|

|

Post by 2strokd on Feb 25, 2010 8:45:39 GMT -5

Nice, i like the files, and the price is right!

Thanks for the helpful tips. Very good info!

|

|

|

|

Post by 90GTVert on Feb 25, 2010 8:54:34 GMT -5

While I'm at it, here are a couple more good options for some porting/clean up bits at a good price from Harbor Freight. 249pc. bit set for $19.99. I bought this one. Nice budget kit. You will still need to buy the good tungsten carbide and or diamond tipped cutting bits though. They are about $10 each IIRC. www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=93243Here's a little smaller kit for half the price. www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=96828The aluminum oxide stones in the kits above have given me pretty god results. I used those mostly when doing the aluminum head form my Sunl. You can get the $9.99 kit and it's cheaper than if you just buy the stones individually. If you have a better bulk source for those stones though, please share. If you really wanna get into the ports from the inside of the cylinder you need to get something that more resembles a dentistry tool. These get pricey. I am considering something like this, but the price keeps stopping me. www.ccspecialtytool.com/ |

|

|

|

Post by 2strokd on Feb 25, 2010 9:13:33 GMT -5

I gotta invest in some more good tips and bits too, thanks for the goody links...I did pick up some diamond tip bits yesterday. Oh, i forgot to show you this link to the timing gaskets, sorry. Looks like they are out right now anyway  www.provoscooter.com/athena-cylinder-gasket-set-70cc.html www.provoscooter.com/athena-cylinder-gasket-set-70cc.html |

|

|

|

Post by 90GTVert on Feb 25, 2010 9:18:34 GMT -5

Thanks for the link. I never even saw them when I looked there. I wouldn't have waited for them to get in stock anyway, so no worries.

|

|

|

|

Post by 90GTVert on Feb 25, 2010 10:12:47 GMT -5

Here's a good link for Dremel grinding bits etc... If you buy 12+ of some of the aluminum oxide stones they're only $0.73 each. I picked up 12 of 2 types that I've had good luck with (pink cones and cylinders). www.widgetsupply.com/page/WS/CTGY/dremel |

|

|

|

Post by 2strokd on Feb 25, 2010 10:34:32 GMT -5

Right on...I like the pink cones and barrels too! Work good on aluminum.

|

|

|

|

Post by 90GTVert on Feb 25, 2010 13:28:25 GMT -5

The machinist is going to stop by my house over the weekend to talk and pick up the cases and other stuff. I stopped by 4 times and finally called. Shoulda just called in the first place. I never do anything right lol.

|

|

|

|

Post by stepthrutuner on Feb 25, 2010 14:34:44 GMT -5

I've thought about posting this before and now seems to be the appropriate time. For those first starting to do port work it might be a good idea to use a very cheap and underpowered rotary grinding tool. Here is the one from Harbor Freight: www.harborfreight.com/cpi/ctaf/Displayitem.taf?itemnumber=94076The add says powerful but powerful it ain't. It is actually a dc device with a small converter that plugs into 120vac. This tool easily stalls out, necessitating the user to apply very little grinding pressure. It forces the user to proceed slowly and avoid over cutting. Also a slip of the tool has less negative consequences. Hell, you can hardly get a decent fast food meal for the price of this tool and it comes with a bunch of grinding etc. attachments.... thought this might be valuable info for 'porting newbies'. |

|

|

|

Post by 90GTVert on Feb 25, 2010 15:36:32 GMT -5

That is a great deal for a starter kit. Never really thought about an underpowered tool for beginners, but it's a cool idea. Anyone used to a Dremel or similar tool would probably become very agitated using it though.

|

|

|

|

Post by 90GTVert on Feb 25, 2010 20:21:44 GMT -5

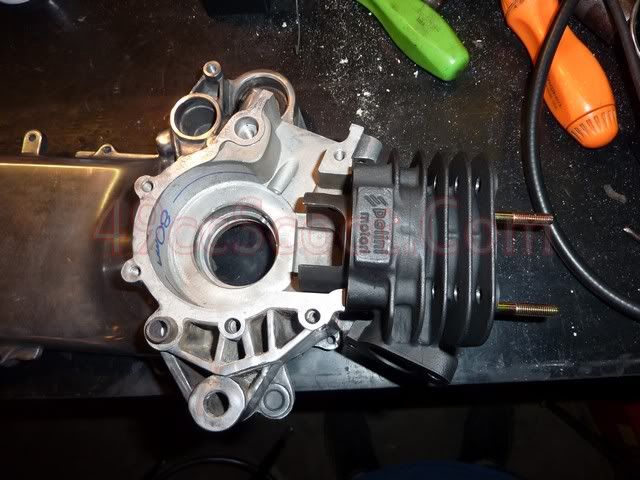

As I said earlier, I'm not completely sure I'll use the Airsal T6. I could use the Polini Contesta (Sport). Might as well do a little prep work to the Polini as well... Knife edged the transfers. No boost or exhaust port bridges to work on the Polini.   I stuck the cylinder onto a case half to see how things look. Tried a base gasket for each cylinder and it looks like either will need quite a bit of case matching. (Yes, I mark the measurements I need machined on my parts. I figure it makes it easier for the machinist and leaves less room for error.)   I decided to enlarge the opening of the boost port just a little as well. Not sure if this will accomplish anything.   I used a tungsten carbide cutter and an aluminum oxide stone for a Dremel to do all of this. I still need to chamfer the ports, but I'll wait till I get my new files in so I can try them out. After handling the aluminum Airsal last night, the iron Polini feels like it weighs a ton. |

|

|

|

Post by Fox on Feb 25, 2010 21:56:44 GMT -5

I really wish I had the tools and knowledge you have Brent. I turned down a guy who wanted me to replace a crank and rear gears on a Minarelli yesterday.  That Triton is bad-ass. It looks like a stealth bomber. Like something the Navy Seals would use at night. Can you imagine the racket a platoon of those things coming would make.  |

|

|

|

Post by 90GTVert on Feb 25, 2010 22:24:50 GMT -5

I'm just learning as I go. Special forces can't use 2 strokes. Even the elite are still human. They'd be distracted trying to wheelie and race each other and talking about how fast they are compared to their 4 strokes and all the terrorists would get away.  |

|

|

|

Post by 190mech on Feb 26, 2010 5:38:54 GMT -5

If the cases look like too much meat might be removed,how about

taking a MM or 2 off of the crank wheels,just a thought...

|

|

|

|

Post by 90GTVert on Feb 26, 2010 7:14:03 GMT -5

Not a bad idea, but I think at 80mm it will be OK. I might get a second opinion from the machinist when he stops by. If he feels more comfortable removing material from the crank, we can go that way. I've seen people cut into the bolt holes before and they say that's still alright as long as you make sure the cases bolt together tight (not that I have any desire to do that). Both times the people used longer bolts that went all the way through both cases and used a nut on the end. After reading more, I do wish I got a 47mm crank though. Some of them are 76mm OD, so the cases only get cut to about 78mm... and it's almost a square bore/stroke.

|

|

|

|

Post by 2strokd on Feb 26, 2010 7:59:33 GMT -5

Not tryin to thread jack or anything but since your on the subject, heres a b&a of my boost transfer. You can see were the bit walked outta the port a couple times  . I guess thats were the practice comes in lol  . Im happy so far.   |

|