|

|

Post by 90GTVert on Mar 21, 2010 6:21:41 GMT -5

I got ya covered here. Displacement, compression ratio, premixing, tire diameter, etc... www.49ccscoot.com/calculators.htmlThe harder way... Cylinder Volume = ((3.1416 x Bore Diameter²) x Stroke) / 4000((3.1416 x 47.6²) x 45) / 4000 ((3.1416 x 2265.76) x 45) / 4000 (7118.11 x 45) / 4000 320315 / 4000 80.08 |

|

|

|

Post by 90GTVert on Mar 21, 2010 6:54:13 GMT -5

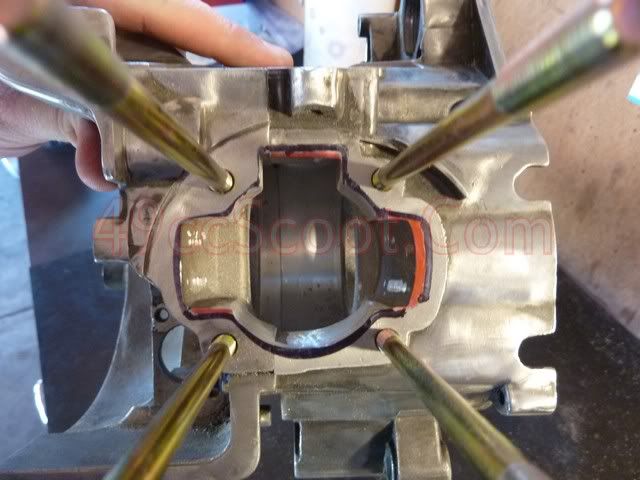

Here are a bunch of pics from yesterday that I was too lazy to upload by the time I came in. I've been finishing the walls of my garage (hopefully done today) and I HAD to get out for a ride on T2 last night. I stuck that lightened flywheel on T2 just to see how it ran. I have been having a trans tuning issue causing sluggish revs on acceleration. The flywheel did seem to make a minor improvement there. It's not a big difference, but it did something. I still need to fix the trans issue regardless. Anyway, back to this project... The cases really aren't aligned well at all stock. Here is the reed block area.  Here's the same area after a bit of filing.  Here's the cylinder area.  Pretty bad.   Before I got started on the matching, I decided to knock the lip off around the hole for the cylinder sleeve.  It will take more than that to make a BIG cylinder fit. Here's my 52mm cylinder trying to fit.  I grabbed a base gasket for the 52mm kit to see what I really needed to remove if I want it to work with a BIG kit at some point.  Here's the Airsal kit's base gasket.  I used a red Sharpie to outline the areas that need material removed to match the Airsal.  I then used a black Sharpie to outline the material that needs to be removed if I wanted to be ready for a BIG kit.  I did get enough material removed yesterday to match up to the Airsal.  I'm not sure if I wanna open it up enough to match the BIG kits or not. If I do, I would have to open the entrances to the transfers and boost port up quite a bit on the Airsal if I wanted it to match. I hate to miss an opportunity to prepare for a bigger kit someday, but I'm not sure if that's a great idea. Any input on that would be appreciated. |

|

|

|

Post by drawkward on Mar 21, 2010 7:28:14 GMT -5

When you do that, how long does it take? Do you use a dremel, or just the hand files? I can't believe they are so off at stock. That's kind of weak that they can't even make a decent mold. "Ya get what ya pay for". Anyways, you did a great job of making their shitty casting smooth and even.

|

|

|

|

Post by 2strokd on Mar 21, 2010 9:06:42 GMT -5

Good job on the case matching and cleaning Brent!

I have only seen a couple that matched nice outta the factory.

I would have to agree with you on leaving it matched to the 47mm

bore cylinder. I think if you went bigger and used a smaller jug you

would be shooting yourself in the foot. Might be a bear to seal too?

Great work!

|

|

|

|

Post by 90GTVert on Mar 21, 2010 11:19:09 GMT -5

I'm thinking that maybe I should get some port durations and see if they're way off. I know 190 said he'd heard that the transfer durations would be crazy on a standard cylinder with a stroker crank. If they look nutty, then perhaps I should just give up on the 80cc and move up to 103cc with a 54mm cylinder that's intended for 45mm stroke? I was interested to see what this setup would be like, but I don't think i'm interested enough to stick it together if the numbers aren't looking good and then have to split the cases to clearance again. I think I could seal the Airsal if I enlarged the ports, I just don't know if the big boost and transfer openings will do more harm than good. I filed the reed passage because it's all flat and didn't need a ton removed. It's still enough to let your arms know you've been working though. lol I use this drill bit on areas that need a lot of material removed. Be careful, this thing will make the aluminum fly.  Then I switch to a dremel with stones, sanding drums, or whatever works for the spot and/or files. It's much easier (to me) to file an area flat than to dremel it. It does take time and patience. I'm sure there are folks faster than me, but I probably spent 2hrs on that bit. If you are good with the rough drill bit you could cut the time a lot, but if it gets away from you it can take a chunk out of something. Some rough files can take a nice chunk if you aren't paying attention too. It doesn't help that I bolted and unbolted the cases from each other over and over checking different stuff. |

|

|

|

Post by 90GTVert on Mar 21, 2010 14:30:25 GMT -5

I traced the 52mm gasket onto the Airsal just to get an idea... and 2strokd was right. No way I'd seal it. Wouldn't be too safe with paper thin walls.  |

|

|

|

Post by drawkward on Mar 21, 2010 15:46:20 GMT -5

Maybe you could compromise and go just a little in, tapered?

|

|

|

|

Post by 90GTVert on Mar 21, 2010 16:20:16 GMT -5

I dunno. Even if I tapered the edges to 50% of what it would need, it would be very thin at the base. I think sometime, maybe Monday or Tuesday, I'm gonna see what numbers I'm looking at on port durations. I'll post 'em here and see what you guys think too.

|

|

|

|

Post by 190mech on Mar 21, 2010 18:42:00 GMT -5

Heck of a mismatch there,almost looks like 2 different halves..

Nice matching job,a bit of lube(WD-40,etc)makes hogging with

a carbide bit go a lot faster.Will be very interested to hear of

the duration numbers when you post them.A BIG bore cyl does

not leave hardly any gasket,how can they market a 'kit' to fit

a 50cc case?

|

|

|

|

Post by 90GTVert on Mar 21, 2010 19:17:04 GMT -5

Yeah, I feel kinda dumb having ever thought a 52mm cylinder would have fit without mods. At the time, Scootertronics' site said it fit with a note that it may require mods. I can;t imagine too many cases being that oversized unless they're the stock strokers.

|

|

|

|

Post by 2strokd on Mar 22, 2010 8:18:45 GMT -5

Im sure Mexicanos 100+ Mina builds started out as 50,s? Now i gotta know!

Hes just started another one in fact. Sorry to stray from the point but hes the first one that popped into my head as he has Tritons also...Ive seen 1mm of base material seal. Well not i person, but on the net i have, unless they lied?

I guess it boils down to what you really want in your set-up? And of course how that port timing is?

|

|

|

|

Post by 90GTVert on Mar 22, 2010 8:37:37 GMT -5

That's one thing that sucks about the net... or real life and people in general for that matter... you never know when someone might be lying to you to save face after a screw up. Not saying I've never left out details lol, but I'm not gonna claim something works fine for me if it doesn't and cost someone else a bunch of time and/or money if I can help it. 1mm could probably seal, but that sounds more like something I'd do if I just wanted to race. I wouldn't trust that seal and that thin aluminum when I was 50 miles from my house.

|

|

|

|

Post by 190mech on Mar 22, 2010 9:15:55 GMT -5

90cc Tritons are plentyful in Mexico,bet he's using a 90 case...

|

|

|

|

Post by 90GTVert on Mar 22, 2010 9:22:15 GMT -5

I know at least one of his Tritons started out as a 90cc.

|

|

|

|

Post by 190mech on Mar 22, 2010 11:25:21 GMT -5

That 90 crate motor is looking better all the time!

|

|