|

|

Post by waltinhawaii on Aug 19, 2013 19:41:08 GMT -5

The ports inside look the same as your pics of the air cooled cylinders. Small sub ports to either side of the main exh port. I plan on trying to work the sub ports up the sides to gain more area... but a bit nervous as I might break through into the water jacket. Anyone done porting on these cylinders? Could use a bit more info on how far I can push the ports up the sides. I just got confirmation from Home Depot that my grinder is in the mail: Dear Walter One or more of the items on your order W224539902 have shipped. Please review shipment details below. - 093184076305 Professional 1/4 in. Air Die Grinder 1 Subtotal: $19.97 Shipping: $0.00 Estimated Sales Tax: $0.94 Order Total: $20.91 Not bad, can't remember the last time I saw a handheld grinder on sale for $20. If any of you guys need one, now's the time to get them... but you have to get $45 or more total or else they don't ship for free. I just got 2 grinders, the other one was not on sale... 90 degree angled pneumatic grinder, same thing but with pistol grip just to get me the free shipping  |

|

|

|

Post by waltinhawaii on Aug 20, 2013 23:19:09 GMT -5

While waiting for the new crank to get here, I lightened the flywheel by removing .050" from the circumference... didn't seem like it did much, though, just by looking at it. Probably not worth it?  Preparing the "porting bench" with sophisticated lighting (taped my fluorescent drop light to a wooden bar so it is directly over the vise)...  |

|

|

|

Post by 190mech on Aug 21, 2013 5:40:36 GMT -5

Love that big ass vise!With my old,weak eyes a clamp light positioned under the cylinder pointing into the bore helps me see what mistakes I'm making...  |

|

|

|

Post by kevin55950 on Aug 21, 2013 6:05:04 GMT -5

I would mostly wonder how much you can open the ports because of the cases. On the cylinder, I've seen one at my friend's house which had epoxy on the ports, inside the water chamber. And surprisingly, it lasted  He even blocked the boosters to enlarge the main exhaust port with epoxy and it didn't failed. |

|

|

|

Post by 190mech on Aug 21, 2013 20:10:13 GMT -5

Ive seen pics of a drag scoot cylinder that had sleeved front stud holes..Huge aux ports were carved and a thin steel sleeve was pressed into an oversized stud hole..Not the best for flow,but lots better than a tinny port..

|

|

|

|

Post by kevin55950 on Aug 21, 2013 20:26:21 GMT -5

Are you talking about the MXS 90 ? They seems well designed, but I'll be afraid of coolant making it's way in the studs/ports...

|

|

|

|

Post by 190mech on Aug 21, 2013 20:41:31 GMT -5

OK,I found the pic,here it is;  |

|

|

|

Post by ryan on Aug 21, 2013 21:05:35 GMT -5

190 what is that book and where can i get some good books on porting etc..just about scooters? or anything related to performance.

|

|

|

|

Post by kevin55950 on Aug 21, 2013 21:09:49 GMT -5

Seems to work well ! If it helps to flow more and get better timings, why not ?  MXS 90 are like this but the studs are cut specifically for each port they interfere with. Or it might be possible to mod a cylinder to be like the Airsal t6 which have no studs (making some fins hold the cylinder base with screws instead of studs, and head bolted on cylinder)? |

|

|

|

Post by waltinhawaii on Aug 21, 2013 23:37:50 GMT -5

Wow, that is a HUGE exh port. I'm surprised the thing starts at all! I guess you can make all kinds of sacrifices if only have to run 1/8 mile or so... My grinders and bits haven't come in yet, but I'm itching to start on something, so I thought I'd do the 'easy' stuff and just do a little bit of blending at the bottom of the cylinder... first up, I noticed the bottoms of the skirts shrouded the path to the reed cages; so cut the corners off...   next, I smoothed out the transfers just a bit. I don't have my extended bits yet so can't reach upwards into the transfers yet. Have other projects I need to do, so this'll have to be it for tonight.  |

|

|

|

Post by waltinhawaii on Aug 22, 2013 23:48:37 GMT -5

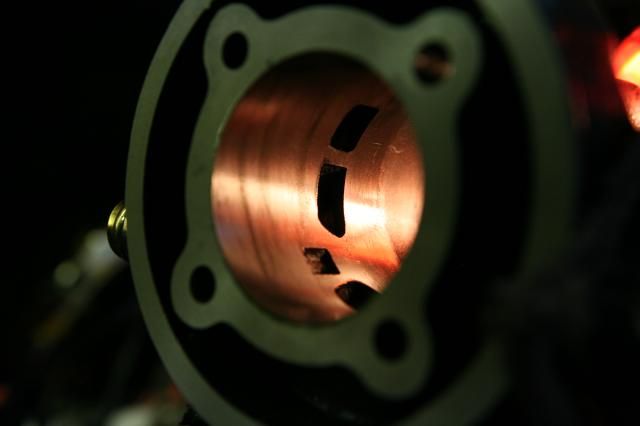

Well Parts for Scooters has sent me the replacement crank... very fast shipping. HOWEVER:  Yes, wrong crank again. They sent me another crank with a 10mm wristpin hole. How hard can this be?? I started to play with the transfers inside my cylinder. Slowly. Here is the stock cylinder:  About an hour later (with some breaks in between:  Boy, this is going to be a sloooooow job. The subports near the exhaust are sitting right on top the studs, that's why the holes are so oblique and clogged up. Can't open them too much. |

|

|

|

Post by ryan on Aug 22, 2013 23:53:43 GMT -5

the 43.5 crank is not 10mm ive owned 2 of them along with the 90cc stockers from them and 45 strokers and all are 12mm. they do not manufacture them with 10mm from hoca. so why is it that you think its to small?

|

|

|

|

Post by waltinhawaii on Aug 23, 2013 0:31:24 GMT -5

Because I don't argue with calipers. Stock crank (12mm wristpin):  43.5mm crank from Parts for Scooters:  |

|

|

|

Post by ryan on Aug 23, 2013 0:41:39 GMT -5

are you using the hoca bearing for the crank, my friend was using a (50cc 12mm crank) and tried using the bearing from that in a hoca (90cc 12mm crank) and it did not fit both were 12mm cranks but the hocas' cranks have smaller OD bearings. the 43.5 is deff a 12mm crank. i just measured my 43.5 and its right around the same readings, took a 50cc 12mm bearing and tried to fit it in and the bearing is bigger than the hole. switched to a hoca 90 bearing and fits perfectley

|

|

|

|

Post by waltinhawaii on Aug 23, 2013 1:10:00 GMT -5

Ah, yes, I'm using the stock roller bearing (wristpin bearing). I went out just now and looked in the cylinder box; could have sworn it came with a wristpin bearing with the piston and cylinder; but can't find one in there. Looks like you're right, if yours measures up the same as mine, then I have the correct crank, but need a bearing cage from hoca to go with this crank.

|

|