|

|

Post by waltinhawaii on Sept 3, 2013 23:48:56 GMT -5

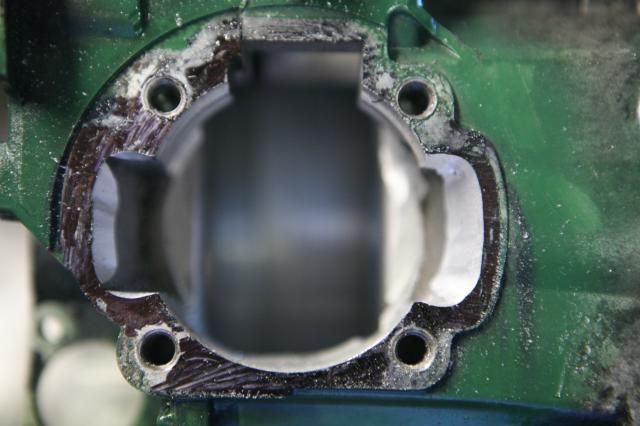

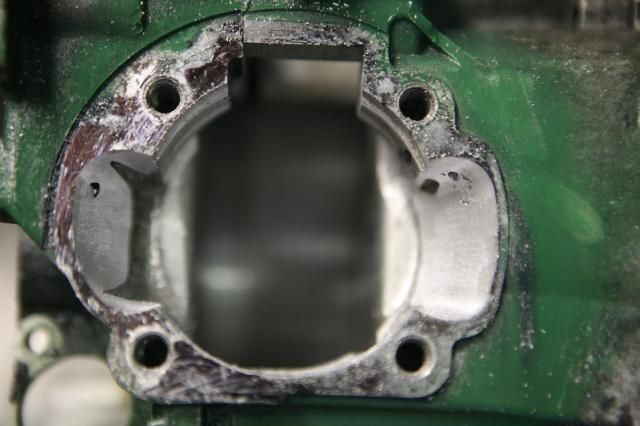

Case porting! Stock  After 10 minutes:  And a few minutes later I'm getting nervous as I'm pretty sure it's not out to where the cylinder is yet, but its pretty thin.... there are places in both left and right upper (aux transfers) where I can see holes developing:  hmmm. hmmmmmmmmm. |

|

|

|

Post by waltinhawaii on Sept 4, 2013 0:04:43 GMT -5

For y'all wondering what the green paint is for, I figured I'd normally roll some paint on the cylinder mating surfaces, then bolt the cylinder up, then when I take the cylinder off, there would be paint mark showing where the cylinder is. I couldn't find liquid paint in the garage and I didn't have a brush. so, i used a sharpie on the cylinder (my favorite) and put the cylinder on, and used a plastic mallet to shock the cylinder a few times, figuring that would leave an impression mark in the sharpie marks... it didn't. So I just put the cylinder back on and figured I'd paint the joint a different color to show me where the cylinder went... and the only color I had was puke green. So the green went on, looked like godzilla used it for a bathroom and was all runny, didn't work so good.

|

|

|

|

Post by 190mech on Sept 4, 2013 4:32:01 GMT -5

Thats looking nice,now you know my comments about "paper thin cases" are lessons learned..Over the years the bean counters have figured how to cut every gram of material off these engines and still run till the warranty is out!

|

|

|

|

Post by 2strokd on Sept 4, 2013 4:49:47 GMT -5

Looking good to me! With some more weldin and some epoxy those hole will have never been there  Keep up the good work! |

|

|

|

Post by waltinhawaii on Sept 4, 2013 10:02:04 GMT -5

The left side (I always refer to directions as you are sitting on the bike, so in the pic above, that would be right side of the picture) has what appears to be a whole gallery of thin skin with webbing behind, I've already welded this once from the other side. I can probably run a bead from THIS side and then smooth it out; but looking at the outside, boy there are some pretty thin spots. Dunno if that would be best... even before, prior to cutting it down, the cases exhibited some melting at a couple points, they were right on the verge of collapsing/holing just from the heat of the other weld. Not sure what this aluminum is, but aluminum never gives you much warning, not like steel which changes color to tell you the temperature. aluminum just goes from solid to liquid form with no warning, so is much more prone to 'holing'. And this stuff is very thin. I'll have to look it over more in daylight.

The right side hole is formerly a blind hole, its threaded, used to hold the ignition plate or something to the case. It should have a bolt in it later, so probably doesn't have to be sealed although the hole itself will cause a small amount of turbulence.

|

|

|

|

Post by 190mech on Sept 4, 2013 14:12:38 GMT -5

EPOXY,epoxy,Epoxy is what the paper thin crankcase whispers to you as you walk toward the welder!  |

|

|

|

Post by aeroxbud on Sept 4, 2013 17:45:51 GMT -5

On the Piaggio engines you take out the port till you get to the head studs. Then Magic Metal the Hole!  |

|

|

|

Post by shakerdriver on Sept 4, 2013 19:10:51 GMT -5

This is how your cylinder should look when done:   Do you think you've got enough phones available John? By the way, great build Walt. Looking cool as hell and a very interesting read. |

|

|

|

Post by waltinhawaii on Sept 5, 2013 0:07:38 GMT -5

EPOXY,epoxy,Epoxy is what the paper thin crankcase whispers to you as you walk toward the welder!  John, I'm sure you will be ecstatic to know that I now am the proud owner of a couple little tubes of JB weld, procured at great personal expense (pride mostly) at the local O'Reilly store, $7. My welder(s) are sulking in the corner and don't want to talk to me right now. If there's anything else I can do for any of you, please don't hesitate to ask  |

|

|

|

Post by waltinhawaii on Sept 5, 2013 0:13:34 GMT -5

Shakerdriver, thanks! It's been a fun project, if somewhat irritating at times (this is the fun part, I know I will get my butt whipped when it comes time to tune the CVT as Puchs never had those). what does shakerdriver mean?

|

|

|

|

Post by waltinhawaii on Sept 5, 2013 1:41:24 GMT -5

Studying the porting done so far, I am not so much worried about the holes as I am THIS:  Specifically, the left lower edge of the transfer tunnel margin was thinned out to a very thin lip, right where the port makes a bottom turn. this rounded bottom looks like it's actually missing the edge of the case and you can't see it much, but the inside of the transfer is very slightly showing if you rock the cylinder slightly. That is another concern, the cylinder has too much play as the central hole in the case is slightly too big. This allows the cylinder to rotate or go up/down on the studs slightly. In use, of course, the actual movement will be nil as it will be bolted down; but it can be set anywhere within a rather high degree of freedom. I was trying to do this deliberately as the original hole I had bored was perfectly sized; the cylinder was a rather tight fit into the hole. Problem was, the hole was SLIGHTLY canted by a couple degrees so the jug was not sitting exactly perpendicular to the bore so bottom sealing would be a problem. Of course, in hindsight what I should have done was simply enlarge the bore by hand with a carbide bit. Instead, I took a 2nd bite with the boring tool and turned out the hole was bored a bit oversized and now the jug can move too much. Can I shim the bore? Sure. But the shims might get loose and get chewed up in the crank. Not a concern if they are soft, like plastic or something. I thought maybe I could use a couple locating dowels, like the 2 trans case halves have to make sure they go together the same way each time. A lot of work and will require precise layout, the tolerance will be plus or minus one thousandth of an inch, about. I can do it, but that's a lot of work and there is no guarantee the cylinder will be dead nuts centered... only that the cylinder will be dead nuts where I put it, which may or may not be centered. I know the bore is not centered enough to use it as a locating guide (its not even very round), meaning I'd have to measure the axis of the crank somehow, very difficult to do as the one and only dummy bearing I have won't locate the crank axis accurately enough. Can't index on the crank webs themselves as they are occluded (can't see the whole crank to measure where the center lies). Interesting problem. the 2nd problem, if you look at this and compare to the other side (sorry, you have to scroll back to look at both of them), is that the right side case transfer is 'drooping' down. If you think the cutouts look like ears, then the right ear is drooping down and is smaller than the left ear.  I can already hear John: "EPOXY DUDE" It's a slightly larger area, though, that has to be built up OUTSIDE the current case, just above where the oil pump was, so that the bottom of the ear can be pulled out and down a bit. The top of the ear has to be moved slightly higher and the ear is too round, needs to be straighter up and down. right now the shape is controlled by the confines of the case metal... the correct shape would be outside the current metal confines. Now, the transfer tunnels have much to do with airflow and the case deformities this far away from the tunnel exits into the working part of the cylinder (I think) probably won't have THAT much of an effect. Notice how honda elites work? the air mixture comes in sideways and then goes up the far side, the near side has the air going into an almost backward loop to get to the transfer tunnel; yet the engines make good power, because the ports into the cylinders are symmetrical. the cases aren't, though. So saying, I think the better part of wisdom is to run away to fight another day and just live with this deformity. I can weld up the outside of the case above the oil pump as I plan to run premix (CHICKEN!) and straighten the earlobe; but this weld will be very close to one of the studs and will probably pull the metal slightly and deform it. also cutting the metal back and ensuring a tight seal with the jug will be tough as my tiny chinese mill cannot fit the cases under the head to cut the sealing surface, so this would have to be done by hand. On a case to cylinder surface that must be airtight, this is a challenging cut to make by hand. If I have to do this with any regularity, I will have to make some sort of holding fixture for my lathe and use the lathe with a boring tool to cut the cylinder hole next time. |

|

|

|

Post by 190mech on Sept 5, 2013 5:00:49 GMT -5

Hey Walt,You took the words out of my mouth!!Think about bedding a rifle stock,,,Maybe some epoxy dabs in the case mouth and a release agent on the cyl skirt to tighten up that sloppy fit??Why not a good dollop of "E" on the outside of the transfer tunnel where the oil pump cutout is,then dress it smooth to build up the flange area?And you know what I'll say about getting the transfer tunnels to match the cyl,so I'm not going to say it! The 90cc cases do have a bigger case mouth casting so all of your headaches wouldnt be there,but I too have done a few 50 to 90+ motors and that "cold weld" stuff always comes out of the drawer..Also Jan Thiel(worlds greatest 2T tuner)did a number of dyno tests when he worked at Aprillia and found no HP increase with carefully matched cases!He even tried it with sloppy cut base gaskets,,no change!I cant bring myself to assemble a build without matching them though... I like to clean a case with MEK and sand blast the area to be epoxied to provide good grip Jason,Thats not my pic!I got that off the KiwiBiker bucketracer thread here; www.kiwibiker.co.nz/forums/showthread.php/86554-ESE-s-works-engine-tuner |

|

|

|

Post by 2strokd on Sept 5, 2013 8:23:02 GMT -5

CPI style (or any for that matter) Mina cases never match. Maybe the casting will, but the trans tunnels never seem to. I had a problem with cylinder/head "walking" around at high RPM. Thought about a dowel pin or something maybe if there was more room to play with. You are finding more and more just how thin these cases get. I know, i know, epoxy, epoxy, epoxy lol  |

|

|

|

Post by moofus02 on Sept 5, 2013 10:45:36 GMT -5

John keeps talking about mek I know it is great stuff haven't used it since I stopped working on helicopters don't know if I can even get it locally but it is really good stuff. Just reminiscing lol

Sent from my SPH-L720 using proboards

|

|

|

|

Post by waltinhawaii on Sept 5, 2013 10:50:04 GMT -5

About what I thought. John, I was not aware there was a different casting available. 90cc case? This is a long case, that much I know; wasn't aware they made them in 2 thicknesses, though. What models have the thick case and are they common? Can I find them used anywhere? I think scrappy used to sell complete 90cc long engines for a great deal but I can't seem to find their ad now, might have sold out?

I WISH I had a sandblaster! and full sized mill while I'm doing the wishing thing!

|

|