|

|

Post by pitobread on Sept 28, 2018 20:09:35 GMT -5

Clickbait AF

|

|

|

|

Post by pitobread on Sept 22, 2018 9:25:08 GMT -5

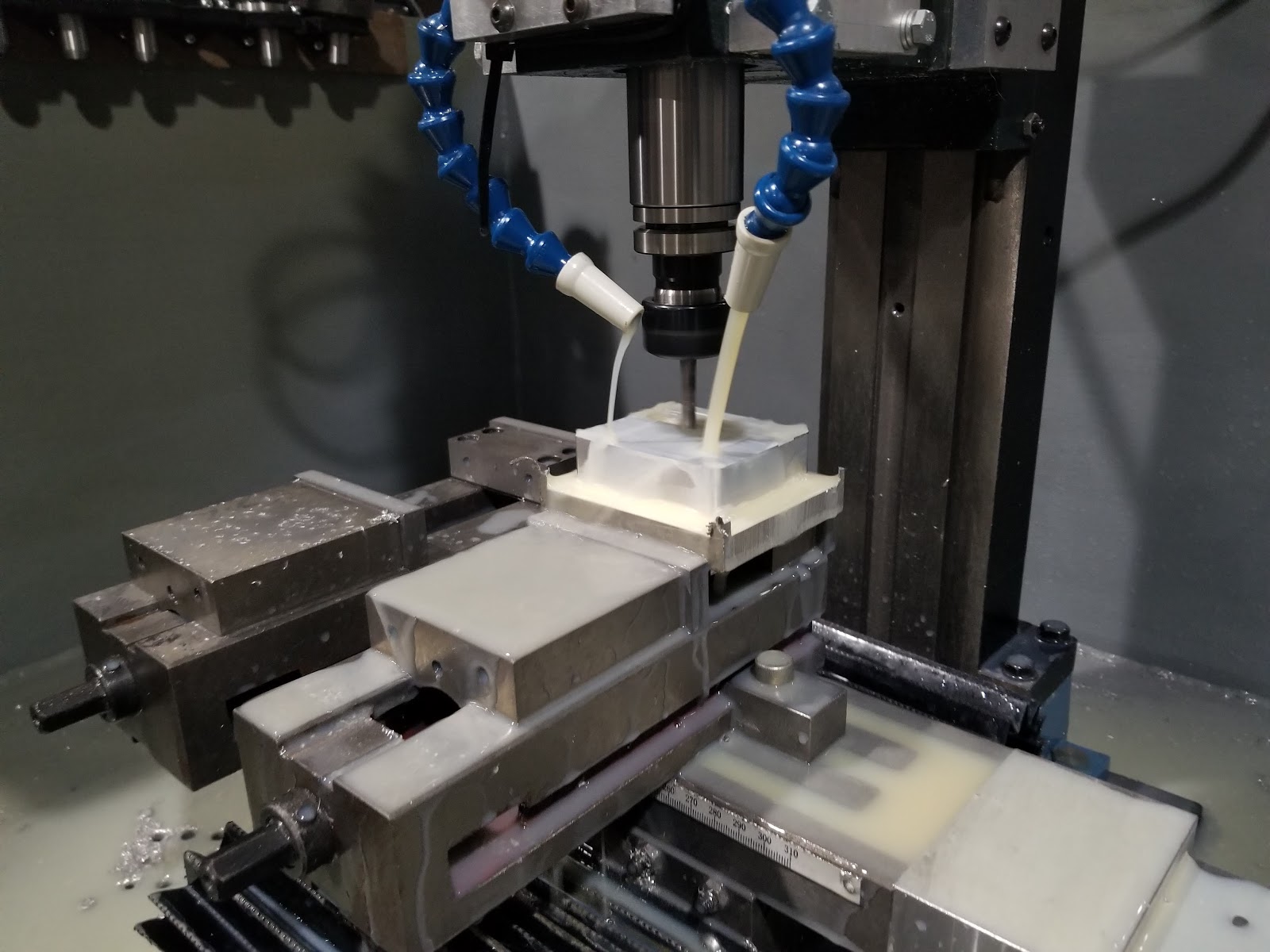

Well got the DT175 Reed Valve in the RS100 Cylinder with some help from my CNC. I also got the boot on as well, which turns out shares the part number with the 75 MX100(16hp). Has a bit of a built in reed stuffer.    I need to find some single petal reeds for this cage though either fiberglass or carbon .030. The only ones I can find are the boyesen dual reeds. I suppose I can make some with some sheet but perhaps someone knows other available reeds that will work on the DT/MX reed blocks. I also re stumbled on this guys blog, everything is in japanese, and he does both 2t and 4t stuff but he also does some pretty amazing dry clutch retrofits on small bore stuff. Kinda got the wheels spinning. Don't know if I will bite the bullet on that one yet. blogs.yahoo.co.jp/forgworkyasuji/MYBLOG/yblog.htmlStill waiting on piston and rod so I can see if my plan will even work. |

|

|

|

Post by pitobread on Sept 16, 2018 19:54:37 GMT -5

Look into wintergreen oil and acetone to permanently soften old hardened rubber.

Works great, used it on a few bits on old corollas.

|

|

|

|

Post by pitobread on Sept 16, 2018 12:22:56 GMT -5

Start using Devcon Aluminum or Belzona.. $$$$

|

|

|

|

Post by pitobread on Sept 14, 2018 1:36:56 GMT -5

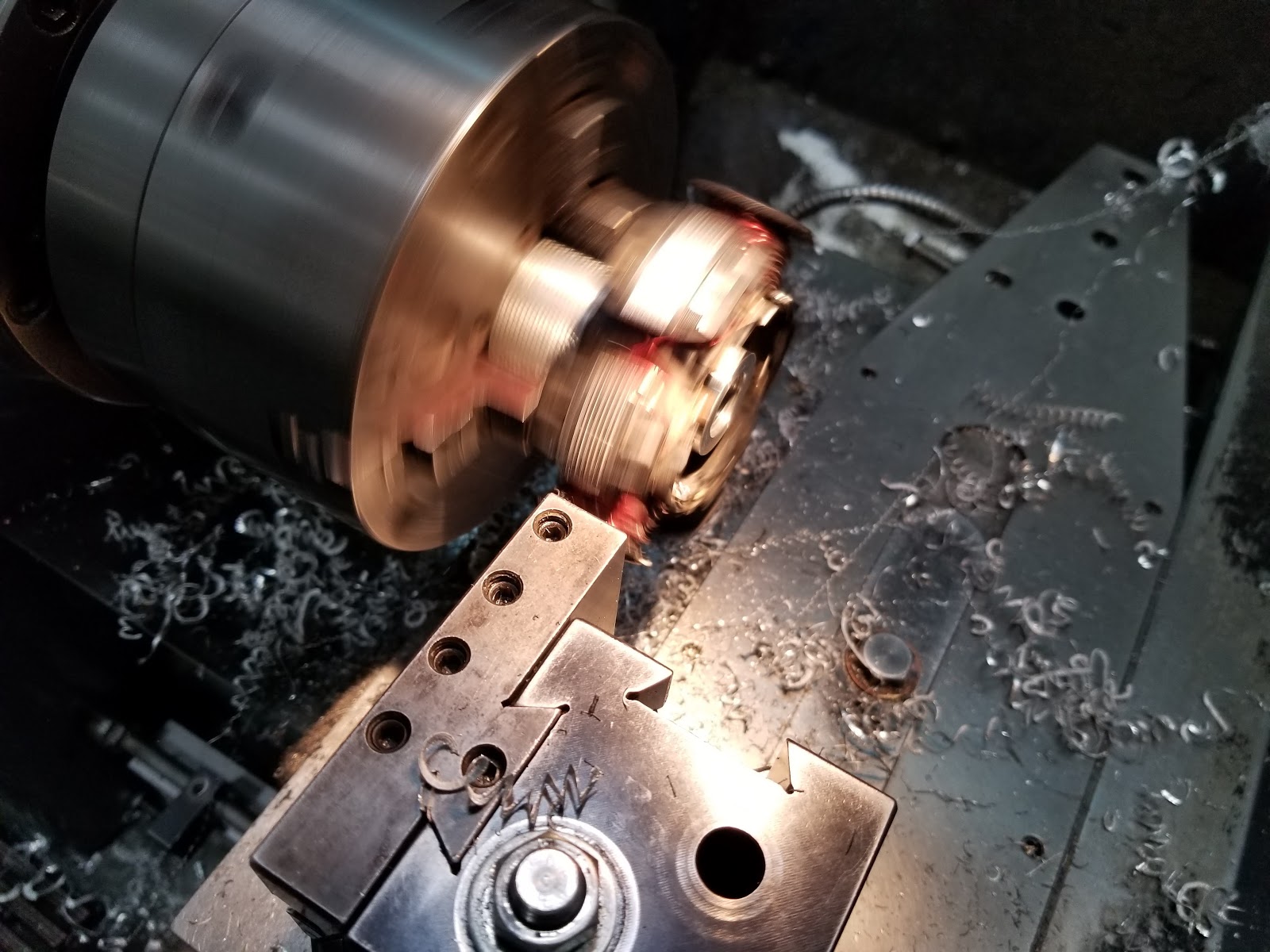

Well more progress So it seems like the reed inlet on the RS Cylinder is a no go for a bigger reed block. I have a KX65 Vforce 3 block that will fit, but would like to put in something bigger. Unfortunately due to the external sizing, I can't hog it out big enough to take any decent reed blocks here. The MX Cast cylinder will already accept one of the bigger reed blocks I have here, and also a GasGas TXT250 reed block, and probably would take a KX85 block. I may end up just using the cast iron cylinder, but it's sooooo heavy. I have also made my stator plate and rewound it, I need to make some more holes in it tomorrow but it's ready as well. Started with a Honda Dio Stator, I have tons of these. I turned the OD Down 1.5mm   Then I cut out a backing plate for the MX ignition pickup and the Dio backing. I also cut one of the poles off the plate to make room for the pickup.  Then I had to rewind the stator, it's fairly simple as it is single phase. Magnet wire and make sure you have the poles reversed every second one N/S/N/S in my case. This achieved by reversing the winding direction every pole. I have to tap the half wave in between two of the pairs of poles for my Regulator/Rectifier(Also off a Dio)  Other than I made the OD 1mm too big, It's a success. I will fix this problem and put thru holes for the wires in tomorrow and all done.  |

|

|

|

Post by pitobread on Sept 11, 2018 14:30:00 GMT -5

s.click.aliexpress.com/e/BHXS9ZkcThat is what I have, it's stupid cheap. I'm sure it won't last forever but it works pretty good for what it is. Has both straight and 90 and they are tiny.

|

|

|

|

Post by pitobread on Sept 11, 2018 10:25:11 GMT -5

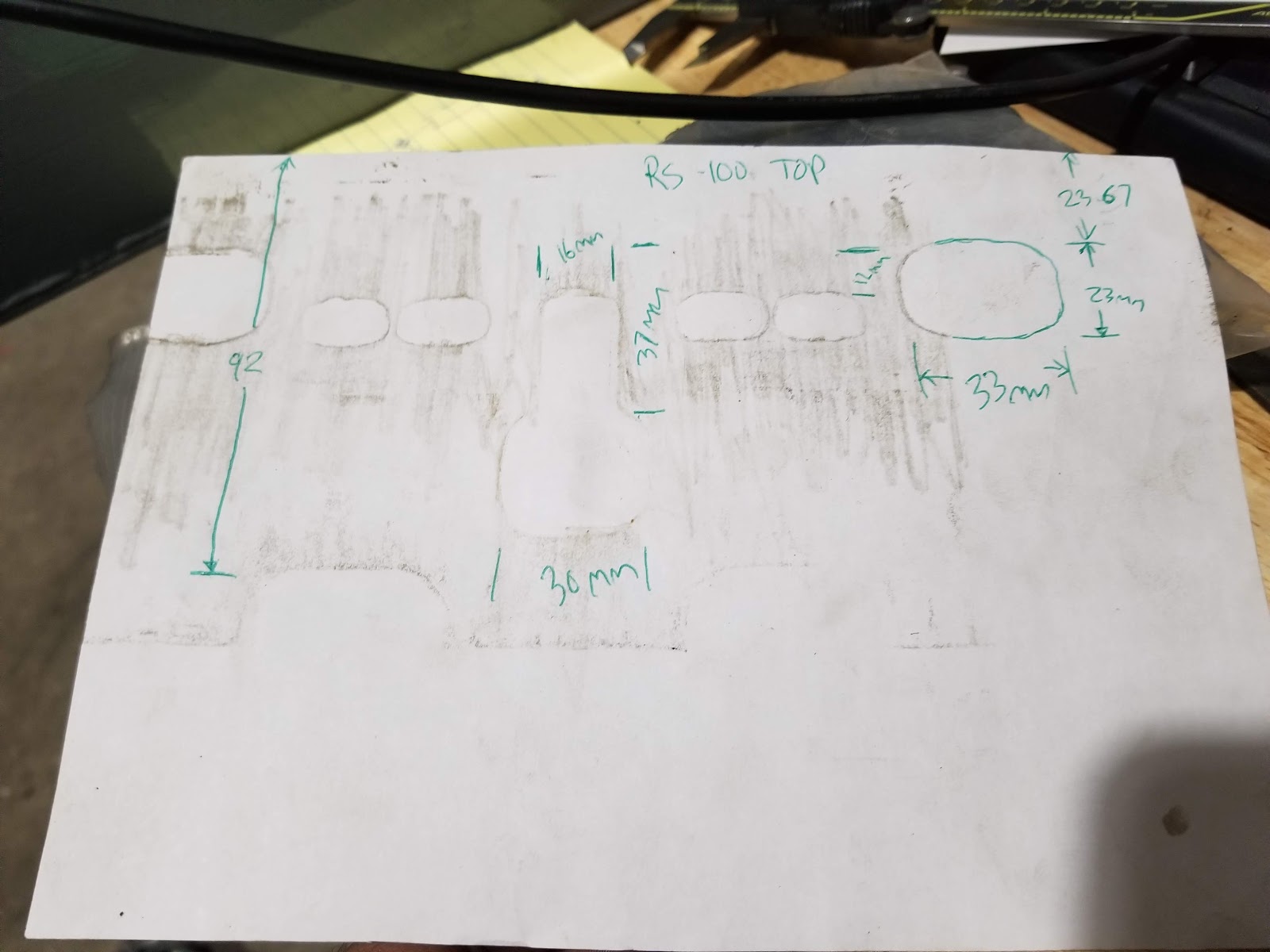

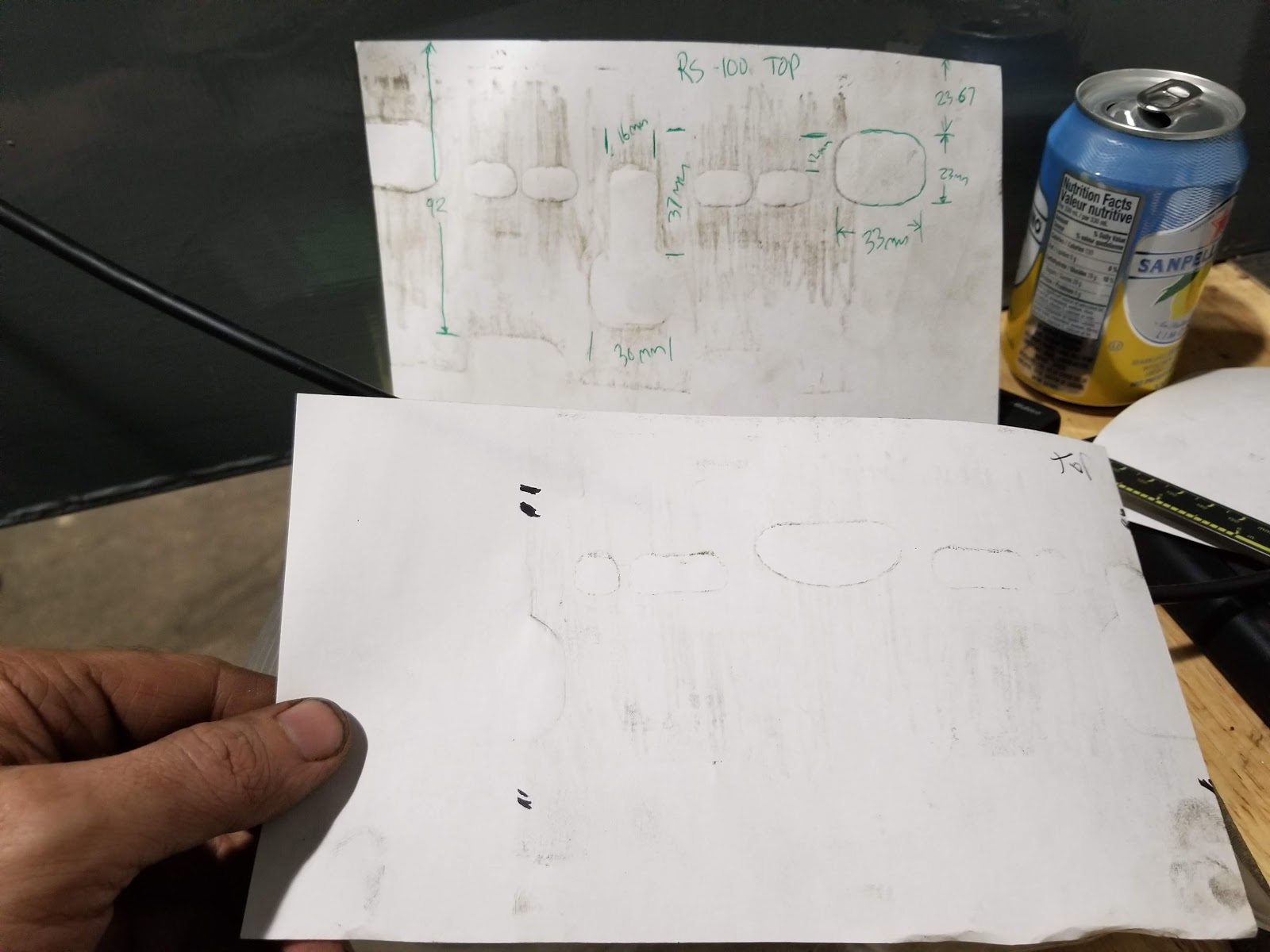

Here is an interesting turn of events. So i did some cylinder rubs, the new "MX/DT" is pretty sad. Lots of casting flash and the exhaust port is nice and wide, but small. Nice domed piston though. The RS though.. I mean from what I can measure from a service manual MarkT sent me, is pretty close to the good 73 MX cylinder... and the head has an Ok squish band as well.. But the RS uses a flat top piston, unlike both the old and new MX which from my research uses a domed piston. Also instead of having a small/large transfer setup, it has 2 of the same sized transfers. So it seems like I already have an MX cylinder of sorts. Or something that can be modified to be one fairly easily I have also found the rod, KTM 150sx, and using a prox bearing I can put the KX100 piston on there... will hopefully be on order soon from mongoose machine.   i will measure up the MX/DT cylinder next |

|

|

|

Post by pitobread on Sept 9, 2018 21:14:46 GMT -5

yup, checking all dimensions, it seems good. I will need to grind down the big end to fit the crank by .5mm a side but it will work.

Now to order up a .030 oversize KX100 piston and a rod.

|

|

|

|

Post by pitobread on Sept 9, 2018 12:06:21 GMT -5

That seems perfect. I will check it out when I get back from camping. If I can get a bearing to take up the extra mm on the small end it should work great.

|

|

|

|

Post by pitobread on Sept 7, 2018 22:24:47 GMT -5

I need a 28mm big end unfortunately

|

|

|

|

Post by pitobread on Sept 7, 2018 11:49:52 GMT -5

Well I made some dummy bearings last night so I can install the crank and check the timings to see where I am at with what cylinders.

I also hate the head designs, there is no real squish band, just a big cascading dome. So the machinist in me wants to make a better head.

Rod/Stroke ratio ain't bad. I do need to replace the rod and bearing. I am currently trying to find a longer rod (110mm) that has a 28mm big end and 18mm small end. Then I could possibly use a KX100 Wiseco piston kit, which would also have the benefit of a lower compression height, but would require extensive cylinder modification to get the port timing back to normal.

Also going make a crank pin stuffer and possibly stuff the cutouts

|

|

|

|

Post by pitobread on Sept 6, 2018 20:54:35 GMT -5

Now now, 190Mech. You know I don't let stock specs keep me down. I have torn down all my parts engines and have them scattered throughout various parts washers. Soon I will be making up a battle plan.

I have a 50mm crank at home out of the DT125.

|

|

|

|

Post by pitobread on Sept 6, 2018 20:50:15 GMT -5

Sounds good, there are basically brand new CST tires on them as well. If it paid for the typhoon wheel I bought I would be stoked.

|

|

|

|

Post by pitobread on Sept 6, 2018 11:49:29 GMT -5

They are just sitting around, I have no use for them if you made me an offer of what they are worth to you I would happily send them your way.

I also have a 4t motor sitting here not doing much of anything, it has something wrong internally I haven't verified.

|

|

|

|

Post by pitobread on Sept 6, 2018 11:25:42 GMT -5

^^^ Thats a beaut! I have to stay under 110cc for the cheap insurance. I have a DT125 engine here, 2 of the 3 bolt holes line up for the engine. It is neat the CT1 bolts in. The cases are similar but slightly different. I was heavy into the fiche last night, So the MX100 and the DT100 both use the same cylinder yet the DT is rated at 10HP at 7500 RPM and the MX is 16 at 10500! Different pipe and carb, and electronic ignition make all the difference If I wanted to as well it seems I can increase the stroke to 50mm by using various TY175 YZ100 and YZ125 cranks from certain years. It may require cutting the cases a bit. Got the rear wheel on, made a few pieces, trying to get the correct placement for the rear set I have to make.  |

|