|

|

Post by thephranc on Oct 11, 2016 17:27:54 GMT -5

Looked for weeks for a part, got a lead, part is back ordered for 3-4 weeks, bought raw material, 20 min of work with a sawzall and bastard file later I have the part I need. I even chamfered all the edges.  Now for some bolts and the proper rear brake assembly and this drive train unit will be ready to bolt to the frame and I can move on to fuel and electric. |

|

|

|

Post by thephranc on Oct 13, 2016 17:50:39 GMT -5

I got stopping power!  |

|

|

|

Post by thephranc on Oct 16, 2016 13:51:40 GMT -5

Major setback. The swing arm casting burst trying to press the bearing in. It didn't even get all the way in before the thing let go. Now its tweaked in other places too. Looks like stresses in the casting were too much so when I hit the tapper it couldn't hold together anymore..  |

|

|

|

Post by PIG on Oct 16, 2016 14:03:37 GMT -5

That sucks man. What's the plan now?

|

|

|

|

Post by thephranc on Oct 16, 2016 14:07:51 GMT -5

Buy another one when funds are available. I will not be deterred.

Its just crap timing because I had enough to start final assembly of everything but cooling and electric.

|

|

|

|

Post by niz76 on Oct 16, 2016 15:45:55 GMT -5

Well crap that sux! Did you do any heating and cooling? Might go in a little safer the next time with the bearing cooled to shrink it, and the aluminum heated to expand it? Glad you're not deterred! Hate these annoying setbacks!

|

|

|

|

Post by thephranc on Oct 16, 2016 15:53:01 GMT -5

Ill at least freeze the bearing. The swing arm is painted so heat will be hard to get in it with out burning .

|

|

|

|

Post by niz76 on Oct 16, 2016 16:39:00 GMT -5

Always exciting too see your progress on this bad a$$ mofo so I'm bummed to see this setback for ya man!

|

|

|

|

Post by thephranc on Oct 28, 2016 16:48:37 GMT -5

And we now return to your regularly scheduled build.....

Ordered new swing arm and a new bead roller today. Eastwood is having a decent one day sale on the roller.

|

|

|

|

Post by thephranc on Oct 30, 2016 15:24:37 GMT -5

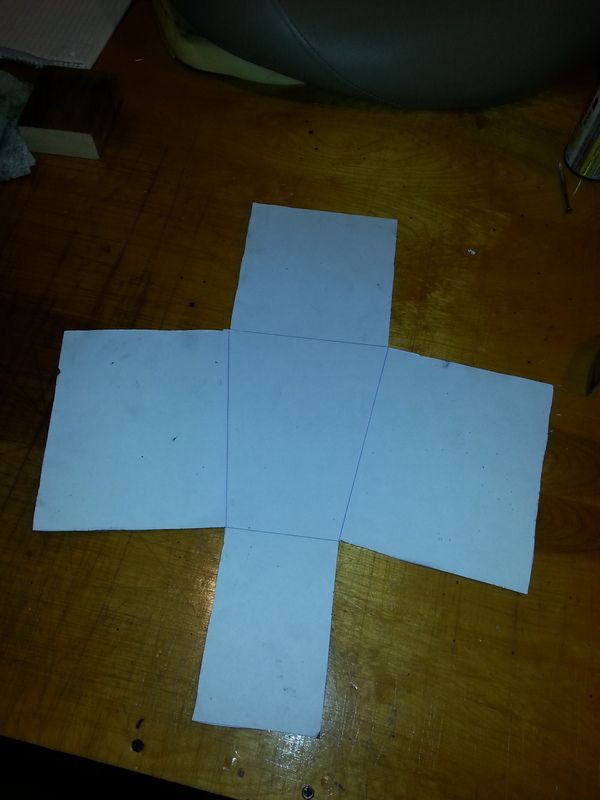

Battery box started. Its a really thin gauge steal pilfered from some old file cabinets. Its really hard to weld because its so thin, may end up using rivets. At least the bead roller should make easy work out of it.  Started working on the seat today. Made a pattern its 18" x 8" at the widest with a tapper to 6".  Did a materials test setting a 1/4"-20 nutsert into some PVC sheet. Works good but I will add some adhesive to shore it up. The PVC will give me a base to staple the seat vinyl to and then bolt that to an aluminum frame for strength and bolt that to the scooter frame. I really like the PVC as a building material. Its light can be easily cut and heat formed ( unlike wood ) and its cheap enough you dont mind mistakes as much.  |

|

|

|

Post by thephranc on Nov 2, 2016 18:00:20 GMT -5

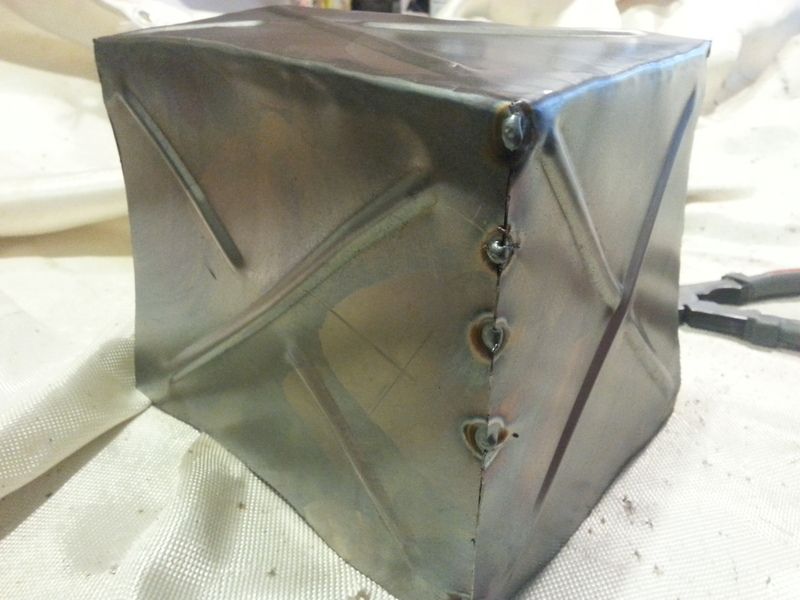

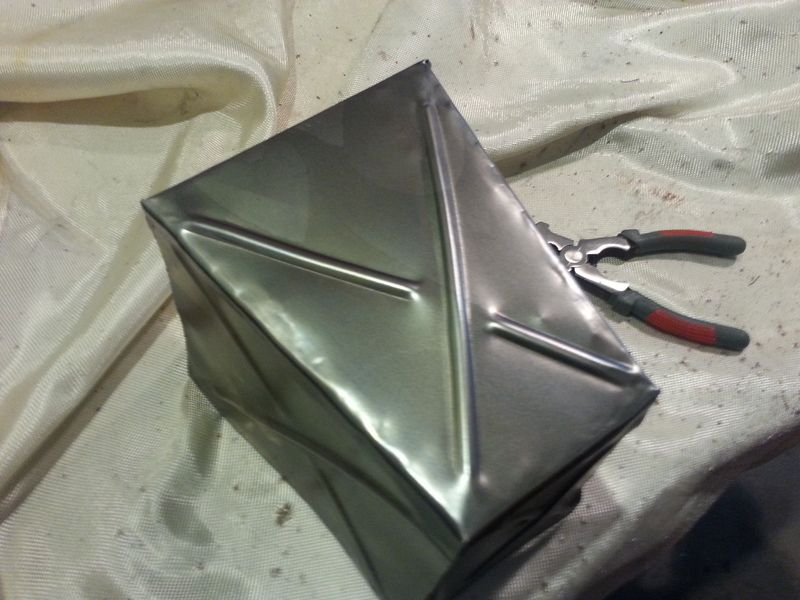

Got the bead roller set up today and made a halfassed battery box. The roller worked great, operator skill level sucks. In my haste I failed to prestretch. The metal is too thin to weld even with my little mig. Lack of a break hurt too as I couldn't get crisp bends. I hammer and dollied way more than I wanted to. I will more than likely try again and do individual panels that are mechanically fastened. Also instead of a round over bead I might do a step down around the perimeter. Then use a 1/4 x 1/4 angle and rivet it all together with brass solid rivets. Purely aesthetic in reason. I also did some re-design to the seat, making the aluminum frame skeletonized. Welds are awful, they blow away even at the lowest setting.  You can see the lack of prestretch how it warps the plane of the metal.  |

|

|

|

Post by thephranc on Nov 4, 2016 17:34:32 GMT -5

Got the swing arm installed and everything is bolted up! Took pictures but photobucket is down. Not all swing arms are created equal.Some things need to be tweeked to get everything to line up.

My next conundrum is if I want a second shock. Tomorrow I'll assemble the frame and fork with bars so I can route the brake line and see if the throttle works.

Also need to find out if the 50cc fuel system is big enough to feed 250cc.

|

|

|

|

Post by joeorange on Nov 4, 2016 17:49:47 GMT -5

Got the swing arm installed and everything is bolted up! Took pictures but photobucket is down. Not all swing arms are created equal.Some things need to be tweeked to get everything to line up. My next conundrum is if I want a second shock. Tomorrow I'll assemble the frame and fork with bars so I can route the brake line and see if the throttle works. Also need to find out if the 50cc fuel system is big enough to feed 250cc. the fuel tank should feed it fine, but the distance you can travel with the 50cc tank would be very limited. |

|

|

|

Post by thephranc on Nov 5, 2016 9:49:59 GMT -5

Here you can see after bolting it all up the difference in the swing arms. I believe it was the same reason the casting blew out, twisted stresses.  |

|

|

|

Post by thephranc on Nov 5, 2016 18:45:47 GMT -5

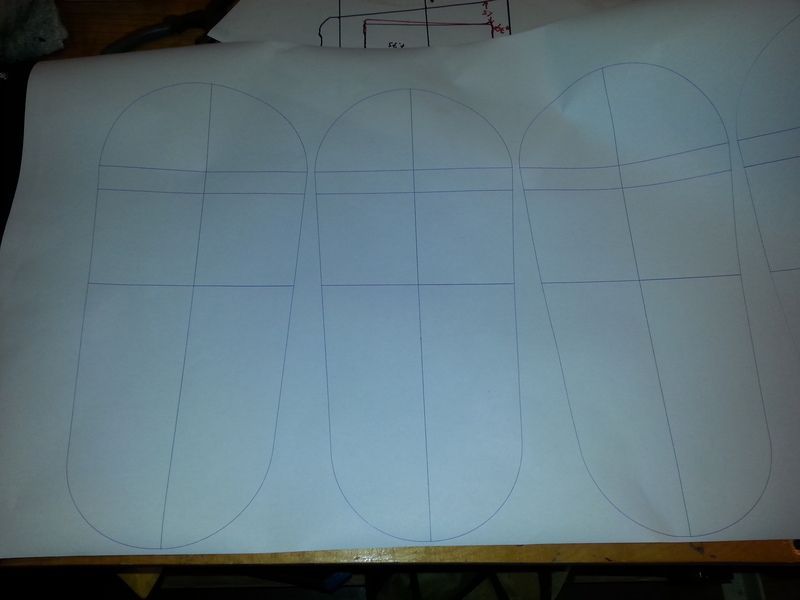

Spent most of today working on the seat. This is the alum frame pattern I remade.  And the finished product  Tomorrow I'll get work started on the PVC part. And I still need to get the padding cover designed. I may get a newer sewing machine. As much as I love my vintage Singer clone from the 50s its become temperamental and teh 70s era electric motor mod just doesn't have the safety built into it. |

|