|

|

Post by 190mech on Sept 1, 2013 16:30:29 GMT -5

Well Explained Walt!I always worry over true TDC,but why??We are looking for durations of port openings so any number should work!!   |

|

|

|

Post by waltinhawaii on Sept 1, 2013 16:34:23 GMT -5

I had another identical LC cylinder lying around, so stuck it on and degree'd it... numbers are:

transfer open 118 degrees = (180 - 118) * 2 = 124 degree duration

exh port: 91 degrees = (180 - 91) * 2 = 178 degree duration

this is again, without base gasket. So adding a base gasket will give me decent transfer and ok exh times with a little massaging necessary... but damn, I put too much time into this cylinder already to change over. And looking into the exh port, the piston STILL is high at BDC, same problem I'm having already. This casting sucks, the literature it came with said it was for a 42mm crank but clearly it likes longer strokes than that.

Well, I hate to use the cylinder like this, the piston partially blocking the ports at BDC will interrupt flow and as John pointed out, the entering gas will not cool the piston crown as much as they should. But, this is not a roadrace cylinder (which would run closer to 200+ degrees of exh duration) and it is liquid cooled, so can handle civilian heat loads without crying. Truth of the matter is, the large part of gas transfer into a cylinder happens when the ports are just being uncovered, soon as the piston cracks the ports open; that's when pressure is highest. By the time the piston reaches BDC, the pressure differential has dropped significantly, although transfer still happens, it is usually a pipe controlled function that late although there will be turbulence as the edge of the piston is still interfering into the path of flow.

My choices; make a spacer under the cylinder to raise it? this will uncover the transfers and exh at BDC but will raise the transfers up quite a bit. I could chamfer the edges of the piston crown next to the transfer ports, but this will means the ports close unacceptably late, same as raising the cylinder. crap.

Put a base gasket (paper) onto the jug and put it back on to re-measure:

transfer duration: 133-134 degrees

exh duration: nevermind, can grind it but was around 180? which doesn't make sense as it was 184? before. Should be more.

depends on how much coffee I've had, I guess. It is relatively subjective depending on where you call the "port open" ...you might think its clear cut, but there is a judgment call here as the piston movement is tiny compared to the degree wheel. A good deal depends on your eyesight. When I was younger I could see punchmarks in steel that differed by a couple thousandths of an inch. Nowdays, forget it. Having to bust out magnifying lenses all the time. If only they had magnifying lenses for the brain. Hah.

Hmm. A transfer duration that high will put me in about the 11k-12k powerband... not bad, I can live with that if I adjust the pipe cones a bit on the shallow side so they reach down below the peak. John? whaddaya think?

|

|

|

|

Post by waltinhawaii on Sept 1, 2013 17:32:27 GMT -5

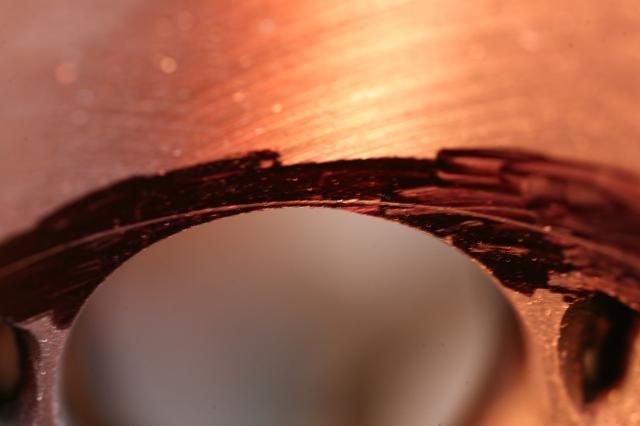

OK, with 134 degrees of transfer timing I'm committed to a rather high rpm range; I think I'll need mid 190's duration. so I'll need exh open at near 83 degrees for 194 duration... marked it out and it looks like this:  Holy holes, batman! are you SURE your numbers are correct??? that looks awful big to me. |

|

|

|

Post by 190mech on Sept 1, 2013 20:13:39 GMT -5

I have had good luck with epoxy in transfers since the 70's when I over ported many Hodaka's till I could see daylight..Still use it today!The simple solution is to RUN IT,the Ex port hogging is typical for this type of jug.The top tuners always open the main Ex port then the Aux ports about 1.5mm later,spozed to direct the flow better..I see you are getting a taste of the 'one size fits all' products us scooter tuners have to deal with. My gut level on the best setup is fab an aluminum cylinder base spacer,epoxy the Trans ports,massage the Ex,step cut the head for proper squish,but that takes time and you are much like me,"no time,even less money!"  |

|

|

|

Post by moofus02 on Sept 1, 2013 20:50:49 GMT -5

I'm still trying to wrap my head around all this. When you raise the Cylinder you increase durations. You use epoxy on the transfers to lower their duration?

Sent from my SPH-L720 using proboards

|

|

|

|

Post by 190mech on Sept 1, 2013 21:12:41 GMT -5

Yes!We want the piston dome to be flush with the bottom of the Trans ports with around 130* duration,so in order to make chicken soup out of this chicken s**t,we must add epoxy or say "thats good enough"!!

|

|

|

|

Post by waltinhawaii on Sept 1, 2013 22:58:25 GMT -5

John, I think you are right about the correct fix. EXCEPT for the fact that you're dealing with the biggest procrastinator who ever got his hands on a roll of duct tape. I'll run it as-is for now and pretend it's a GP machine, eh? Oh, sorry, it's moto GP now, is it?

Had to take a break and mull things over with Harry Potter. After a few more sessions I ended up with this:

uh, nevermind. will have to post it a bit later, our ISP seems to be having problems, can't upload any large files right now, keeps timing out. Finished the middle exh port, the main one, ran out of daylight before I could start on the sub exh ports. The main port is rounder than I like, should be a touch more squared out at the corners, but it should do, especially in light of the new rpm ceiling, this will be gentler on the rings. I'll continue with the sub exh ports tomorrow. I should start on porting the cases soon. My compressor is having a workout on these pneumatics. Have to tighten the belt.

|

|

|

|

Post by waltinhawaii on Sept 2, 2013 0:26:01 GMT -5

OK...just freehanded it. For newbies, you should draw a template so you can flip it over left to right and have a guide to follow. The lower your rpm ceiling, the more square the port can be and the more efficient it will be, but the harder on rings it will be. Rounder ports can rev to higher rpms without too much problems, but are less efficient at flowing gas due to less area. I don't know how much ring development has gone, if rings are stronger than they were 30 years ago, this may be moot and you can use pretzel shapes for ports now.  |

|

|

|

Post by 190mech on Sept 2, 2013 5:00:00 GMT -5

Looks like a nice safe Ex port!The rings on these scoots are likely worse than 30 years ago because most are made with quality steels and tooling in China..

|

|

|

|

Post by waltinhawaii on Sept 2, 2013 5:16:57 GMT -5

Thanks John, ya really know how to instill confidence in a fella  Actually the tooling I buy from china seems to be not bad quality, although since acquiring some scooter parts I reserve the right to modify that opinion at a later time. That India parts, on the other hand... watch out. I bought some holders for my lathe that are so out of spec that the carbide TPG inserts refuse to go into those holders, and I can't modify them (hardened). I saw Brent's build where he cut some 'mini trenches,' more on the large case side; the small side of the case had almost nothing. Is it that thin?? I was looking over my case today and noticed my cut inside the case to make room for the larger crank web had gone a little too far... will post a pic tomorrow. There is a small hole right in the corner of the clearance cut for the crank. I was thinking I should have used a slight radius in that corner, but wasn't sure if the cranks also had a slight radius in the outside edge of the web. Arghhh. More welding to do.... |

|

|

|

Post by 190mech on Sept 2, 2013 8:35:08 GMT -5

Most all do break thru when the diameter is increased,I epoxy them from the outside..Trench cutting will break thru too,best to clean and fill the suspect areas with epoxy from the outside also before the die grinder starts making chips..

Yeah,I have 2 Grizzly lathes and they do the job well at a modest price.Agreed on the India tooling,waaay hard and brittle!!

|

|

|

|

Post by waltinhawaii on Sept 2, 2013 21:49:58 GMT -5

Whew. Long day. First of all who said bench racing was not hazardous?  A couple days ago, the cylinder I was working on slid out of the vise and was on its way to the concrete garage floor, where it would probably crack or break; I stuck my foot out to try to slow the fall and it caught my leg near the shin. Lots of sharp edges on that thing... it took off a piece of flesh a little bigger than a half dollar, then bounced to the floor. Looked ok, but my leg needed a wrapup. This meant making a change, the leather piece I was using as a cushion between the vice jaws and the cylinder was replaced by a piece of nylon backed rubber, thicker and has a 'give' to it which grips the cylinder more securely. It's actually a piece of a conveyor belt that I have a big roll of. It's old, but tuff stuff. ...if any brothers need some of this stuff, I can send you some if you send me a SASE to me. I cut pieces of it to use as bottoms of legs for stands, friction surfaces for rests, under my grinder/vibration matting... good stuff.  I measured up the exh port chord width (just curious)... only about 55 degrees.  Here, I've made a tiny bit of 'trench' cut. If brent's was a baby trench, then mine is an embryo trench. That is not a crack in the trench, it's where the case had a hole in it and I welded it from the other side, see earlier in the build, I cut the cylinder clearance hole too big.  Clearance cut for boost port;  Putting in the brand new reed cage (oversized) to see how the trench fits.  As a side note, reed cages don't pass gas (ha!) via osmosis. Nor do they use fedex. Think of the reeds as doors and doors have hinges. The reeds bend open around a pivot point and share the bend along the reed. The gas mostly goes through at the tip of the reed, so that's where my trench is pointed. When you have a large SLR camera in one hand and trying to position a reedcage and engine case in the other, you are bound to drop things:  Cheapo plastic cages! Now I have to re-use my old cage... Spent some time making a holder I really needed... my welding wire was all over the table, have to make a holder:  Ah, no more looking for TIG wire on the ground under the welding table...  |

|

|

|

Post by waltinhawaii on Sept 2, 2013 21:59:35 GMT -5

I'm tired. I was going to start on the case transfer porting, but I have to mirror image the port dimensions onto the case carters to give me an idea of how far I have to cut...

|

|

|

|

Post by kevin55950 on Sept 3, 2013 0:29:31 GMT -5

You seems to have a lot of experience for a first build  There's a lot of time invested in this engine, I hope the results will be there, keep up the good work ! |

|

|

|

Post by waltinhawaii on Sept 3, 2013 1:32:38 GMT -5

Hi Kevin. You and John are too kind with your praise. I used to race 2 strokes a long time ago, had a yamaha TZ350 and rode RD400s on the street (modded within in inch of their lives of course). Also fooled around in the dirt a little. I had to learn to modify my own bikes as who could afford to hire a mechanic to do everything you wanted? but when I left racing to do other things, I never stopped loving 2 strokes.

I did build a few street 2 strokes (Puchs) but back then, there were no aftermarket speed parts at all. That market completely didn't exist back then. If you wanted to go faster, you had to make your own parts. Now, I'm coming back to it a little as my work has just moved to an office very close to where I live, so I am trying to put this **&$@!! thing together as a way to get in a short ride to the office everyday.

Technically, its not my first build... more like my first build in 3 or 4 decades, and the very first build I've done that enjoyed the benefit of having some real tools (last build was done with exactly 1 dremel tool, 1 hammer and assorted craftsman hand tools). However, I have no idea what kind of parts are available out there now, so I'm sorta shooting in the dark here. John and Brent via their builds have really shown me the skinny on what's available nowdays for not much money, as I have not followed 2 stroke tech for a long time. The tech has not changed much, there are subtle changes like inertial stall which was introduced in the 80's (I distinctly remember reading an article by Kevin Cameron which first described it in detail), but for the most part its much the same, just logical progression in the growth of port sizes. Overlapping transfers and exh is very interesting, made possible by stalling the mixture... having it displace the spent gas upwards instead of relying on primary compression to shoot it out the transfers and avoiding a pure schneurle loop.

If you see me doing something stupid, by all means, please pipe up. there's a lot I don't know as far as what people have done in the last few decades, I'm still playing catch up here, but this is a good site, people don't jump all over you here.

Yeah, its a lot of work. But, I enjoy it.

|

|