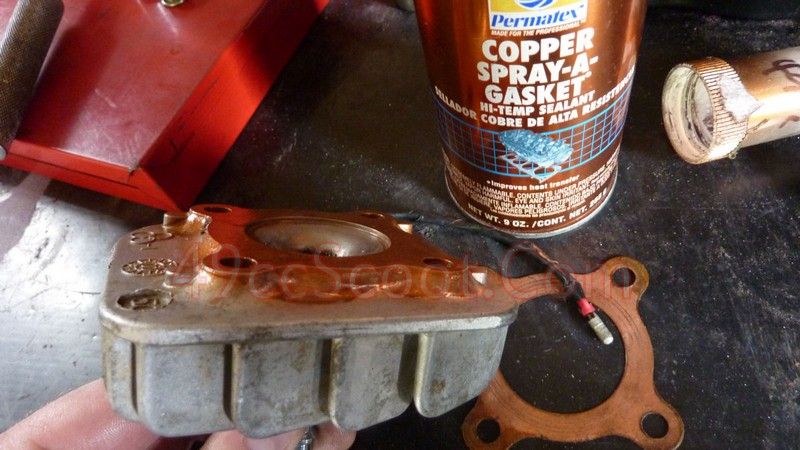

I hope so. I put the top end back together and checked compression. I expected it to drop from the piston modification and larger exhaust port. I had hoped it wouldn't drop from 180psi to 157psi.  I used copper spray in lieu of a head gasket and compression increased to 166psi.   There is still more than enough squish clearance with a minimum of about 1.7mm. |

|

|

|

Post by palezu on Jul 22, 2012 14:52:06 GMT -5

Nice work but you have to chamfer the ports upper and lower edges, otherwise the piston rings will not last long if the edges are sharp. Actually I noticed in one of your 90cc projects that you had a early piston ring failure and the port looked like it had sharp edges. About 2mm wide chamfers on both edges of the port should be fine. Other than that, nice work 90gtvert, your work has helped me a lot with my damned 1E40QMB. Here in Finland we mopedboys tune these a lot and everybody seems to have noticed the same thing, for some reason these just wont rev past 10 000 even with 70cc cylinders and it is widely accepted that the problem is in the ignition system but well, it'll be interesting to see if your porting helps to this. I'm new to this forum but I'm sure I'm going to visit here a lot, especially your project 90gtvert  |

|

|

|

Post by 90GTVert on Jul 22, 2012 17:16:45 GMT -5

I recently read Coppercoat kills spark plugs,have you had any issues with it? I run it on basically everything anymore, even with head gaskets most of the time. It's not killing my plugs any faster than I would normally replace them. Nice work but you have to chamfer the ports upper and lower edges, otherwise the piston rings will not last long if the edges are sharp. I dunno if they were chamfered or not in that pic to be honest. I took 140 pics to get those. As I said earlier, for some reason I've been struggling to get decent pics. I always do all ports on a new cylinder and anything I mod with files. I prob do 'em wrong since they aren't huge chamfers, but they've been working for me. The really fast fail was quite a large port and I don't really believe even a perfect chamfer would have saved it. Here in Finland we mopedboys tune these a lot and everybody seems to have noticed the same thing, for some reason these just wont rev past 10 000 even with 70cc cylinders and it is widely accepted that the problem is in the ignition system but well, it'll be interesting to see if your porting helps to this. This thing doesn't like to go much above 7,500RPM in stock form. lol It takes more duration than this to do 10,000RPM and beyond with much success. My hope is that it's comfortable around 9,000RPM. Not sure if we'll see that with a stock pipe, but hopefully it'll work well with the pipes I have. My 103cc minarelli does as much as 12,000RPM. It has an aftermarket ign now, but it did just fine with stock ign at those revs. Are your cases as badly mis-matched as they appear in the pictures? Sadly, it's very common for these to be pretty far off. I did work on them some before I ever put this engine together, but I didn't go over that area. For whatever reason, I think most of my engines have more of a bulge on that side right there, even when they aren't mismatched as bad elsewhere. Here's a pic of them as I got them.  Here is what I did before the project ever started.  |

|

|

|

Post by reveeen on Jul 22, 2012 18:46:31 GMT -5

You have to excuse me, I haven't taken a clone apart before, just oem Mineralli. The mis-match seems to run all the way through from the cylinder to the intake port....... you don't see this (as much?) with oem.

I'm wondering if, as the timing increases, the overall compression importance kinda drops off? With a chamber that is working properly the supercharging effect should increase as port size and duration increases........... (more power less torque?) We see this with foolish durations on 4 cycle engines.

I would be moving my ignition timing back into the "stock" area until you see what is what?

|

|