|

|

Post by FrankenMech on Jul 30, 2020 17:48:20 GMT -5

What brand of taps were you buying?

|

|

|

|

Post by 90GTVert on Jul 30, 2020 17:52:36 GMT -5

The first was Snap-On. The set of 3 was Irwin, which I read was supposed to be made by the same folks that make Snap-On.

|

|

|

|

Post by FrankenMech on Jul 30, 2020 18:08:34 GMT -5

Wow, that is terrible. Most of my taps are Hanson, Starret (STC), or Greenlee (GTD) . I have never seen one that wasn't concentric. I have some that are unidentified though.

I suppose that taps made for machine tapping have to be better than taps ostensibly used for hand tapping or in a hand drill.

You might have better luck with buying taps from a regular tool company that specializes in industrial tools for lathes or Mills.

|

|

|

|

Post by 190mech on Jul 30, 2020 19:26:18 GMT -5

Only way to make a concentric inner thread with an outer diameter is cutting it with a single point tool which is an operation with absolute focus on the task at hand..  |

|

|

|

Post by FrankenMech on Jul 30, 2020 22:44:46 GMT -5

Small diameters are a tap only type operation. A lot depends on how concentric the hole for the tap is. I have done inner dia single point threading of 3/4" threads but nothing smaller. I don't think I could see well enough or be coordinated enough to do that anymore. Single point threading up to a shoulder or the bottom of a hole or counter bore is a hair raising task. When I worked on the pipe die line most of the threading was done at 100RPM and 12 threads per inch. That was a high 'pucker factor' operation.

|

|

|

|

Post by 90GTVert on Feb 1, 2021 7:35:54 GMT -5

|

|

|

|

Post by oldgeek on Feb 1, 2021 9:29:41 GMT -5

Those are very nice, especially the carriage stop. Thanks! |

|

|

|

Post by 90GTVert on Jun 30, 2021 12:24:55 GMT -5

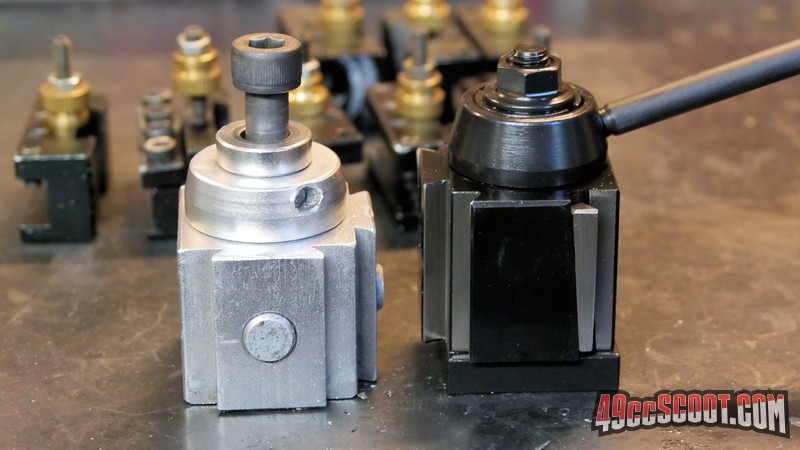

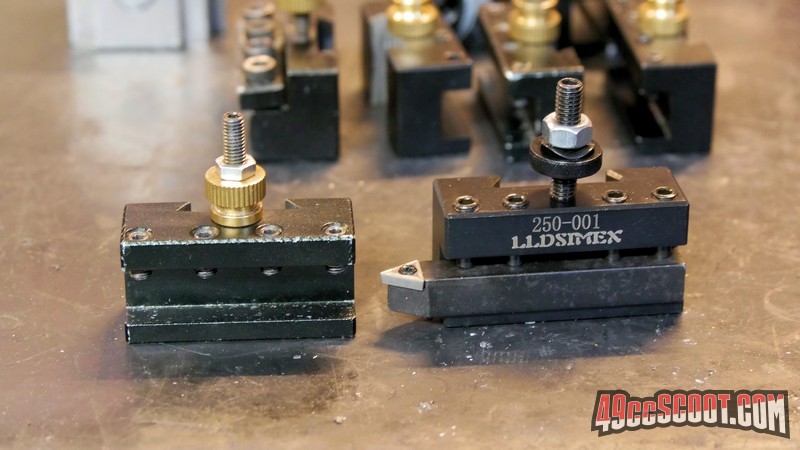

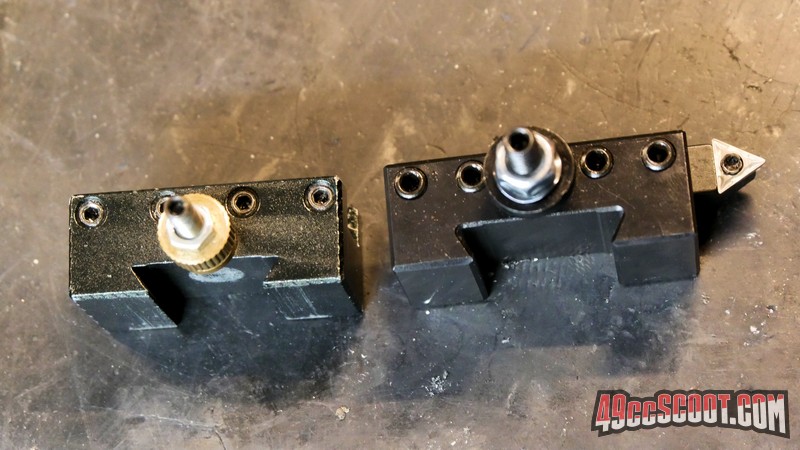

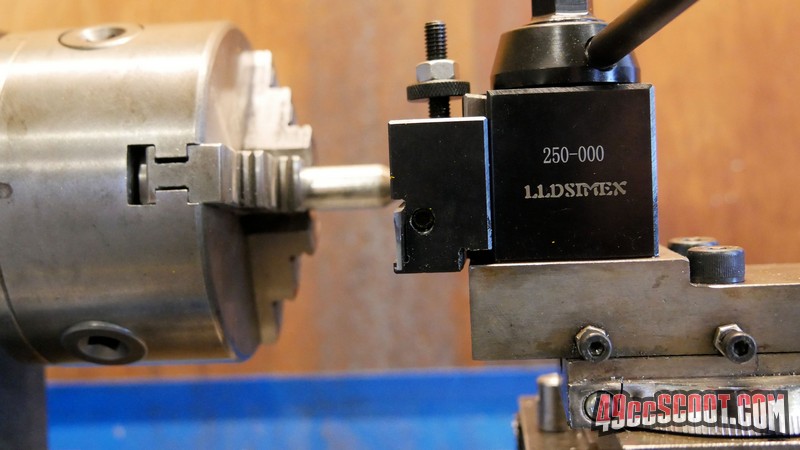

The quick change tool post that the guys gave me when I got the lathe has totally stripped the threads out on the locking lever. I used a hex key as a lever for a bit, which actually didn't work that bad. It really should be drilled and tapped or a new part could be made, but it would have to be bored eccentric to work. I've heard that there are better setups, with tool holders made to a size standard that is easy to find for getting spares/replacements. I found THIS SET on amazon and decided to pick it up, plus 4 addition TURNING TOOL HOLDERS. They are 0XA, and there doesn't appear to be any shortage of parts for them. With the original set, it's either $18 each plus ship for turning tool holders from LittleMachineShop or what I did was get spares from China. Those were cheap, but took months to arrive.  The old post is on the left, new on the right. All of the bits and pieces of the old setup is aluminum, aside from fasteners. The new stuff is all steel. I think the new locking mechanism is a little better too. The old one uses a button that pushes out into the holders. The new one uses, for lack of whatever the proper term is, tapered jibs that slide up and down.  The 0XA posts are a little bigger and all of the hardware steps up a size.   The 0XA holders are also ground for a more precise fit. When I ordered replacements for the aluminum style, I had to file some of them to make them fit on the post.  The only thing that I noticed that isn't quite right out of the box is the parting tool holder. It holds the tool at a 4° angle, and that's just enough that I couldn't adjust it low enough to be set properly. I read that in amazon reviews, so it was expected. Nothing 5 minutes with a hacksaw wouldn't fix. I sawed off the bottom section enough to provide plenty of room for the holder to drop down now.   I haven't used them yet, but just from handling them and setting them up, they are very heavy and feel more solid. It seems like they lock into place better, and having steel hardware worries me less when turning the lever to lock them down. Some reviews say that they improve rigidity enough to see a difference in finish. I don't expect any miracles, but I'll take any help I can get and I think the beefier construction overall will be nice. Before all of that went on, I took the cross slide, carriage and so on off and cleaned/adjusted it as well. Way overdue. |

|

|

|

Post by FrankenMech on Jul 4, 2021 12:41:17 GMT -5

That parting tool as shown has a large overhang from the cross slide. Avoid overhang, keep the tool load directly over the carriage and directly into the lathe bed. Overhang increases deflection and vibration, which reduces accuracy and surface finish. Deflection and vibration tend to break tooling and ruin parts especially in cutoff operations. You may want to make some large knurled depth adjustments from steel for the new tool holders, like the brass ones from the old tooling.

Your cutoff tool shows some discoloration from where it was sharpened. Use coolant and go slow when sharpening tool steel to avoid any discoloration which destroys the temper in the steel.

|

|

|

|

Post by 90GTVert on Jan 21, 2022 23:29:16 GMT -5

|

|