|

|

Post by 2strokd on Oct 27, 2009 9:31:23 GMT -5

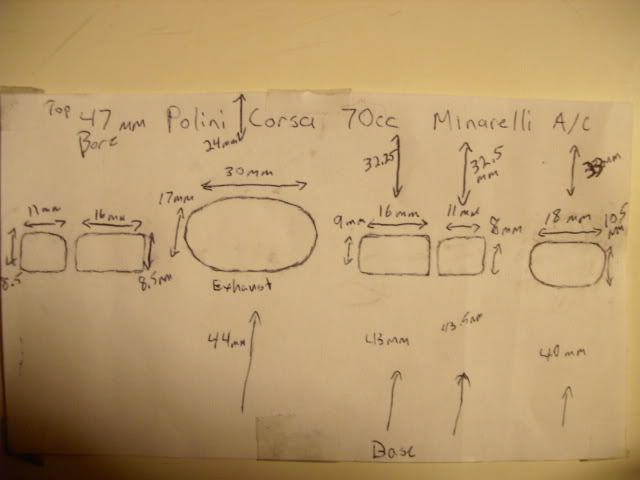

The scanner and i arent getting along well this morning so i just took a pic of my first port map(well second, first was practice). It needs much improvement but its a start.  |

|

|

|

Post by Reign on Oct 27, 2009 11:35:18 GMT -5

I love how everytime I see you guys talking about sizes, it's always in mm. I never knew how to measure in inches before, and now that I've been working on these scooter and everything is metric, it makes me wonder why we even use the inch scale. Metric is so much easier to use.

|

|

|

|

Post by 90GTVert on Oct 27, 2009 16:44:32 GMT -5

Nice work on the map, thanks for posting.

I used to hate metric because I was so used to standard, now I too like the metric system much more for these measurements.

|

|

|

|

Post by 190mech on Oct 27, 2009 19:23:56 GMT -5

Great portmap!Do you have a degree wheel to give exhaust port

openings?That would help if some pipe calculations were needed...

|

|

|

|

Post by 2strokd on Oct 27, 2009 22:16:15 GMT -5

Good question, i need to make one  |

|

|

|

Post by Enviromoto on Oct 28, 2009 9:40:52 GMT -5

Yea I have a set of each in my toolbox and I would much rather just have metric in there. Talk about having a ton more room.

|

|

|

|

Post by 2strokd on Nov 4, 2009 9:22:55 GMT -5

I am finally going to use my tool today and do a leak test. If all is well i will be trying a 21mm Dellorto out with this stock Polini sport cylinder. Then if i get it tuned good with the dello and all is well, i will be pulling this cylinder again for some port work. It will be more like practice porting than "real" porting. I plan on moving the ex. port up a tad and messaging the trans. ports a little to try and get a little more out of this cylinder. What do you all think? Any suggestions?  |

|

|

|

Post by 190mech on Nov 4, 2009 9:44:52 GMT -5

Do a degree wheel check before pulling it off,that way you can

calculate what you have now.'blowdown' is important,search around a bit on this subject,i also see folks widen instead of

raising the exhaust port,you keep max torque that way.Do you

have the A.G. Bell book?Has a bunch on port layout and how it all

works.I found a free download of his book on the web,its been

a great education for me!

|

|

|

|

Post by 2strokd on Nov 4, 2009 10:31:28 GMT -5

I have Bells book but a refresher never hurts  . I havent read it all, just hop and skip through the good stuff  . The man is a magician with 2T,s ;D |

|

|

|

Post by stepthrutuner on Nov 4, 2009 10:36:35 GMT -5

I would suggest reading A. Graham Bell's chapter on cylinder porting and scavenging and tune from a standpoint of exhaust and transfer durations according to his suggestions per the rpm you wish to operate at. From a reliability standpoint, for me that is 10,500-11,000 rpm. But my understanding is that Piaggio's(mine) operate at higher rpm easier with the stock crankshaft than do Minarelli's.

Suggest you make yourself one of Vert's degree wheels and place a piece of 0.002-0.004" feeler gage on top of your piston and trap it at the piston/port top margin. This will give you an accurate way to judge exact port opening points.

For that rpm range you're talking about around 194 deg. exh. and 130 deg. transfer duration(or maybe a degree or two less) according to Bell. Don't go crazy with compression ratio or squish either unless you're willing to make accurate combustion chamber volume measurements and have machine work done on your head. Probably the most practical way to play with the compression ratio boundary is with a head temp gage.

As far as your Dellorto goes.... I'm running a 45 idle jet and that is way too rich. Also, remember the air screw works backwards from most carbs(cw leans it out.... I went crazy trying to figure this out for a while). I run a K&N and good main jetting wound up being around 100.

|

|

|

|

Post by 2strokd on Nov 4, 2009 10:44:55 GMT -5

Thanks for the info Reg. I didnt know that about the Dellorto idle/air.

|

|

|

|

Post by 2strokd on Nov 4, 2009 12:20:36 GMT -5

Well i have good news  , and bad news  . The good news is 1.My new leak tester tool works 2.I will be building a Minarelli from the crank up, or side  , front, whatever. The bad news is 1.I discovered a VERY bad crank seal leak 2.I will be building a Minarelli from the crank to the head  ;D. I went out and pulled the seat and the plastic off, took the fan shroud, carb, pipe off. Put the piston at BDC, plugged the ex. port (my plug fits snug w/o even test fitting first  ),and slid the adapter into the intake, it fit too w/o a test fit. Then i started pumping away. After about 15 pumps im thinking "ok weres the pressure"? Nothing, so i spray the intake, ex., base, head gaskets etc. No leak, "what the hell"  ?.....".Ohh NNOOOOO, its not". By then im tryin to pull the cvt cover off with my fingers crossed at the same time lol. I get the cover off, the starter clutch and shim out of the way and for the fisrt time i REALLY LOOK at my crank seal...Im thinking "ohh, that dont look so good". I grab the soapy water and the pump, i spray and pump away..... and its just blowin air at me singing "but just think how well it ran with blown seals"  !!! It didnt even bubble the air was flowing soo fast  Now i feel dumb knowing i had something so obvious i overlooked always blaming something else like the carb  . I should have checked the obvious the first time i thought it may have a leak. Instead i was always trying to tune a busted motor. Man i feel stupid  |

|

|

|

Post by 90GTVert on Nov 4, 2009 13:37:21 GMT -5

Wait, so the only thing leaking is the clutch side crank seal? The only oil seals on the crank are on the outside of the case. I've never done just the seals before, but can't they be replaced without removing the crank? Do you just wanna tear the whole thing apart?

|

|

|

|

Post by 2strokd on Nov 4, 2009 13:59:02 GMT -5

|

|

|

|

Post by 90GTVert on Nov 4, 2009 19:18:31 GMT -5

That looks like excessive play to me.

|

|