|

|

Post by oldgeek on Jan 5, 2013 21:26:47 GMT -5

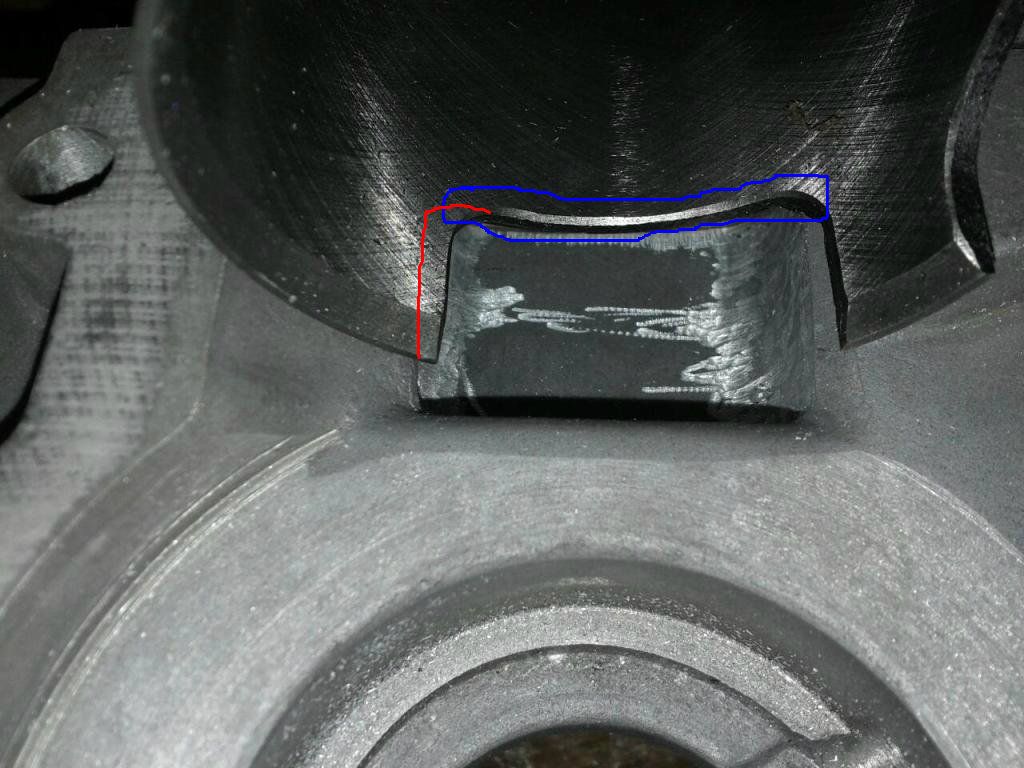

I did a small amount of matching the boost port on the cylinder (orange) and i am thinking about trimming the cylinder on the black marks to match it to the transfers a little better (red). Is this ok to do?  |

|

|

|

Post by 190mech on Jan 6, 2013 5:13:46 GMT -5

Yes,trim them,be sure to round the cylinder base where the mixture flows into the transfer tunnels.. :thumb:

|

|

|

|

Post by oldgeek on Jan 6, 2013 7:47:32 GMT -5

Are you talking about the area I have marked in blue? BTW, I will be rolling past you Monday on I-20. I have to take my daughter back up to Spartanburg for college.  |

|

|

|

Post by 90GTVert on Jan 6, 2013 9:17:25 GMT -5

I try to round or smooth all of the edges down there a bit. Not sure if it's really beneficial in all spots.  |

|

|

|

Post by 190mech on Jan 6, 2013 18:55:23 GMT -5

Good pic Brent!Thats what i was talking about!! :cheers:

|

|

|

|

Post by oldgeek on Jan 6, 2013 21:01:19 GMT -5

Thats what I was looking for thanks!

Mine will be a little different cause its thin cast iron. The one in your picture is aluminum I believe?

I also need to open up the boost port on the cylinder just a bit.

|

|

|

|

Post by 90GTVert on Jan 6, 2013 21:43:22 GMT -5

It's a stock 40mm iron cylinder in the pic.

|

|

|

|

Post by martyd on Jan 6, 2013 22:12:34 GMT -5

So is porting a have to thing or is it just a way to try and squeeze every bit of hp out of the motor ? I have read alot about this but am still confused

|

|

|

|

Post by 190mech on Jan 7, 2013 5:36:38 GMT -5

Marty, You can just bolt on a cylinder and ride! If you want the engine to run as good as the designers made it before the manufacturers and bean counters started cutting corners,porting is needed..  =John= |

|

|

|

Post by 90GTVert on Jan 7, 2013 5:47:52 GMT -5

The main things that you should check if you just wanna bolt on a cylinder kit are the port chamfers. You don't even have to do that, but it's best to remove rough edges from the ports where they enter the bore.

|

|

|

|

Post by oldgeek on Jan 7, 2013 6:55:41 GMT -5

It's a stock 40mm iron cylinder in the pic. Oh, ok. The thickness was throwing me off. I am trying to figure out how much can i take off of the boost port "tabs" on the cylinder without worrying that they are too thin. In your picture It looks like you were able to remove quite a bit, but mine are much thinner. I did see in project90 I think, where you ended up with a very small tab after you finished porting. I guess its about time to finish screwing with the cases, install the crank and see how the piston looks in the bore. |

|

|

|

Post by 90GTVert on Jan 7, 2013 7:51:27 GMT -5

I really don't know the limits. Anything that will see a lot of miles I tend to be much more conservative.

|

|

|

|

Post by oldgeek on Jan 7, 2013 9:54:14 GMT -5

I really don't know the limits. Anything that will see a lot of miles I tend to be much more conservative. Very good point, Thanks for reminding me. I do want this build to last a long time. I tend to forget the end goal along the way! |

|

|

|

Post by oldgeek on Jan 8, 2013 19:56:44 GMT -5

Ok I have a couple questions to ask. Has anyone used the replacement for three bond 1194, since they no longer make it? Should I just use Permatex ultra grey? The replacement is 1184. I ordered 1194, but they sent me this.  I have crank bearings from NACHI and TPI. The TPIs came labeled HOCA. Does anyone know which are better? And finally what torque values do I use for the crankcase halves, I don't recall seeing that info anywhere. |

|

|

|

Post by 90GTVert on Jan 8, 2013 23:48:31 GMT -5

I use a 1/4" ratchet with the 8mm hex and just get the case bolts snug. Not sure on a tq figure.

From what I read, the 1184 sounds fine.

|

|