|

|

Post by 190mech on Mar 26, 2010 16:42:43 GMT -5

Brent,the "samples" will be 8x11"!!

|

|

|

|

Post by 90GTVert on Mar 26, 2010 17:24:07 GMT -5

Wow. lol Thanks.

|

|

|

|

Post by 90GTVert on Mar 26, 2010 19:42:24 GMT -5

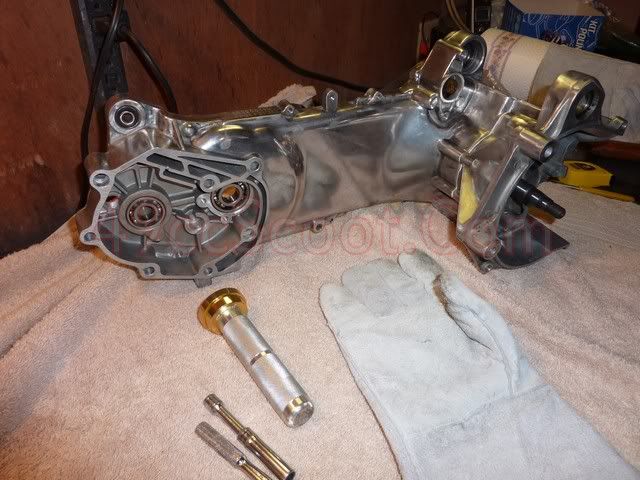

I ended up heating one case to finish the crank install. Poor dusty crank installer. lol Since I wasn't going to freeze the case half with the crank installed in it, I decided to bump the temp up to 385 degrees. Still for 45 minutes.  It was about 45 degrees in the garage, so I left the other case out there. Just before the case in the oven was well done, I went out and applied a coat of Three Bond 1194 to the mating surfaces. I tried using my fingers, but that was cumbersome so I ended up using a Q-Tip.  I brought the case inside just as the oven timer was going off. I'd like to say it went perfectly smooth, but I'd rather be honest and help someone else avoid a mistake. I sat the cold case down so the mating surface was facing up. I pulled the hot case from the oven and went to put it down over the crank. As I tilted the hot case over, the crank bearing fell out. One of the bearings in the transmission fell partially out as well. I stuck the bearing on the crankshaft and then pushed the case down over everything else. Not quite as I planned it, but it did go together. Once I had it all together I put the case bolts in. I really didn't expect the bearings to loosen up that much. I kinda thought they'd heat with the case a little more.  I took the case outside and tapped the transmission bearing back in with a bearing and seal driver, and installed a new transmission bearing that I needed to install soon anyway. It didn't take much force at all with the cases still so hot.  |

|

|

|

Post by 190mech on Mar 26, 2010 20:07:53 GMT -5

Its lookin nice!!

|

|

|

|

Post by 90GTVert on Mar 26, 2010 21:01:34 GMT -5

Thanks. Here's something that doesn't look too good. A bit of video I captured of the bearing and crank installs. It's more like what not to do. The first clip is a bearing being installed in a case half. One dropped in, this one started a little crooked and took a sec. The second clip went as planned and the crank slid right into the bearing. The third and fourth clips are the final case joining. Clip three is the bearing falling out of the case. I cut the vid there because I checked everything over for a few secs before finally sticking the cases together awkwardly in the fourth clip. Even being my first attempt at this and things not going 100% right, it really isn't that bad and I think the vid helps to illustrate that. As embarrassing as it is, feel free to watch and laugh...  |

|

|

|

Post by 190mech on Mar 27, 2010 6:06:46 GMT -5

Looks good to me,I'd be stupid and try that with no gloves!

The old Spanish MX motorcycles had 'oven' cases and one

could think up new cuss words while assembling them...

|

|

|

|

Post by 90GTVert on Mar 27, 2010 6:49:09 GMT -5

Not a chance of me doing that without gloves. Those are welding gloves (albeit cheap ones) and it was hot through the gloves at 385 degrees. You are the man if you can do that without gloves.

|

|

|

|

Post by 90GTVert on Mar 27, 2010 7:05:40 GMT -5

I got the crank seals in last night. Got up this morning and did a very rough polish on the trans case and assembled the transmission. I ordered this trans cover gasket direct from Vento (when they were still in business) for a 2004 Triton R4i looking right at a diagram. Not even close. I'm trying this ThreeBond on everything, whether I want to or not.  As it sits.  Progress will be slowing and coming to a halt before long. I realized last night that I have no stator. I stuck that on T2 when it's stator went bad. I'm missing a woodruff key for the crank too. Ordered those. I forgot to check if I still have a CDI for this thing, that might have went on T1 too. Crap. Still need a carb and an intake to accept the carb. 190mech is going to start a custom pipe for this engine very soon! ;D |

|

|

|

Post by 90GTVert on Mar 27, 2010 12:27:15 GMT -5

|

|

|

|

Post by 90GTVert on Mar 27, 2010 16:06:23 GMT -5

Found a clutch nut. Found out that a fuel injector o-ring that fits my 'stang fits great between the CVT bearing and the clutch bell nut.  I really wish I vented this cover different, but it was the first one I ever did.  |

|

|

|

Post by drawkward on Mar 27, 2010 19:52:21 GMT -5

Better to be overcooled than undercooled.  |

|

|

|

Post by 190mech on Mar 27, 2010 20:27:22 GMT -5

|

|

|

|

Post by 90GTVert on Mar 27, 2010 21:08:50 GMT -5

That's beautiful work John... and that is one monster header. You really need to build your own stroker after this. With all the knowledge you've been sharing and your fabrication skills I'd love to see what you'd build for your own scoot.

|

|

|

|

Post by stepthrutuner on Mar 27, 2010 21:30:26 GMT -5

I installed the Malossi Torsion control in the Hoca rear pulley setup. That black torque spring is short, but the coils are pretty beefy. I would say it's equal to a 1000RPM spring or more. Seemed like more when I was trying to compress it to get the belt on.  A coil spring is nothing more than a spiraled up torsion bar. The shorter the bar and/or coil spring the stiffer the resulting product. Of course bar or individual coil thickness matters too.... just a little mechanics of materials 101.  |

|

|

|

Post by 2strokd on Mar 28, 2010 9:09:40 GMT -5

Looks great Brent ;D! I gotta lil nervous myself when the bearing fell outta the case  ! Worked out well tho, good job! Sweet work John  ! Always a pleasure to see your progress photos  |

|