Post by 90GTVert on Mar 12, 2010 14:50:38 GMT -5

I had to go to the town where the machine shop is so I carried my parts along. I didn't really expect to see the machinist in, but you never know. Surprise! He was there. ;D He said his boss is gone next week so he'll be in the shop all week and should get this stuff done. I never knew he had another job. It's crazy to me that one of the few people in my area that will do nearly any machine work is not full time in it.

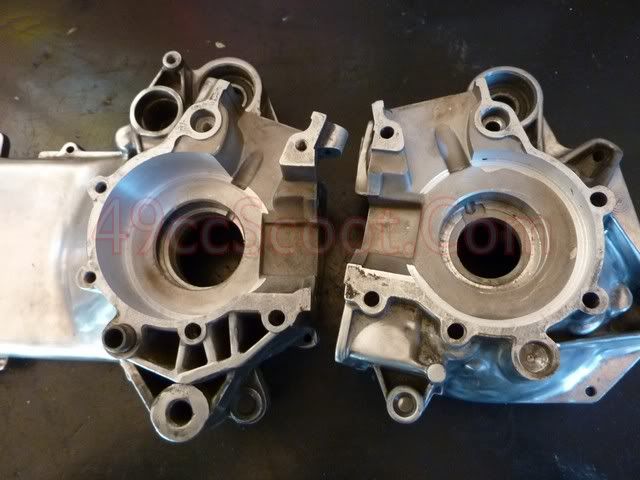

I dropped off the cases, the crankshaft, my dummy bearings for test fits, both my 2T flywheels, and my Sunl's flywheel. I told him that ideally the crankcase would be taken to 78mm diameter and the crankshaft would be reduced to 76mm. I said, "I don't know if that will affect the balance or if you are willing to do that". He told me the balance would be fine. He said he does that to the crankshaft in any serious racing engine that he builds whether it's a lawnmower of a small block Chevy. He said they are amazingly responsive when you reduce crankshaft and flywheel weight. When done to racing extremes he claims that his engines will rev nearly instantly when you hit the gas, as opposed to the sort of buildup of revs that most people are accustomed to. He proceeded to warn me that by taking material off of the crankshaft, this isn't going to be an engine that granny can hop on and ride around town all day. lol He said removing that much weight can cause driveability issues at low revs and may necessitate a high idle to keep it running, which could be really bad if my clutch is engaged all the time. I told him I can handle that. He said he'd look it all over and see what he felt safe with. He also said he could separate the crank and remove even more weight. I told him not to worry about all that just yet. I think it will be fine with the weight it has or will have because it's such a big full circle crank anyway. He also warned me about needing spacers or special pistons for the stroker and offered to make spacers if necessary. He offered to port match the cases too. It's nice to talk to someone that actually understands 2Ts around here.

Then I moved on to showing him the flywheels. He said, "there goes more of that weight". lol I told him I had seen people take .060" off the radius or .120" total of the diameter with no issues. If he feels comfortable that it will be safe, I told him he could go farther. He didn't wanna do the 4T flywheel, saying it has a different balance method. I assume perhaps he thinks it would be counterbalanced? I kinda thought all scooter flywheels were done with a zero balance, but I really don't know. The Sunl is slow anyway, so I'm not worried about that for now.

While I was there I told him about the Sunl and the work I had done trying to make it faster. I told him I suspect raising the compression may have a really good effect and he agreed from what I had told him. I told him about the 50cc head I spent a ton of time poritng and polishing then burnt the exhaust valve thanks to me knicking the valve seats. He said he could recut the seats. He's the only person in my area willing to touch that. He also said a guy talked to him about modding a 50cc 4T to try to hit 70MPH. He said he asked the guy what was wrong with him, he should be shooting for 80MPH and told him he'd make it run that hard or blow itself apart trying. lol The guy never showed up... just like 1/2 the people that talk to me about scooter work.

If you can't tell, it makes me happy to talk to a true gearhead. He could care less if it's a scooter or a Top Fueler. He likes doing this kinda stuff and seeing what he can make an engine do. It's worth the wait to me to know that's the kind of person machining my parts.

I dropped off the cases, the crankshaft, my dummy bearings for test fits, both my 2T flywheels, and my Sunl's flywheel. I told him that ideally the crankcase would be taken to 78mm diameter and the crankshaft would be reduced to 76mm. I said, "I don't know if that will affect the balance or if you are willing to do that". He told me the balance would be fine. He said he does that to the crankshaft in any serious racing engine that he builds whether it's a lawnmower of a small block Chevy. He said they are amazingly responsive when you reduce crankshaft and flywheel weight. When done to racing extremes he claims that his engines will rev nearly instantly when you hit the gas, as opposed to the sort of buildup of revs that most people are accustomed to. He proceeded to warn me that by taking material off of the crankshaft, this isn't going to be an engine that granny can hop on and ride around town all day. lol He said removing that much weight can cause driveability issues at low revs and may necessitate a high idle to keep it running, which could be really bad if my clutch is engaged all the time. I told him I can handle that. He said he'd look it all over and see what he felt safe with. He also said he could separate the crank and remove even more weight. I told him not to worry about all that just yet. I think it will be fine with the weight it has or will have because it's such a big full circle crank anyway. He also warned me about needing spacers or special pistons for the stroker and offered to make spacers if necessary. He offered to port match the cases too. It's nice to talk to someone that actually understands 2Ts around here.

Then I moved on to showing him the flywheels. He said, "there goes more of that weight". lol I told him I had seen people take .060" off the radius or .120" total of the diameter with no issues. If he feels comfortable that it will be safe, I told him he could go farther. He didn't wanna do the 4T flywheel, saying it has a different balance method. I assume perhaps he thinks it would be counterbalanced? I kinda thought all scooter flywheels were done with a zero balance, but I really don't know. The Sunl is slow anyway, so I'm not worried about that for now.

While I was there I told him about the Sunl and the work I had done trying to make it faster. I told him I suspect raising the compression may have a really good effect and he agreed from what I had told him. I told him about the 50cc head I spent a ton of time poritng and polishing then burnt the exhaust valve thanks to me knicking the valve seats. He said he could recut the seats. He's the only person in my area willing to touch that. He also said a guy talked to him about modding a 50cc 4T to try to hit 70MPH. He said he asked the guy what was wrong with him, he should be shooting for 80MPH and told him he'd make it run that hard or blow itself apart trying. lol The guy never showed up... just like 1/2 the people that talk to me about scooter work.

If you can't tell, it makes me happy to talk to a true gearhead. He could care less if it's a scooter or a Top Fueler. He likes doing this kinda stuff and seeing what he can make an engine do. It's worth the wait to me to know that's the kind of person machining my parts.