Project TaoTao : ATM50-A1 Four-Stroke Experiences & Upgrades

Jul 16, 2013 21:55:54 GMT -5

2strokd likes this

Post by 90GTVert on Jul 16, 2013 21:55:54 GMT -5

Well, I wish it were as easy as cleaning the CVT or swapping the contra spring like I thought at the last update. While cleaning the CVT, I also ground the stock contra a little to sorta smooth it out.

No such luck. Still did the same thing. Replaced the stock contra spring with a Hoca 1,000RPM blue spring and ground it as well.

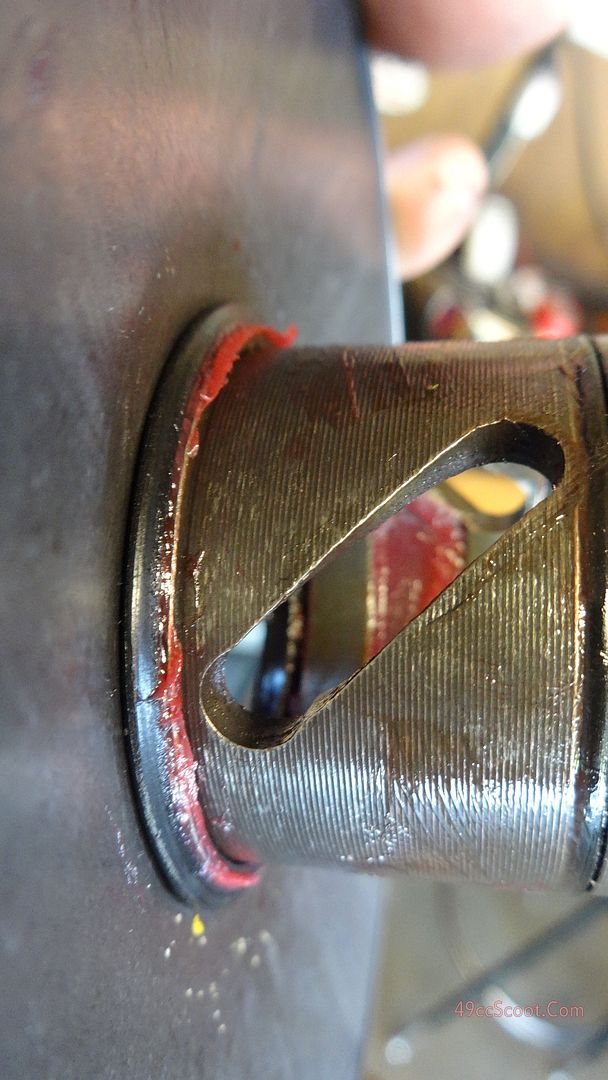

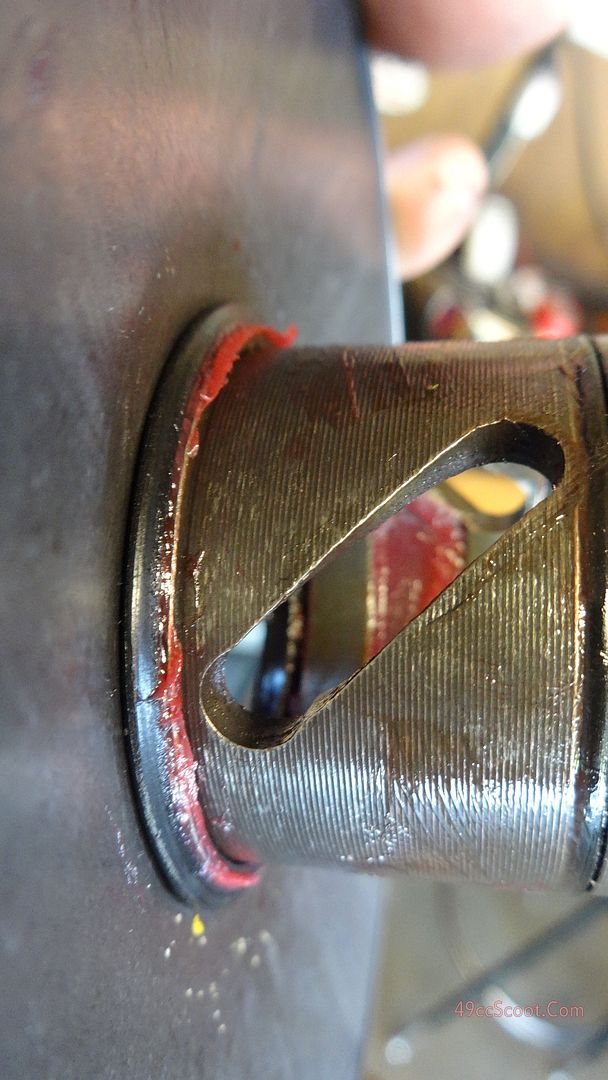

Nope. Still not right. I could get the revs up but there was always this shift at or near WOT cruise speeds. I noticed something in the torque driver when I cleaned it, but was hoping I'd get lucky and it wasn't the problem. The torque driver grooves are all wearing and making it so there's a little resistance to open all the way and then more resistance to move once in high gear. This seems to happen every time I do a project and just want things to be consistent.

Luckily I did have another torque driver around from the SunL days (my first and only other 139QMB). Seems better made... which is amazing if any of you remember my opinion of the SunL's quality. lol

I swapped that in with the 1K contra and worked on finding the right weights. I got them dialed in to either 5.25 or 5.5g as the better performers... but speed was low. I was averaging about 32MPH max speed on my test runs. Normally I had been averaging 33-34MPH WOT cruise speeds before all of this. I had wanted to keep the 1000RPM contra in hopes that it would be less likely to fade than the stock spring, but I thought maybe I should try going back to the old setup. I swapped the stock contra back in with 4.75g sliders, just as it had been running well before. Then I saw 33 or so avg speed, but RPM was low and I got more of a drop off at the top of the speeds. For example, with the 1000 contra one run was 7850RPM avg and 32.3MPH avg, while with the stock contra I saw 33.2MPH avg speed and 7300RPM avg. With the stocker it would hit maybe 7500-7600 for a bit, but then drop down somewhere over 30MPH to about 7100RPM and start pulling up again. Nothing I did was making the acceleration smooth as it was, unless I sacrificed speed.

That made me wonder about the spring rates and if maybe it had something to do with how much force it takes to compress the spring at first, near installed height, and then toward the end, compressed height. Maybe the stock spring is just too soft period, or maybe if the force needed is not linear it could throw things off? I tried to check real quick, but maybe I was wrong and there was coil bind with the 1000RPM? Just not sure what to think ATM.

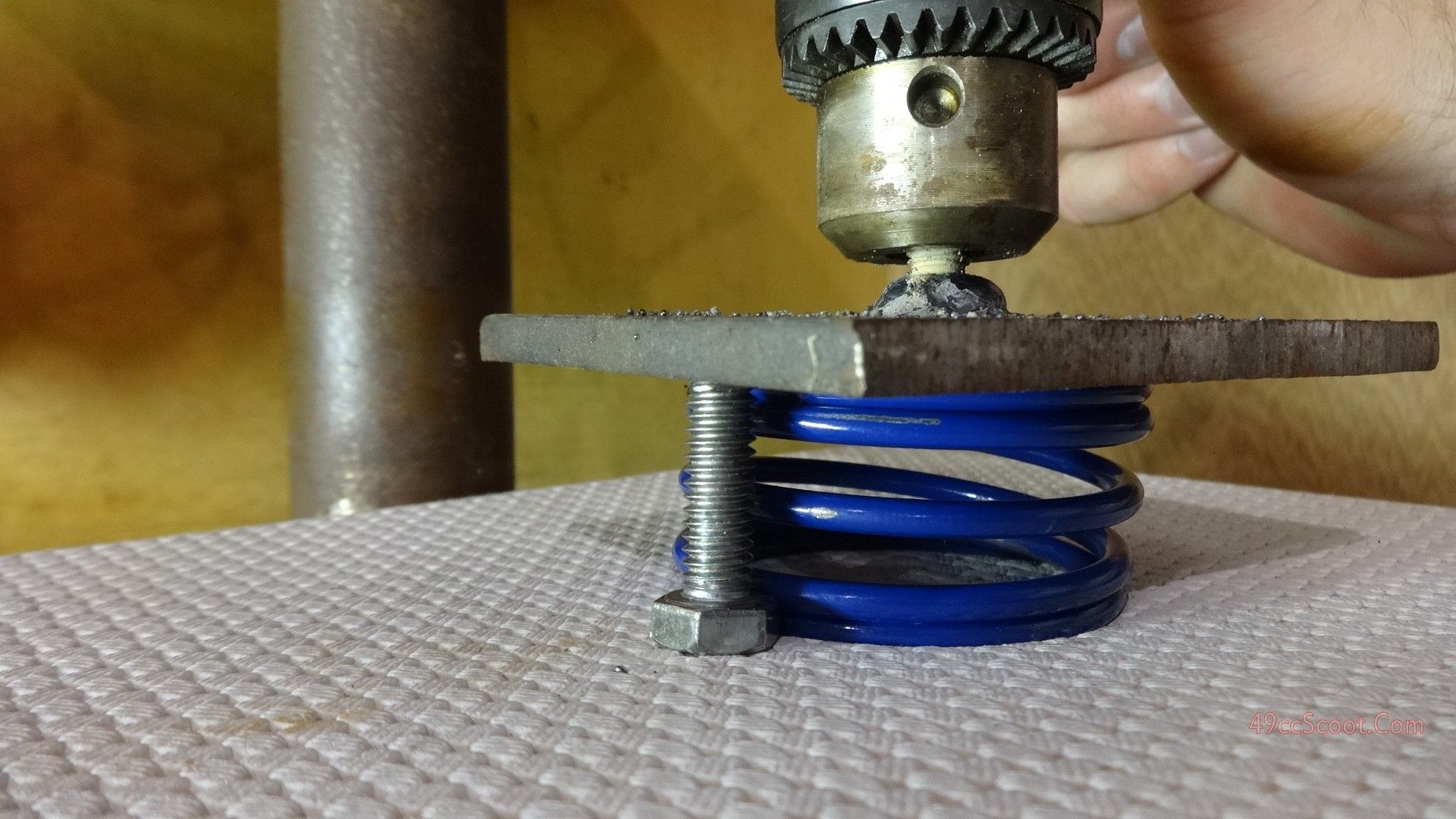

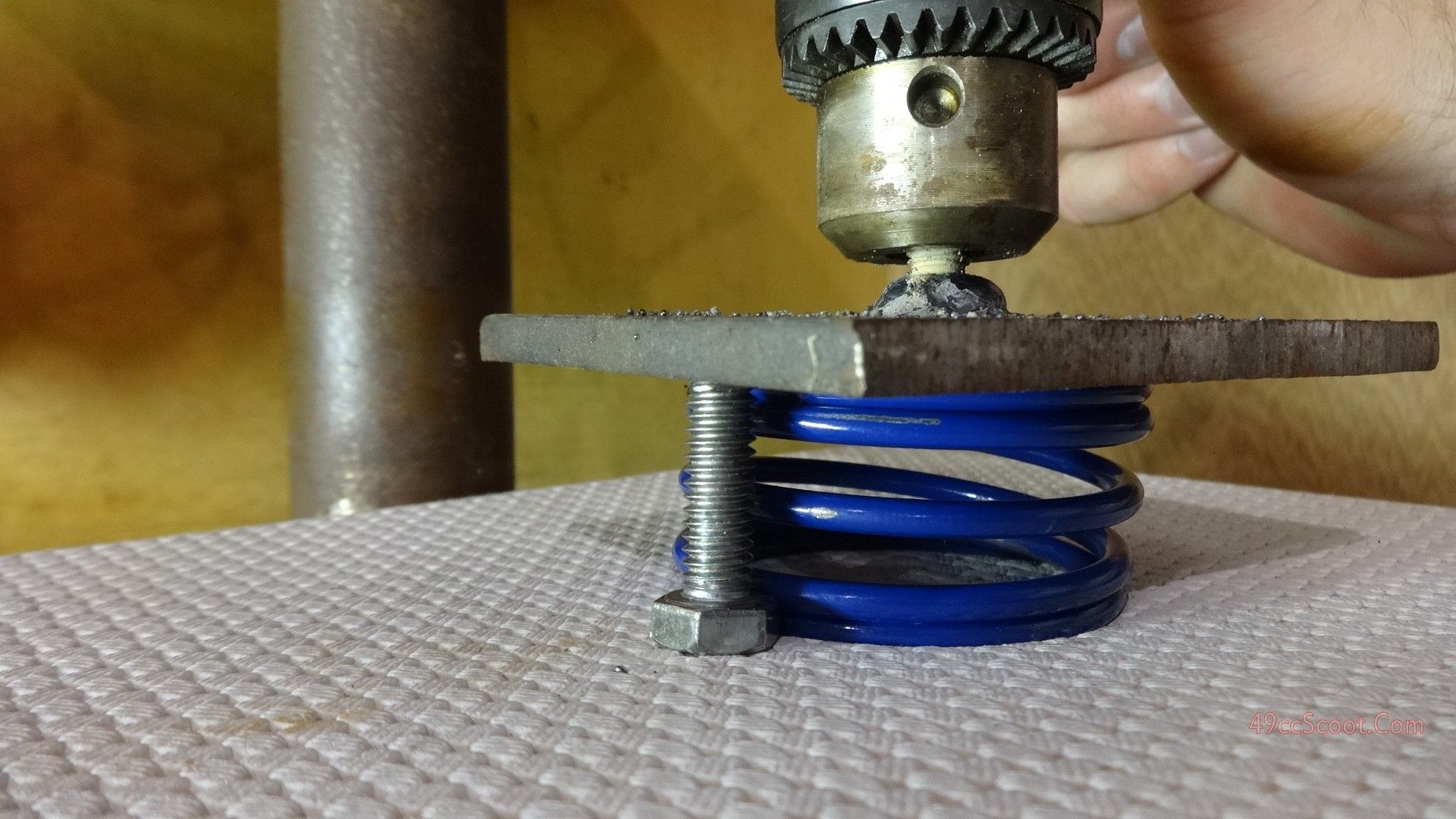

Might as well try to measure the spring rates. I was frustrated with riding up and down the road and swapping things to no avail anyway. I had a piece of 1/4" steel left over from something long ago, so I welded a bolt to the center of it. This way I could chuck the plate into a drill press.

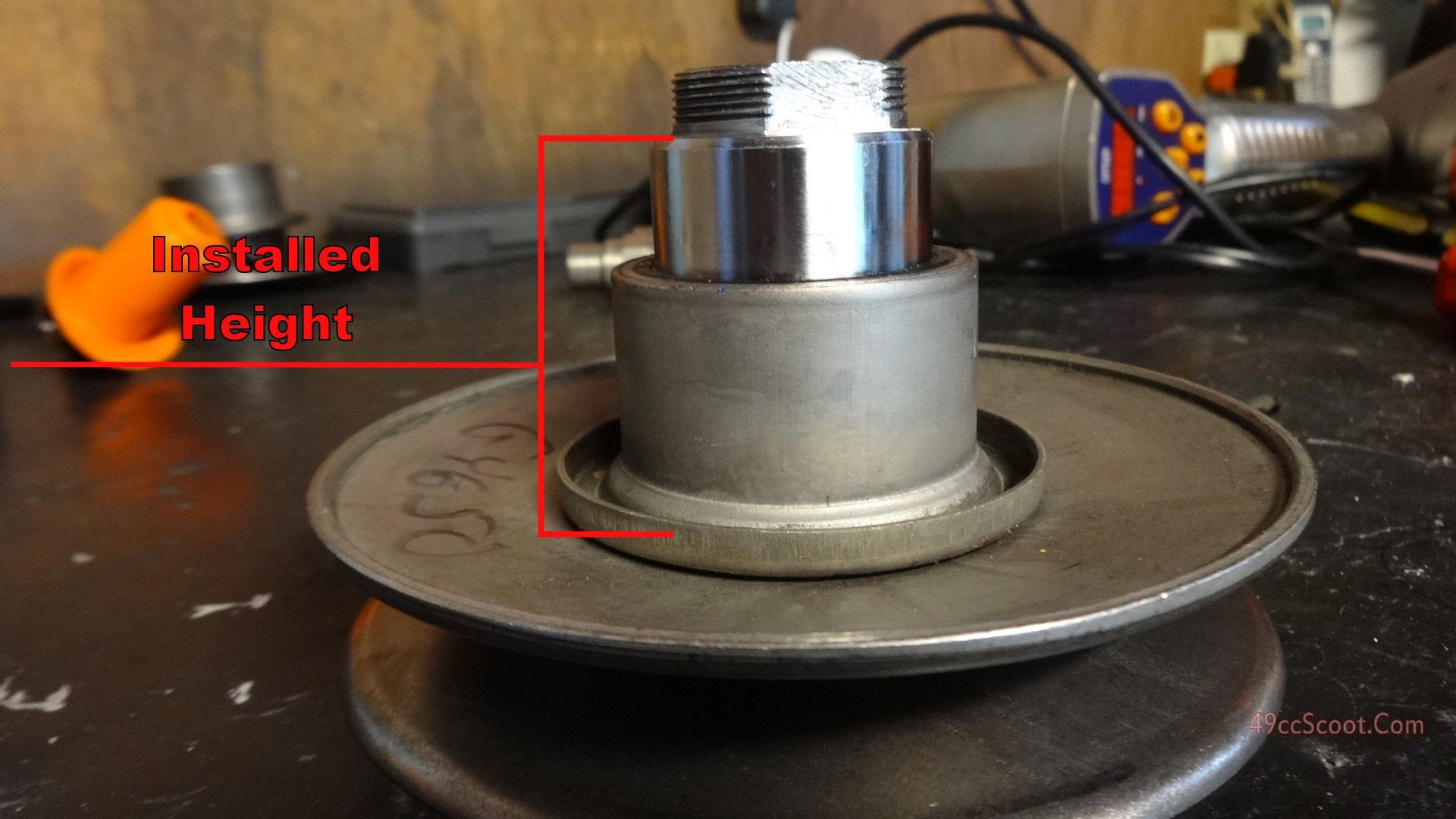

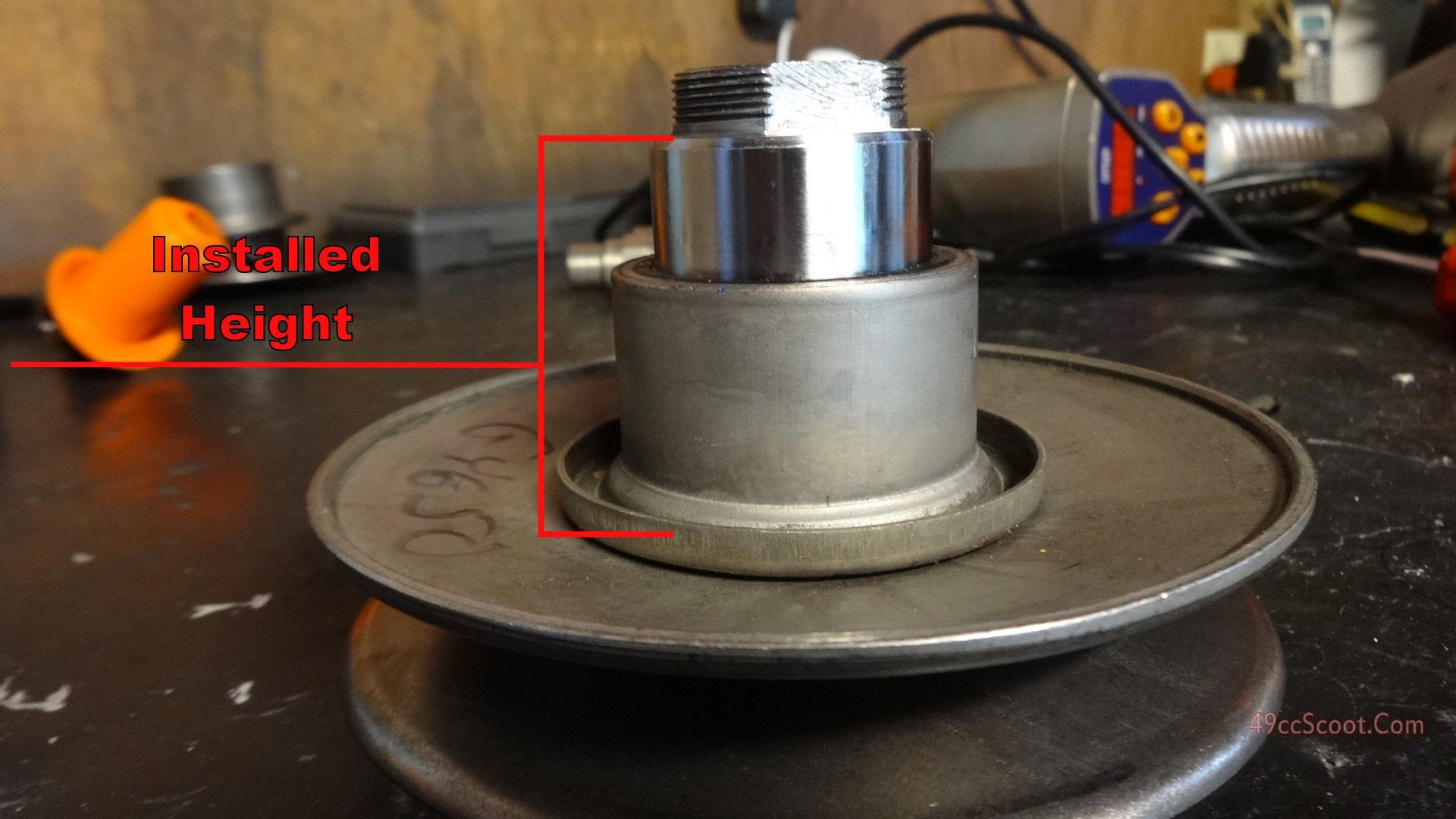

Then I measured the installed and compressed heights.

I needed a way to stop the springs in the same spot at both heights. I used a really quick option. After measuring the heights (28.5mm compressed, 43.5mm installed), I ground one bolt to each height to use as stops.

I used a bathroom scale to measure force applied.

Also makes it really easy to see if there's binding.

The stock spring goes from 61lb installed to 88lb compressed. The 1000RPM spring is 86lb installed and 120lb compressed. 27lb spread on the stock spring, 34lb spread on the 1K. As percentages, the stock spring increases stiffness by 69% as it is compressed, and the 1K increases stiffness by 72%.

Not sure if any of that means much of anything right now, but I'm sure I'll find some use for the spring test stuff in the future.

No such luck. Still did the same thing. Replaced the stock contra spring with a Hoca 1,000RPM blue spring and ground it as well.

Nope. Still not right. I could get the revs up but there was always this shift at or near WOT cruise speeds. I noticed something in the torque driver when I cleaned it, but was hoping I'd get lucky and it wasn't the problem. The torque driver grooves are all wearing and making it so there's a little resistance to open all the way and then more resistance to move once in high gear. This seems to happen every time I do a project and just want things to be consistent.

Luckily I did have another torque driver around from the SunL days (my first and only other 139QMB). Seems better made... which is amazing if any of you remember my opinion of the SunL's quality. lol

I swapped that in with the 1K contra and worked on finding the right weights. I got them dialed in to either 5.25 or 5.5g as the better performers... but speed was low. I was averaging about 32MPH max speed on my test runs. Normally I had been averaging 33-34MPH WOT cruise speeds before all of this. I had wanted to keep the 1000RPM contra in hopes that it would be less likely to fade than the stock spring, but I thought maybe I should try going back to the old setup. I swapped the stock contra back in with 4.75g sliders, just as it had been running well before. Then I saw 33 or so avg speed, but RPM was low and I got more of a drop off at the top of the speeds. For example, with the 1000 contra one run was 7850RPM avg and 32.3MPH avg, while with the stock contra I saw 33.2MPH avg speed and 7300RPM avg. With the stocker it would hit maybe 7500-7600 for a bit, but then drop down somewhere over 30MPH to about 7100RPM and start pulling up again. Nothing I did was making the acceleration smooth as it was, unless I sacrificed speed.

That made me wonder about the spring rates and if maybe it had something to do with how much force it takes to compress the spring at first, near installed height, and then toward the end, compressed height. Maybe the stock spring is just too soft period, or maybe if the force needed is not linear it could throw things off? I tried to check real quick, but maybe I was wrong and there was coil bind with the 1000RPM? Just not sure what to think ATM.

Might as well try to measure the spring rates. I was frustrated with riding up and down the road and swapping things to no avail anyway. I had a piece of 1/4" steel left over from something long ago, so I welded a bolt to the center of it. This way I could chuck the plate into a drill press.

Then I measured the installed and compressed heights.

I needed a way to stop the springs in the same spot at both heights. I used a really quick option. After measuring the heights (28.5mm compressed, 43.5mm installed), I ground one bolt to each height to use as stops.

I used a bathroom scale to measure force applied.

Also makes it really easy to see if there's binding.

The stock spring goes from 61lb installed to 88lb compressed. The 1000RPM spring is 86lb installed and 120lb compressed. 27lb spread on the stock spring, 34lb spread on the 1K. As percentages, the stock spring increases stiffness by 69% as it is compressed, and the 1K increases stiffness by 72%.

Not sure if any of that means much of anything right now, but I'm sure I'll find some use for the spring test stuff in the future.