|

|

Post by scoottrash1990 on Sept 29, 2013 12:43:19 GMT -5

thanks Brent....i checked the gap on the pick up and i can just get a .010" feeler gauge in there so thats good....i found the service manual for the triton r4....in the manual it says to check the resistance between the black/red stripe wire from the pickup to a ground....the manual gives a spec of 140-220 ohms....when i tested it i got 0.750 ohm....i guess thats the problem...now my question is can i buy just the pickup coil? if so where? i looked at parts for scooters and all i can find is the whole stator..

|

|

|

|

Post by 90GTVert on Sept 29, 2013 13:06:25 GMT -5

I've always bought whole stators.

|

|

|

|

Post by 90GTVert on Sept 29, 2013 13:11:40 GMT -5

|

|

|

|

Post by scoottrash1990 on Sept 29, 2013 15:44:35 GMT -5

thanks again Brent.....i just went with the whole stator.....what makes a stator go bad? i wonder if i messed something up when i wrecked it not to long ago...i have never had one go bad without physical damage....

|

|

|

|

Post by 90GTVert on Sept 29, 2013 18:02:32 GMT -5

Other than the obvious stuff like physical damage/broken connections and corrosion, I don't exactly know. I'm sure all of the vibration these single cylinders experince and Chinese quality control don't help anything. Sorry, not enough of an electronics whiz. It's not uncommon though. Stators and CDIs going out is fairly common and why I suggest keeping spares if possible.

|

|

|

|

Post by scoottrash1990 on Sept 29, 2013 20:39:12 GMT -5

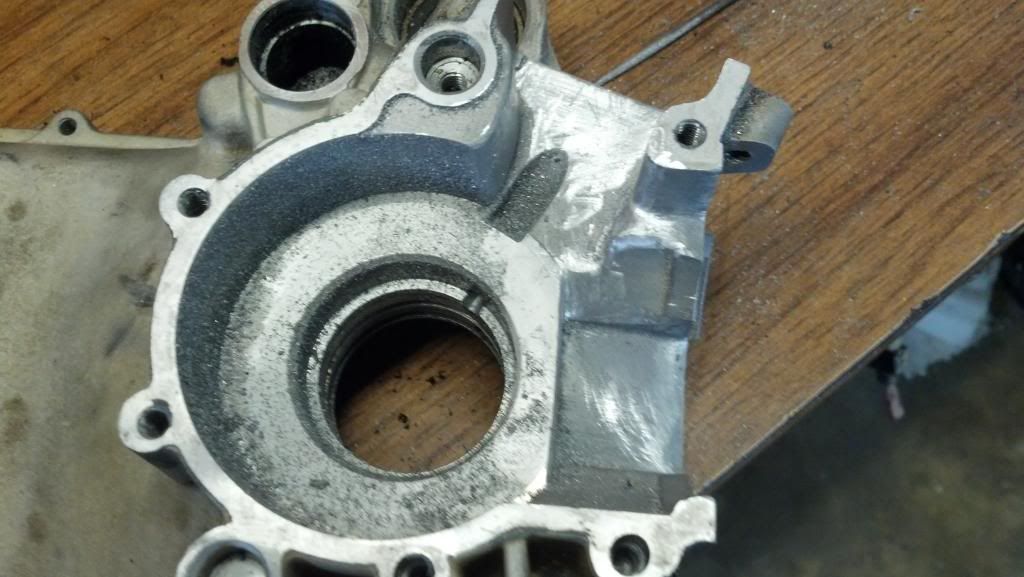

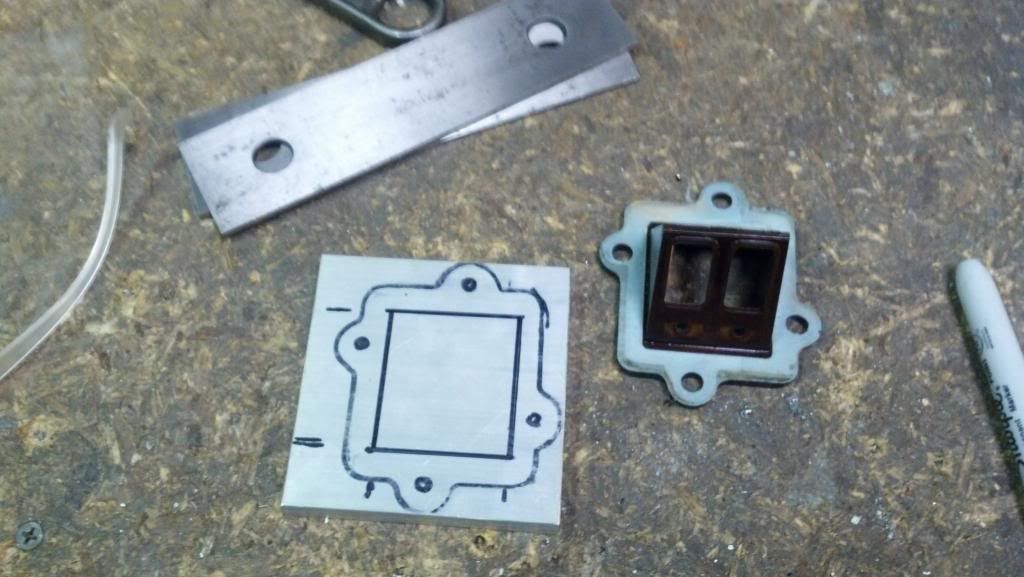

i ran behind on updating my build post as i went along so here is what i have done... i got the cases and cylinder ported....nothing crazy just matching everything up and smoothing out the sharp edges.....       i had some free time at work so i made a reed spacer.   my zx-r pipe wouldn't match up to the new cylinder so i had to put a cut in it, bend it to where i needed it and weld it up....in the pic its kinds hard to see but the cut is by the first weld on the pipe...  all lined up now  i took a page right out of Brent's handbook and welded washers to the pipe flange to get rid of the goofy slots that come on the pipe....now i know that the exhaust port is lined up with the pipe....  heres the cut i had to make all welded back up  mounted  exhaust poet opened up and smoothed out  im not into the polished look(to much work to keep up with) i painted the cases with header paint  i have more but i have to upload the pics... |

|

|

|

Post by moofus02 on Sept 29, 2013 20:55:07 GMT -5

Looking good

Sent from my SPH-L720 using proboards

|

|

|

|

Post by scoottrash1990 on Sept 29, 2013 20:59:58 GMT -5

thanks....and no boring was needed...the 45mm crank dropped right in....90 cases rock...  |

|

|

|

Post by ryan on Sept 29, 2013 21:12:11 GMT -5

hey are you in the market for a base gasket 2mm thick?

|

|

|

|

Post by ryan on Sept 29, 2013 21:12:49 GMT -5

also how did you prep the cases for paint?

|

|

|

|

Post by scoottrash1990 on Sept 30, 2013 6:05:21 GMT -5

i got the hoca tall cylinder...its set up for the 45mm crank so i did not have to use any spacer....thanks tho...

|

|

|

|

Post by scoottrash1990 on Sept 30, 2013 6:16:09 GMT -5

for the paint i scrubbed down the cases with a really good degreaser and a wire brush....the degreaser i used is called super clean...you can get it at almost every auto parts store...i use it straight for engine parts....if you use it make sure to have rubber gloves on because it is very harsh on skin......scrub it down with the degreaser, wash it off with water and blow it dry with an air compressor...the cases are already rough so i didn't do any sanding....

|

|

|

|

Post by ryan on Sept 30, 2013 9:55:43 GMT -5

i was saying could you make me a 2mm aluminum base gasket? i seen your work with the spacer

|

|

|

|

Post by scoottrash1990 on Sept 30, 2013 10:08:06 GMT -5

let me see what i can do and i will let you know....

|

|

|

|

Post by ryan on Sept 30, 2013 10:27:26 GMT -5

awsome. also what paint it looks nice and its def hard to keep up with on the aluminum. what pipe you gonna run?

|

|