Post by 90GTVert on Apr 6, 2020 22:37:22 GMT -5

The tailstock has been giving me more and more trouble and eventually just wouldn't turn in/out at all. I've been looking at parts for a while and the parts aren't available to my knowledge. A new tail stock would be roughly $100 shipped, gone up since I looked last in March. That's too much money. I'd be better off to try to make these parts, but I'm not ready to go there just yet.

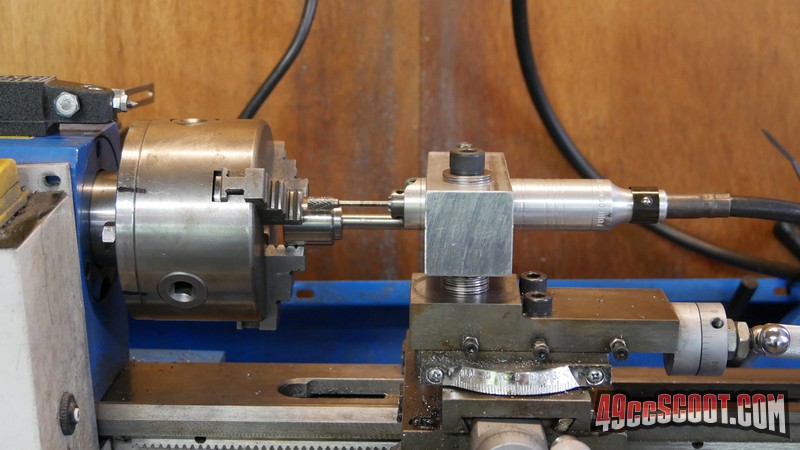

While looking at parts, I noticed that it looks like most of these don't rely on a taper, but rather a flat disc basically on the shaft that rides in a piece with a flat section. It's hard to see in the pic, but everything from mine is tapered.

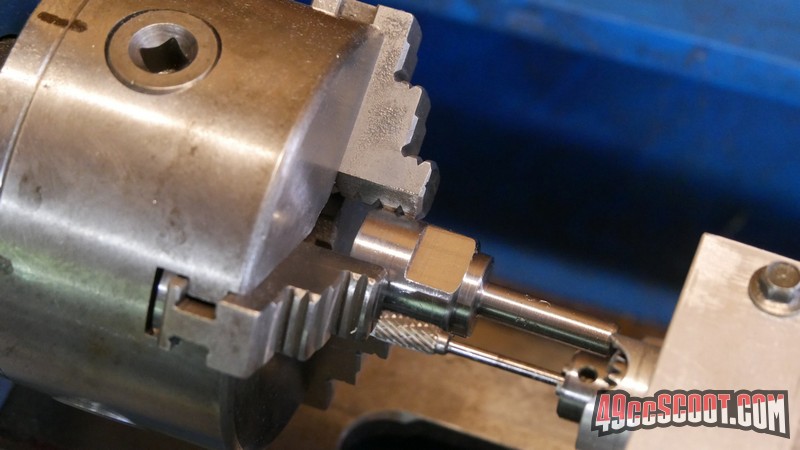

So I cut a sharp ledge into the end piece and welded the rod up and cut a sharp raised area into it. Looks like I forgot the pic of the rod.

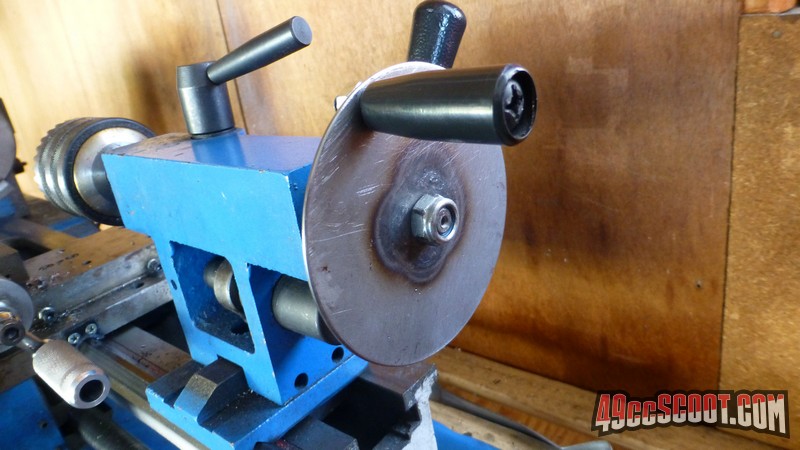

The wheel to turn it is also cracked badly. It was cracked a bit and then when it got really tough to turn the tailstock I cracked it worse. I put a cap screw in there instead of the little set screw to try to keep the handle going with the rod, but it didn't really work.

I don't have anything around large enough to make a handle anywhere near properly. I had the center from when I made the steel degree wheel for my 2T still sitting in the piece that held it in the lathe. It's about the only thing I had around with a large enough diameter and thick enough to maybe work. I ended up welding it to the steel collar that was inside of the old plastic wheel. Then I drilled it and used the grip from the old wheel with it.

That's gotta be one of the worst hand wheels ever on a lathe. It's better than nothing ATM. The good news is that the tailstock now operates way more smoothly than it has for a very long time. I don't actually think it moved in and out this well when new.

I also had some quick change tool holders sitting around. I ordered them in early 2019 for I think $5-10 total from China. Finally got them in late 2019 and only 1 of 4 would actually go onto the tool post. I fixed that today. They were poorly machined and needed filing. Now they all fit.

Hey oldgeek; have you spent any more time getting accustomed to your mini-lathe?

While looking at parts, I noticed that it looks like most of these don't rely on a taper, but rather a flat disc basically on the shaft that rides in a piece with a flat section. It's hard to see in the pic, but everything from mine is tapered.

So I cut a sharp ledge into the end piece and welded the rod up and cut a sharp raised area into it. Looks like I forgot the pic of the rod.

The wheel to turn it is also cracked badly. It was cracked a bit and then when it got really tough to turn the tailstock I cracked it worse. I put a cap screw in there instead of the little set screw to try to keep the handle going with the rod, but it didn't really work.

I don't have anything around large enough to make a handle anywhere near properly. I had the center from when I made the steel degree wheel for my 2T still sitting in the piece that held it in the lathe. It's about the only thing I had around with a large enough diameter and thick enough to maybe work. I ended up welding it to the steel collar that was inside of the old plastic wheel. Then I drilled it and used the grip from the old wheel with it.

That's gotta be one of the worst hand wheels ever on a lathe. It's better than nothing ATM. The good news is that the tailstock now operates way more smoothly than it has for a very long time. I don't actually think it moved in and out this well when new.

I also had some quick change tool holders sitting around. I ordered them in early 2019 for I think $5-10 total from China. Finally got them in late 2019 and only 1 of 4 would actually go onto the tool post. I fixed that today. They were poorly machined and needed filing. Now they all fit.

Hey oldgeek; have you spent any more time getting accustomed to your mini-lathe?