|

|

Post by Enviromoto on Nov 12, 2011 20:07:31 GMT -5

That's right a Scootercross racer is on the table but first I have a few questions.

1. Whats the most you feel comfortable cutting off of the intake side skirting.

2. Max squish band should I run with the LeoVince Exhaust.

3. Port timing 101?

|

|

|

|

Post by 90GTVert on Nov 12, 2011 20:16:17 GMT -5

|

|

|

|

Post by 2strokd on Nov 13, 2011 5:18:35 GMT -5

Hey man, Sorry about the delay in that vid on port timing we talked about. Maybe Vert or someone else can help? Im currently unable to help with that. We spoke of port timing and the ease to check it. I told J i really only worry about total exhaust port duration, and transfer duration. Once i get those right, then i worry about squish settings. IMO, the easiest way to check port duration (and this has been mentioned before) is to just set the degree wheel at 0 when you get the piston just starting to open a port. A flashlight shining into the ex port from the outside (ex side to piston) in works great. You can really see it when that light starts peeking though. Once the piston has traveled down and back up again, pay close attention to the light shining in the port and slowly turn the crank until the moment you DONT see the light anymore. STOP! Look at the degree wheel. That is your total port duration. The same is applied to the transfer ports... I think you should be shooting for around 180-185degrees of exhaust duration to get the most out of the engine set-up. Good choice in power plants BTW  Cant go wrong with a stroked out smallblock Mina  |

|

|

|

Post by 2strokd on Nov 13, 2011 5:21:39 GMT -5

As far as squish goes.. I push it as tight as Bell suggests and go from there. You will no if its too tight by the way the engine acts/sounds when warm. Ide shoot low .7-1mm and go from there. You can always add a gasket later if it gets hot?.

|

|

|

|

Post by reveeen on Nov 13, 2011 8:00:09 GMT -5

If, it is your intention, to off-road what you are building, I'm not too sure I would fall into the porting trap (at least not too far). If you are following Brent's 90-100cc build, it seems, that the ATV variants of the Mina engine, are ported mildly, for torque generating purposes. As you add timing duration the torque will disappear (to be replaced by high rpm power) which I'm not convinced is a real good idea in an off-road type scooter.

|

|

|

|

Post by Enviromoto on Nov 13, 2011 9:02:41 GMT -5

Thanks for the help guys. You know the last four years have been mostly 4t tuning with my 2t experience just mostly bolt on's without any porting or mods to the case. With this build I want to make most of my power down low for the hills and torque off jumps ect. I will also be using stock gears, and the LeoVince BWS 100cc exhaust that's only going to make power up to about 9k. I have already trenched the case, jb welded, and I will be cutting the piston skirt, and intake side for the piston today. Along with some port timing as Vert's instructions show me. Another question is how do you guys get the cooling fan shroud to fit? Here is what I'm going for just a little nicer, on a budget.  |

|

|

|

Post by Enviromoto on Nov 13, 2011 9:06:20 GMT -5

Right now I can tell you the squish is over 1.5mm (largest soder I have is 1.5). I have a milled head here and it just touches the 1.5 soder, this is with both the base and head gasket installed.

|

|

|

|

Post by 90GTVert on Nov 13, 2011 9:34:01 GMT -5

I mention it in the link, but if you need power across a wider range of RPM, DON'T flatten the exhaust port's roof. The Venus has a very curved roof and P90 has a pretty flat roof and there's a big difference in low rev loss between the two. The Venus will chug along happily at 4500RPM or so and respond well from there. P90 is just dead below 6000 completely. You feel like looking at your watch if the revs drop down there waiting on it to pick up. That said, for a racer I'd think you could get the CVT setup and keep it at 7500-9500 most of the time. You can always play it safe and shape it less aggressively and then remove more on the roof later if you feel it would work. Can't put the metal back and make it more mild though.

The fan shrouds on these fit pretty crappy TBH. If you are trying to use a 49cc cylinder shroud, you need one from a 90. Even then some of the heads don't clear very well and will burn lines though.

If you go .7mm squish plan on a gasket or combustion chamber mods or race fuel. Any 90-100 I've ever built would have crazy compression at .7mm squish. You can read Bell's book and it will explain what the tight clearance is supposed to do. In real life I have tried a wider squish with a smaller combustion chamber and then opening up the combustion chamber and using a tighter squish. I set them both up with similar compression and I didn't really see the difference.

|

|

|

|

Post by stepthrutuner on Nov 13, 2011 10:29:18 GMT -5

I say don't be so concerned with a narrow squish clearance. It is mainly important in delaying detonation onset when the throttle is held pinned on long straights. This condition probably doesn't exist at your motocross venues. C.r. as high as possible that the use conditions will support safely is important for good grunt.

I think a stiff contra will help downshifting on inclines, btw. And you'll probably want straight cut slots in the t/d pulley to abet this.

|

|

|

|

Post by Enviromoto on Nov 13, 2011 11:30:29 GMT -5

My work so far.  I let Quinn have a go at cleaning up my rough cut and he ended up filing it at an angle instead of straight across. O well I managed to salvage the with some JB Weld but the front didn't turn out so well. I didn't want to match the small carter as that would render it useless in the future.  Here's how much I was planing on cutting off the skirt, should be good to go I think, but a second opinion never hurts. The view from my desk this morning :riding:  |

|

|

|

Post by Enviromoto on Nov 13, 2011 11:41:52 GMT -5

Any luck keeping the stock starter? Too much compression?

|

|

|

|

Post by 90GTVert on Nov 13, 2011 12:05:06 GMT -5

Man I wish one of those were parked in my shop. :drool:

The stock starter should work if it's the right kind. I found that some of the 49ccs have a chrome starter and that thing just doesn't make enough torque to pump the bigger engines with good compression effectively. Sometimes upgrading starter cables can help a little too, depending how it's setup stock. If you go nuts with compression it ain't gonna work. At 180psi, prob lower than you'll see on your racer, the stock starter with upgraded cables is having no trouble on mine. It cranked T1's 103 over at 210psi when I was trying to get the squish and compression figured out on that.

How far is the piston down in relation to the cylinder at BDC? Is that what the mark around it is?

|

|

|

|

Post by Enviromoto on Nov 13, 2011 12:31:32 GMT -5

The mark around is how much I'm going to take off for the intake side of the skirt.

|

|

|

|

Post by Enviromoto on Nov 13, 2011 14:45:35 GMT -5

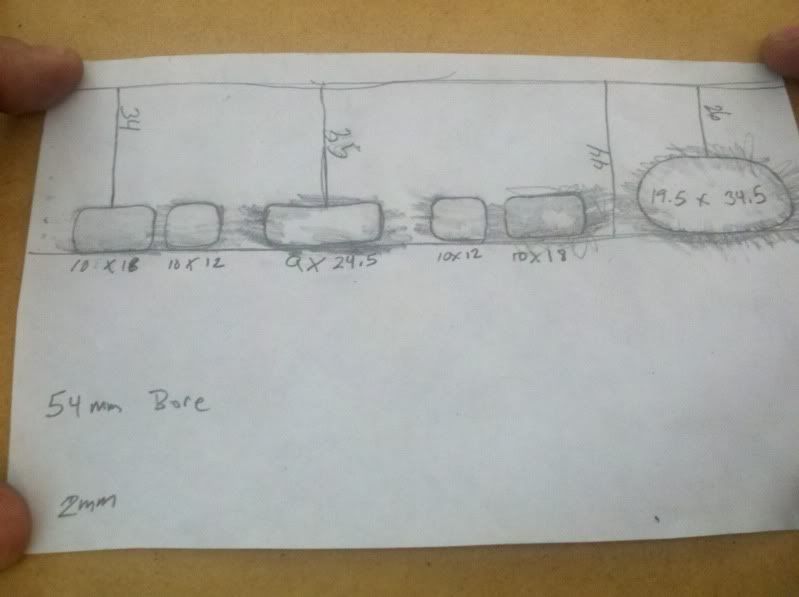

Here is why I want to cut the skirt, more flow.  Here is my port map.  From what I see my cord width is 63.8% of the cylinder bore. Suggestions? |

|

|

|

Post by 2strokd on Nov 13, 2011 15:25:08 GMT -5

Lol, my 103 would never start with an electric starter. Ide like to get an honest compression reading from it.

|

|