|

|

Post by thephranc on Sept 4, 2016 17:29:51 GMT -5

The weather today was perfect! Managed to get my mount fully welded into the frame. With the splayed supports it should be able to hold my fat ass with no issues.    Also managed to bolt my disc to the rim. Not a sexy thing but its progress.  Only a few more things to weld to the frame, shock mounts ( have to get the swing arm sussed out first ), seat supports, a bar from the upright to the frame, mounting tabs for the radiator, mounting tabs for the lights, and maytbe mounting tabs for some fairings. |

|

|

|

Post by thephranc on Sept 11, 2016 13:45:23 GMT -5

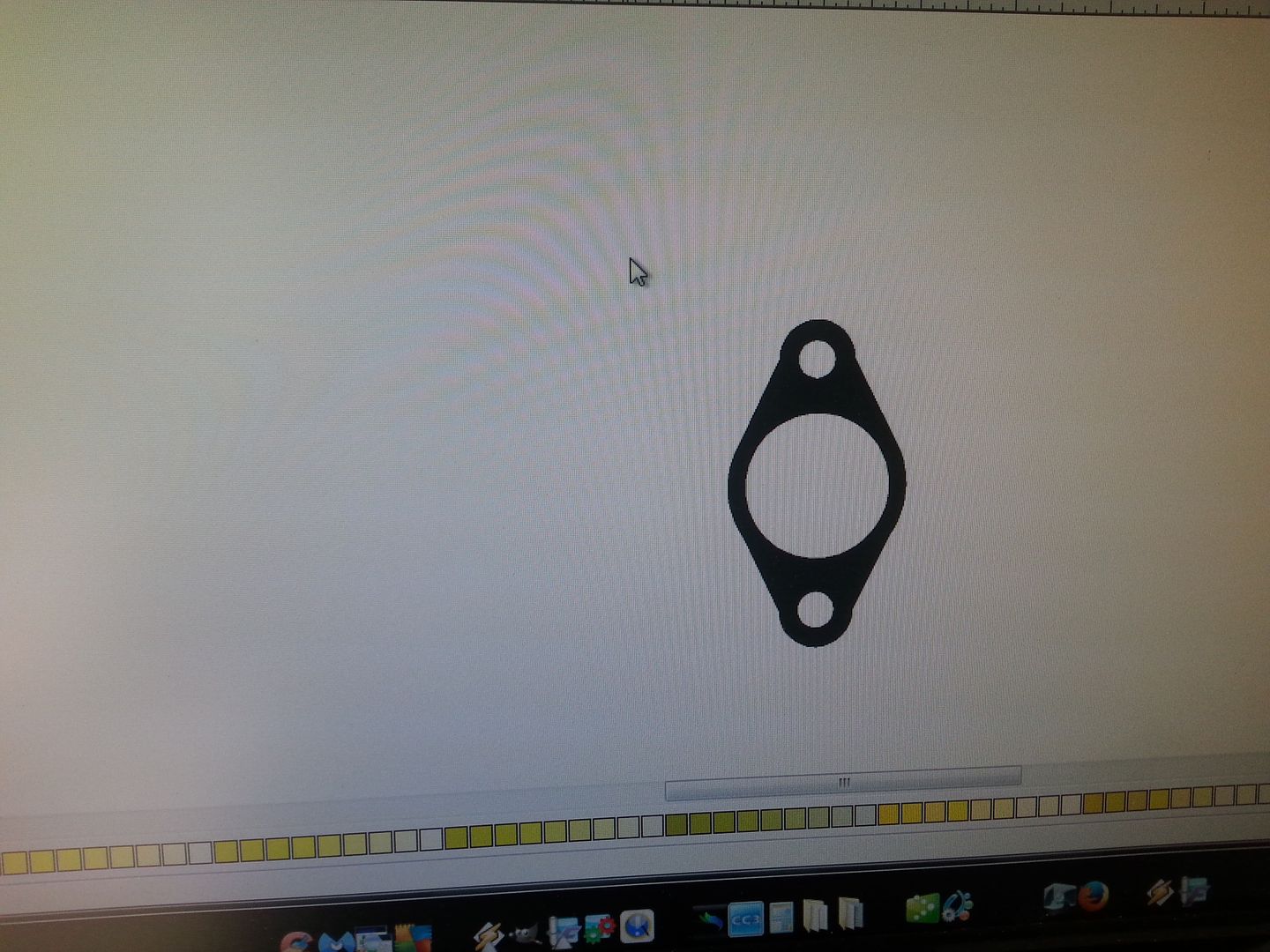

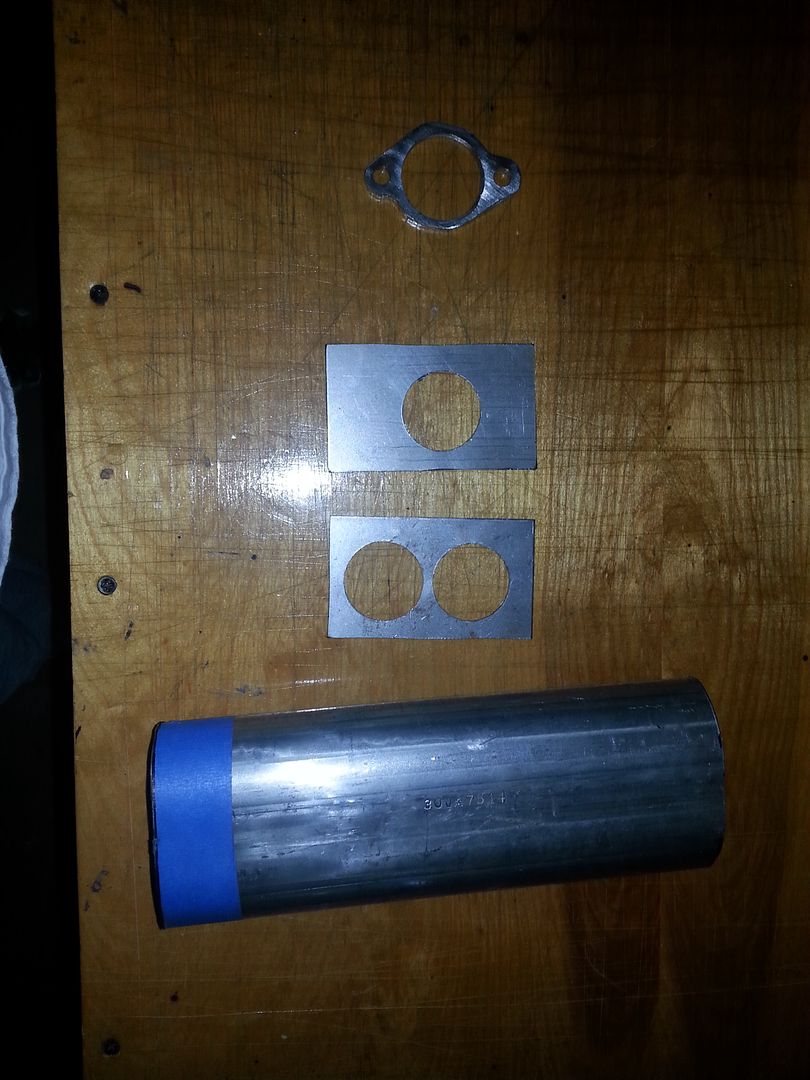

Spent a good 2 hours cleaning up welds both my own and from the factory then started working on the exhaust flange. Started with some CAD templates made after much careful measuring.... that had to be adjusted a few times in paper.  Hard metal plate with the holes cut out perfectly.  Took an angled pick and used it as a scratch awe to get the exact shape of the head mounting area then followed up with a fine point felt tip pen for visibility. I'll take this to work tomorrow to see if the choloos across the lot can use their exhaust expanding machine to fit a pipe tight in there before welding. Then come home and order something in a 14 or 16g to fab the exhaust out of.  |

|

|

|

Post by thephranc on Sept 12, 2016 18:33:44 GMT -5

Got some monday fab work in. Contoured the flange.  Muffler started. Two arbor plates, one press and two blocks of wood. Not the best squish since I don't really have anything to contain the outward expansion but it will work.  While not an oval, I do like the shape and it provides a good amount of space for batting.  |

|

|

|

Post by thephranc on Sept 13, 2016 18:25:18 GMT -5

Another week day in the shop. Love this weather. Not much done, did manage to cut the muffler to 10" and made the end plates. 1 in 2 out.  |

|

|

|

Post by thephranc on Sept 16, 2016 18:24:59 GMT -5

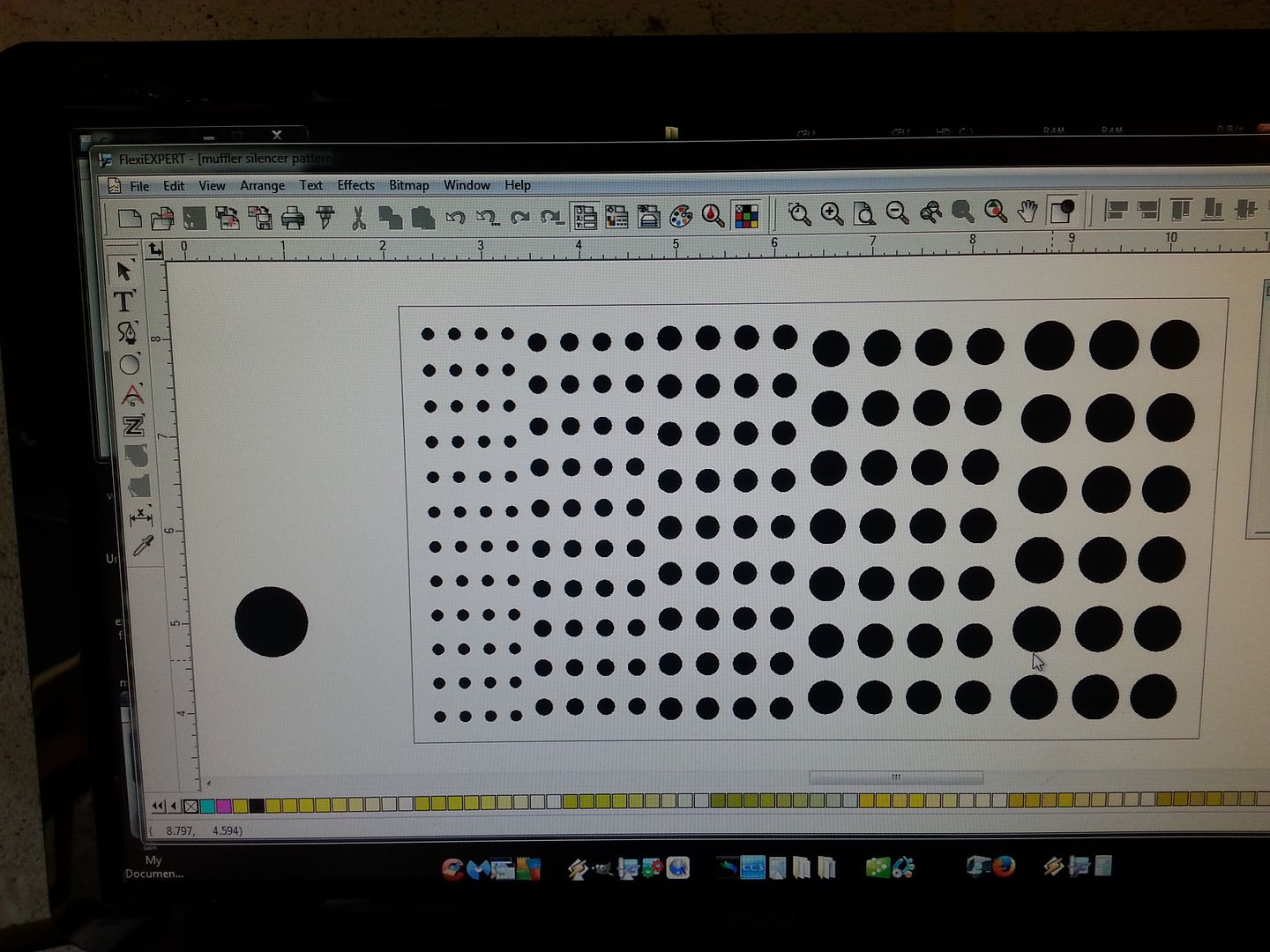

Ordered 2 of these to make the exhaust. Its about the same as the scoot's frame except much eastier to get good penetration without blowing through.  Tacked the first pipe in place the 90* bend and slack in the fit for the flange gave me a perfect angle. Used some blue drywall screw sets as spacers. Waiting on the swing arm to show up so I can get my next angles.  Started making the drill pattern for the inside of the muffler. 1/8 to 1/5 inch. I wish I knew how to determine the hole size to sound frequency ratio so I could better plot out holes. I may also change it to a spiral pattern so I get a better mix of sizes all the way down the tube. I just winging it with just enough knowledge to be dangerous.  |

|

|

|

Post by thephranc on Sept 24, 2016 19:29:43 GMT -5

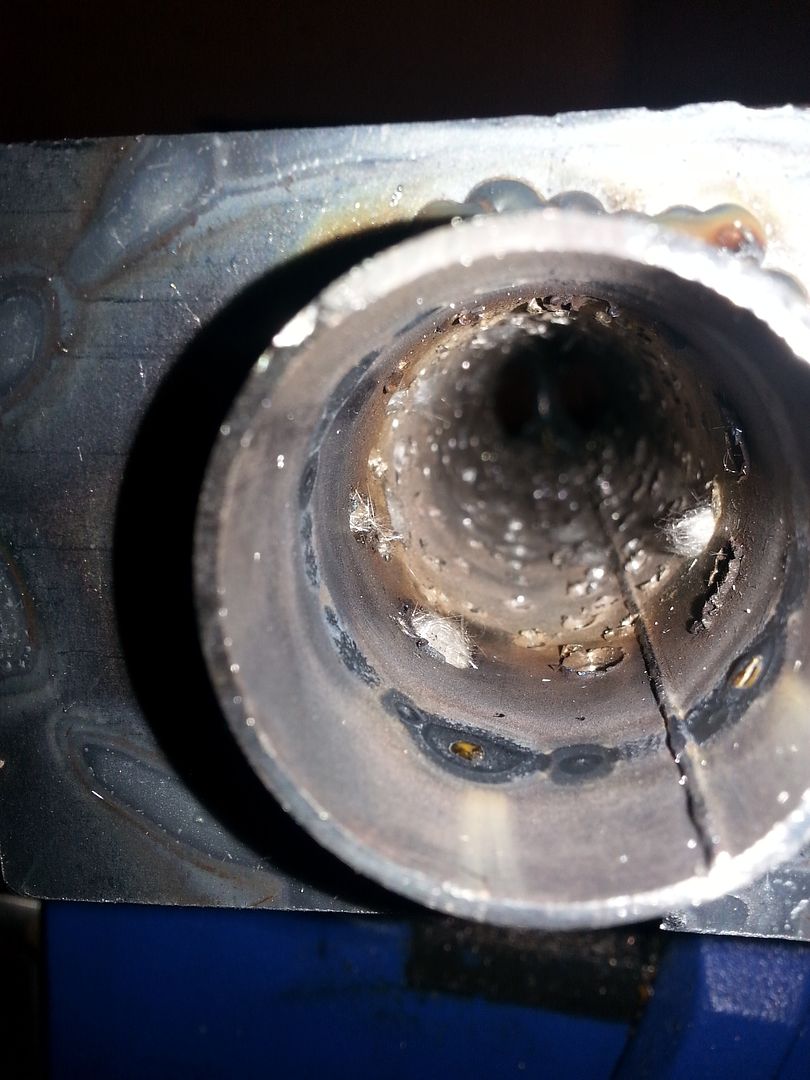

Spent a lot of hours in the shop this week. Managed to build a muffler. Baffle tube with lots of holes, even more than pictured.  Burrs inside  Some crappy metal work. I had to fill in a lot of gaps  Wrapped in muffler packing. Also stuffed as much as possible in the sides.  end caps installed  0ne in 2 out.  |

|

|

|

Post by joeorange on Sept 24, 2016 21:04:02 GMT -5

awesome job, cant wait to hear what it sounds like.

|

|

|

|

Post by 90GTVert on Sept 24, 2016 21:12:49 GMT -5

Very cool! This is gonna be one bad little scoot. I'd also love to hear it if you can do a sound clip or vid for us one day.

|

|

|

|

Post by ryan_ott on Sept 24, 2016 21:50:03 GMT -5

Nice fab on the muffler. I like the one in two out.  Home Depot and lowes has expanded sheet metal I use for baffle tubes.  |

|

|

|

Post by thephranc on Sept 24, 2016 22:24:52 GMT -5

I have a feeling its going to be loud and obnoxious.

That screen would have saved me a lot of drilling.

|

|

|

|

Post by thephranc on Sept 27, 2016 16:43:38 GMT -5

Swing arm finally arrived! Headder pipe runs right into it but I expected a need to cut and section.  Initial muffler location. It will be easy to mount to the two forward holes with washers steel bar and washers.  Need to jump that gap.  |

|

|

|

Post by thephranc on Sept 29, 2016 19:17:18 GMT -5

Carb showed up.  I've been thinking of how to use 2 of the 50cc carbs |

|

|

|

Post by thephranc on Oct 6, 2016 17:21:53 GMT -5

Rear break assembly came in..... wrong caliper. Fits rthe wrong swing arm I have. Looks like there are a few places with mislabeled parts, putting the gy6 style 250cc in the same as the other 250cc motor.

|

|

|

|

Post by thephranc on Oct 9, 2016 12:35:23 GMT -5

|

|

|

|

Post by niz76 on Oct 9, 2016 14:25:34 GMT -5

Boom Shakalaka! Looks mean!

|

|