|

|

Post by 90GTVert on Jul 25, 2013 9:26:01 GMT -5

I was just out there looking it over and I realized that some use a different o-ring. Some set it on top of that little ledge, and others have it around that ledge on the TD. I'm gonna see if the other style works with this TD cover.

|

|

|

|

Post by 2strokd on Jul 25, 2013 9:27:50 GMT -5

Great point! I noticed this when installing a new OEM rear pulley on my Truck..

Forgot all about that.

|

|

|

|

Post by kevin55950 on Jul 25, 2013 9:39:31 GMT -5

Removing the sponge filter and installing a pod filter on the tip of the airbox makes a bigger ''air reserve'' between the carburetor and filter which CVK carburetors seems to like when you install a big bore cyl. kit or other performance parts (with my pretty little experience mines liked a volume similar or sightly bigger than the engine volume between filter and carbs).

I experienced this while tuning my ATV's last year while I wasn't having a stock airbox for the 500, which didn't fit my frame. I calculated between 250 and 300cc of hose volume per carburetor (500cc twin), added small pod filters on both and it ran the best for me. My 250cc single cyliner was running strangely at lower RPM with a pod filter directly on the carb, adjusted or not, and ran the best with the hose and pod.

These CVK carb seems to like having some kind of restriction and air reserve to perform better. Free-flow and it perform worse than stock. But that's with my experience it might be really different on 4T scooters.

|

|

|

|

Post by 90GTVert on Jul 26, 2013 6:22:19 GMT -5

I've been wondering why it's taking so long to get the torque driver ball bearing base from PFS . I just looked up the order and tracking. Turns out it was out for delivery last Saturday... but I never got it. It does say delivery status not updated on Sunday. It should say delivered so I don't know what the local post office has done with it. I get my neighbors' mail regularly so someone else may have got it and kept it or tossed it out or it's rolling around a mail truck somewhere or on it's way back to PFS ? I've seen boxes lying in the road before that have fallen off of the mail truck too, so that's another possibility. Picked one up for someone out of my ditch about a month ago and took it back to the post office. I guess everything about this torque driver experience is going to be a pain.

|

|

|

|

Post by moofus02 on Jul 26, 2013 6:52:20 GMT -5

The mail can suck. Spi mails California to Michigan takes 3 days I returned something the same way on July 3rd it was in California on 5th but took another 7 days to get delivered go figure. Had some papers shipped to me by FedEx for a sat delivery I got it Monday when my neighbor dropped it off. I've got one of those reflective address signs at end of my driveway but FedEx missed my by half a mile. I drive truck and if I pulled either one those methods week late or deliver to wrong customer I'd get fired

Sent from my SPH-L720 using proboards

|

|

|

|

Post by 90GTVert on Jul 26, 2013 10:21:08 GMT -5

Parts For Scooters got back to me already. They said if it doesn't show up today, let them know and they'll send out a new order. All they asked is that I verify my address, which was correct, and I told them I don't see it at all as their fault since it made it all the way to the post office and onto the mail truck according to tracking numbers.

|

|

|

|

Post by 2strokd on Jul 26, 2013 10:41:31 GMT -5

Let em send it.. They have coverage for it, more than we do anyway  |

|

|

|

Post by 90GTVert on Jul 26, 2013 11:29:43 GMT -5

Yeah, I won't argue. I'm just not used to getting that kind of service. lol Not from them, but I mean when I've had issues anywhere else lately it's a hassle. I ordered something off of eBay a month ago and when the seller sent the wrong item he didn't even wanna cover shipping on something that was clearly his mistake until he realized what he sent was worth 4X what I bought and I told him not to worry about it I'd just keep it if shipping charges were unfair to him.  |

|

|

|

Post by 90GTVert on Jul 26, 2013 13:14:25 GMT -5

I mounted the GoPro to watch the Trail Tech. I figured this way I could watch speed/RPM over and over if I'd like to evaluate runs with different TD groove angles and also it could come in handy in a video update.  I made a pass with both angles of the NCY torque driver. Vids aren't exactly super clear because of glare, aliasing of the video, and vibration, but it's still easy enough to see speed and RPM as I accelerate. When I first put in the new Hoca 1K contra spring it looked like there was a larger spread of RPM with the 50 degree groove vs the 53 degree. As time went on, it seemed that the RPM fluctuation changed as the spring/CVT heated up and it stayed in a more narrow range. Not a huge difference, but it was enough that I questioned the choice of the 53 degree groove, which seemed counter-intuitive to me anyway with such a low power setup. Of course I had tested them back to back though, and I trust results vs thoughts or theories generally. Now that the spring has been broken in with some riding, it seems that the 50 degree groove is indeed the better performer. RPM spread is close with the 2 angles, but (as I would have thought) the 50 degree groove is reacting a little better with the low power setup/fat rider. That's probably gonna be the winner this time around, but I'm not done yet. As much as I'd like to get the show on the road and go back to trying out igntion components, I'm going to wait on the Hoca ball bearing seat and get it working with that. I am noticing that the most heat in the spring is clearly at the base when I swap things so hopefully the Hoca part will help to eliminate some heat and make things more reliable if nothing else. Maybe that will save some future headaches like this go-round from popping up? I don't think I'm gonna worry so much about trying to match any previous benchmarks. I'd like to, but I don't really think I will be able to get an exact match up short of getting another TaoTao driver that will likely wear in the same way with haste. I'm just looking for a good reliable setup to compare to at this point. I still may not get it, but the Taiwan made TD and springs may be more likely to provide it that the stock Chinese stuff. I can dream anyway. lol At least some good news is that the front brake does seem to be working a little more freely with the new caliper. I also didn't feel the cruise speed vibrations on my very brief test runs, so I'm hoping that the DynaBeads did their job. I won't really know till I cruise for a bit. |

|

|

|

Post by 90GTVert on Jul 26, 2013 14:18:21 GMT -5

My mail hasn't even showed up yet and PFS decided they wanted to get the spring base to me so they just went ahead and shipped it at no cost to me and via UPS this time. Thank you to them!

|

|

|

|

Post by 2strokd on Jul 26, 2013 14:31:49 GMT -5

Love the GoPro,s hair  |

|

|

|

Post by 90GTVert on Jul 26, 2013 14:59:36 GMT -5

lol Can't use an open back panel to catch more engine noise without it. Doesn't seem to work much beyond 30MPH, but the Tao is slow so it works great for now.  |

|

|

|

Post by 90GTVert on Jul 28, 2013 10:43:45 GMT -5

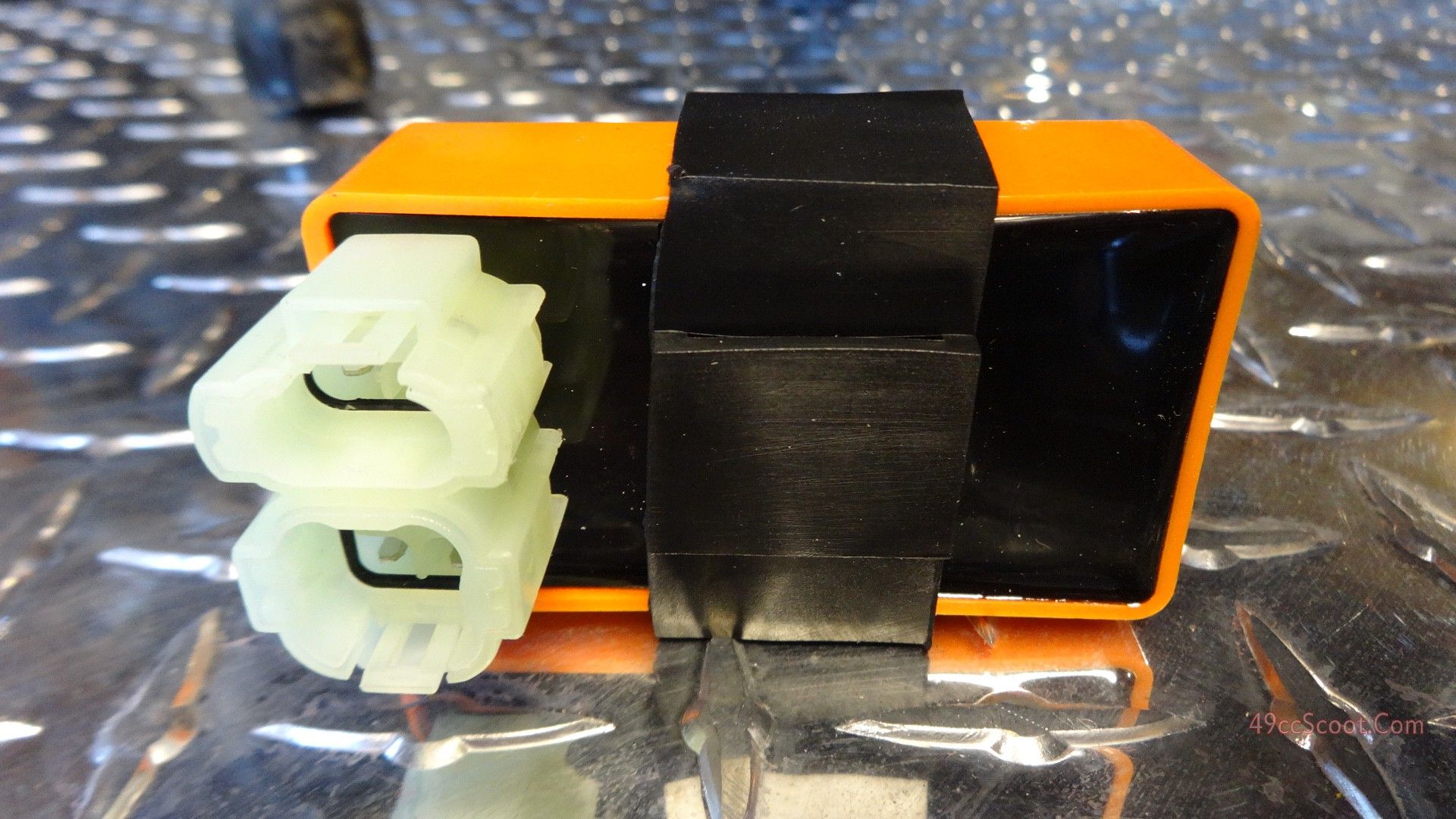

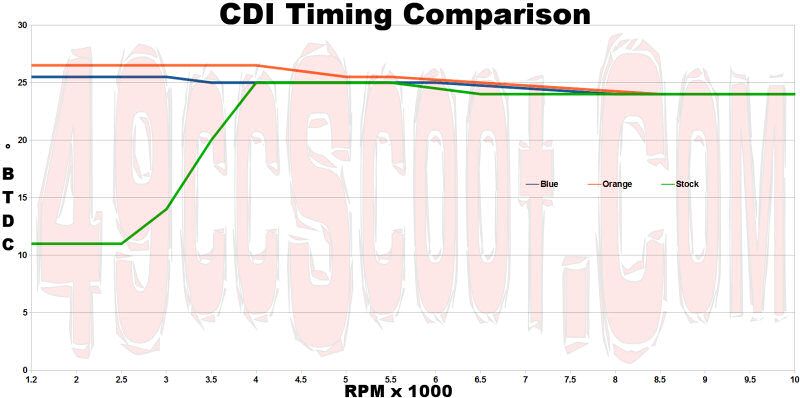

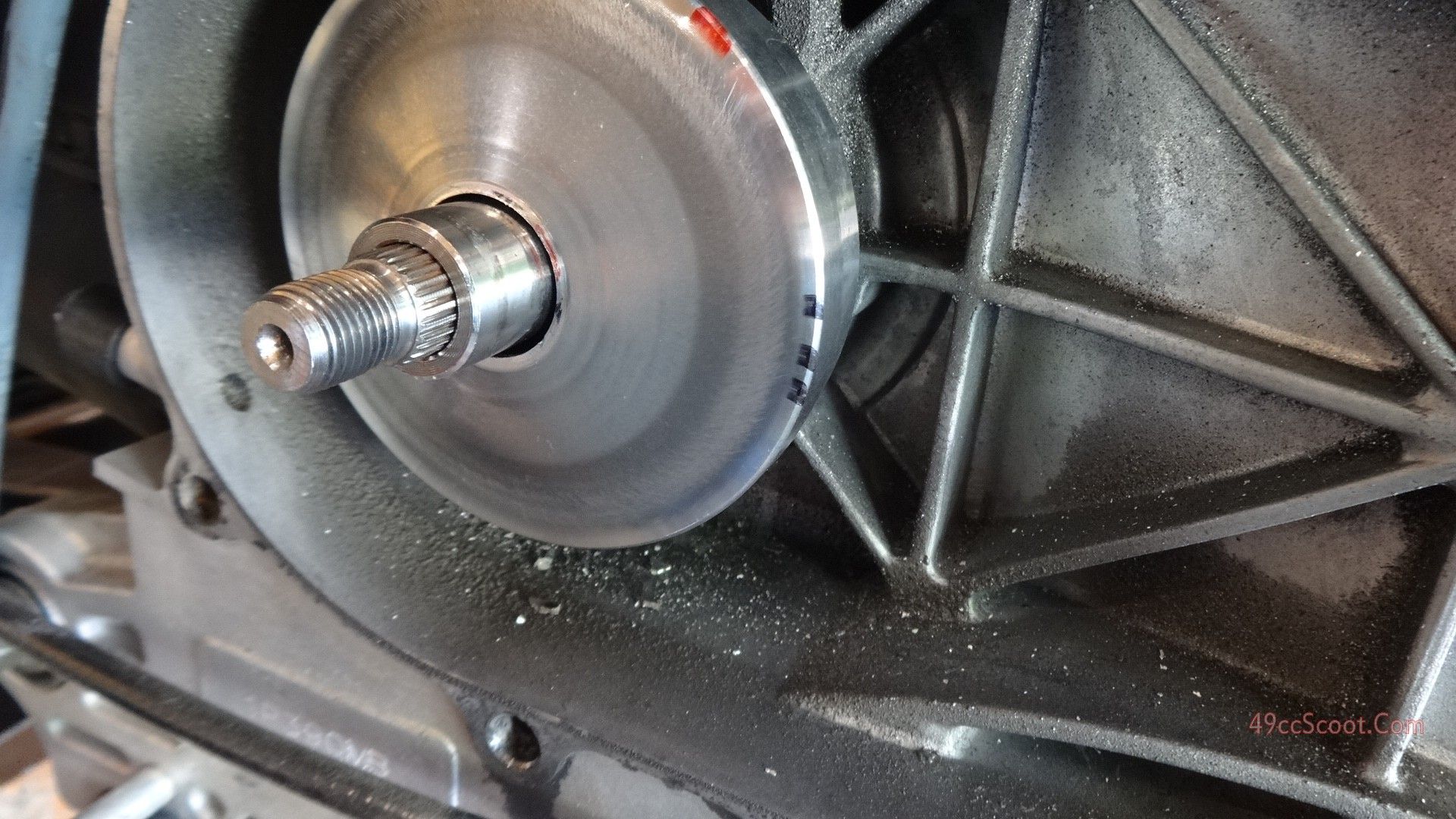

Since I'm sitting around waiting on a part, I got the timing info together for the stock and performance/racing CDIs that I planned to have tried awhile ago. The CDIs are stock, a blue racing/performance CDI from ScrappyDog and the orange racing/performance CDI from ScrappyDog.  Blue CDI description... "Here it is for those of you that must have the best. Racing CDI for GY6 based engines in 139qmb and 157qmj and also the 125cc version also. Works with any AC ignition systems with this type plug on it. This is similar to our orange performance CDI, but a more agressive ignition advance curve. Recommended for the serious build."  Orange CDI description... "Scrap that limited stock CDI and drop in this unlimited performance CDI with no governer, and an advanced spark timing. This will increase acceleration and top speed by 5-10%, if all else is well." I used my timing light and the stock pointer/flywheel timing marks for these numbers. I removed the variator and belt to make things a little safer and easier.  Above 6-7000RPM I had to switch to 4-stroke mode on my timing light, otherwise it jumped around. 4T mode means 1 spark every 2 revolutions vs 1 every revolution as it should operate since these 4Ts are "wasted spark" setups. Hopefully it's still reasonably accurate. What's pretty clear is that the blue CDI is not all that much different from the orange, and has less advance even though it's description says it has more. Maybe these are busted like the red hot coil I tried to use, or maybe it just shows that a lot of dealers are like us... they believe whatever the packaging says. Max advance that I see on any of them is 26.5° BTDC and that's the orange CDI up to 4000RPM. The blue CDI is at 25° at that point and the stock CDI starts off at 11° and works to meet up with the blue CDI at 25° by 4000RPM. After that the difference in orange and the rest gets even smaller until they all equal out by around 8000RPM at 24°. The next largest span is 1°at 6500 RPM between the orange (25°) and stock (24°) CDIs. The thing that was most clear without really testing is that the scooter is harder to start with the aftermarket CDIs. The scoot goes from starting very quickly with stock to needing to crank a bit with either aftermarket CDI. With my CVT tune (as best I know it will be) the clutch isn't really grabbing till over 6000RPM and then I'm accelerating and cruising in the 7000-8000RPM range primarily with even max speeds generally occurring at 8200RPM or less. That makes most of the stuff below 6000RPM somewhat useless when speaking of speed and acceleration. It seems to me that the stock CDI has the better curve of the three, simply because it allows for easier starting. Aside from that, they aren't all that far apart. I'm gonna do test rides and 0-30s with them anyway once I get the CVT stuff settled, but I think modifying the pickup mount so it can move a little would not only be cheaper (free if you have the tools/time) but also more effective and cause less starting headaches. |

|

|

|

Post by 90GTVert on Jul 28, 2013 10:49:08 GMT -5

Oh, almost forgot. On top of trying to check timing to 10,000RPM I did also verify that the stock will rev beyond 10,000RPM. I saw almost 12,000RPM (11,740 IIRC) with a rev of the throttle on the stand. That's beyond anywhere any standard setup would ever need to rev.

|

|

|

|

Post by 90GTVert on Jul 30, 2013 18:44:46 GMT -5

I went for a test ride last night to see how it's doing with the NCY torque driver using the 50 degree grooves. I was pleased to see that my average WOT cruise speed was back to 33-34MPH. It still doesn't perform as it did with the stock TD though. It's pretty obvious whenever I have to get in and out of the throttle that it needs more power to better use the angles of the NCY piece. If there's a 47-48 degree grooved torque driver made, it would probably be nice for the stock engine so it could stay in a more narrow RPM range easier (my stockers were 49 degrees). Max speed was about 37MPH and fuel economy was right about on par with the 53 degree grooves, at 86.8MPG. Nothing to write home about, but on the way to a reliable setup I thought and that's what I'm really wanting ATM. The strange vibration that I have mentioned and hoped may be in the tires was still present. Either the DynaBeads didn't work or it's not the tires. I discovered that the instrument cluster panel is cracking. By the time I finished the ride mentioned below, more chunks were missing than what is shown in the pic below. Most of the plastic that has this look on the scoot is more pliable, but for some reason they used brittle plastic here.  I went out today to make some 0-30MPH runs and get a couple of pics for scooter tag. The scooter tag I did was on a dirt road. I thought I was gonna wipeout for a second on a turn where dirt goes back to pavement when I hit some loose dirt. Caught it though and continued on. Then I started noticing that the vibration was changing and it was accompanied by some noise. Everything seemed to be getting a little more sluggish. When I stopped at a stop sign and took off, it was as if the clutch never disengaged. Then at the next stop it did. I thought maybe the open CVT cover and messing around on dirt roads had caught up with me and I may need to do a good CVT cleaning. I got the scoot home and sand was falling out of it, so it seemed like a reasonable idea.  When I popped the CVT cover off I no longer suspected dirt as the issue. I found metal chunks and dust and the variator was riding quite loosely on the drive boss.  Here's a look with the vari removed.  This is what I dumped out of the variator.  Note the marks from the variator grinding on the boss.  Parts of the variator are busted off and chewed up.   The bushing is jacked up.  Sliders have been nearly indestructible for me with lots of CVT failures on other scoots, but this time the 4.5g sliders got chewed up.   That's a first for me. Never had one do that. I ordered a new variator to replace it and another set of sliders. Within 600 miles or less half the CVT has screwed up, seal issues, and plastic has been cracking off left and right. It figures. The Hoca ball bearing base showed up today, so I almost got back on track.   Stuck again waiting on parts. I did at least take it out and clean everything up to get the crap out of the CVT area and all of the dirt and dust off of the scooter.  |

|