|

|

Post by kevin55950 on May 19, 2013 0:33:03 GMT -5

Second layer of epoxy done (inside of the case, outside is solid) Need some sanding, I took 1mm off to apply a layer of epoxy everywhere without making thicker the reed area, so I'll always sand epoxy and not epoxy and aluminium (same hardness everywhere will make sanding easier for me) I'll drill the bearing lube holes once set properly. I'll also drill second lube holes in the transfert/cyl ports area. I'll recieve my exhaust on monday and MVT Digital Direct ignition in ?? days. I'll get a 5 degree reed spacer to match with the case work also. |

|

|

|

Post by kevin55950 on May 21, 2013 21:13:46 GMT -5

Beginning of the frame work How does it look ?  Zuma wheels and forks Pretty tricky to install ( the T bearings aren't the same and the diameter is different, but parts will be machined tomorrow)  |

|

|

|

Post by moofus02 on May 22, 2013 5:12:37 GMT -5

Beginning of the frame work How does it look ?  Zuma wheels and forks Pretty tricky to install ( the T bearings aren't the same and the diameter is different, but parts will be machined tomorrow)  Sharp i like it Sent from my PG86100 using proboards |

|

|

|

Post by kevin55950 on May 22, 2013 12:05:14 GMT -5

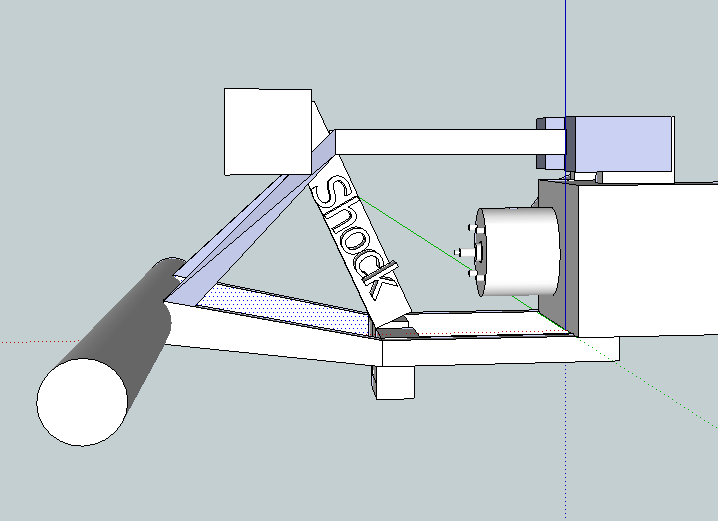

Now I have to repair and modify my engine mount for rear facing carb, or I've been thinking about something like this :  I made it very fast.. But that's just to show the ''system''. But with this system I need to get a more solid bracket welded on my case (where there is normally the center stand, it's cracked on my case and it's not very solid from factory), which can be pretty expensive but the scooter can have a pretty long suspension travel with this, ideal for lapping races and I can lock it for drag racing (steel bar). |

|

|

|

Post by aeroxbud on May 23, 2013 5:06:29 GMT -5

Those wheels look good on there  |

|

|

|

Post by kevin55950 on May 25, 2013 0:28:16 GMT -5

I received my exhaust and ignition. Pictures tomorrow !

|

|

|

|

Post by kevin55950 on May 27, 2013 14:25:17 GMT -5

And here it is ! The Cylinder fitment is pretty huge, 34-35mm. (where the flange fits, around 30mm after the flange fitment) It has the ''race'' silencer which is more silent than the ''run'' silencer, which is smaller and all Kevlar covered, not black like mine. The ''Race'' is the the silencer I hoped to receive because the other one is way too loud to even go at my local drag strip. Weldings are well done !   this is where the cylinder flange fits  These are the different length flanges that came with the exhaust:  Ignition :  The only strange thing: Why did it doesn't come with spark plug wire and cap ?! At the price they sell the ignition, why doesn't including it ? |

|

|

|

Post by 90GTVert on May 27, 2013 16:27:23 GMT -5

Great looking exhaust. Swappable flanges are a cool idea. I had an adjustable stinger on an old 2T midbike pipe that helped to change when it hit. It's good finally see something of the sort on a scoot pipe.

|

|

|

|

Post by kevin55950 on May 27, 2013 17:10:14 GMT -5

Any flange is a good idea IMO. Easier to install on different scooter models.

|

|

|

|

Post by aeroxbud on May 27, 2013 17:23:36 GMT -5

Real nice looking pipe  |

|

|

|

Post by kevin55950 on May 27, 2013 17:24:29 GMT -5

Thank you  I hope it performs as well as it looks |

|

|

|

Post by kevin55950 on May 29, 2013 21:07:45 GMT -5

Some issues with epoxy (didn't dried completely at some places), I took the undried epoxy out and added new one weighted with a more precise balance. I brought a Stage6 reinforced gear cover which doesn't fit. I'll epoxy the 2 places where the screws doesn't fit and machine the case. The stage6 one is less large at 2 places, so I'll fab a flat aluminium plate and add epoxy where needed. the aluminium plate will be used to keep it flat as much as possible.   |

|

|

|

Post by kevin55950 on May 29, 2013 21:47:58 GMT -5

Finally the cover will not fit that well

the wheel shaft is loose in the cover and I don't want to screw with this...

MBK Nitro wheel shaft are pretty expensive and now having 40hrs+ at work makes those fitting jobs to avoid as I will miss time to do all the things I have to do.

Gonna sell it ..

|

|

|

|

Post by kevin55950 on Jun 5, 2013 12:23:53 GMT -5

After 2 hours of sanding the case at 180 grit, that's how it looks. Need to fill some holes with epoxy and file the reed area (not cyl side, wheel side) to fit 5 degree reed spacer.  Is there an advantage to fit the reed valves the Piaggio way ? Mina reeds are larger but the angle of the piaggio reed block ( perpendicular to Mina reeds) seems to perform better. |

|

|

|

Post by 190mech on Jun 5, 2013 19:50:05 GMT -5

|

|