|

|

Post by moofus02 on Aug 30, 2013 18:19:40 GMT -5

That's some good looking parts

Sent from my SPH-L720 using proboards

|

|

|

|

Post by 190mech on Aug 30, 2013 19:56:48 GMT -5

Now thats a nice cylinder head!!  |

|

|

|

Post by syko on Aug 30, 2013 20:24:58 GMT -5

Nice job so far bro keep up the good work

|

|

|

|

Post by kevin55950 on Aug 30, 2013 22:15:16 GMT -5

If I finally start it, this would be on a stock jog wiring in pretty rough shape with the odd engine mount. I'm waiting my training at the machine shop and on SolidWorks to make a new engine mount. And I'll have stock handle bars because I can't decide on which model of naked handle bars to take...

|

|

|

|

Post by kevin55950 on Sept 2, 2013 21:01:11 GMT -5

Shop was closed so I wasn't able to get the bearings, seals and shorter nuts for the head.

So I tried to find something to cut my glass plate ( need some more meat on cases around the crankshaft to seal well, I needed a flat surface but my glass plate is just too large to do a good job) and the hardware store was closed too...

SO, it was not a productive week-end.

|

|

|

|

Post by kevin55950 on Sept 9, 2013 20:31:37 GMT -5

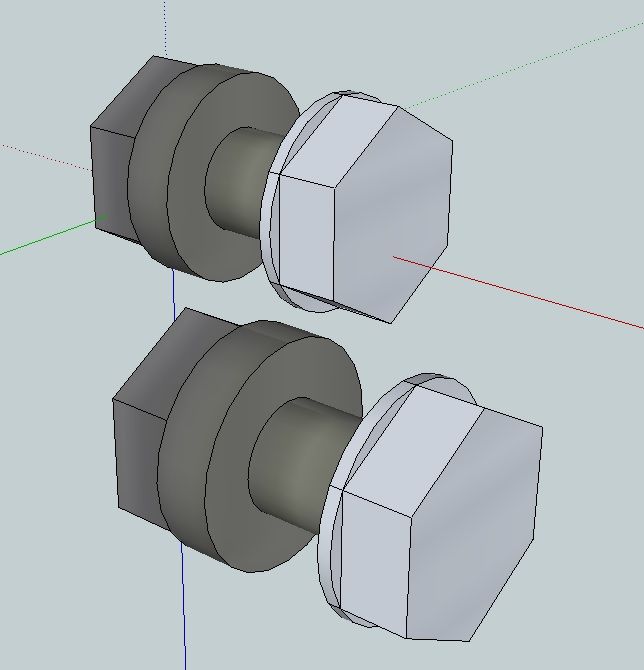

Shop had only 3 head bolts... I'll try to find one at home. I'm waiting for the epoxy to dry completely (making a better seal around the cases), then I'll make the surface between the 2 cases flat, then assembly. I found a mini lathe on eBay, I had an idea for my motor mounts... I'll try to confirm if it's good with a teacher, and I'll do it on solidworks. The cost of the lathe will be low ($175 if I remember) compared to how it will cost me at a machine shop to make it fabricated ( I can't do any personal work at school --') and I'll be sure it suits my needs, instead of taking it to the machine shop to have something bad again. Lathe will be used to machine this (if design work) :  dark grey will be the kind of bolts that goes into the case bearing, pale gray is the screw. I'm looking for a 2-part engine mount where 2 bolts on each side of the case are holding the ''motor side mount'' to the ''frame side mount'' via bushings so I eliminate vibration and I can use my intake. I tried to do a port map of my cylinder, but result is very not precise. I'll do it again tomorrow. |

|

|

|

Post by kevin55950 on Sept 10, 2013 20:49:02 GMT -5

Cases were a little sticked to the glass, but the Mother's Carnuba wax made a good finish. Here you can see it's a big improvement in sealing surface over stock. Next step: paint the cases, install crankshaft (I found a die today, some kind of nut especially made to repair and clean threads) and assemble engine. I need to find adapters for my radiator connections which are way larger than my hoses size.  |

|

|

|

Post by kevin55950 on Sept 16, 2013 21:50:09 GMT -5

I installed the crankshaft using the method shown in the Malossi video. The only thing I would add is that I used some drops of varsol (cheap kerosene I think) on the crankshaft where the bearing fits to make it slide easier in the bearings. Little work every day should make it run pretty soon     Now it's waiting the rest of the parts   On the engine mount bearings and in the gearbox, I've put grease so the paint doesn't stick. Now I need to change gear bearings. My friend have a MIG welder so I'll look for nuts and bolts, I'll tack weld the nut to the bearing then screw the nut so they'll come out. That's the only way I think about to take these out, as most of pullers at local stores are not small enough to fit the bearings. |

|

|

|

Post by moofus02 on Sept 17, 2013 4:08:35 GMT -5

Some good looking work I like the huge trench cuts epoxy must be your best friend lol should be a monster

Sent from my SPH-L720 using proboards

|

|

|

|

Post by kevin55950 on Sept 17, 2013 17:43:43 GMT -5

I hope so  I made a port map but it's looking like crap, when I'll have a good one I'll install the cylinder kit. I think it will be useful to compare it with other cylinder kits that aren't in the same class/range, maybe if it does perform great we could manage to port a 54mm bbk or another engine the same way ?  |

|

|

|

Post by 2strokd on Sept 18, 2013 8:32:57 GMT -5

And that theory works well. We kept working our 54mm bore (slow speed, dual ring) iron cylinder before switching to a 52mm iron kit with about the same numbers as an MHR kit. It runs closer than i thought it would for sure!

|

|

|

|

Post by kevin55950 on Sept 18, 2013 10:10:32 GMT -5

As I know, a square or sightly oversquare 2 stroke is running at it's best.

MVT 90 is 1.12946 (50,6mm bore, 44,8mm stroke)

MVT 80 is 1.05 (47,6mm bore, 44,8mm stroke)

And 54X42 is... 1.29

You're talking about the 52X45 ? It makes 1.155, malossi MHR 86( 50mmX44mm) is 1.136. Yes they are pretty near lol.

OEM 50cc minarelli (40X39.2) is 1.02.

|

|

|

|

Post by 2strokd on Sept 18, 2013 12:11:01 GMT -5

As I know, a square or sightly oversquare 2 stroke is running at it's best. MVT 90 is 1.12946 (50,6mm bore, 44,8mm stroke) MVT 80 is 1.05 (47,6mm bore, 44,8mm stroke) And 54X42 is... 1.29 You're talking about the 52X45 ? It makes 1.155, malossi MHR 86( 50mmX44mm) is 1.136. Yes they are pretty near lol.  OEM 50cc minarelli (40X39.2) is 1.02. Yep, the tall one. We matched the port durations as much as possible as well.  The looks are priceless when you tell em your running a "carlos" 52mm ATV A/C iron jug and a Peace Pipe! The cylinder literally came out of the trash, had a bent piston with it lol. I just went through it this AM and its still looking like its ready for duty. Enough about me tho, back to your build |

|

|

|

Post by kevin55950 on Sept 18, 2013 12:14:17 GMT -5

I ordered BCD handlebars and stem, finally. I wasn't decided if I was getting the expensive BCD short stem or a cheap one, but I decided to take it, because if I don't get one now, I'll never be able to get the BCD RX one as they'll be out of production.

|

|

|

|

Post by 2strokd on Sept 18, 2013 13:11:57 GMT -5

I hear ya man! You know i want one for Skeedr  |

|