|

|

Post by toslowtogo on Oct 14, 2014 9:02:31 GMT -5

Painting old plastic pnls. I'm using VHT Gloss Black Epoxy. Do not wipe with Iso or lacquer thinner. It causes crinkles in the paint when you sand it has pitted the plastic. It does it to any paint, primer or enamel paint. Make sure your paint is cured before try rubbing with store bought compound or polish. It will soften the paint as you rub. My first 2 rubs are pumice and bloodstone. You just put it in a bottle and mix with water. The old plastic is hard to paint. My scooter is 5 years and never sat inside so the pnl.s were in rough shape. I have mistakes orange peel mostly. The pumice will make the surface smooth. The bloodstone polishes it then Mcquires compound and then polish. Then black wax. The pumice and bloodstone will work on your lenses if you have cloudy.

|

|

|

|

Post by toslowtogo on Oct 15, 2014 9:56:17 GMT -5

I have been reading about you guys porting and polishing. Do you have flow benches. I have taken cyl. right to the edge and would do a little more and the bottom would drop out of the numbers on the bench. On the intake in the bend do not polish. You need the roughness to to get the air and fuel mixed good. When doing this are you doing 5 angle valve jobs? I put the NCY cam in mine. It is a higher lift and longer duration compared to stock. I think the next engine I build I'll go with the big valve head.

|

|

|

|

Post by 90GTVert on Oct 15, 2014 10:23:52 GMT -5

Haven't done tons of porting with the 4T. No valve work. I wish I had a bench. Considered a simple floating pressure rig (shop vac, manometer) if I mess with my 4T's head later. No intentions of going as far as getting a Helgesen plate and trying to measure CFM, but just something where changes may be seen. Not even sure if I'll do that. If you're using a bench that outputs CFM, I'd enjoy hearing some numbers from stock to modified or any details you care to provide.

|

|

|

|

Post by toslowtogo on Oct 15, 2014 20:41:00 GMT -5

I haven't worked on recips in a long time. I did the cyl. work on a prototype Lanceair. At sea level he was getting 34 pounds of manifold pressure on a naturally aspirated. That is where I learned about flow benches. We hot rodded aircraft recips.We balanced, CC'd the heads,all cyl.s got 5 angle valve jobs. I'm thinking of selling and repairing scooters after the 1st of the year. I wish I had a flow bench and valve grinding tools. I have learned when you do one thing go all the way. If you don't work it all you limit your mods effectiveness.On the heads you have to think about convergent and divergent ducts.In my thinking the intake should be convergent pack that air in and the exhaust should be divergent get the exhaust out of the cyl. fast.

|

|

|

|

Post by 90GTVert on Oct 15, 2014 21:44:57 GMT -5

In stock form the ports should be somewhat convergent and divergent. On the inlet side, at least of the head I cut, the diameter near the valve doesn't look like it'd be way off of the diameter near the port entry, but the guides on these, and the form to support around them, take up so much room. The short turn radius is very small on these, not to mention some are cast in a way that there's almost a little ledge rather than a "smooth abrupt" turn. If you did want to rework the port, you'd be at a great risk of cutting into the valve spring seat area at one point. Even those doing the common idea of porting (just make it all bigger) could cut through. The head I sawed in half had maybe 0.020" in one spot. Add in how hard it is to get tools inside of the ports and do what you want, and it seems like big changes could be tough. Then again, maybe a small detail here or there smoothing it out would work wonders?

|

|

|

|

Post by toslowtogo on Oct 15, 2014 22:36:49 GMT -5

I'll look tomorrow. I found a big valve head they say is port and polished and 3 angle. If I can find it again. I also found an exhaust bracket fix that I can't find now.

When you start doing it. It takes a few tries. We were using cyl. that were out of serviceable specs to practice on.0.020 is very thin. One slip and that is it.

Oh I found my starter problem. I pulled the eng. over a year ago. I forgot I had the grd. that goes to the eng from the harness hang up and it got removed. The new harness fixed it. I found the grd. after I had the new harness in. Oh well that is what happens when projects get put on the back burner.

Amazon has the front exhaust pipe w/o the brackets welded on for 44.00

|

|

|

|

Post by 90GTVert on Oct 15, 2014 22:49:47 GMT -5

|

|

|

|

Post by toslowtogo on Oct 15, 2014 23:20:49 GMT -5

I have dual shocks. Was thinking of running a longer shock bolt and a spacer for the clamp. Yes that is the head.

|

|

|

|

Post by toslowtogo on Oct 23, 2014 13:50:12 GMT -5

Did you know on an air cooled engine. The richer you run the cooler the eng. runs. If you have CHT check it out. Now the leaner you run you get better power at a higher temp. Heat is a killer on them. Well heat hurts just about anything.

|

|

|

|

Post by 90GTVert on Oct 23, 2014 14:33:25 GMT -5

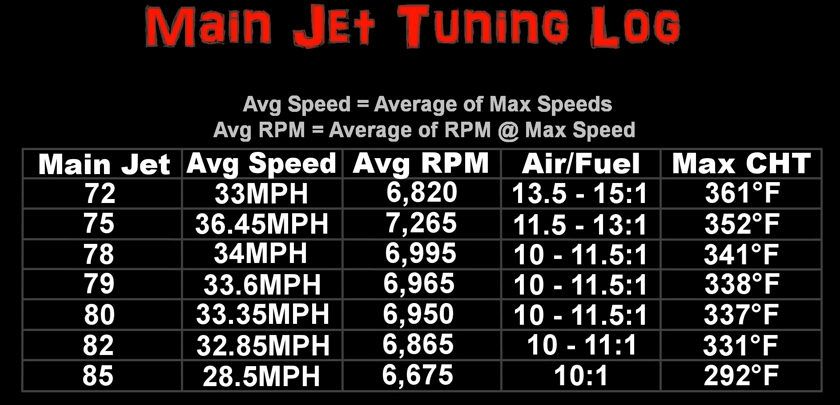

Not really sure why you'd even bother to install a CHT if not aware of that. It's a good tuning tool. It is said that very lean mixtures will cause cool CHTs because you don't have enough mixture burning to create the heat. I have not seen this personally. All of my 2Ts soft seize well before this, because I just see elevated CHT and then seize. The 4T I tend to watch my wideband more than CHT, but still power seems to taper off so it has been hot as expected on lean conditions I've had. Here's a tuning log from some main jet trials when I first tuned my TaoTao. This was something like 1 mile each way WOT. It will get hotter on long runs.  |

|

|

|

Post by toslowtogo on Oct 24, 2014 6:20:03 GMT -5

To lean will cause detonation. Which is not good. Are you running a different fan or venting the CVT. If you go to rich they say you can wash the rings. I have never went that far. I always go till it starts running rough and go back till it runs smooth. How did you get your mix ratio? We alodined a cyl and painted one to see how much heat the paint would trap. It was 1 degree. You do want to keep them from corroding. Corrosion will cause it to run hotter since the fins don't dissipate the heat very well.The chrome fan I got has double the area as the stock one.

|

|

|

|

Post by 90GTVert on Oct 24, 2014 11:43:20 GMT -5

On the 4T stock fan. The CVT cover has a hole in the front and over the clutch.  You have to be really rich to wash down the cylinder walls. By then it should be obvious that it's not in a good state of tune I'd think. I have a wideband on my TaoTao to read the AFR. It's great. Not at all worth the money if you just wanna ride and not mod anything, but really nice if you wanna tune or enjoy seeing what's going on easily. I have a wideband, CHT, tach, oil temp. Oil temp is basically useless for tuning and I rarely pay it any mind these days. It responds so much more to how I'm riding and what the weather is than anything related to the tune. I mainly got it because it was cheap and I was curious what the oil runs at.  |

|

|

|

Post by toslowtogo on Oct 25, 2014 19:51:43 GMT -5

I marked TDC with a white ultra fine marker. You can't miss it. Well pulling the new harness to finish the mods to get it to work. Still pondering the exhaust.

|

|